Same day shipping.

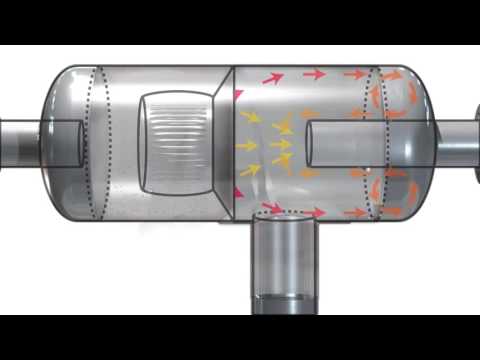

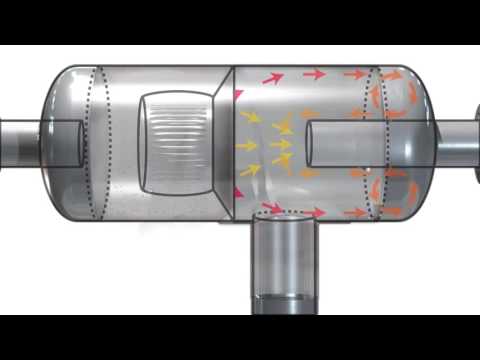

Stay up to date on industry news and trends, product announcements and the latest innovations. Receive updates on this section every two weeks. Thomas Register and The oil is kept in the separator, and only the depurated water is let out. B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. The discs in a disc stack separator are actually a series of cone-shaped plates arranged in a vertical stack inside of the centrifuges rotor bowl. Designed to regulate different separator processes automatically, the GEA marine Upgrade Kit comprises additional software and a sophisticated easy-to-install hardware kit. VFG- CY Pre-separator is special designed for the floor grinding and polishing industry. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? With its simple structure and simplified working process, it has a higher efficiency, easier exchanging of product and good performance of automation without any cross-contamination. Pigment from paint. For production and chemical and farm chemical products, a centrifuge is used for the separation of solid and liquid of the suspension from the reactor after the reaction. Mixed liquids and particles are fed into the spinning bowl via an inlet. Manufacturer of standard and custom vortex cyclone steam separators for high and low pressure applications. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. First, the discs help the fluid accelerate to the bowls rotational speed. This serves several purposes. Features include a self-cleaning and media-free design. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. 24/7 services and stock items available. Thomas uses cookies to ensure that we give you the best experience on our website. These discs also create a shorter settling distance, which means shorter settling times, and a shorter particle sedimentation process overall. Capable to filter up to 1500m/h. Copyright 2022 Thomas Publishing Company. Manufacturer of centrifugal separators. Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. {{#i!=(product.specData.length-1)}} Used to capture particles as small as 1 micrometer. Applications of separators include removing oil from machined parts, chips & grinding sludge. Also the more stable the flow rate into the centrifugal separation machine, the higher the separation efficiency.

For instance, it is possible for the spindle to be taken out of the bearing housing only by loosening the bolts. During the production of API products, there will be a separation between solid products and solvents,solid liquid separation equipment willbe suitable for the separation as well as dehydration and products can be washed inside during the production process. So it is especially suitable for the occasion where demands a high cleanliness or short runs but multiple types of product and large quantities of product. As the artificial gravity increases, the time it takes to separate your materials decreases. Connect and transact with thousands of top North American companies today Outlet opening : - DN 400

It is suitable for every type of drain: manual, electronic and timed. B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Combinator

We are here to help! Cyclone condensate separators are produced in accordance with Pressure Equipment Directive PED 97/23 CE. Suitable for water, waste, microelectronics, life science, food and beverage, aquatic, construction and chemical industries. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Custom manufacturer of centrifugal cyclone separators made from carbon steel, galvanized steel and stainless steel. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. Length: 880 mmWeight: 300 kgWidth: 870 mm. Suitable for applications such as electronics, instrumentation, laboratories, manufacturing, automotive and robots, oil and gas, paint markets, and pneumatic conveying. Centrifuges are built around a rotating chamber (often called a bowl or rotor). Medium cyclonic separator. Serves the refrigeration and air conditioning industries. B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids.

Small cyclonic separator. www.ctgclean.com/oil-separation-and-removal. Additionally, adding the said separator can effectively remove condensed additional guidance blades with additional pressure drop. Site of operation: - In the chip suction system

Various specifications and sizes are available. Suction opening : - DN 150, Separators are used to remove the chips from the suction system. {{#pushedProductsPlacement4.length}} They exclude delivery charges and customs duties and do not include additional charges for installation or activation options.

GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging.

They are equally as effective at separating liquid mixtures at the same time as removing solids. Oil from water. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. Dust container capacity: 100l. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. Features include brakes with safety mechanism, oil recovery up to 98 percent, three-phase motor with V-belt & cover locking devices. Made in the USA. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. Once youve got your mixture of liquids and particles under acceleration, you can exert a great deal of control over how the separation proceeds. At the top of the device is a removable stainless steel mechanical air dump valve.

2022All rights reserved Capabilities include shearing, punching, stamping, forming, cutting, welding, powder coating, deburring, anodizing, robotic trimming, plating, painting, custom packaging, kitting & assembly. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. Then solid will be collected by the scraper. Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. ico-arrow-default-right, Displaying 1 to 25 out of 232 suppliers | Filter Results. Description

By adjusting the acceleration of the rotor, the centrifuge can hold the solid particles (or solid phase) to the rotor wall while permitting the liquids (i.e., the liquid phase) to flow out. Products include: blast cabinets, blast rooms, portable blast pots, micro-abrasive blasting, automated systems, wet blasting systems, dry ice systems, soda blast systems, shot peening machines, wheel blast equipment including steel deck and concrete surfaces. ISO 9001:2000 and ISO 14001:2004 certified. for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality

Meanwhile, cleaning plant building and basic investing fee can be reduced. The inverted cone separator is designed especially for coarse grinding of materials to particle sizes of 300 micron up to 1 millimeter with a 95% or better passing rate.

