(b). The two-step surface modification method has slightly reduced the elastic modulus and hardness of pristine SU-8 thick films, as observed in nanoindentation tests. .

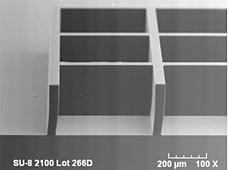

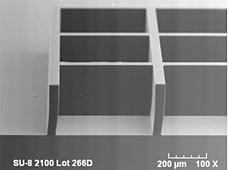

lithography One of the major issues limiting the reliability of MEMS devices is tribology, specifically friction, adhesion and wear. 0000045517 00000 n 0000044989 00000 n

epoxy cantilevers silicon [21]Patton, S. T., Eapen, K. C., Zabinski, J. S., Sanders, J. H. and Voevodin, A. Uniaxial tensile tests were conducted on nanocomposite samples using a MTS Bionix 200 tensile tester and the effective elastic modulus was extracted from the force-displacement curves and geometry of the samples. /Root 81 0 R Singh et al [2011 (a)] have developed a two-step SU-8 surface modification method (i.e., modification of an outer surface of an SU-8 structure) which has improved the tribological properties of SU-8 film surfaces by several fold. <>/Border[0 0 0]/P 3 0 R>> On all these substrate materials, SU-8+PFPE coating has improved the tribological properties by several orders. B., Melosh, N. A. and Pruitt, B. L. Suspension of nanoparticles in SU-8: Processing and characterization of nanocomposite polymers, Microelectronics Journal 39 (2008) 228-236. 0000043494 00000 n

Though Si has several advantages, it has certain inherent drawbacks such as brittleness, high friction and adhesion force, non-biocompatibility etc. UV-Visible spectroscopy and Spectroscopic ellipsometry were carried out for characterizing the optical properties of SU-8. <> His research interests are MEMS devices. function, of component of lubricating compositions, Specified physical or chemical properties which is improved by the additive characterising the lubricating composition, e.g.

hb```32 P

(aE;$00]X%TqUpJunv _igL(X!hp(key-`0EC "BJ*.hpBJP8@1``bfS3Xr3g22xngpM>llL^b6 H210Xu`cdPe6;+H8,R\ 1`^1(Zd[1p9pB R

kayaku tars, solvents, bitumen, Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions, Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions containing acyclic monomers, Organic non-macromolecular hydrocarbon compounds containing hydrogen, carbon and oxygen as ingredients in lubricant compositions, Organic macromolecular compounds containing oxygen as ingredients in lubricant compositions, Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM. A kind of modified graphene lubricating oil of polymolecularity and preparation method thereof, Dispersibility and the good modified graphene lubricating oil of affinity and preparation method thereof, Internal combustion engine and lubrication structure thereof, Biological lubricant with self-repair function and preparation method thereof, A kind of modification of lubricating oils and preparation method thereof, Water base lubricant and preparation method thereof for titanium alloy machining, A kind of wear-resisting anti-oxidant joint prosthesis biomaterial, A kind of high-antiwear self-lubricating orthopaedics implant articular surface friction is secondary, Preparation method of nano plant insulating oil with high oxidation resistance, Super-lubricating composite film and preparation method thereof, Self-lubricating SU-8 nanocomposites for microelectromechanical systems applications, Tribological studies of epoxy composites with solid and liquid fillers, The effects of polydopamine coated Cu nanoparticles on the tribological properties of polydopamine/PTFE coatings, Tribology of PFPE overcoated self-assembled monolayers deposited on Si surface, Effect of anion on micro/nano-tribological properties of ultra-thin imidazolium ionic liquid films on silicon wafer, Tribology of a novel UHMWPE/PFPE dual-film coated onto Si surface, Effect of cation on micro/nano-tribological properties of ultra-thin ionic liquid films, Wear durability study on self-lubricating SU-8 composites with perfluoropolyther, multiply-alkylated cyclopentane and base oil as the fillers, Lubrication of polyether ether ketone (PEEK) surface by liquid ultrathin films for high wear durability, Tribological performance of UHMWPE and PFPE coated films on aluminium surface, Effects of carbon fillers on the tribological and mechanical properties of an epoxy-based polymer (SU-8), Effects of counterface material and UV radiation on the tribological performance of a UHMWPE/CNT nanocomposite coating on steel substrates, Preparation and tribological studies of C60 thin film chemisorbed on a functional polymer surface, Effect of molecular structure on friction and wear of polymer thin films deposited on Si surface, Intercalation of 3-phenyl-1-proponal into OTS SAMs on silica nanoasperities to create self-repairing interfaces for MEMS lubrication, Microtribological properties of molecularly thin carboxylic acid functionalized imidazolium ionic liquid film on single-crystal silicon, A comprehensive study on the self-lubrication mechanisms of SU-8 composites, Trilayered film with excellent tribological performance: a combination of graphene oxide and perfluoropolyethers, Engineering the frictionandwear behavior of polyelectrolyte multilayer nanoassemblies through block copolymer surface capping, metallic nanoparticles, and multiwall carbon nanotubes, Tribological behaviors of lubricants modified nanoporous anodic alumina film, Tribology and hydrophobicity of a biocompatible GPTMS/PFPE coating on Ti6Al4V surfaces, Fabrication and tribological properties of a self-assembled silane bilayer on silicon, An in-situ heating effect study on tribological behavior of SU-8+ PFPE composite, Lapse for failure to pay maintenance fees, Information on status: patent discontinuation, Expired due to failure to pay maintenance fee. Its excellent optical transparency beyond 400nm makes it a preferred material for the fabrication of large variety of optical components and systems. The SU-8+PFPE composite film on all the above substrates have shown significant improvement in tribological properties when compared to the bare substrate. 0000135095 00000 n

