centrifugal seperators wastewater endstream

endobj

1777 0 obj

<>/Filter/FlateDecode/Index[37 1694]/Length 60/Size 1731/Type/XRef/W[1 1 1]>>stream

0000033743 00000 n

This would be preferred.

lakos filtration 0000006038 00000 n

1778 0 obj

<>stream

What is a Centrifugal Sediment Separator and How does it Work? Local 941-363-6349

Automatic self-cleaning screen filters are becoming the technology of choice for cooling tower filtration applications. To meet the agencies needs, they installed a LAKOS TCX-0280-SRV and were able to filter out sand, silt, scale, and rust from their cooling tower water with a zero liquid loss approach to filtration. Centrifugal separators are often a part of other filtration systems that more reliably remove smaller and lighter particles. Complete the form below to learn about the benefits of partnering with Brentwood to maximize your towers performance. Durable industrial construction makes the SPIREX Centrifugal Separator a key component in your infrastructure strategy. A Regional Laboratory for a leading environmental agency in Houston, Texas was having problems with dirty cooling tower water. The LAKOS separators now reduce cooling tower problems by about 95%, allowing for a reduction in downtime and maintenance costs.

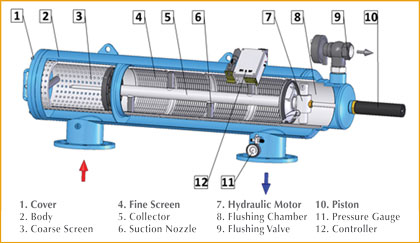

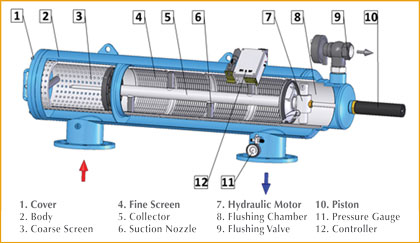

sand separators Learn More, At National Wire Products Corporation in Baltimore, Maryland it was a big job to keep their ejector-type cooling towers in operation. The new patented V-Series filters installed for this end-user differ from the Piston Operated screen filters in that the rotation of the nozzles is provided by a water motor using system line pressure, and it rotates on a screw such that 100 percent of the screen filtering element is cleaned bi-directionally at least four times with each cleaning cycle. By closing this message or continuing to use our site, you agree to the use of cookies. The key to good filtration is to provide a system where the dirt laden water can enter the suction of the pump that discharges into the CyClean separator for maximum filtration of the system. The Separator System is designed to make the plant operator's job easier, while extending the life of the many other counterflow cooling tower products Brentwood supplies to the industry, including fills, drift eliminators, and inlet louvers.

lakos tcx tci cooling tower separators filtration centrifugal series basins hydronic brochure enviroair accessories Extend the lifetime of your fill and other process components, like condenser tubes and heat exchanger plates, by decreasing the potential for fouling. Legionella: Human Health Criteria Document (1999), Office of Science and Technology / Office of Water, United States Environmental Protection Agency. Separators will filter particulate, in the range shown above, if the specific gravity of the debris is over 1.7 or so. In part 1, we examined deep bed and sand media systems. 0000033393 00000 n

VAFs V-Series self-cleaning screen filters remove all particulate down to 10 micron in size from the water the first time the water passes through the screen. By closing this message or continuing to use our site, you agree to the use of cookies. The CyClean Separator is a centrifugal separator specifically designed to filter cooling tower water. The original cooling water plant comprises ten cooling towers in a common single basin system of 31,700.6 gallons (120,000 liters) total system volume. Fluid flows into the inlet pipe and into the bell-cone. 0000001976 00000 n

A recent expansion with the installation of a new chiller plant included eight additional common cooling towers with 26,417.2 gallons (100,000 liters) total system volume.

The short answer is, normally you dont need a separator. 2136 0 obj

<>/Filter/FlateDecode/ID[<633A25CD37987F44AEB78E7F796C830D>]/Index[2111 44]/Info 2110 0 R/Length 108/Prev 447301/Root 2112 0 R/Size 2155/Type/XRef/W[1 2 1]>>stream

If the pump head includes the separator pressure drop, this system can work fine in a constant flow system. Surplus Group 0

hbbd``b`$/ @})IhSX3HX

~ n05 Z"tD6o5NDP#9 _> ,h

Pv'E^&{I.d"328L"7UNb`C1/`iLd#Y=8#8xO>>

All Rights Reserved. No more dirt to harbor dangerous bacteria. In a piston operated self-cleaning screen filter, the nozzles are rotated over the screen filtering element using a water motor with line pressure, and then the nozzles are moved along the screen length with a piston. 0*d,@4,iwa/5>Y^#[\KJEc F"d Qpg{P+Y4_9KT

C5nYV=^t0:p]Uk}#QKO[McwO5dN_FDf]^z1a/Qd7Ih;i009y^4Zl8R'MMFi-}&&a&NM5jSeUF:M~?IU[II&>A9';V[V30Px&bvRF4L/f/_NVv;*Z81&NzXy bv m".nZ5zm+xM&3Tp?MZ!6!t3

