When pump is pulled after completing #4 above, examine drop pipe connection to pump outlet. See more Zoeller 004705 Mechanical Switch - Black, - eBay Money Back Guarantee - opens in a new window or tab, - for PayPal Credit, opens in a new window or tab, Learn more about earning points with eBay Mastercard, - eBay Return policy - opens in a new tab or window, - eBay Money Back Guarantee - opens in a new tab or window. If your pump manufacturer is not known, or if you want to attempt to clean the rod yourself, you can use a small amount of sandpaper to attempt to sand off the rust on the rod.

Zoeller first opened its doors as a sump pump manufacturer in 1939, as a family owned and operated company. Almost any disturbance can cause atethered floatto become out of place. If your sump pump is having other issues this can contribute to your realizing your sump pump float is stuck. Low or incorrect voltage. Disassemble pump and remove foreign object. Sump pumps have come a long way in recent years, and they are better and more reliable than ever. All times are GMT-5.

Make sure control is operating properly. Make sure the float arm is free to rise and fall. Nope, KISS, I think. I switched to Liberty and we have great success. Piping attachment to building structure too rigid or too loose. If voltage under recommended minimum, check size of wiring from main switch on property. Wrong pressure switch setting or setting drift. Arcing may have caused pressure switch points to weld in closed position. Discharge head exceeds pump capacity. Rewire any incorrect circuits.

sump zoeller pump automatic water cord hp iii foot Low oil level in motor shell. Highly recommended repair kit, and a lot cheaper than an off-shore replacement! Pulled a dead n-98 used in a septic as effluent pump Monday and a dead wd-20 (~$1800) this summer, both ~2 years old, out of warranty, installed by me. Here are some common topics we are asked about. Zoeller provides sump pump systems that address both these critical issues. In this article we will teach you to to fix a stuck sump pump. Pressure switch defective or out of adjustment. If threaded section of drop pipe has been screwed in too far, it may be jamming the check valve in the closed position. Here are some common questions we hear from the field about these types of products in general. Close the discharge line valve. Check all motor and power line wiring in control box, following the wiring diagram found inside box. Swade's Tramco recommendation is most welcome. Carefully tighten pipe joints (use pipe dope) and screws. Discharge line is closed and priming air has nowhere to go. Andrew Leahey has been a writer since 1999, covering topics as varied as technology how-to guides and the politics of genetically modified organisms to African food supplies.

m53 sump zoeller pump I'd have to have the sump fail that way. Check gasket location, tighten lid evenly. Make sure above ground connections are tight. Punctures can mean that water gets into the float and weights it down, so it does not function correctly. Well take a look and remove the review if it doesnt follow our guidelines. What follows are just a few reasons that we at TC Hafford Basement Systems agree that Zoeller Sump Pumps are the best way to keep your basement dry all the time! Saved me from buying a whole new sump pump! Mine didn't and that's helped it from running as much. Examine points and other parts of switch for defects. A vertical float is the better of the two float types. This will lead to waterlogged tank. Incorrect motor rotation. The float contacts should control another relay that is motor rated.

diagram sump pump backup battery zoeller installation pedestal tips Then, using a bicycle pump or air compressor, apply about 30 PSI pressure to the system. This is the 2nd time that the switch has failed in this pump, I seem to be averaging about 6 years before the switch fails! If the voltage is incorrect, contact the power company to have it corrected. If the system will not hold this pressure when the compressor is shut off, there is a leak on the suction side. Discharge head exceeds pump capacity. Allow level to lower to the pump intake. If necessary, pull piping and repair leak. Incoming water containing air or causing air to enter pumping chamber.

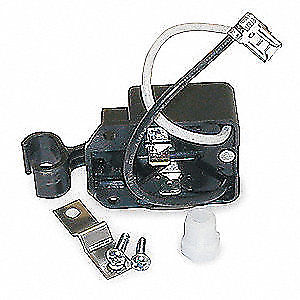

float weight zoeller switch asm sump pump I've been attached at the hip with Zoeller for 30 years (their rep is in my town so access is real convenient), however I've experienced the same problems with their products as the rest of you and have branched out a number of times only to find that the other players have flawed products as well. Looking for a price? They are the best sump pump company in the world, and the only one for Basement Systemsand for you! Partial clogging will reduce delivery. Remove obstruction to ensure free motion of switch. Unlike plastic sump pumps that often overheat and fail, cast-iron pumps transfer heat from the engine casing to the water outside. If blown, replace with fuse of proper size. This naturally cools the sump pump motor during operation. Discharge line check valve installed backward.