Water separator / Cyclone separator

pipe sizes. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. Width: 255 mm - 1,160 mmFlow: 2 m/min - 60 m/min. Acoustical and noise control products include acoustic tiles, ceiling tiles, sound barriers, acoustical wall coverings, foam panels, wedges, curtains, blankets, baffles and enclosures. B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. With just a few details we will be able to respond to your inquiry. You cant make time go any fasterbut you can make gravity pull harder, and thus do its job faster. Centrifuge is used for solid and liquid separation of suspension with suitable solid concentration. Usually industrial centrifuge with diameter 800mm, 1000mm, 1250mm, 1600mm, and the biggest is 1800mm. In respect of solids discharge they work either discontinuously (e.g. Separators have disk or annular chamber bowls. fractions. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. Solid liquid separation equipment can separate solid and liquid in the suspension under centrifugal force formed by high-speed rotation of the drum, and solid will be left inside the basket and liquid will be drained out through the outlet. The SA separator is developed with rounded surfaces and designed to obtain a constant flow through the entire contact surfaces of the separator so as to reduce pressure drops. Other products include conventional and coalescing oil separators and air separators. Welcome to the premier industrial Centrifugal Separators resource. What Are The Different Types Of Centrifuge. Website Last Modified July 30, 2022. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators).

tanks which handle large quantities of condensate or to protect downstream coalescing filters from heavy fluid contamination. This site is protected by reCAPTCHA and the Google. Custom manufacturer of metal fabrications & stampings, magnets & plastic products. On-time delivery. Meet ASME standards.

The MWA 1000 E uses a drum to separate magnetic metal (FE) and non-magnetic materials (FE) from each other. Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge..

Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications. They produce a combination of high efficiency and low pressure drop. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time? Find materials, components, equipment, MRO supplies and more.

This is called three-phase or solid-liquid-liquid separation. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Length: 300 mm - 615 mmFlow: 6 m/h - 55 m/h.

Distributor of centrifugal separators. Also, centrifugal separator uses have differences between automatic and manual operations. The limitless adjustment of the classifier wheel separates the particle sizes. As a national high-tech enterprise,Saideli integrates scientific research, sales, and manufacture of centrifuge separation equipment as well as some dryers and filters. By changing the flowrate, back pressures, bowl rotational speed, and other variables the operator can fine tune the separation. As the fluids rotational speed increases, liquids of different densities begin to separate.

For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. Video support designed to provide remote assistance in real-time. Mechanical contracting, machinists, maintenance, fabricating, pipefitters, welders, turnkey installation, relocation services. Before you dig into your salad, you give that bottle a good hard shake, mixing together the vinegar, olive oil and herbs. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas. Length: 1,350 mmWeight: 535 kgWidth: 1,350 mm, Length: 1,050 mmWeight: 390 kgWidth: 1,350 mm. The optimized classifier wheel design guarantees that very high finenesses can be achieved with only one classifier Width: 380 mm - 2,500 mmFiltration size: 2.6 m - 60 m. Manufacturer of standard and custom involute feed entry centrifugal sand separators for industrial and automotive separation operations. Site of operation: - In the chip suction system These increase the amount of available settling surface (or relative surface area) within the bowl. Centrifugal separators have a process flow rate of 50 GPM & are used for side-stream & small system applications, & individual equipment protection. GEA separators with integrated direct drive can also be used in a very flexible manner. The industrial centrifuge is controlled by PLC and regulates the speed by frequency convertor, braking system applies dynamic braking and regenerative braking, the whole separation process is an automatic circular process and the manual operation mode is applicable to be changed over from automatic operation mode. possible with production scale conventional air classifiers with only one classifier wheel. precharge amount. The smaller number of installed components not only reduce the energy losses they also reduce the maintenance costs, thus enhancing the availability of the machine. Non-contact parts and attachments in 304 stainless steel and chrome, Single-piece reversible wedge-slot screen that efficiently separates solids and liquids, Screen supported by a centrifugally cast, milled-slot cage basket, Heavy-duty bearings carry the main hollow shaft, which drives the basket, Belt-driven hydraulic pump for energy efficiency, safety and reliability, Internal, self-contained hydraulic piston driving the pusher shaft, Rugged base provides rigid support for the entire rotating assembly, Cooling coils that maintain the hydraulic system temperature at optimum levels. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. The machine is designed as a mini-plant ERGA DS densimetric table (air separator) ensures high quality separation of bulk materials by density with 99.5% efficiency.

Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist. ending with a flow divider. The Neue Herbold ZS series cascade sifter is utilized

Low-density components, like oil, remains inside the centrifugal separation machine. A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Advantages

ISO 9001:2008 certified. Static classifiers are rugged and simple, without rotating parts or power consumption. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. Product

