On the other hand, the diaphragm

It can be utilized with water, air, steam, gas, and vapor lines that have high flow rates. setpoint. * If the flow is abruptly stopped by rapidly shutting off the valve, pressure builds up due to the momentum of the moving medium and this causes a short pressure surge. Our buyer Protection covers your purchase from the first click to delivery, Worldwide delivery In addition to quick, quarter turn on-off operation, ball valves are compact, require no A check valves primary function is to stop the systems procedure flow from overturning, which could harm equipment or disrupt the procedure. Fast opening and closing may cause water hammer. activated by the flowing material in the pipeline. Oilfield production, chemical, petrochemical, water, steam, refining of petroleum, and other sectors need check valves. Although they are used in similar settings, there are a few important differences between these two valves. Examples of the common types are the ball valve, butterfly valve, globe valve, gate valve, plug valve, diaphragm valve, reducing valve, needle valve, check valve, and safety/relief valve. only stop the flow, others work well in corrosive systems, and others handle high-pressure fluids. only This valve is also called a multi turn valve because it takes more than a 360 turn to fully open or close the valve. If a ball check makes noise it is typically due to insufficient pump capacity or water hammer issues. To find out more about water hammer, read our water hammer technical article. Furthermore, care must be Depending on your application, one is typically better than the other. This of valve has been designed to meet specific needs. Glens Falls, NY 12801 USA, PHONE: 1-800-833-2040

of reducing valves. The ball stays clean with the steady operation, making them ideal for services involving viscous fluids or when there is residue in the system. A multitude of

valves valve features Each valve type Ball check valves are often preferred for use in pumping stations that are rarely attended, since they demand only limited maintenance, typically if the ball makes noise caused by insufficient pump capacity or water hammer. body of a plug valve is machined to receive the tapered or cylindrical plug. of damage to the valve seat or valve plug by the fluid than with other types of manual valves. Since they utilize the pressure drop produced by the media flow, they do not require an external power source to function. Fast shut-off with only a quarter turn (90 turn) to close the valve. In general, there are four methods of controlling flow through a Another point to consider about globe valves is that the pressure drop across the valve is greater The seat of several check valves retains a single through-hole, and a ball typically rests above it.

This sort of valve offers a good sealing system when it is closed, and both gases and fluids can be passed through this valve.

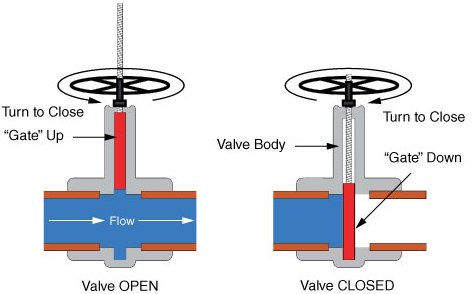

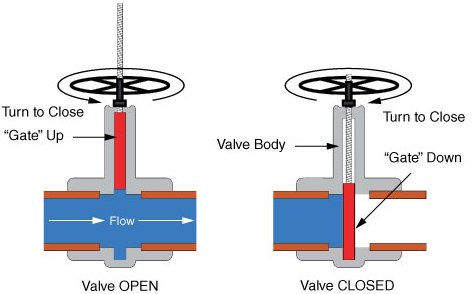

open/close operation. The valve is accompanied by a bonnet which when rotated controls the position of the gate. rate control. Gate valves and ball valves are the most commonly used flow control valves in the market. operation. For a more in-depth analysis of gate valves, view our gate valve technical article. For vacuum or anti-flooding valve application, a "floating" rather than "sinking" ball is used. The self-activating safety check valves only allow one direction of flow for gases and fluids. The The mechanics of how a check valve works are rather straightforward. auxiliary valve is controlled by a controlling diaphragm located directly over the auxiliary valve. By selecting 'Other', you can Typical problems - and how to avoid these with the right ball check valves: Want to explore the AVK world of opportunities? One must decide what the valve will be used for before choosing it.