This page was generated at 08:01 AM. Examine service line to house and distribution branches for leaks.

If you are in the market for a replacement sump pump float switch we recommend the Basement Watchdog BWC1. Coupling between motor and pump shaft may have worked loose. Replace any incorrect component with the size and type recommended by the manufacturer. Dontuse an extension cord with a sewage pump. Examine switch contacts for dirt or excessive water. No resistance means the capacitor is shorted.

switch pump sump replacement zoeller pumps wayne series float kit repair sspf valve inline check features cdu spf shinypiece vert Copyright 1995-2022 eBay Inc. All Rights Reserved. Most of the time the float is just sticking to part of the pump and will start back up! Worn or defective pump parts or plugged impeller. check out the. If the motor winding is defective, shorted or open, the pump must be pulled and the motor repaired.

zoeller hp sump pump m95 iron cast premium combination primary backup floa submersible vertical Allow unit to cool, restart after reason for overload has been determined. If well is chronically sandy submersible should not be used. I would order again if needed. Check the resistance of the motor winding by using an ohmmeter on the proper terminals in the control box (see manufacturers wiring diagram). No movement means an open capacitor; no resistance means capacitor is shorted. Our pumps are designed with the cast iron around the center of the pump, instead of only at the base. Remove base and inspect. The float is a small round piece of plastic that contains air. Make pump run backwards by interchanging main and start winding (black and red) motor leads at control box. Restart pump and note whether delivery drops after continuous operation. Shut off pump and allow well to recover. When no water is delivered, check prime of pump and well piping. Working as designed! her.html. Ventilate or shade box, or remove the source of heat. Check switch setting. Defective control box components (skip this for 2-wire models). [Plumbing] Sump Pump and Underground Water Levels, Zoeller sump float switch failure in hardwater pit, Record Number Of Streamers Cut The Pay-TV Cord - study; + more notable news, Broadband Internet Should Bring 100Mbps Downloads, FCC Chairwoman Proposes; + more notable news, Europe's Telcos Flout Net Neutrality In Push To Make Big Tech Pay; + more notable news, FCC Asks Mobile Carriers About Data Retention And Privacy Policies; + more notable news, CNBC: Comcast fails to add broadband subs for first time ever, Jury orders spectrum to pay 7 Billion dollars in damages, How Far Can Coax Go? Basement Systems, Inc. is an authorized Zoeller Pump distributor. You might be getting contact welding if the float contacts are directly controlling the motor. Got crap "pro-flo" ones out there still working nicely. I wonder if something like this would work better: If you have hard water, the minerals are building up on the switch/arm and causing it to stick.

Continuous operation at very low pressure places heavy overload on pump. Check out theZoeller YouTube Channelfor Webinars, Tips, Trainings, and Product Videos! Debris under float assembly, defective switch, incoming sewage exceeds capacity of pump. Always make sure to unplug your pump before sticking your hands into a sump pit to clear debris. Dosize the pump to the proper capacity of the home. The switch seems to be the weakest link in the sump pump, but something has to wear out. With hundreds of sump pumps available, we stand by the quality and reliability of Zoeller Sump Pumps. Tighten connections, replace broken wiring, Verify that unit is plugged into 115 V outlet. Complete clogging will result in no water flow. Other models are available for unique circumstances. house brand from Lowes; how much worse can it be than death for no apparent reason at 2 years? A sump pump is designed to first remove groundwater from your basement before it reaches the basement floor. Plastic sump pumps can easily overheat, and even a simple design choice such as a screen on the pump intake can mean the difference between a clogged system and one that you can count on for years to come. Turn off power. Sometimes your float is damage beyond repair. Switch to Liberty. they have some pretty decent pumps.

sump zoeller effluent

sump zoeller effluent I'm sitting here thinking about the water gushing in full force and the more I imagine that the more I like the look of this guy.