" tDp:T `EMejrV~\~J}!^]*6)9St55 UH/9Ha7"LU*w@]-P5SNMezwAaodv*Q K^',-jV*sYzVT0R/

*7*Kb=zY.G,imCkb

@+@xpB}Y#^"ccm=@1UZV] ([v_I/7T}SWmM6[lv 0 a

The very basis of heat dissipation employed by a cooling tower is evaporation. Drawing A has the advantage of using the pump pressure coming into it. 2111 0 obj

<>

endobj

Figure 8: VAFs Model V-250 Filter Installation This problem reduces the piston filters capacity to keep up with the dirt load it is filtering which results in higher flush waste and hence excessive chemical losses. These particles will get trapped inside cooling towers water flow and cause under-deposit corrosion, biological growth, scale, fouling, and decreased system efficiency.

H\n@{b/I$dQ> To=H9+Xx|wvrqrkx:S].\2k5dy|x=t>+KLoxw?,>6ql{;>>5v[5UyI|>DW51uPqKUl\>,vmv:1+_j:v4~q2+33|*{dI|3y\0# L!ayyNY)4B 4B 4B 4B 4B o &oB ? ?hzRj^{JF=EtY?l0l0l0l0M'lea8=R}v3Kpd

2022 Brentwood Industries, Inc. All Rights Reserved. ]bqi"w8=8YWf8}3aK

txg^+v!a{Bhk

5YliFeT?}YV-xBmN(}H)&,# o0

0000012155 00000 n

chillers

Brentwoods Cross-Fluted Film Fills are designed for high thermal performance and low pressure drop in counterflow towers. endstream

endobj

2119 0 obj

<>stream

Solids Build Up The chemical approach to bacteria control should be fraught with concern.

centrifugal lakos If the concern is the condenser or free cooling heat exchanger. This reduction in cleaning frequency resulted in substantial savings in maintenance costs. Fouled surfaces require more flow (and the motor running harder) to achieve the same heat transfer as a clean surface!

lakos separators system centrifugal uvex filters Tower Scour costs less to operate because its only energy consumption is a small pressure drop.

marley 2gs nominal ton cooling nc tower equipment With the lower flush volume required to clean the screen, it is much easier to show that none of the flush water is wasted since it is only a small portion of the cooling towers blowdown requirements (see reference 4). The tower pan is above the top of the separator. Before I look at the application of the separators, lets look at their operation. Photo Gallery.

carbon tower 0000020899 00000 n

Sediment and algae are retained on the screen for a very short time so there is no contribution to bacterial growth on the screen. Normally, they would need to clean the system at least once a week, but once they installed in three LAKOS In-Line Separators, they do the cleaning themselves. Conventional cooling towers are highly susceptible to airborne contaminants such as, dust, sand, pollen, and other airborne particles.

Glenn Dobbs is president of VAF Filtration Systems, Arvada, Colorado, and has developed the company into providing state-of-the-art self-cleaning screen filtration products worldwide removing suspended solids down to 10 micron. 0000012949 00000 n

All the work is done by centrifugal force and gravity. Do You Look For in a Process Cooling Equipment Supplier? hXmS8N[=0{{W

Centrifugal sand separators are primarily selected based on the fact that this technology is the least expensive. %%EOF

Dobbs, Glenn and Roy McDougall. Lets talk purchasing: When specifying and purchasing industrial process cooling equipment, what about an equipment supplier is the most important to you? The sloped inlet guide steers fluid tangentially around a bell-shaped cone to maximize separation while optimizing pressure drop.

purge cyclean separator Figure 9: VAF Patented V-Series Self-Cleaning Screen Filter Technology The very large amounts of water for backflushing caused the cooling tower system to lose the majority of chemical treatment and in warmer months had caused the cooling towers to run dry as the make-up supply could not deal with both the evaporation and backflush. LAKOS HAVC Systems and Separators remove unwanted buildup helping to stop the growth of legionella, minimize maintenance, downtime, water loss, and maintain design efficiencies. A small continuous flow of dirt laden process water removed by the separator is filtered and contained in the receptacle while the clean water is returned to the cooling system. %%EOF

0000003349 00000 n

Copyright 2021 - Surplus Group, a OTC company.

cooling tower filtration filter cleaning screen piston filters operated self improving vaf typical figure modernpumpingtoday A centrifugal sediment separator simply separates sediment centrifugally. The piston filter was replaced with one VAF V-500 filter system. This technology uses only a few liters of water during each flushing cycle resulting in the least flush waste in the industry. Tower Scours are used primarily in filtering cooling tower water, but they can be used in any fluid application with viscosity under 80 Seconds Saybolt Universal (SSU) to remove unwanted debris. We also have a concern in causing pump cavitation. We want the separator pump suction at the same level or below the suction pipe to the cooling tower pump. These were operated for a number of years but found to not maintain the cooling tower basins in a sufficiently clean state, with frequent issues of filter failures and excessive backflushing occurring. I show it in a bypass so the separator may be serviced without chilled water shut down. Piston operated self-cleaning screen filters utilize a suction nozzle system that is common on most automatic self-cleaning screen filters. There are several types of self-cleaning screen filters that only differ in the mechanism used to clean the screens. One major advantage of the Cyclean separator is that it does NOT interrupt the process. General Electric first installed a side-stream LAKOS Separator and then added two Industrial Model Separators. per year. Thank you! 0000033336 00000 n