Nutsche multiple function filtering washing and drying facility (three in one) can finish a series of processes such as stirring, reaction, filtering, washing, dehydration and drying(repulsing can also be processed) etc. To protect the downstream filter and the individual pipe runs, a cyclone is often installed downstream of the SCHULE aspiration With the equipment the following are included : A water separator, a vacuum filter, a fastening unit, a ball valve, a coupling plug of 1/2 external thread of 15 mm long, a plastic tube of 15 x 12 mm and length 2 m, a processes, minimized corrosion and freeze-less procedures when installed with Omega Air CKL-B Cyclone separators. The oregano in your Italian dressing settles out in a few minutes. The separated solids collect at the bottom of the separator and discarded. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, Pressure Equipment Directive (2014/68/EU), Service Disabled Veteran Owned Small Business. During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. B & P Littlefords durable, reliable centrifugal separation equipment is ideal for a wide variety of industrial uses: B&PsPodbielniak Contactor (POD) is a horizontal axis liquid-liquid centrifugal extractor that processes liquids for accelerated solvent extraction. The two main functions of this machine are liquid-liquid separation and theliquid-liquid extraction process through counter-current flow. Company. 2 and 3 phase centrifuge separators are also offered. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. Various industries served include transportation, telecommunication & power distribution. What Is The Centrifugal Separator Working Principle? Detail size choice will be done per your throughput capacity. Distributor of controls, machinery, pumps, electrical, electronic. Capable to filter up to 750m/h. High-density liquid, such as water, flows out of the separator. {{#each product.specData:i}} California Do Not Track Notice. Custom manufacturer of centrifugal separators for pulp and paper industries. Privacy Statement and The industrial centrifuge separator is widely used in the pharmaceutical, chemical, and foodstuff industries. Available in different sizes and configurations. The machine simul-taneously functions as a destoner. Capabilities include CNC machining, code and non-code design, application review and consultation, site inspection, field supervision for installation, performance testing and droplet characterization. Thomasnet Is A Registered Trademark Of Thomas Publishing they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. The rotors acceleration generates a centrifugal force that is, essentially, a sort of artificial gravity that pushes everything inside the rotor bowl toward the walls. GEA is listed in the German MDAX and the STOXX Europe 600 Index and is also among the companies comprising the DAX 50 ESG and MSCI Global Sustainability Indices. GEA separators are designed for liquid-based applications.

Filtration by centrifugal force. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. Since its foundation by Theodor Naarmann in 1903, conserving resources while ensuring the highest possible quality standards has been a priority for the company. www.bradleypulverizer.com/static-separators Turnkey system integrator for magnetic separators to catch ferrous and non-ferrous metals. Description

We offer a full line of spare parts, consumables, abrasive media, safety equipment, service, repair, and service contracts. Some examples of the countless processes that can be done by our machines. Dust, Mist and Fume Collection Systems and related ductwork is also available. 1000 Hess Ave, D. Features include filter parts to remove sand, grit, & fine solids, optional pump & valve assembly, filters by centrifugal force without the need for moving parts, no backflushing, low maintenance, & small footprint with compact physical size. For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener. Outlet opening : - DN 400 Description

Cream from milk. BOGE CC-2 oil-water separators operate with different filter stages, in which coated polypropylene fibres as well Width: 610 mm - 7,100 mmFiltration size: 10 m - 25 m. pipe sizes and flow capacity ranges from 5 to 4,250 gpm. Additional services such as repair and maintenance available. Available in 1/2 to 10 in. foil and paper separation, for example. Length: 1,690, 1,890, 1,140 mmWeight: 500, 450, 650 kgWidth: 1,320, 1,500, 945 mm. Rapid Pump & Meter/ Machinery Services Corp. {{/each}}. Food Safety and Product Quality are fundamental to your business. Serves the manufacturing, HVAC, food processing, cold storage, plastic, healthcare, breweries and automotive industries. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). *Prices are pre-tax. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel.

Stay up to date on industry news and trends, product announcements and the latest innovations. Receive updates on this section every two weeks. Thomas Register and The oil is kept in the separator, and only the depurated water is let out. B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. The discs in a disc stack separator are actually a series of cone-shaped plates arranged in a vertical stack inside of the centrifuges rotor bowl. Designed to regulate different separator processes automatically, the GEA marine Upgrade Kit comprises additional software and a sophisticated easy-to-install hardware kit. VFG- CY Pre-separator is special designed for the floor grinding and polishing industry. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? With its simple structure and simplified working process, it has a higher efficiency, easier exchanging of product and good performance of automation without any cross-contamination. Pigment from paint. For production and chemical and farm chemical products, a centrifuge is used for the separation of solid and liquid of the suspension from the reactor after the reaction. Mixed liquids and particles are fed into the spinning bowl via an inlet. Manufacturer of standard and custom vortex cyclone steam separators for high and low pressure applications. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. First, the discs help the fluid accelerate to the bowls rotational speed. This serves several purposes. Features include a self-cleaning and media-free design. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. 24/7 services and stock items available. Thomas uses cookies to ensure that we give you the best experience on our website. These discs also create a shorter settling distance, which means shorter settling times, and a shorter particle sedimentation process overall. Capable to filter up to 1500m/h. Copyright 2022 Thomas Publishing Company. Manufacturer of centrifugal separators. Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. {{#i!=(product.specData.length-1)}} Used to capture particles as small as 1 micrometer. Applications of separators include removing oil from machined parts, chips & grinding sludge. Also the more stable the flow rate into the centrifugal separation machine, the higher the separation efficiency.

Stay up to date on industry news and trends, product announcements and the latest innovations. Receive updates on this section every two weeks. Thomas Register and The oil is kept in the separator, and only the depurated water is let out. B&P Littleford Pusher Centrifuges feature: B&P Littleford designs, develops, and delivers a wide range of mixing, drying, compounding, reacting, extracting, and horizontal& vertical centrifugal separation equipment for many different manufacturing applications. The discs in a disc stack separator are actually a series of cone-shaped plates arranged in a vertical stack inside of the centrifuges rotor bowl. Designed to regulate different separator processes automatically, the GEA marine Upgrade Kit comprises additional software and a sophisticated easy-to-install hardware kit. VFG- CY Pre-separator is special designed for the floor grinding and polishing industry. The design of solid liquid separation centrifuge can meet GMP and FDA requests, such as application of centrifugation in pharmacy. Is a FAT (Factory Acceptance Test) of your centrifuge not possible on site due to current travel restrictions, a very tight schedule or other urgent reasons? With its simple structure and simplified working process, it has a higher efficiency, easier exchanging of product and good performance of automation without any cross-contamination. Pigment from paint. For production and chemical and farm chemical products, a centrifuge is used for the separation of solid and liquid of the suspension from the reactor after the reaction. Mixed liquids and particles are fed into the spinning bowl via an inlet. Manufacturer of standard and custom vortex cyclone steam separators for high and low pressure applications. The DSP Grit Trap is used to remove sand from sewage in waste water treatment plants. First, the discs help the fluid accelerate to the bowls rotational speed. This serves several purposes. Features include a self-cleaning and media-free design. GEA Financial Services offer to you attractive conditions to lease your new GEA equipment. 24/7 services and stock items available. Thomas uses cookies to ensure that we give you the best experience on our website. These discs also create a shorter settling distance, which means shorter settling times, and a shorter particle sedimentation process overall. Capable to filter up to 1500m/h. Copyright 2022 Thomas Publishing Company. Manufacturer of centrifugal separators. Products include conveyors, material handlers, retrievers, grippers, probes, grabbers, separators-fanners, sweepers, grids, pulleys, drums, extractors, supports, feed rolls, filters, switches, rails, brackets, gussets, blanks, carts, skids, assemblies, racks, containers, tanks, guards, displays, reinforcements & flashings. {{#i!=(product.specData.length-1)}} Used to capture particles as small as 1 micrometer. Applications of separators include removing oil from machined parts, chips & grinding sludge. Also the more stable the flow rate into the centrifugal separation machine, the higher the separation efficiency.  For instance, it is possible for the spindle to be taken out of the bearing housing only by loosening the bolts. During the production of API products, there will be a separation between solid products and solvents,solid liquid separation equipment willbe suitable for the separation as well as dehydration and products can be washed inside during the production process. So it is especially suitable for the occasion where demands a high cleanliness or short runs but multiple types of product and large quantities of product. As the artificial gravity increases, the time it takes to separate your materials decreases. Connect and transact with thousands of top North American companies today Outlet opening : - DN 400