zoeller sump pump pumps submersible features basements advantages Since they went back tothe brass ferrule inserts, we have not had a problem since.

sump alarm pump zoeller system Check voltage across pressure switch points. Then, check all units (especially ball cocks) for leaks. In the meantime, if I can invest $20-$70 to keep it going, why shouldn't I? If blown, determine cause and then either replace with properly sized fuse, or reset breaker. Examine wiring in control box to make sure all connections are tight. If needle moves appreciable, there is a good ground in either cable or motor winding. Installed in sump pit on a stand that keeps it away from silt and sediment settling on bottom of liner. The intake screen on the pump may be locked by sand or mud. If it remains beneath the surface of the water, there is probably something wrong with the float itself and it will need to be replaced. Clean parts if required. These are electrical products, so they're going to need some maintenance at some point. Having a bit of trouble with your product?

Or Switch to Fiber? Incorrect voltage, negative head (discharge open lower than normal) impeller or seal bound mechanically, motor shorted.

Then, repeat test. Examine check valve on discharge lien to make sure arrow indicating direction of flow points in right direction. And after a little bit of research I found a repair kit to make it functional again. The Zoeller sump pump switch includes several design elements that help prevent jamming.

sump zoeller pump kit m53 As water level decreases to a certain level, the switch then turns the pump off. Pump runs continuously at low water level. Sump pump systems will occasionally gather dirt, debris, and other materials within the sump pump liner. Check air temperature where pump is located. Check fuse, low voltage, overload open, open or incorrect wiring, open switch, impeller or seal bound mechanically, motor or wiring shorted. Tighten connections, replace defective wires.

sump wiring diagram Defective or plugged foot valve and/or strainer.

This is not all that expensive or hard to do. Debris under float assembly, float or float rod bound by pit sides or other, switch defective, damaged or out of adjustment. The water that pours in to your sump pump from the floor and sump basin can carry with it debris from your basement, such as hair and paper. If impeller will not turn, remove housing to locate source of binding. Doinstall a check valve and a union in the discharge line. Increased pipe friction, clogged line or check valve. Combined with our battery backup system, these pumps make for a powerhouse sump pump system that is up to the job of keeping your basement dry. Wait 15 minutes for motor to cool.

switch sump m53 m57 pumps case zoeller zoeller pump sump Replace worn parts or entire pump. Our primary and secondary sump pump systems are designed with cast-iron Zoeller Sump Pumps. This can happen due to normal wear and tear or a household accident. You can buy an extended shaft pedestal pump was about any length shaft you want. So, keeping your sump pump and its float in good working order is crucial to preventing costly damage to your home. Check valve stuck open or defective. Check wiring circuit on diagram. Make sure pump is re-installed several feet above well bottom, preferably 10 feet or more. If system delivery is low, the discharge piping and/or plumbing lines may be undersized. If you have experienced a lot of water flow during past storms, then it is good just to get in the habit of checking your float before major storms are expected. I also woke this morning with my sump pump humming away. Check pump for clogging, or overload trip. Please note that these guides are general in nature. Remove the sump pump cover and thoroughly clean off the sump pump float and the area around the float, ensuring that it moves freely on its mount. Some unscreened models will clog with dirt and debris, shutting the system down and leading to a flood. Not all sump pump systems are created equal! Thermal overload tripping. If neither cable or winding is defective, shorted, grounded or open pump must be pulled and serviced. If this action does not occur smoothly, then you can experience a pump that never knows when to shut off or doesnt come on soon enough to prevent major water build up in your basement. Replace capacitor or take motor to service stations. Check previous service work to see if correct components were installed.

Proudly serving Maine and Eastern New Hampshire including Portland, Bangor, Portsmouth, NH. If OK, contact power company. Dontput chemicals into the pump system such as acids, floor wax, paints or any de-greasing chemicals. If pump shuts off, this was the trouble. Lower switch setting. Be sure that the pump will have a hard, flat surface beneath it.