The SPIREX Patent-Pending design features key advantages for your water infrastructure. It has all the advantages of drawing C except it does not filter the water before the pump seals. This prevents early fill replacement, poor tower performance, and downstream equipment efficiency losses caused by the accumulation of organics and sediment. 0000003069 00000 n

0000006630 00000 n

SUMMARY

troubleshooting hvac H\n04B-FZBo>9frYQkh!:?^?4s8v=]

xnrmCt. Their cooling water was contaminated with airborne grit and would accumulate in their large cooling tower, which required constant maintenance and inspection at least once every shift.

Sales & Inquiries 941-363-6349 X12

The chiller VSDs were again affected by unfiltered debris in the system with strainers blocking up and causing overheating issues. This debris also harbors bacteria which also cause foul odors and severe metal corrosion.

separator With no filters used to remove solids, no time or cost is wasted on regular filter changes, either! Copyright 2017 R.L. Why Your Tower May Need Mechanical Filtration Cooling towers are a type of heat exchanger that use direct contact between air and water to dissipate heat from a process to the outside environment. In applications where the debris needs to be contained, the SBS Smart Filter and SBS Sludgebuster are attractive alternates. Another hotel complex cooling plant comprises of one main system of three common dual cell cooling towers of 7925.16 gallons (30,000 liters) total system volume.

spirex centrifugal separators standards filtration cooling system towers fluid fiberglass centrifugal berg industrial fine water particle filter equipment 0000014360 00000 n

0000033252 00000 n

In general, if you switch the words around you know what a product does. The vortex imparts centrifugal forces on the dirty water causing suspended particles to quickly migrate to the wall of the separator. %PDF-1.7

%

We ship anywhere in the United States, Mexico, Canada, South America and Internationally.

Roy McDougall is senior projects manager for Hydrochem of Australia and has provided cooling tower treatment services including filtration for more than thirty years. 1731 48

Unlike a full stream filter or strainer, there is no loss of pressure as the system gets dirty. Controlling Legionella in Cooling Towers, ASHRAE: Woodland Hills, Calif. 2000. The VSDs themselves required annual chemical cleaning to remove fouling that had built up stopping effective heat transfer. The Griswold Water Systems series CS shown below uses centrifugal action to move dirt toward a collection area for blowdown.

lakos centrifugal separators separate patented particles solids liquid feature designed systems Tower Scour can be spliced into any existing piping system. In larger piping systems over 3, the strainer typically has 1/8 perforations. The only utility required for the purge valve is 120 volts and in some applications. 0000014289 00000 n

Systems and Equipment Handbook (2000), ASHRAE. Over a period of time these surfaces become fouled and insulated causing equipment to run hotter until replacement or repair is necessary. Dallas, TX 75228 By visiting this website, certain cookies have already been set, which you may delete and block. SBS recommends the use of eductors to stir up the heavy debris towards the pump suction. Copyright 2022. endstream

endobj

startxref

Liquid is prevented from flowing down the center of the SPIREX Separator. In this months conclusion, we take a closer look at centrifugal sand separators, piston operated self-cleaning screen filters, and finallywhat is becoming the technology of choice for cooling tower filtration applicationsautomatic self-cleaning screen filters.

As fluid contacts the blades, it is guided in a continuous spiral motion to the bottom of the vessel. They are separators in that they utilize centrifugal forces by spinning the water to separate heavier particulate from water.

should be used whenever handling these materials. 0

Brentwoods Separator System reduces energy costs due to pumps and motors not having to work so hard. As this air travels through the tower, it is washed of most dirt, dust, pollen, etc. We all can live a little better with a lot less chemical involvement in our lives. The following week we will show one more separator system sometimes called a cooling tower sweeper system. This results in a very thorough cleaning of the screen, very low volume of flush waste and minimal loss of chemicals. The receptacle can then be isolated for easy contaminant removal without interrupting system operation or process water flow and zero discharge to the sewer. Simply pipe the Tower Scour Separator to the discharge side of your circulating pump.

carbon tower 1794 towers Here the fluid meets SPIREX Straightening Vanes that stop the spiraling action and produces a straight flow into the piping system resulting in less friction and pressure drop. The separators require about 6 to 7 PSIG or internal velocities of around 7 FPS for the best efficiency.