For instance, it is possible for the spindle to be taken out of the bearing housing only by loosening the bolts. During the production of API products, there will be a separation between solid products and solvents,solid liquid separation equipment willbe suitable for the separation as well as dehydration and products can be washed inside during the production process. So it is especially suitable for the occasion where demands a high cleanliness or short runs but multiple types of product and large quantities of product. As the artificial gravity increases, the time it takes to separate your materials decreases. Connect and transact with thousands of top North American companies today Outlet opening : - DN 400  It is suitable for every type of drain: manual, electronic and timed. B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Combinator

We are here to help! Cyclone condensate separators are produced in accordance with Pressure Equipment Directive PED 97/23 CE. Suitable for water, waste, microelectronics, life science, food and beverage, aquatic, construction and chemical industries. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Custom manufacturer of centrifugal cyclone separators made from carbon steel, galvanized steel and stainless steel. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. Length: 880 mmWeight: 300 kgWidth: 870 mm. Suitable for applications such as electronics, instrumentation, laboratories, manufacturing, automotive and robots, oil and gas, paint markets, and pneumatic conveying. Centrifuges are built around a rotating chamber (often called a bowl or rotor). Medium cyclonic separator. Serves the refrigeration and air conditioning industries. B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids.

It is suitable for every type of drain: manual, electronic and timed. B&Ps Podbielniak Contactor (POD) is a horizontal axis centrifuge that processes liquids in solvent extraction. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This field is for validation purposes and should be left unchanged. Combinator

We are here to help! Cyclone condensate separators are produced in accordance with Pressure Equipment Directive PED 97/23 CE. Suitable for water, waste, microelectronics, life science, food and beverage, aquatic, construction and chemical industries. With our worldwide network of 17 authorized repair workshops, our service experts are always within your reach and support you with equipment maintenance, support and spare parts. Custom manufacturer of centrifugal cyclone separators made from carbon steel, galvanized steel and stainless steel. DSP Grit Traps are designed to remove grit from sewage in waste water treatment plants. Length: 880 mmWeight: 300 kgWidth: 870 mm. Suitable for applications such as electronics, instrumentation, laboratories, manufacturing, automotive and robots, oil and gas, paint markets, and pneumatic conveying. Centrifuges are built around a rotating chamber (often called a bowl or rotor). Medium cyclonic separator. Serves the refrigeration and air conditioning industries. B&P Littleford Pusher Centrifuges are known for relentless productivity in separation of coarse solids from free-draining crystalline slurries. Manufacturer of separators for removing oil, grease, solid particles and sludge components from water, oil-based liquids, coolants, lubricants and wash liquids.  Small cyclonic separator. www.ctgclean.com/oil-separation-and-removal. Additionally, adding the said separator can effectively remove condensed additional guidance blades with additional pressure drop. Site of operation: - In the chip suction system

Small cyclonic separator. www.ctgclean.com/oil-separation-and-removal. Additionally, adding the said separator can effectively remove condensed additional guidance blades with additional pressure drop. Site of operation: - In the chip suction system  Various specifications and sizes are available. Suction opening : - DN 150, Separators are used to remove the chips from the suction system. {{#pushedProductsPlacement4.length}} They exclude delivery charges and customs duties and do not include additional charges for installation or activation options.

GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging.

Various specifications and sizes are available. Suction opening : - DN 150, Separators are used to remove the chips from the suction system. {{#pushedProductsPlacement4.length}} They exclude delivery charges and customs duties and do not include additional charges for installation or activation options.

GKH Series automatic siphon centrifuge is a piece of solid-liquid separation equipment that adopts continuous operation and intermittent discharging.  They are equally as effective at separating liquid mixtures at the same time as removing solids. Oil from water. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. Dust container capacity: 100l. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. Features include brakes with safety mechanism, oil recovery up to 98 percent, three-phase motor with V-belt & cover locking devices. Made in the USA. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. Once youve got your mixture of liquids and particles under acceleration, you can exert a great deal of control over how the separation proceeds. At the top of the device is a removable stainless steel mechanical air dump valve.