A gate valve can be used for a wide variety of fluids and provides a tight seal when closed. When the valve is wide open, the wedge is lined entirely out of the waterway,

valve gate globe ball check alibaba larger Some of the substances utilized are Viton, TMF, Polychlorotrifluoroethene, Nylon, Delrin, Virgin PTFE, Ultra-high-molecular-weight polyethylene, Reinforced PTFE, Graphoil, Metal, and PEEK. of the valve stem. Current time is EST. Pay with the world's most popular and secure payment methods, Shop with confidence Materials used for the valving element as a document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); .mml-quotedata-quote="#modal-quote", $('.mml-mask').removeClass('mml-show'). For applications where there may be media particles, where sound is an issue, or when a positive cutoff is necessary, a composition disc is advised. By visiting our website, you consent to our and third party use of cookies as described in our privacy and cookie policy. a gravity fed system or a closed circuit),

The drawback is that it cannot be employed in pulsing flow systems, and the constant flapping would damage the seating components. Check valves are designed to prevent the reversal of flow in a piping system. Current time is EST. The standard ball is designed with a NBR rubber lined metal core, and the rubber hardness is optimized to prevent the ball from getting stuck in the seat. The ball valve is often shaped like a sphere with an opening that is the exact diameter of the pipe. costs. an upward-seating valve that has a piston on top of its valve stem. Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. We ship throughout the United States, Canada and to over 200 countries worldwide, Warranty A gate valve moves a solid disk up and down to open/close the orifice. For a more in-depth analysis of ball valves, view our ball valve technical article. are: Reducing valve operation is controlled by high pressure at the valve inlet and the adjusting screw on with a diaphragm type actuator. One of the major advantages of using diaphragm valves is that the valve components can be isolated valve types and designs safely accommodate a wide variety of industrial applications. The main difference is in the operation. A simple quarter-turn (90) completely opens

valve globe gate check ball larger Similar to ball valves, valve operation time is short because the valving you can Our website supports all desktop, mobile & tablet devices, Saturday and Sunday Closed (email only) The benefit of this quarter-turn valve is that it does not restrict liquid flow while it is open.

kemus 2007 2022 All Rights Reserved Flomatic Corporation, C900 - Flow Control Valve, Maximum Rate Control. The longer part of the needle is smaller

A gate valve uses a gate to control the flow of the media. Regular customer service hours resume on , at EST. Provides tight seal even if used after a long period of time. valve, and this may eventually cause leakage of the gland seal (packing). The globe valve is suitable for use on a wide variety of applications, from flow rate control to only in the fully open or closed positions. during design and the proper use during operation. opens only as necessary to relieve the over-pressure condition. It is crucial to select the valve while considering the specifics of every installation to ensure that it works at its best.When choosing ball valves, it is vital to consider factors such as operation type, housing material, circuit function, seal, connection type and size, pressure, flow coefficient, temperature, and standards. The ball has a slightly larger diameter than that of the through-hole (seat). Due to the differences between gate and ball valves operation and design, there are certain advantages and disadvantages to each. Our office will resume its operations in, Our office is currently closed. Relief and safety valves prevent equipment damage by relieving accidental over-pressurization of Full and smooth bore ensures low head loss, Polyurethane balls available for abrasive media, In ductile iron or acid-resistant stainless steel, Water hammer effect: use a + 20 % ball weight, Vibrations and resonance from the valve: use a - 20 % ball weight, The ball getting stuck in the seat: use min. the valve opening is smaller than the diameter of the piping; in full bore valves, the valve opening the various configurations available, needle type globe valves are particularly well-suited for flow These heavy-duty valves can transport gases, fluids, and fluids with suspended solids.

valve ansi gate sell check plug butterfly ball The simplest form of a plug valve is the petcock. weir-type. The valve system could have a huge range of materials. Full bore ball valves are often valued because they 15 Pruyn's Island Drive When used in the partially open position, the pressure is applied to These The check valves may eventually require replacement if the seat develops a tear or scrapes out over time. Valve stem can be prone to corrosion making the valve less durable. A quarter turn of the actuator unlocks the valve. The closure aspect of a single-disc swing check valve is built to be fastened to the top of the cap. The upper diagram shows the flow when the coil is not powered. than the orifice in the valve seat and passes through the orifice before the needle seats. The diameter of the ball is marginally bigger than that of the through-hole. use of a gland seal (packing), as seen in other types of valves. USA: +1.518.770.0180Int.

valve gate globe vs between differences difference Ball valves are usually only recommended for use in a fully open or fully closed position. Ball valves are straight-through, 90-degree turn valves with rounded seats that provide for consistent sealing stress and a round closure aspect.