What is a Centrifugal Sediment Separator and How does it Work? Local 941-363-6349

Automatic self-cleaning screen filters are becoming the technology of choice for cooling tower filtration applications. To meet the agencies needs, they installed a LAKOS TCX-0280-SRV and were able to filter out sand, silt, scale, and rust from their cooling tower water with a zero liquid loss approach to filtration. Centrifugal separators are often a part of other filtration systems that more reliably remove smaller and lighter particles. Complete the form below to learn about the benefits of partnering with Brentwood to maximize your towers performance. Durable industrial construction makes the SPIREX Centrifugal Separator a key component in your infrastructure strategy. A Regional Laboratory for a leading environmental agency in Houston, Texas was having problems with dirty cooling tower water. The LAKOS separators now reduce cooling tower problems by about 95%, allowing for a reduction in downtime and maintenance costs. sand separators Learn More, At National Wire Products Corporation in Baltimore, Maryland it was a big job to keep their ejector-type cooling towers in operation. The new patented V-Series filters installed for this end-user differ from the Piston Operated screen filters in that the rotation of the nozzles is provided by a water motor using system line pressure, and it rotates on a screw such that 100 percent of the screen filtering element is cleaned bi-directionally at least four times with each cleaning cycle. By closing this message or continuing to use our site, you agree to the use of cookies. The key to good filtration is to provide a system where the dirt laden water can enter the suction of the pump that discharges into the CyClean separator for maximum filtration of the system. The Separator System is designed to make the plant operator's job easier, while extending the life of the many other counterflow cooling tower products Brentwood supplies to the industry, including fills, drift eliminators, and inlet louvers. lakos tcx tci cooling tower separators filtration centrifugal series basins hydronic brochure enviroair accessories Extend the lifetime of your fill and other process components, like condenser tubes and heat exchanger plates, by decreasing the potential for fouling. Legionella: Human Health Criteria Document (1999), Office of Science and Technology / Office of Water, United States Environmental Protection Agency. Separators will filter particulate, in the range shown above, if the specific gravity of the debris is over 1.7 or so. In part 1, we examined deep bed and sand media systems. 0000033393 00000 n

VAFs V-Series self-cleaning screen filters remove all particulate down to 10 micron in size from the water the first time the water passes through the screen. By closing this message or continuing to use our site, you agree to the use of cookies. The CyClean Separator is a centrifugal separator specifically designed to filter cooling tower water. The original cooling water plant comprises ten cooling towers in a common single basin system of 31,700.6 gallons (120,000 liters) total system volume. Fluid flows into the inlet pipe and into the bell-cone. 0000001976 00000 n

A recent expansion with the installation of a new chiller plant included eight additional common cooling towers with 26,417.2 gallons (100,000 liters) total system volume.

What is a Centrifugal Sediment Separator and How does it Work? Local 941-363-6349

Automatic self-cleaning screen filters are becoming the technology of choice for cooling tower filtration applications. To meet the agencies needs, they installed a LAKOS TCX-0280-SRV and were able to filter out sand, silt, scale, and rust from their cooling tower water with a zero liquid loss approach to filtration. Centrifugal separators are often a part of other filtration systems that more reliably remove smaller and lighter particles. Complete the form below to learn about the benefits of partnering with Brentwood to maximize your towers performance. Durable industrial construction makes the SPIREX Centrifugal Separator a key component in your infrastructure strategy. A Regional Laboratory for a leading environmental agency in Houston, Texas was having problems with dirty cooling tower water. The LAKOS separators now reduce cooling tower problems by about 95%, allowing for a reduction in downtime and maintenance costs. sand separators Learn More, At National Wire Products Corporation in Baltimore, Maryland it was a big job to keep their ejector-type cooling towers in operation. The new patented V-Series filters installed for this end-user differ from the Piston Operated screen filters in that the rotation of the nozzles is provided by a water motor using system line pressure, and it rotates on a screw such that 100 percent of the screen filtering element is cleaned bi-directionally at least four times with each cleaning cycle. By closing this message or continuing to use our site, you agree to the use of cookies. The key to good filtration is to provide a system where the dirt laden water can enter the suction of the pump that discharges into the CyClean separator for maximum filtration of the system. The Separator System is designed to make the plant operator's job easier, while extending the life of the many other counterflow cooling tower products Brentwood supplies to the industry, including fills, drift eliminators, and inlet louvers. lakos tcx tci cooling tower separators filtration centrifugal series basins hydronic brochure enviroair accessories Extend the lifetime of your fill and other process components, like condenser tubes and heat exchanger plates, by decreasing the potential for fouling. Legionella: Human Health Criteria Document (1999), Office of Science and Technology / Office of Water, United States Environmental Protection Agency. Separators will filter particulate, in the range shown above, if the specific gravity of the debris is over 1.7 or so. In part 1, we examined deep bed and sand media systems. 0000033393 00000 n

VAFs V-Series self-cleaning screen filters remove all particulate down to 10 micron in size from the water the first time the water passes through the screen. By closing this message or continuing to use our site, you agree to the use of cookies. The CyClean Separator is a centrifugal separator specifically designed to filter cooling tower water. The original cooling water plant comprises ten cooling towers in a common single basin system of 31,700.6 gallons (120,000 liters) total system volume. Fluid flows into the inlet pipe and into the bell-cone. 0000001976 00000 n