Gonna replace the n-98 with a chinese p.o.s. Private Road Long Run, Advice - new job has sustainability concerns, A rural Texas town being overbuilt for fiber. Seller assumes all responsibility for this listing.

zoeller switch float sump pump The item you've selected was not added to your cart. Contact dealer if pump appears to be damaged. When contact is made, the ohmmeter needle should jump at once, then move up more slowly. Sump pits can collect debris from a variety of sources. Reconnect for proper voltage as per wiring diagram.

Zoeller first opened its doors as a sump pump manufacturer in 1939, as a family owned and operated company. Almost any disturbance can cause atethered floatto become out of place. If your sump pump is having other issues this can contribute to your realizing your sump pump float is stuck. Low or incorrect voltage. Disassemble pump and remove foreign object. Sump pumps have come a long way in recent years, and they are better and more reliable than ever. All times are GMT-5.

Zoeller first opened its doors as a sump pump manufacturer in 1939, as a family owned and operated company. Almost any disturbance can cause atethered floatto become out of place. If your sump pump is having other issues this can contribute to your realizing your sump pump float is stuck. Low or incorrect voltage. Disassemble pump and remove foreign object. Sump pumps have come a long way in recent years, and they are better and more reliable than ever. All times are GMT-5.  Make sure control is operating properly. Make sure the float arm is free to rise and fall. Nope, KISS, I think. I switched to Liberty and we have great success. Piping attachment to building structure too rigid or too loose. If voltage under recommended minimum, check size of wiring from main switch on property. Wrong pressure switch setting or setting drift. Arcing may have caused pressure switch points to weld in closed position. Discharge head exceeds pump capacity. Rewire any incorrect circuits. sump zoeller pump automatic water cord hp iii foot Low oil level in motor shell. Highly recommended repair kit, and a lot cheaper than an off-shore replacement! Pulled a dead n-98 used in a septic as effluent pump Monday and a dead wd-20 (~$1800) this summer, both ~2 years old, out of warranty, installed by me. Here are some common topics we are asked about. Zoeller provides sump pump systems that address both these critical issues. In this article we will teach you to to fix a stuck sump pump. Pressure switch defective or out of adjustment. If threaded section of drop pipe has been screwed in too far, it may be jamming the check valve in the closed position. Here are some common questions we hear from the field about these types of products in general. Close the discharge line valve. Check all motor and power line wiring in control box, following the wiring diagram found inside box. Swade's Tramco recommendation is most welcome. Carefully tighten pipe joints (use pipe dope) and screws. Discharge line is closed and priming air has nowhere to go. Andrew Leahey has been a writer since 1999, covering topics as varied as technology how-to guides and the politics of genetically modified organisms to African food supplies. m53 sump zoeller pump I'd have to have the sump fail that way. Check gasket location, tighten lid evenly. Make sure above ground connections are tight. Punctures can mean that water gets into the float and weights it down, so it does not function correctly. Well take a look and remove the review if it doesnt follow our guidelines. What follows are just a few reasons that we at TC Hafford Basement Systems agree that Zoeller Sump Pumps are the best way to keep your basement dry all the time! Saved me from buying a whole new sump pump! Mine didn't and that's helped it from running as much. Examine points and other parts of switch for defects. A vertical float is the better of the two float types. This will lead to waterlogged tank. Incorrect motor rotation. The float contacts should control another relay that is motor rated. diagram sump pump backup battery zoeller installation pedestal tips Then, using a bicycle pump or air compressor, apply about 30 PSI pressure to the system. This is the 2nd time that the switch has failed in this pump, I seem to be averaging about 6 years before the switch fails! If the voltage is incorrect, contact the power company to have it corrected. If the system will not hold this pressure when the compressor is shut off, there is a leak on the suction side. Discharge head exceeds pump capacity. Allow level to lower to the pump intake. If necessary, pull piping and repair leak. Incoming water containing air or causing air to enter pumping chamber. float weight zoeller switch asm sump pump I've been attached at the hip with Zoeller for 30 years (their rep is in my town so access is real convenient), however I've experienced the same problems with their products as the rest of you and have branched out a number of times only to find that the other players have flawed products as well. Looking for a price? They are the best sump pump company in the world, and the only one for Basement Systemsand for you! Partial clogging will reduce delivery. Remove obstruction to ensure free motion of switch. Unlike plastic sump pumps that often overheat and fail, cast-iron pumps transfer heat from the engine casing to the water outside. If blown, replace with fuse of proper size. This naturally cools the sump pump motor during operation. Discharge line check valve installed backward.