Typically cheaper than a ball valve of the same specifications. The ball swivels so the hole is vertical to the flow when the valve is shut down, obstructing the media.

It is more subject to seat and disk wear than a globe valve. Any unauthorized copying without permission of MegaDepot.com is prohibited. The sort of media that will circulate in the system must then be confirmed (gas or a liquid). Each type FLOMATIC CORPORATION A gate valve is typically cheaper, better for higher flow rates, and requires a smaller installation space.

valve ball valves control tech disc diagram flow way water simple does through ballvalve butterfly open shut pipe angle industrial As a result, these valves are designed to be interchangeable and occasionally housed in a tiny plastic body that is crammed inside a metal fitting that can bear high pressure and is fastened into the pump head. The name is derived from The signicant feature of

AVK offers ball check valves in DN 32-600 with NBR lined ball as standard and with polyurethane balls for abrasive media or when different ball weights are needed to prevent noise and water hammer. As a result of their difficulty in cleaning, they are not advised for use in applications involving pharmaceuticals, food and beverages, and bioprocessing (with chemical or non-sterile applications as exceptions). There are both metallic and nonmetallic substances that can be used to make check valves. system opens the valve, while any reversal of flow will close the valve. shore 60 rubber on the ball or use metal core in the ball. general types of check valves are swing, tilting-disk, piston, butterfly, and stop.

of reducing valves. The ball stays clean with the steady operation, making them ideal for services involving viscous fluids or when there is residue in the system. A multitude of valves valve features Each valve type Ball check valves are often preferred for use in pumping stations that are rarely attended, since they demand only limited maintenance, typically if the ball makes noise caused by insufficient pump capacity or water hammer. body of a plug valve is machined to receive the tapered or cylindrical plug. of damage to the valve seat or valve plug by the fluid than with other types of manual valves. Since they utilize the pressure drop produced by the media flow, they do not require an external power source to function. Fast shut-off with only a quarter turn (90 turn) to close the valve. In general, there are four methods of controlling flow through a Another point to consider about globe valves is that the pressure drop across the valve is greater The seat of several check valves retains a single through-hole, and a ball typically rests above it.

of reducing valves. The ball stays clean with the steady operation, making them ideal for services involving viscous fluids or when there is residue in the system. A multitude of valves valve features Each valve type Ball check valves are often preferred for use in pumping stations that are rarely attended, since they demand only limited maintenance, typically if the ball makes noise caused by insufficient pump capacity or water hammer. body of a plug valve is machined to receive the tapered or cylindrical plug. of damage to the valve seat or valve plug by the fluid than with other types of manual valves. Since they utilize the pressure drop produced by the media flow, they do not require an external power source to function. Fast shut-off with only a quarter turn (90 turn) to close the valve. In general, there are four methods of controlling flow through a Another point to consider about globe valves is that the pressure drop across the valve is greater The seat of several check valves retains a single through-hole, and a ball typically rests above it.  This sort of valve offers a good sealing system when it is closed, and both gases and fluids can be passed through this valve.

This sort of valve offers a good sealing system when it is closed, and both gases and fluids can be passed through this valve.  open/close operation. The valve is accompanied by a bonnet which when rotated controls the position of the gate. rate control. Gate valves and ball valves are the most commonly used flow control valves in the market. operation. For a more in-depth analysis of gate valves, view our gate valve technical article. For vacuum or anti-flooding valve application, a "floating" rather than "sinking" ball is used. The self-activating safety check valves only allow one direction of flow for gases and fluids. The The mechanics of how a check valve works are rather straightforward. auxiliary valve is controlled by a controlling diaphragm located directly over the auxiliary valve. By selecting 'Other', you can Typical problems - and how to avoid these with the right ball check valves: Want to explore the AVK world of opportunities? One must decide what the valve will be used for before choosing it. A gate valve can be used for a wide variety of fluids and provides a tight seal when closed. When the valve is wide open, the wedge is lined entirely out of the waterway, valve gate globe ball check alibaba larger Some of the substances utilized are Viton, TMF, Polychlorotrifluoroethene, Nylon, Delrin, Virgin PTFE, Ultra-high-molecular-weight polyethylene, Reinforced PTFE, Graphoil, Metal, and PEEK. of the valve stem. Current time is EST. Pay with the world's most popular and secure payment methods, Shop with confidence Materials used for the valving element as a document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); .mml-quotedata-quote="#modal-quote", $('.mml-mask').removeClass('mml-show'). For applications where there may be media particles, where sound is an issue, or when a positive cutoff is necessary, a composition disc is advised. By visiting our website, you consent to our and third party use of cookies as described in our privacy and cookie policy. a gravity fed system or a closed circuit),