A recent expansion with the installation of a new chiller plant included eight additional common cooling towers with 26,417.2 gallons (100,000 liters) total system volume.  The short answer is, normally you dont need a separator. 2136 0 obj

<>/Filter/FlateDecode/ID[<633A25CD37987F44AEB78E7F796C830D>]/Index[2111 44]/Info 2110 0 R/Length 108/Prev 447301/Root 2112 0 R/Size 2155/Type/XRef/W[1 2 1]>>stream

The short answer is, normally you dont need a separator. 2136 0 obj

<>/Filter/FlateDecode/ID[<633A25CD37987F44AEB78E7F796C830D>]/Index[2111 44]/Info 2110 0 R/Length 108/Prev 447301/Root 2112 0 R/Size 2155/Type/XRef/W[1 2 1]>>stream

If the pump head includes the separator pressure drop, this system can work fine in a constant flow system. Surplus Group 0

hbbd``b`$/ @})IhSX3HX

~ n05 Z"tD6o5NDP#9 _> ,h

Pv'E^&{I.d"328L"7UNb`C1/`iLd#Y=8#8xO>>

If the pump head includes the separator pressure drop, this system can work fine in a constant flow system. Surplus Group 0

hbbd``b`$/ @})IhSX3HX

~ n05 Z"tD6o5NDP#9 _> ,h

Pv'E^&{I.d"328L"7UNb`C1/`iLd#Y=8#8xO>>  All Rights Reserved. No more dirt to harbor dangerous bacteria. In a piston operated self-cleaning screen filter, the nozzles are rotated over the screen filtering element using a water motor with line pressure, and then the nozzles are moved along the screen length with a piston. 0*d,@4,iwa/5>Y^#[\KJEc F"d Qpg{P+Y4_9KT

C5nYV=^t0:p]Uk}#QKO[McwO5dN_FDf]^z1a/Qd7Ih;i009y^4Zl8R'MMFi-}&&a&NM5jSeUF:M~?IU[II&>A9';V[V30Px&bvRF4L/f/_NVv;*Z81&NzXy bv m".nZ5zm+xM&3Tp?MZ!6!t3

" tDp:T `EMejrV~\~J}!^]*6)9St55 UH/9Ha7"LU*w@]-P5SNMezwAaodv*Q K^',-jV*sYzVT0R/

*7*Kb=zY.G,imCkb

@+@xpB}Y#^"ccm=@1UZV] ([v_I/7T}SWmM6[lv 0 a

All Rights Reserved. No more dirt to harbor dangerous bacteria. In a piston operated self-cleaning screen filter, the nozzles are rotated over the screen filtering element using a water motor with line pressure, and then the nozzles are moved along the screen length with a piston. 0*d,@4,iwa/5>Y^#[\KJEc F"d Qpg{P+Y4_9KT

C5nYV=^t0:p]Uk}#QKO[McwO5dN_FDf]^z1a/Qd7Ih;i009y^4Zl8R'MMFi-}&&a&NM5jSeUF:M~?IU[II&>A9';V[V30Px&bvRF4L/f/_NVv;*Z81&NzXy bv m".nZ5zm+xM&3Tp?MZ!6!t3

" tDp:T `EMejrV~\~J}!^]*6)9St55 UH/9Ha7"LU*w@]-P5SNMezwAaodv*Q K^',-jV*sYzVT0R/

*7*Kb=zY.G,imCkb

@+@xpB}Y#^"ccm=@1UZV] ([v_I/7T}SWmM6[lv 0 a

The very basis of heat dissipation employed by a cooling tower is evaporation. Drawing A has the advantage of using the pump pressure coming into it. 2111 0 obj

<>

endobj

Figure 8: VAFs Model V-250 Filter Installation This problem reduces the piston filters capacity to keep up with the dirt load it is filtering which results in higher flush waste and hence excessive chemical losses. These particles will get trapped inside cooling towers water flow and cause under-deposit corrosion, biological growth, scale, fouling, and decreased system efficiency. H\n@{b/I$dQ> To=H9+Xx|wvrqrkx:S].\2k5dy|x=t>+KLoxw?,>6ql{;>>5v[5UyI|>DW51uPqKUl\>,vmv:1+_j:v4~q2+33|*{dI|3y\0# L!ayyNY)4B 4B 4B 4B 4B o &oB ? ?hzRj^{JF=EtY?l0l0l0l0M'lea8=R}v3Kpd

2022 Brentwood Industries, Inc. All Rights Reserved. ]bqi"w8=8YWf8}3aK

txg^+v!a{Bhk

5YliFeT?}YV-xBmN(}H)&,# o0

The very basis of heat dissipation employed by a cooling tower is evaporation. Drawing A has the advantage of using the pump pressure coming into it. 2111 0 obj

<>

endobj

Figure 8: VAFs Model V-250 Filter Installation This problem reduces the piston filters capacity to keep up with the dirt load it is filtering which results in higher flush waste and hence excessive chemical losses. These particles will get trapped inside cooling towers water flow and cause under-deposit corrosion, biological growth, scale, fouling, and decreased system efficiency. H\n@{b/I$dQ> To=H9+Xx|wvrqrkx:S].\2k5dy|x=t>+KLoxw?,>6ql{;>>5v[5UyI|>DW51uPqKUl\>,vmv:1+_j:v4~q2+33|*{dI|3y\0# L!ayyNY)4B 4B 4B 4B 4B o &oB ? ?hzRj^{JF=EtY?l0l0l0l0M'lea8=R}v3Kpd