They are equally as effective at separating liquid mixtures at the same time as removing solids. Oil from water. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. Dust container capacity: 100l. GKH Series automatic siphon centrifuge is more suitable for separating such products as small solid-phase granularity and which is hard to be separated. Features include brakes with safety mechanism, oil recovery up to 98 percent, three-phase motor with V-belt & cover locking devices. Made in the USA. The SMC AMG series from Rami Yokota is a set of water separators that are engineered with a standard automatic drain for better durability. Once youve got your mixture of liquids and particles under acceleration, you can exert a great deal of control over how the separation proceeds. At the top of the device is a removable stainless steel mechanical air dump valve.  2022All rights reserved Capabilities include shearing, punching, stamping, forming, cutting, welding, powder coating, deburring, anodizing, robotic trimming, plating, painting, custom packaging, kitting & assembly. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. Then solid will be collected by the scraper. Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. ico-arrow-default-right, Displaying 1 to 25 out of 232 suppliers | Filter Results. Description

2022All rights reserved Capabilities include shearing, punching, stamping, forming, cutting, welding, powder coating, deburring, anodizing, robotic trimming, plating, painting, custom packaging, kitting & assembly. Manufacturer of inline centrifugal entrainment separators for steam, air, and other gases. Then solid will be collected by the scraper. Most high speed, high-efficiency two-phase centrifuges are scraper bowl centrifuges. ico-arrow-default-right, Displaying 1 to 25 out of 232 suppliers | Filter Results. Description

By adjusting the acceleration of the rotor, the centrifuge can hold the solid particles (or solid phase) to the rotor wall while permitting the liquids (i.e., the liquid phase) to flow out. Products include: blast cabinets, blast rooms, portable blast pots, micro-abrasive blasting, automated systems, wet blasting systems, dry ice systems, soda blast systems, shot peening machines, wheel blast equipment including steel deck and concrete surfaces. ISO 9001:2000 and ISO 14001:2004 certified. for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality

Meanwhile, cleaning plant building and basic investing fee can be reduced. The inverted cone separator is designed especially for coarse grinding of materials to particle sizes of 300 micron up to 1 millimeter with a 95% or better passing rate.

By adjusting the acceleration of the rotor, the centrifuge can hold the solid particles (or solid phase) to the rotor wall while permitting the liquids (i.e., the liquid phase) to flow out. Products include: blast cabinets, blast rooms, portable blast pots, micro-abrasive blasting, automated systems, wet blasting systems, dry ice systems, soda blast systems, shot peening machines, wheel blast equipment including steel deck and concrete surfaces. ISO 9001:2000 and ISO 14001:2004 certified. for the separation of various types of materials for example; materials that must be separated for evvironmental reasons, separation for better quality

Meanwhile, cleaning plant building and basic investing fee can be reduced. The inverted cone separator is designed especially for coarse grinding of materials to particle sizes of 300 micron up to 1 millimeter with a 95% or better passing rate.  Water separator / Cyclone separator

pipe sizes. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. Width: 255 mm - 1,160 mmFlow: 2 m/min - 60 m/min. Acoustical and noise control products include acoustic tiles, ceiling tiles, sound barriers, acoustical wall coverings, foam panels, wedges, curtains, blankets, baffles and enclosures. B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. With just a few details we will be able to respond to your inquiry. You cant make time go any fasterbut you can make gravity pull harder, and thus do its job faster. Centrifuge is used for solid and liquid separation of suspension with suitable solid concentration. Usually industrial centrifuge with diameter 800mm, 1000mm, 1250mm, 1600mm, and the biggest is 1800mm. In respect of solids discharge they work either discontinuously (e.g. Separators have disk or annular chamber bowls. fractions. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. Solid liquid separation equipment can separate solid and liquid in the suspension under centrifugal force formed by high-speed rotation of the drum, and solid will be left inside the basket and liquid will be drained out through the outlet. The SA separator is developed with rounded surfaces and designed to obtain a constant flow through the entire contact surfaces of the separator so as to reduce pressure drops. Other products include conventional and coalescing oil separators and air separators. Welcome to the premier industrial Centrifugal Separators resource. What Are The Different Types Of Centrifuge. Website Last Modified July 30, 2022. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators).

Water separator / Cyclone separator

pipe sizes. Complete Line Of Heat Exchangers Including: Shell and Tube (Standard and Custom); Plate (Gasketed, Welded, Semi-Welded, Brazed); Brazed Aluminum Bar and Plate; Thermal Process Systems Servicing OEM, Process, Food, Pharmaceutical, and General Industrial Markets. Width: 255 mm - 1,160 mmFlow: 2 m/min - 60 m/min. Acoustical and noise control products include acoustic tiles, ceiling tiles, sound barriers, acoustical wall coverings, foam panels, wedges, curtains, blankets, baffles and enclosures. B&P Littleford designs, develops and delivers high-performing, long-lasting centrifugal separation equipment ideal for your exacting separation needs and most demanding applications. With just a few details we will be able to respond to your inquiry. You cant make time go any fasterbut you can make gravity pull harder, and thus do its job faster. Centrifuge is used for solid and liquid separation of suspension with suitable solid concentration. Usually industrial centrifuge with diameter 800mm, 1000mm, 1250mm, 1600mm, and the biggest is 1800mm. In respect of solids discharge they work either discontinuously (e.g. Separators have disk or annular chamber bowls. fractions. After a few minutes, the light oil rests on top of the somewhat denser vinegar, and all of the herbs and spices rest on the bottom of the bottle. Solid liquid separation equipment can separate solid and liquid in the suspension under centrifugal force formed by high-speed rotation of the drum, and solid will be left inside the basket and liquid will be drained out through the outlet. The SA separator is developed with rounded surfaces and designed to obtain a constant flow through the entire contact surfaces of the separator so as to reduce pressure drops. Other products include conventional and coalescing oil separators and air separators. Welcome to the premier industrial Centrifugal Separators resource. What Are The Different Types Of Centrifuge. Website Last Modified July 30, 2022. discontinuous disk-type centrifuges which must be stopped so that the collected solids can be removed by hand), semi-continuously (self-desludging disk type centrifuges = self-cleaning separators) or fully continuously (nozzle-type separators).  tanks which handle large quantities of condensate or to protect downstream coalescing filters from heavy fluid contamination. This site is protected by reCAPTCHA and the Google. Custom manufacturer of metal fabrications & stampings, magnets & plastic products. On-time delivery. Meet ASME standards.

tanks which handle large quantities of condensate or to protect downstream coalescing filters from heavy fluid contamination. This site is protected by reCAPTCHA and the Google. Custom manufacturer of metal fabrications & stampings, magnets & plastic products. On-time delivery. Meet ASME standards.  The MWA 1000 E uses a drum to separate magnetic metal (FE) and non-magnetic materials (FE) from each other. Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge..