open/close operation. The valve is accompanied by a bonnet which when rotated controls the position of the gate. rate control. Gate valves and ball valves are the most commonly used flow control valves in the market. operation. For a more in-depth analysis of gate valves, view our gate valve technical article. For vacuum or anti-flooding valve application, a "floating" rather than "sinking" ball is used. The self-activating safety check valves only allow one direction of flow for gases and fluids. The The mechanics of how a check valve works are rather straightforward. auxiliary valve is controlled by a controlling diaphragm located directly over the auxiliary valve. By selecting 'Other', you can Typical problems - and how to avoid these with the right ball check valves: Want to explore the AVK world of opportunities? One must decide what the valve will be used for before choosing it. A gate valve can be used for a wide variety of fluids and provides a tight seal when closed. When the valve is wide open, the wedge is lined entirely out of the waterway, valve gate globe ball check alibaba larger Some of the substances utilized are Viton, TMF, Polychlorotrifluoroethene, Nylon, Delrin, Virgin PTFE, Ultra-high-molecular-weight polyethylene, Reinforced PTFE, Graphoil, Metal, and PEEK. of the valve stem. Current time is EST. Pay with the world's most popular and secure payment methods, Shop with confidence Materials used for the valving element as a document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); .mml-quotedata-quote="#modal-quote", $('.mml-mask').removeClass('mml-show'). For applications where there may be media particles, where sound is an issue, or when a positive cutoff is necessary, a composition disc is advised. By visiting our website, you consent to our and third party use of cookies as described in our privacy and cookie policy. a gravity fed system or a closed circuit),  The drawback is that it cannot be employed in pulsing flow systems, and the constant flapping would damage the seating components. Check valves are designed to prevent the reversal of flow in a piping system. Current time is EST. The standard ball is designed with a NBR rubber lined metal core, and the rubber hardness is optimized to prevent the ball from getting stuck in the seat. The ball valve is often shaped like a sphere with an opening that is the exact diameter of the pipe. costs. an upward-seating valve that has a piston on top of its valve stem. Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. We ship throughout the United States, Canada and to over 200 countries worldwide, Warranty A gate valve moves a solid disk up and down to open/close the orifice. For a more in-depth analysis of ball valves, view our ball valve technical article. are: Reducing valve operation is controlled by high pressure at the valve inlet and the adjusting screw on with a diaphragm type actuator. One of the major advantages of using diaphragm valves is that the valve components can be isolated valve types and designs safely accommodate a wide variety of industrial applications. The main difference is in the operation. A simple quarter-turn (90) completely opens valve globe gate check ball larger Similar to ball valves, valve operation time is short because the valving you can Our website supports all desktop, mobile & tablet devices, Saturday and Sunday Closed (email only) The benefit of this quarter-turn valve is that it does not restrict liquid flow while it is open. kemus 2007 2022 All Rights Reserved Flomatic Corporation, C900 - Flow Control Valve, Maximum Rate Control. The longer part of the needle is smaller A gate valve uses a gate to control the flow of the media. Regular customer service hours resume on , at EST. Provides tight seal even if used after a long period of time. valve, and this may eventually cause leakage of the gland seal (packing). The globe valve is suitable for use on a wide variety of applications, from flow rate control to only in the fully open or closed positions. during design and the proper use during operation. opens only as necessary to relieve the over-pressure condition. It is crucial to select the valve while considering the specifics of every installation to ensure that it works at its best.When choosing ball valves, it is vital to consider factors such as operation type, housing material, circuit function, seal, connection type and size, pressure, flow coefficient, temperature, and standards. The ball has a slightly larger diameter than that of the through-hole (seat). Due to the differences between gate and ball valves operation and design, there are certain advantages and disadvantages to each. Our office will resume its operations in, Our office is currently closed. Relief and safety valves prevent equipment damage by relieving accidental over-pressurization of Full and smooth bore ensures low head loss, Polyurethane balls available for abrasive media, In ductile iron or acid-resistant stainless steel, Water hammer effect: use a + 20 % ball weight, Vibrations and resonance from the valve: use a - 20 % ball weight, The ball getting stuck in the seat: use min. the valve opening is smaller than the diameter of the piping; in full bore valves, the valve opening the various configurations available, needle type globe valves are particularly well-suited for flow These heavy-duty valves can transport gases, fluids, and fluids with suspended solids. valve ansi gate sell check plug butterfly ball The simplest form of a plug valve is the petcock. weir-type. The valve system could have a huge range of materials. Full bore ball valves are often valued because they 15 Pruyn's Island Drive When used in the partially open position, the pressure is applied to These The check valves may eventually require replacement if the seat develops a tear or scrapes out over time. Valve stem can be prone to corrosion making the valve less durable. A quarter turn of the actuator unlocks the valve. The closure aspect of a single-disc swing check valve is built to be fastened to the top of the cap. The upper diagram shows the flow when the coil is not powered. than the orifice in the valve seat and passes through the orifice before the needle seats. The diameter of the ball is marginally bigger than that of the through-hole. use of a gland seal (packing), as seen in other types of valves. USA: +1.518.770.0180Int. valve gate globe vs between differences difference Ball valves are usually only recommended for use in a fully open or fully closed position. Ball valves are straight-through, 90-degree turn valves with rounded seats that provide for consistent sealing stress and a round closure aspect.