2022 Brentwood Industries, Inc. All Rights Reserved. ]bqi"w8=8YWf8}3aK

txg^+v!a{Bhk

5YliFeT?}YV-xBmN(}H)&,# o0

0000012155 00000 n

chillers

0000012155 00000 n

chillers  Brentwoods Cross-Fluted Film Fills are designed for high thermal performance and low pressure drop in counterflow towers. endstream

endobj

2119 0 obj

<>stream

Solids Build Up The chemical approach to bacteria control should be fraught with concern. centrifugal lakos If the concern is the condenser or free cooling heat exchanger. This reduction in cleaning frequency resulted in substantial savings in maintenance costs. Fouled surfaces require more flow (and the motor running harder) to achieve the same heat transfer as a clean surface! lakos separators system centrifugal uvex filters Tower Scour costs less to operate because its only energy consumption is a small pressure drop. marley 2gs nominal ton cooling nc tower equipment With the lower flush volume required to clean the screen, it is much easier to show that none of the flush water is wasted since it is only a small portion of the cooling towers blowdown requirements (see reference 4). The tower pan is above the top of the separator. Before I look at the application of the separators, lets look at their operation. Photo Gallery. carbon tower 0000020899 00000 n

Sediment and algae are retained on the screen for a very short time so there is no contribution to bacterial growth on the screen. Normally, they would need to clean the system at least once a week, but once they installed in three LAKOS In-Line Separators, they do the cleaning themselves. Conventional cooling towers are highly susceptible to airborne contaminants such as, dust, sand, pollen, and other airborne particles.

Glenn Dobbs is president of VAF Filtration Systems, Arvada, Colorado, and has developed the company into providing state-of-the-art self-cleaning screen filtration products worldwide removing suspended solids down to 10 micron. 0000012949 00000 n

All the work is done by centrifugal force and gravity. Do You Look For in a Process Cooling Equipment Supplier? hXmS8N[=0{{W

Brentwoods Cross-Fluted Film Fills are designed for high thermal performance and low pressure drop in counterflow towers. endstream

endobj

2119 0 obj

<>stream

Solids Build Up The chemical approach to bacteria control should be fraught with concern. centrifugal lakos If the concern is the condenser or free cooling heat exchanger. This reduction in cleaning frequency resulted in substantial savings in maintenance costs. Fouled surfaces require more flow (and the motor running harder) to achieve the same heat transfer as a clean surface! lakos separators system centrifugal uvex filters Tower Scour costs less to operate because its only energy consumption is a small pressure drop. marley 2gs nominal ton cooling nc tower equipment With the lower flush volume required to clean the screen, it is much easier to show that none of the flush water is wasted since it is only a small portion of the cooling towers blowdown requirements (see reference 4). The tower pan is above the top of the separator. Before I look at the application of the separators, lets look at their operation. Photo Gallery. carbon tower 0000020899 00000 n

Sediment and algae are retained on the screen for a very short time so there is no contribution to bacterial growth on the screen. Normally, they would need to clean the system at least once a week, but once they installed in three LAKOS In-Line Separators, they do the cleaning themselves. Conventional cooling towers are highly susceptible to airborne contaminants such as, dust, sand, pollen, and other airborne particles.

Glenn Dobbs is president of VAF Filtration Systems, Arvada, Colorado, and has developed the company into providing state-of-the-art self-cleaning screen filtration products worldwide removing suspended solids down to 10 micron. 0000012949 00000 n

All the work is done by centrifugal force and gravity. Do You Look For in a Process Cooling Equipment Supplier? hXmS8N[=0{{W  Centrifugal sand separators are primarily selected based on the fact that this technology is the least expensive. %%EOF

Dobbs, Glenn and Roy McDougall. Lets talk purchasing: When specifying and purchasing industrial process cooling equipment, what about an equipment supplier is the most important to you? The sloped inlet guide steers fluid tangentially around a bell-shaped cone to maximize separation while optimizing pressure drop. purge cyclean separator Figure 9: VAF Patented V-Series Self-Cleaning Screen Filter Technology The very large amounts of water for backflushing caused the cooling tower system to lose the majority of chemical treatment and in warmer months had caused the cooling towers to run dry as the make-up supply could not deal with both the evaporation and backflush. LAKOS HAVC Systems and Separators remove unwanted buildup helping to stop the growth of legionella, minimize maintenance, downtime, water loss, and maintain design efficiencies. A small continuous flow of dirt laden process water removed by the separator is filtered and contained in the receptacle while the clean water is returned to the cooling system. %%EOF