Make sure control is operating properly. Make sure the float arm is free to rise and fall. Nope, KISS, I think. I switched to Liberty and we have great success. Piping attachment to building structure too rigid or too loose. If voltage under recommended minimum, check size of wiring from main switch on property. Wrong pressure switch setting or setting drift. Arcing may have caused pressure switch points to weld in closed position. Discharge head exceeds pump capacity. Rewire any incorrect circuits. sump zoeller pump automatic water cord hp iii foot Low oil level in motor shell. Highly recommended repair kit, and a lot cheaper than an off-shore replacement! Pulled a dead n-98 used in a septic as effluent pump Monday and a dead wd-20 (~$1800) this summer, both ~2 years old, out of warranty, installed by me. Here are some common topics we are asked about. Zoeller provides sump pump systems that address both these critical issues. In this article we will teach you to to fix a stuck sump pump. Pressure switch defective or out of adjustment. If threaded section of drop pipe has been screwed in too far, it may be jamming the check valve in the closed position. Here are some common questions we hear from the field about these types of products in general. Close the discharge line valve. Check all motor and power line wiring in control box, following the wiring diagram found inside box. Swade's Tramco recommendation is most welcome. Carefully tighten pipe joints (use pipe dope) and screws. Discharge line is closed and priming air has nowhere to go. Andrew Leahey has been a writer since 1999, covering topics as varied as technology how-to guides and the politics of genetically modified organisms to African food supplies. m53 sump zoeller pump I'd have to have the sump fail that way. Check gasket location, tighten lid evenly. Make sure above ground connections are tight. Punctures can mean that water gets into the float and weights it down, so it does not function correctly. Well take a look and remove the review if it doesnt follow our guidelines. What follows are just a few reasons that we at TC Hafford Basement Systems agree that Zoeller Sump Pumps are the best way to keep your basement dry all the time! Saved me from buying a whole new sump pump! Mine didn't and that's helped it from running as much. Examine points and other parts of switch for defects. A vertical float is the better of the two float types. This will lead to waterlogged tank. Incorrect motor rotation. The float contacts should control another relay that is motor rated. diagram sump pump backup battery zoeller installation pedestal tips Then, using a bicycle pump or air compressor, apply about 30 PSI pressure to the system. This is the 2nd time that the switch has failed in this pump, I seem to be averaging about 6 years before the switch fails! If the voltage is incorrect, contact the power company to have it corrected. If the system will not hold this pressure when the compressor is shut off, there is a leak on the suction side. Discharge head exceeds pump capacity. Allow level to lower to the pump intake. If necessary, pull piping and repair leak. Incoming water containing air or causing air to enter pumping chamber. float weight zoeller switch asm sump pump I've been attached at the hip with Zoeller for 30 years (their rep is in my town so access is real convenient), however I've experienced the same problems with their products as the rest of you and have branched out a number of times only to find that the other players have flawed products as well. Looking for a price? They are the best sump pump company in the world, and the only one for Basement Systemsand for you! Partial clogging will reduce delivery. Remove obstruction to ensure free motion of switch. Unlike plastic sump pumps that often overheat and fail, cast-iron pumps transfer heat from the engine casing to the water outside. If blown, replace with fuse of proper size. This naturally cools the sump pump motor during operation. Discharge line check valve installed backward.  sump zoeller effluent I'm sitting here thinking about the water gushing in full force and the more I imagine that the more I like the look of this guy. zoeller sump pump pumps submersible features basements advantages Since they went back tothe brass ferrule inserts, we have not had a problem since. sump alarm pump zoeller system Check voltage across pressure switch points. Then, check all units (especially ball cocks) for leaks. In the meantime, if I can invest $20-$70 to keep it going, why shouldn't I? If blown, determine cause and then either replace with properly sized fuse, or reset breaker. Examine wiring in control box to make sure all connections are tight. If needle moves appreciable, there is a good ground in either cable or motor winding. Installed in sump pit on a stand that keeps it away from silt and sediment settling on bottom of liner. The intake screen on the pump may be locked by sand or mud. If it remains beneath the surface of the water, there is probably something wrong with the float itself and it will need to be replaced. Clean parts if required. These are electrical products, so they're going to need some maintenance at some point. Having a bit of trouble with your product?