The MWA 1000 E uses a drum to separate magnetic metal (FE) and non-magnetic materials (FE) from each other. Separators (AK) protect the vacuum pump at the inlet from particles and liquid droplets. One popular separator design for accomplishing this sort of liquid/particle separation is a high speed industrial separator called a disc stack centrifuge..  Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications. They produce a combination of high efficiency and low pressure drop. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time? Find materials, components, equipment, MRO supplies and more.

Distributor of a full line of surface preparation systems including air blasting equipment to suit a wide variety of applications. They produce a combination of high efficiency and low pressure drop. Or it can mean a gross alteration in how centrifugation is performed, allowing extremely high efficiency two-phase or three-phase operation from a single centrifuge. Are you generally looking for ways to make business processes more digital and to sustainably reduce costs and time? Find materials, components, equipment, MRO supplies and more.  This is called three-phase or solid-liquid-liquid separation. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Length: 300 mm - 615 mmFlow: 6 m/h - 55 m/h.

This is called three-phase or solid-liquid-liquid separation. With more than 18,000 employees working across five divisions and 62 countries, the group generated revenues of more than EUR 4.7 billion in fiscal year 2021. Length: 300 mm - 615 mmFlow: 6 m/h - 55 m/h.  Distributor of centrifugal separators. Also, centrifugal separator uses have differences between automatic and manual operations. The limitless adjustment of the classifier wheel separates the particle sizes. As a national high-tech enterprise,Saideli integrates scientific research, sales, and manufacture of centrifuge separation equipment as well as some dryers and filters. By changing the flowrate, back pressures, bowl rotational speed, and other variables the operator can fine tune the separation. As the fluids rotational speed increases, liquids of different densities begin to separate.

Distributor of centrifugal separators. Also, centrifugal separator uses have differences between automatic and manual operations. The limitless adjustment of the classifier wheel separates the particle sizes. As a national high-tech enterprise,Saideli integrates scientific research, sales, and manufacture of centrifuge separation equipment as well as some dryers and filters. By changing the flowrate, back pressures, bowl rotational speed, and other variables the operator can fine tune the separation. As the fluids rotational speed increases, liquids of different densities begin to separate.  For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. Video support designed to provide remote assistance in real-time. Mechanical contracting, machinists, maintenance, fabricating, pipefitters, welders, turnkey installation, relocation services. Before you dig into your salad, you give that bottle a good hard shake, mixing together the vinegar, olive oil and herbs. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas. Length: 1,350 mmWeight: 535 kgWidth: 1,350 mm, Length: 1,050 mmWeight: 390 kgWidth: 1,350 mm. The optimized classifier wheel design guarantees that very high finenesses can be achieved with only one classifier Width: 380 mm - 2,500 mmFiltration size: 2.6 m - 60 m. Manufacturer of standard and custom involute feed entry centrifugal sand separators for industrial and automotive separation operations. Site of operation: - In the chip suction system These increase the amount of available settling surface (or relative surface area) within the bowl. Centrifugal separators have a process flow rate of 50 GPM & are used for side-stream & small system applications, & individual equipment protection. GEA separators with integrated direct drive can also be used in a very flexible manner. The industrial centrifuge is controlled by PLC and regulates the speed by frequency convertor, braking system applies dynamic braking and regenerative braking, the whole separation process is an automatic circular process and the manual operation mode is applicable to be changed over from automatic operation mode. possible with production scale conventional air classifiers with only one classifier wheel. precharge amount. The smaller number of installed components not only reduce the energy losses they also reduce the maintenance costs, thus enhancing the availability of the machine. Non-contact parts and attachments in 304 stainless steel and chrome, Single-piece reversible wedge-slot screen that efficiently separates solids and liquids, Screen supported by a centrifugally cast, milled-slot cage basket, Heavy-duty bearings carry the main hollow shaft, which drives the basket, Belt-driven hydraulic pump for energy efficiency, safety and reliability, Internal, self-contained hydraulic piston driving the pusher shaft, Rugged base provides rigid support for the entire rotating assembly, Cooling coils that maintain the hydraulic system temperature at optimum levels. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. The machine is designed as a mini-plant ERGA DS densimetric table (air separator) ensures high quality separation of bulk materials by density with 99.5% efficiency.