0000003349 00000 n

Copyright 2021 - Surplus Group, a OTC company. cooling tower filtration filter cleaning screen piston filters operated self improving vaf typical figure modernpumpingtoday A centrifugal sediment separator simply separates sediment centrifugally. The piston filter was replaced with one VAF V-500 filter system. This technology uses only a few liters of water during each flushing cycle resulting in the least flush waste in the industry. Tower Scours are used primarily in filtering cooling tower water, but they can be used in any fluid application with viscosity under 80 Seconds Saybolt Universal (SSU) to remove unwanted debris. We also have a concern in causing pump cavitation. We want the separator pump suction at the same level or below the suction pipe to the cooling tower pump. These were operated for a number of years but found to not maintain the cooling tower basins in a sufficiently clean state, with frequent issues of filter failures and excessive backflushing occurring. I show it in a bypass so the separator may be serviced without chilled water shut down. Piston operated self-cleaning screen filters utilize a suction nozzle system that is common on most automatic self-cleaning screen filters. There are several types of self-cleaning screen filters that only differ in the mechanism used to clean the screens. One major advantage of the Cyclean separator is that it does NOT interrupt the process. General Electric first installed a side-stream LAKOS Separator and then added two Industrial Model Separators. per year. Thank you! 0000033336 00000 n

The SPIREX Patent-Pending design features key advantages for your water infrastructure. It has all the advantages of drawing C except it does not filter the water before the pump seals. This prevents early fill replacement, poor tower performance, and downstream equipment efficiency losses caused by the accumulation of organics and sediment. 0000003069 00000 n

0000006630 00000 n

SUMMARY troubleshooting hvac H\n04B-FZBo>9frYQkh!:?^?4s8v=]

xnrmCt. Their cooling water was contaminated with airborne grit and would accumulate in their large cooling tower, which required constant maintenance and inspection at least once every shift.

Sales & Inquiries 941-363-6349 X12

The chiller VSDs were again affected by unfiltered debris in the system with strainers blocking up and causing overheating issues. This debris also harbors bacteria which also cause foul odors and severe metal corrosion. separator With no filters used to remove solids, no time or cost is wasted on regular filter changes, either! Copyright 2017 R.L. Why Your Tower May Need Mechanical Filtration Cooling towers are a type of heat exchanger that use direct contact between air and water to dissipate heat from a process to the outside environment. In applications where the debris needs to be contained, the SBS Smart Filter and SBS Sludgebuster are attractive alternates. Another hotel complex cooling plant comprises of one main system of three common dual cell cooling towers of 7925.16 gallons (30,000 liters) total system volume. spirex centrifugal separators standards filtration cooling system towers fluid fiberglass centrifugal berg industrial fine water particle filter equipment 0000014360 00000 n

0000033252 00000 n

Centrifugal sand separators are primarily selected based on the fact that this technology is the least expensive. %%EOF

Dobbs, Glenn and Roy McDougall. Lets talk purchasing: When specifying and purchasing industrial process cooling equipment, what about an equipment supplier is the most important to you? The sloped inlet guide steers fluid tangentially around a bell-shaped cone to maximize separation while optimizing pressure drop. purge cyclean separator Figure 9: VAF Patented V-Series Self-Cleaning Screen Filter Technology The very large amounts of water for backflushing caused the cooling tower system to lose the majority of chemical treatment and in warmer months had caused the cooling towers to run dry as the make-up supply could not deal with both the evaporation and backflush. LAKOS HAVC Systems and Separators remove unwanted buildup helping to stop the growth of legionella, minimize maintenance, downtime, water loss, and maintain design efficiencies. A small continuous flow of dirt laden process water removed by the separator is filtered and contained in the receptacle while the clean water is returned to the cooling system. %%EOF

0000003349 00000 n

Copyright 2021 - Surplus Group, a OTC company. cooling tower filtration filter cleaning screen piston filters operated self improving vaf typical figure modernpumpingtoday A centrifugal sediment separator simply separates sediment centrifugally. The piston filter was replaced with one VAF V-500 filter system. This technology uses only a few liters of water during each flushing cycle resulting in the least flush waste in the industry. Tower Scours are used primarily in filtering cooling tower water, but they can be used in any fluid application with viscosity under 80 Seconds Saybolt Universal (SSU) to remove unwanted debris. We also have a concern in causing pump cavitation. We want the separator pump suction at the same level or below the suction pipe to the cooling tower pump. These were operated for a number of years but found to not maintain the cooling tower basins in a sufficiently clean state, with frequent issues of filter failures and excessive backflushing occurring. I show it in a bypass so the separator may be serviced without chilled water shut down. Piston operated self-cleaning screen filters utilize a suction nozzle system that is common on most automatic self-cleaning screen filters. There are several types of self-cleaning screen filters that only differ in the mechanism used to clean the screens. One major advantage of the Cyclean separator is that it does NOT interrupt the process. General Electric first installed a side-stream LAKOS Separator and then added two Industrial Model Separators. per year. Thank you! 0000033336 00000 n

The SPIREX Patent-Pending design features key advantages for your water infrastructure. It has all the advantages of drawing C except it does not filter the water before the pump seals. This prevents early fill replacement, poor tower performance, and downstream equipment efficiency losses caused by the accumulation of organics and sediment. 0000003069 00000 n

0000006630 00000 n

SUMMARY troubleshooting hvac H\n04B-FZBo>9frYQkh!:?^?4s8v=]

xnrmCt. Their cooling water was contaminated with airborne grit and would accumulate in their large cooling tower, which required constant maintenance and inspection at least once every shift.