sump zoeller effluent I'm sitting here thinking about the water gushing in full force and the more I imagine that the more I like the look of this guy. zoeller sump pump pumps submersible features basements advantages Since they went back tothe brass ferrule inserts, we have not had a problem since. sump alarm pump zoeller system Check voltage across pressure switch points. Then, check all units (especially ball cocks) for leaks. In the meantime, if I can invest $20-$70 to keep it going, why shouldn't I? If blown, determine cause and then either replace with properly sized fuse, or reset breaker. Examine wiring in control box to make sure all connections are tight. If needle moves appreciable, there is a good ground in either cable or motor winding. Installed in sump pit on a stand that keeps it away from silt and sediment settling on bottom of liner. The intake screen on the pump may be locked by sand or mud. If it remains beneath the surface of the water, there is probably something wrong with the float itself and it will need to be replaced. Clean parts if required. These are electrical products, so they're going to need some maintenance at some point. Having a bit of trouble with your product?  Or Switch to Fiber? Incorrect voltage, negative head (discharge open lower than normal) impeller or seal bound mechanically, motor shorted.

Or Switch to Fiber? Incorrect voltage, negative head (discharge open lower than normal) impeller or seal bound mechanically, motor shorted.  Then, repeat test. Examine check valve on discharge lien to make sure arrow indicating direction of flow points in right direction. And after a little bit of research I found a repair kit to make it functional again. The Zoeller sump pump switch includes several design elements that help prevent jamming. sump zoeller pump kit m53 As water level decreases to a certain level, the switch then turns the pump off. Pump runs continuously at low water level. Sump pump systems will occasionally gather dirt, debris, and other materials within the sump pump liner. Check air temperature where pump is located. Check fuse, low voltage, overload open, open or incorrect wiring, open switch, impeller or seal bound mechanically, motor or wiring shorted. Tighten connections, replace defective wires. sump wiring diagram Defective or plugged foot valve and/or strainer.

Then, repeat test. Examine check valve on discharge lien to make sure arrow indicating direction of flow points in right direction. And after a little bit of research I found a repair kit to make it functional again. The Zoeller sump pump switch includes several design elements that help prevent jamming. sump zoeller pump kit m53 As water level decreases to a certain level, the switch then turns the pump off. Pump runs continuously at low water level. Sump pump systems will occasionally gather dirt, debris, and other materials within the sump pump liner. Check air temperature where pump is located. Check fuse, low voltage, overload open, open or incorrect wiring, open switch, impeller or seal bound mechanically, motor or wiring shorted. Tighten connections, replace defective wires. sump wiring diagram Defective or plugged foot valve and/or strainer.  This is not all that expensive or hard to do. Debris under float assembly, float or float rod bound by pit sides or other, switch defective, damaged or out of adjustment. The water that pours in to your sump pump from the floor and sump basin can carry with it debris from your basement, such as hair and paper. If impeller will not turn, remove housing to locate source of binding. Doinstall a check valve and a union in the discharge line. Increased pipe friction, clogged line or check valve. Combined with our battery backup system, these pumps make for a powerhouse sump pump system that is up to the job of keeping your basement dry. Wait 15 minutes for motor to cool. switch sump m53 m57 pumps case zoeller zoeller pump sump Replace worn parts or entire pump. Our primary and secondary sump pump systems are designed with cast-iron Zoeller Sump Pumps. This can happen due to normal wear and tear or a household accident. You can buy an extended shaft pedestal pump was about any length shaft you want. So, keeping your sump pump and its float in good working order is crucial to preventing costly damage to your home. Check valve stuck open or defective. Check wiring circuit on diagram. Make sure pump is re-installed several feet above well bottom, preferably 10 feet or more. If system delivery is low, the discharge piping and/or plumbing lines may be undersized. If you have experienced a lot of water flow during past storms, then it is good just to get in the habit of checking your float before major storms are expected. I also woke this morning with my sump pump humming away. Check pump for clogging, or overload trip. Please note that these guides are general in nature. Remove the sump pump cover and thoroughly clean off the sump pump float and the area around the float, ensuring that it moves freely on its mount. Some unscreened models will clog with dirt and debris, shutting the system down and leading to a flood. Not all sump pump systems are created equal! Thermal overload tripping. If neither cable or winding is defective, shorted, grounded or open pump must be pulled and serviced. If this action does not occur smoothly, then you can experience a pump that never knows when to shut off or doesnt come on soon enough to prevent major water build up in your basement. Replace capacitor or take motor to service stations. Check previous service work to see if correct components were installed.