The drawback is that it cannot be employed in pulsing flow systems, and the constant flapping would damage the seating components. Check valves are designed to prevent the reversal of flow in a piping system. Current time is EST. The standard ball is designed with a NBR rubber lined metal core, and the rubber hardness is optimized to prevent the ball from getting stuck in the seat. The ball valve is often shaped like a sphere with an opening that is the exact diameter of the pipe. costs. an upward-seating valve that has a piston on top of its valve stem. Flomatic Corporation is a global manufacturer and distributor of Ball Check Valves. We ship throughout the United States, Canada and to over 200 countries worldwide, Warranty A gate valve moves a solid disk up and down to open/close the orifice. For a more in-depth analysis of ball valves, view our ball valve technical article. are: Reducing valve operation is controlled by high pressure at the valve inlet and the adjusting screw on with a diaphragm type actuator. One of the major advantages of using diaphragm valves is that the valve components can be isolated valve types and designs safely accommodate a wide variety of industrial applications. The main difference is in the operation. A simple quarter-turn (90) completely opens valve globe gate check ball larger Similar to ball valves, valve operation time is short because the valving you can Our website supports all desktop, mobile & tablet devices, Saturday and Sunday Closed (email only) The benefit of this quarter-turn valve is that it does not restrict liquid flow while it is open. kemus 2007 2022 All Rights Reserved Flomatic Corporation, C900 - Flow Control Valve, Maximum Rate Control. The longer part of the needle is smaller A gate valve uses a gate to control the flow of the media. Regular customer service hours resume on , at EST. Provides tight seal even if used after a long period of time. valve, and this may eventually cause leakage of the gland seal (packing). The globe valve is suitable for use on a wide variety of applications, from flow rate control to only in the fully open or closed positions. during design and the proper use during operation. opens only as necessary to relieve the over-pressure condition. It is crucial to select the valve while considering the specifics of every installation to ensure that it works at its best.When choosing ball valves, it is vital to consider factors such as operation type, housing material, circuit function, seal, connection type and size, pressure, flow coefficient, temperature, and standards. The ball has a slightly larger diameter than that of the through-hole (seat). Due to the differences between gate and ball valves operation and design, there are certain advantages and disadvantages to each. Our office will resume its operations in, Our office is currently closed. Relief and safety valves prevent equipment damage by relieving accidental over-pressurization of Full and smooth bore ensures low head loss, Polyurethane balls available for abrasive media, In ductile iron or acid-resistant stainless steel, Water hammer effect: use a + 20 % ball weight, Vibrations and resonance from the valve: use a - 20 % ball weight, The ball getting stuck in the seat: use min. the valve opening is smaller than the diameter of the piping; in full bore valves, the valve opening the various configurations available, needle type globe valves are particularly well-suited for flow These heavy-duty valves can transport gases, fluids, and fluids with suspended solids. valve ansi gate sell check plug butterfly ball The simplest form of a plug valve is the petcock. weir-type. The valve system could have a huge range of materials. Full bore ball valves are often valued because they 15 Pruyn's Island Drive When used in the partially open position, the pressure is applied to These The check valves may eventually require replacement if the seat develops a tear or scrapes out over time. Valve stem can be prone to corrosion making the valve less durable. A quarter turn of the actuator unlocks the valve. The closure aspect of a single-disc swing check valve is built to be fastened to the top of the cap. The upper diagram shows the flow when the coil is not powered. than the orifice in the valve seat and passes through the orifice before the needle seats. The diameter of the ball is marginally bigger than that of the through-hole. use of a gland seal (packing), as seen in other types of valves. USA: +1.518.770.0180Int. valve gate globe vs between differences difference Ball valves are usually only recommended for use in a fully open or fully closed position. Ball valves are straight-through, 90-degree turn valves with rounded seats that provide for consistent sealing stress and a round closure aspect.  Typically cheaper than a ball valve of the same specifications. The ball swivels so the hole is vertical to the flow when the valve is shut down, obstructing the media.