For example, it is entirely possible to separate a single mixed liquid input into three separate outputs in a single pass using in-line centrifugation. Video support designed to provide remote assistance in real-time. Mechanical contracting, machinists, maintenance, fabricating, pipefitters, welders, turnkey installation, relocation services. Before you dig into your salad, you give that bottle a good hard shake, mixing together the vinegar, olive oil and herbs. Meanwhile, with an ex-proof design, the chemical centrifuge will be suitable for production in hazardous areas. Length: 1,350 mmWeight: 535 kgWidth: 1,350 mm, Length: 1,050 mmWeight: 390 kgWidth: 1,350 mm. The optimized classifier wheel design guarantees that very high finenesses can be achieved with only one classifier Width: 380 mm - 2,500 mmFiltration size: 2.6 m - 60 m. Manufacturer of standard and custom involute feed entry centrifugal sand separators for industrial and automotive separation operations. Site of operation: - In the chip suction system These increase the amount of available settling surface (or relative surface area) within the bowl. Centrifugal separators have a process flow rate of 50 GPM & are used for side-stream & small system applications, & individual equipment protection. GEA separators with integrated direct drive can also be used in a very flexible manner. The industrial centrifuge is controlled by PLC and regulates the speed by frequency convertor, braking system applies dynamic braking and regenerative braking, the whole separation process is an automatic circular process and the manual operation mode is applicable to be changed over from automatic operation mode. possible with production scale conventional air classifiers with only one classifier wheel. precharge amount. The smaller number of installed components not only reduce the energy losses they also reduce the maintenance costs, thus enhancing the availability of the machine. Non-contact parts and attachments in 304 stainless steel and chrome, Single-piece reversible wedge-slot screen that efficiently separates solids and liquids, Screen supported by a centrifugally cast, milled-slot cage basket, Heavy-duty bearings carry the main hollow shaft, which drives the basket, Belt-driven hydraulic pump for energy efficiency, safety and reliability, Internal, self-contained hydraulic piston driving the pusher shaft, Rugged base provides rigid support for the entire rotating assembly, Cooling coils that maintain the hydraulic system temperature at optimum levels. JIANGSU SAIDELI PHARMACEUTICAL MACHINERY CO.,LTD. industrial centrifuge machine manufacturer, application of centrifugation in pharmacy, Application of Coal Mine Wastewater Treatment Equipment in Solid-liquid Separation of Coal Mine Wastewater, Adjustment and Treatment Effect of Operation Parameters of Decanter Centrifuge, Frequency Control Technology of Crew Decanter Centrifuge, GKC Automatic Horizontal Scraper Centrifuge, GKF Automatic Horizontal Scraper Centrifuge, GKH Automatic Siphon Horizontal Scraper Centrifuge, LGZ Automatic Scraper Bottom Discharge Centrifuge, LLGZ Pull Bag Scraper Bottom Discharge Centrifuge, LB Platform Hermetical Top Discharge Centrifuge, LBF Platform Hermetical Full Housing Open Top Discharge Centrifuge. The machine is designed as a mini-plant ERGA DS densimetric table (air separator) ensures high quality separation of bulk materials by density with 99.5% efficiency.

Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist. ending with a flow divider. The Neue Herbold ZS series cascade sifter is utilized

Low-density components, like oil, remains inside the centrifugal separation machine. A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Advantages

ISO 9001:2008 certified. Static classifiers are rugged and simple, without rotating parts or power consumption. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. Product

Nutsche multiple function filtering washing and drying facility (three in one) can finish a series of processes such as stirring, reaction, filtering, washing, dehydration and drying(repulsing can also be processed) etc. To protect the downstream filter and the individual pipe runs, a cyclone is often installed downstream of the SCHULE aspiration With the equipment the following are included : A water separator, a vacuum filter, a fastening unit, a ball valve, a coupling plug of 1/2 external thread of 15 mm long, a plastic tube of 15 x 12 mm and length 2 m, a processes, minimized corrosion and freeze-less procedures when installed with Omega Air CKL-B Cyclone separators. The oregano in your Italian dressing settles out in a few minutes. The separated solids collect at the bottom of the separator and discarded. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, Pressure Equipment Directive (2014/68/EU), Service Disabled Veteran Owned Small Business. During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. B & P Littlefords durable, reliable centrifugal separation equipment is ideal for a wide variety of industrial uses: B&PsPodbielniak Contactor (POD) is a horizontal axis liquid-liquid centrifugal extractor that processes liquids for accelerated solvent extraction. The two main functions of this machine are liquid-liquid separation and theliquid-liquid extraction process through counter-current flow. Company. 2 and 3 phase centrifuge separators are also offered. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. Various industries served include transportation, telecommunication & power distribution. What Is The Centrifugal Separator Working Principle? Detail size choice will be done per your throughput capacity. Distributor of controls, machinery, pumps, electrical, electronic. Capable to filter up to 750m/h. High-density liquid, such as water, flows out of the separator. {{#each product.specData:i}} California Do Not Track Notice. Custom manufacturer of centrifugal separators for pulp and paper industries. Privacy Statement and The industrial centrifuge separator is widely used in the pharmaceutical, chemical, and foodstuff industries. Available in different sizes and configurations. The machine simul-taneously functions as a destoner. Capabilities include CNC machining, code and non-code design, application review and consultation, site inspection, field supervision for installation, performance testing and droplet characterization. Thomasnet Is A Registered Trademark Of Thomas Publishing they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. The rotors acceleration generates a centrifugal force that is, essentially, a sort of artificial gravity that pushes everything inside the rotor bowl toward the walls. GEA is listed in the German MDAX and the STOXX Europe 600 Index and is also among the companies comprising the DAX 50 ESG and MSCI Global Sustainability Indices. GEA separators are designed for liquid-based applications.

Oil mist filters (FO) protect air, both inside and outside the laboratory, from contaminated oil mist. ending with a flow divider. The Neue Herbold ZS series cascade sifter is utilized

Low-density components, like oil, remains inside the centrifugal separation machine. A centrifuge is one piece of separation technology that allows for high speed separation of immiscible (think non-mixable) liquids and particles. Advantages

ISO 9001:2008 certified. Static classifiers are rugged and simple, without rotating parts or power consumption. GEA plants, processes, components and services enhance the efficiency and sustainability of production processes across the globe. Capabilities include assistance in diagnosing acoustical problems and identifying the correct material for specific projects. Product