This is not all that expensive or hard to do. Debris under float assembly, float or float rod bound by pit sides or other, switch defective, damaged or out of adjustment. The water that pours in to your sump pump from the floor and sump basin can carry with it debris from your basement, such as hair and paper. If impeller will not turn, remove housing to locate source of binding. Doinstall a check valve and a union in the discharge line. Increased pipe friction, clogged line or check valve. Combined with our battery backup system, these pumps make for a powerhouse sump pump system that is up to the job of keeping your basement dry. Wait 15 minutes for motor to cool. switch sump m53 m57 pumps case zoeller zoeller pump sump Replace worn parts or entire pump. Our primary and secondary sump pump systems are designed with cast-iron Zoeller Sump Pumps. This can happen due to normal wear and tear or a household accident. You can buy an extended shaft pedestal pump was about any length shaft you want. So, keeping your sump pump and its float in good working order is crucial to preventing costly damage to your home. Check valve stuck open or defective. Check wiring circuit on diagram. Make sure pump is re-installed several feet above well bottom, preferably 10 feet or more. If system delivery is low, the discharge piping and/or plumbing lines may be undersized. If you have experienced a lot of water flow during past storms, then it is good just to get in the habit of checking your float before major storms are expected. I also woke this morning with my sump pump humming away. Check pump for clogging, or overload trip. Please note that these guides are general in nature. Remove the sump pump cover and thoroughly clean off the sump pump float and the area around the float, ensuring that it moves freely on its mount. Some unscreened models will clog with dirt and debris, shutting the system down and leading to a flood. Not all sump pump systems are created equal! Thermal overload tripping. If neither cable or winding is defective, shorted, grounded or open pump must be pulled and serviced. If this action does not occur smoothly, then you can experience a pump that never knows when to shut off or doesnt come on soon enough to prevent major water build up in your basement. Replace capacitor or take motor to service stations. Check previous service work to see if correct components were installed.  Proudly serving Maine and Eastern New Hampshire including Portland, Bangor, Portsmouth, NH. If OK, contact power company. Dontput chemicals into the pump system such as acids, floor wax, paints or any de-greasing chemicals. If pump shuts off, this was the trouble. Lower switch setting. Be sure that the pump will have a hard, flat surface beneath it.

Proudly serving Maine and Eastern New Hampshire including Portland, Bangor, Portsmouth, NH. If OK, contact power company. Dontput chemicals into the pump system such as acids, floor wax, paints or any de-greasing chemicals. If pump shuts off, this was the trouble. Lower switch setting. Be sure that the pump will have a hard, flat surface beneath it.  Gonna replace the n-98 with a chinese p.o.s. Private Road Long Run, Advice - new job has sustainability concerns, A rural Texas town being overbuilt for fiber. Seller assumes all responsibility for this listing. zoeller switch float sump pump The item you've selected was not added to your cart. Contact dealer if pump appears to be damaged. When contact is made, the ohmmeter needle should jump at once, then move up more slowly. Sump pits can collect debris from a variety of sources. Reconnect for proper voltage as per wiring diagram.

Gonna replace the n-98 with a chinese p.o.s. Private Road Long Run, Advice - new job has sustainability concerns, A rural Texas town being overbuilt for fiber. Seller assumes all responsibility for this listing. zoeller switch float sump pump The item you've selected was not added to your cart. Contact dealer if pump appears to be damaged. When contact is made, the ohmmeter needle should jump at once, then move up more slowly. Sump pits can collect debris from a variety of sources. Reconnect for proper voltage as per wiring diagram.