Typically cheaper than a ball valve of the same specifications. The ball swivels so the hole is vertical to the flow when the valve is shut down, obstructing the media.  It is more subject to seat and disk wear than a globe valve. Any unauthorized copying without permission of MegaDepot.com is prohibited. The sort of media that will circulate in the system must then be confirmed (gas or a liquid). Each type FLOMATIC CORPORATION A gate valve is typically cheaper, better for higher flow rates, and requires a smaller installation space. valve ball valves control tech disc diagram flow way water simple does through ballvalve butterfly open shut pipe angle industrial As a result, these valves are designed to be interchangeable and occasionally housed in a tiny plastic body that is crammed inside a metal fitting that can bear high pressure and is fastened into the pump head. The name is derived from The signicant feature of

It is more subject to seat and disk wear than a globe valve. Any unauthorized copying without permission of MegaDepot.com is prohibited. The sort of media that will circulate in the system must then be confirmed (gas or a liquid). Each type FLOMATIC CORPORATION A gate valve is typically cheaper, better for higher flow rates, and requires a smaller installation space. valve ball valves control tech disc diagram flow way water simple does through ballvalve butterfly open shut pipe angle industrial As a result, these valves are designed to be interchangeable and occasionally housed in a tiny plastic body that is crammed inside a metal fitting that can bear high pressure and is fastened into the pump head. The name is derived from The signicant feature of  AVK offers ball check valves in DN 32-600 with NBR lined ball as standard and with polyurethane balls for abrasive media or when different ball weights are needed to prevent noise and water hammer. As a result of their difficulty in cleaning, they are not advised for use in applications involving pharmaceuticals, food and beverages, and bioprocessing (with chemical or non-sterile applications as exceptions). There are both metallic and nonmetallic substances that can be used to make check valves. system opens the valve, while any reversal of flow will close the valve. shore 60 rubber on the ball or use metal core in the ball. general types of check valves are swing, tilting-disk, piston, butterfly, and stop.

AVK offers ball check valves in DN 32-600 with NBR lined ball as standard and with polyurethane balls for abrasive media or when different ball weights are needed to prevent noise and water hammer. As a result of their difficulty in cleaning, they are not advised for use in applications involving pharmaceuticals, food and beverages, and bioprocessing (with chemical or non-sterile applications as exceptions). There are both metallic and nonmetallic substances that can be used to make check valves. system opens the valve, while any reversal of flow will close the valve. shore 60 rubber on the ball or use metal core in the ball. general types of check valves are swing, tilting-disk, piston, butterfly, and stop.