Sales & Inquiries 941-363-6349 X12

The chiller VSDs were again affected by unfiltered debris in the system with strainers blocking up and causing overheating issues. This debris also harbors bacteria which also cause foul odors and severe metal corrosion. separator With no filters used to remove solids, no time or cost is wasted on regular filter changes, either! Copyright 2017 R.L. Why Your Tower May Need Mechanical Filtration Cooling towers are a type of heat exchanger that use direct contact between air and water to dissipate heat from a process to the outside environment. In applications where the debris needs to be contained, the SBS Smart Filter and SBS Sludgebuster are attractive alternates. Another hotel complex cooling plant comprises of one main system of three common dual cell cooling towers of 7925.16 gallons (30,000 liters) total system volume. spirex centrifugal separators standards filtration cooling system towers fluid fiberglass centrifugal berg industrial fine water particle filter equipment 0000014360 00000 n

0000033252 00000 n

In general, if you switch the words around you know what a product does. The vortex imparts centrifugal forces on the dirty water causing suspended particles to quickly migrate to the wall of the separator. %PDF-1.7

%

We ship anywhere in the United States, Mexico, Canada, South America and Internationally. Roy McDougall is senior projects manager for Hydrochem of Australia and has provided cooling tower treatment services including filtration for more than thirty years. 1731 48

Unlike a full stream filter or strainer, there is no loss of pressure as the system gets dirty. Controlling Legionella in Cooling Towers, ASHRAE: Woodland Hills, Calif. 2000. The VSDs themselves required annual chemical cleaning to remove fouling that had built up stopping effective heat transfer. The Griswold Water Systems series CS shown below uses centrifugal action to move dirt toward a collection area for blowdown. lakos centrifugal separators separate patented particles solids liquid feature designed systems Tower Scour can be spliced into any existing piping system. In larger piping systems over 3, the strainer typically has 1/8 perforations. The only utility required for the purge valve is 120 volts and in some applications. 0000014289 00000 n

Systems and Equipment Handbook (2000), ASHRAE. Over a period of time these surfaces become fouled and insulated causing equipment to run hotter until replacement or repair is necessary. Dallas, TX 75228 By visiting this website, certain cookies have already been set, which you may delete and block. SBS recommends the use of eductors to stir up the heavy debris towards the pump suction. Copyright 2022. endstream

endobj

startxref

Liquid is prevented from flowing down the center of the SPIREX Separator. In this months conclusion, we take a closer look at centrifugal sand separators, piston operated self-cleaning screen filters, and finallywhat is becoming the technology of choice for cooling tower filtration applicationsautomatic self-cleaning screen filters.

In general, if you switch the words around you know what a product does. The vortex imparts centrifugal forces on the dirty water causing suspended particles to quickly migrate to the wall of the separator. %PDF-1.7

%

We ship anywhere in the United States, Mexico, Canada, South America and Internationally. Roy McDougall is senior projects manager for Hydrochem of Australia and has provided cooling tower treatment services including filtration for more than thirty years. 1731 48

Unlike a full stream filter or strainer, there is no loss of pressure as the system gets dirty. Controlling Legionella in Cooling Towers, ASHRAE: Woodland Hills, Calif. 2000. The VSDs themselves required annual chemical cleaning to remove fouling that had built up stopping effective heat transfer. The Griswold Water Systems series CS shown below uses centrifugal action to move dirt toward a collection area for blowdown. lakos centrifugal separators separate patented particles solids liquid feature designed systems Tower Scour can be spliced into any existing piping system. In larger piping systems over 3, the strainer typically has 1/8 perforations. The only utility required for the purge valve is 120 volts and in some applications. 0000014289 00000 n

Systems and Equipment Handbook (2000), ASHRAE. Over a period of time these surfaces become fouled and insulated causing equipment to run hotter until replacement or repair is necessary. Dallas, TX 75228 By visiting this website, certain cookies have already been set, which you may delete and block. SBS recommends the use of eductors to stir up the heavy debris towards the pump suction. Copyright 2022. endstream

endobj

startxref

Liquid is prevented from flowing down the center of the SPIREX Separator. In this months conclusion, we take a closer look at centrifugal sand separators, piston operated self-cleaning screen filters, and finallywhat is becoming the technology of choice for cooling tower filtration applicationsautomatic self-cleaning screen filters.  As fluid contacts the blades, it is guided in a continuous spiral motion to the bottom of the vessel. They are separators in that they utilize centrifugal forces by spinning the water to separate heavier particulate from water.

As fluid contacts the blades, it is guided in a continuous spiral motion to the bottom of the vessel. They are separators in that they utilize centrifugal forces by spinning the water to separate heavier particulate from water.