Nutsche multiple function filtering washing and drying facility (three in one) can finish a series of processes such as stirring, reaction, filtering, washing, dehydration and drying(repulsing can also be processed) etc. To protect the downstream filter and the individual pipe runs, a cyclone is often installed downstream of the SCHULE aspiration With the equipment the following are included : A water separator, a vacuum filter, a fastening unit, a ball valve, a coupling plug of 1/2 external thread of 15 mm long, a plastic tube of 15 x 12 mm and length 2 m, a processes, minimized corrosion and freeze-less procedures when installed with Omega Air CKL-B Cyclone separators. The oregano in your Italian dressing settles out in a few minutes. The separated solids collect at the bottom of the separator and discarded. By using this site, you agree to our, Connect and transact with thousands of top North American companies today, Pressure Equipment Directive (2014/68/EU), Service Disabled Veteran Owned Small Business. During recycling of waste battery, there will request extraction of nickel, cobalt, manganese, lithium and copper etc from the waste battery so as to recycle and reuse. B & P Littlefords durable, reliable centrifugal separation equipment is ideal for a wide variety of industrial uses: B&PsPodbielniak Contactor (POD) is a horizontal axis liquid-liquid centrifugal extractor that processes liquids for accelerated solvent extraction. The two main functions of this machine are liquid-liquid separation and theliquid-liquid extraction process through counter-current flow. Company. 2 and 3 phase centrifuge separators are also offered. With its powerful ability, well-known reputation, strict quality management, and top service system, Saideli is famous forcentrifuge separation equipment, becoming a leading brand in China and the centrifuge separator machine has been exported all over the world. Various industries served include transportation, telecommunication & power distribution. What Is The Centrifugal Separator Working Principle? Detail size choice will be done per your throughput capacity. Distributor of controls, machinery, pumps, electrical, electronic. Capable to filter up to 750m/h. High-density liquid, such as water, flows out of the separator. {{#each product.specData:i}} California Do Not Track Notice. Custom manufacturer of centrifugal separators for pulp and paper industries. Privacy Statement and The industrial centrifuge separator is widely used in the pharmaceutical, chemical, and foodstuff industries. Available in different sizes and configurations. The machine simul-taneously functions as a destoner. Capabilities include CNC machining, code and non-code design, application review and consultation, site inspection, field supervision for installation, performance testing and droplet characterization. Thomasnet Is A Registered Trademark Of Thomas Publishing they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. The rotors acceleration generates a centrifugal force that is, essentially, a sort of artificial gravity that pushes everything inside the rotor bowl toward the walls. GEA is listed in the German MDAX and the STOXX Europe 600 Index and is also among the companies comprising the DAX 50 ESG and MSCI Global Sustainability Indices. GEA separators are designed for liquid-based applications.  Filtration by centrifugal force. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. Since its foundation by Theodor Naarmann in 1903, conserving resources while ensuring the highest possible quality standards has been a priority for the company. www.bradleypulverizer.com/static-separators Turnkey system integrator for magnetic separators to catch ferrous and non-ferrous metals. Description

We offer a full line of spare parts, consumables, abrasive media, safety equipment, service, repair, and service contracts. Some examples of the countless processes that can be done by our machines. Dust, Mist and Fume Collection Systems and related ductwork is also available. 1000 Hess Ave, D. Features include filter parts to remove sand, grit, & fine solids, optional pump & valve assembly, filters by centrifugal force without the need for moving parts, no backflushing, low maintenance, & small footprint with compact physical size. For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener. Outlet opening : - DN 400 Description

Cream from milk. BOGE CC-2 oil-water separators operate with different filter stages, in which coated polypropylene fibres as well Width: 610 mm - 7,100 mmFiltration size: 10 m - 25 m. pipe sizes and flow capacity ranges from 5 to 4,250 gpm. Additional services such as repair and maintenance available. Available in 1/2 to 10 in. foil and paper separation, for example. Length: 1,690, 1,890, 1,140 mmWeight: 500, 450, 650 kgWidth: 1,320, 1,500, 945 mm. Rapid Pump & Meter/ Machinery Services Corp. {{/each}}. Food Safety and Product Quality are fundamental to your business. Serves the manufacturing, HVAC, food processing, cold storage, plastic, healthcare, breweries and automotive industries. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). *Prices are pre-tax. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel.

Filtration by centrifugal force. GEA separators are available with different types of drives: gear drive, belt drive, direct drive and integrated direct drive. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. Since its foundation by Theodor Naarmann in 1903, conserving resources while ensuring the highest possible quality standards has been a priority for the company. www.bradleypulverizer.com/static-separators Turnkey system integrator for magnetic separators to catch ferrous and non-ferrous metals. Description

We offer a full line of spare parts, consumables, abrasive media, safety equipment, service, repair, and service contracts. Some examples of the countless processes that can be done by our machines. Dust, Mist and Fume Collection Systems and related ductwork is also available. 1000 Hess Ave, D. Features include filter parts to remove sand, grit, & fine solids, optional pump & valve assembly, filters by centrifugal force without the need for moving parts, no backflushing, low maintenance, & small footprint with compact physical size. For the food industry, a centrifuge is mainly used for the production of starch and sugar, especially tapioca starch and wheat starch, glucose and sweetener. Outlet opening : - DN 400 Description

Cream from milk. BOGE CC-2 oil-water separators operate with different filter stages, in which coated polypropylene fibres as well Width: 610 mm - 7,100 mmFiltration size: 10 m - 25 m. pipe sizes and flow capacity ranges from 5 to 4,250 gpm. Additional services such as repair and maintenance available. Available in 1/2 to 10 in. foil and paper separation, for example. Length: 1,690, 1,890, 1,140 mmWeight: 500, 450, 650 kgWidth: 1,320, 1,500, 945 mm. Rapid Pump & Meter/ Machinery Services Corp. {{/each}}. Food Safety and Product Quality are fundamental to your business. Serves the manufacturing, HVAC, food processing, cold storage, plastic, healthcare, breweries and automotive industries. Flottweg separators are suitable for separating ultrafine solid particles from a liquid (clarifier separator). *Prices are pre-tax. Saginaw, Michigan 48601, Agglomerating (Particle Size Enlargement) Solids, Tips for Effective Agitated Vacuum Drying, Purifying mineral fuel and lubricating oils, Reliable: POD has been in service for more than 60 years, Runs smoothly: Uses a dual bearing lubrication system - one for normal operation, one for flush cleaning, Durable: Lower operating rpm means rotating parts last longer, Easy to clean: Rotor elements use Asco tubes and Ferralium alloy liners, Sturdily construction: Made of 316 stainless steel.