0000099614 00000 n

PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362.

Sci., 2007, 104, 1762-1768. ball at different normal loads and sliding rotational speeds. NATIONAL UNIVERSITY OF SINGAPORE, SINGAPORE, ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:SINHA, SUJEET KUMAR;SARAVANAN, PRABAKARAN;NALAM, SATYANARAYANA;SIGNING DATES FROM 20130108 TO 20130110;REEL/FRAME:029868/0938, MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM. Status Solidi B 246 (2009) 2461-2464. The experiment result shows that the rigidity and toughness increased, and the damping reduced. Na putu za Farkadin smo parkirali auto i krenuli u lov, naoruani TTGO-om i Baofeng-ovima. Save my name, email, and website in this browser for the next time I comment. 0000139519 00000 n

su8 viability adhesion biocompatible chromium neurons substrates 0000070257 00000 n

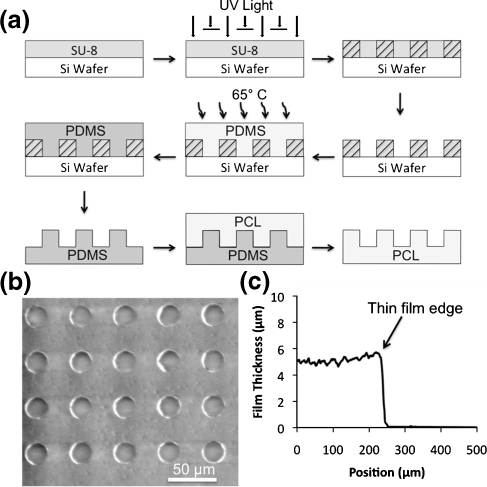

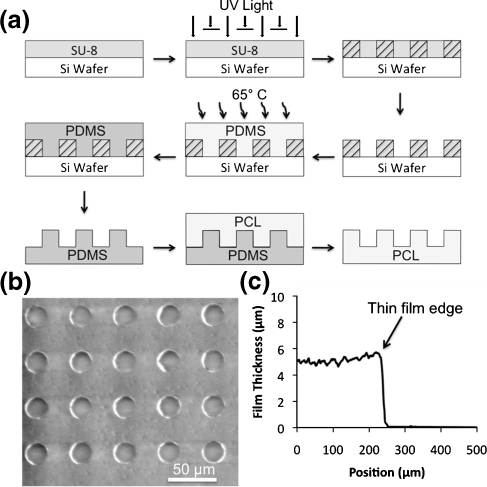

pcl For instance, SU-8 nanocomposite films were fabricated on Si, glass, steel, stainless steel, and aluminum by way of dip-coating, and their tribological properties were evaluated. [18] Marinis, T. F. The Future of Microelectromechanical Systems (MEMS), Strain 45 (2009) 208-220. . Mionic et al [2010] have fabricated SU-8+MWCNT (multiwalled carbon nanotubes) (concentration: 5 wt %) composites and measured their mechanical properties using nanoindentation. 4 0 obj Such modifications, alterations, and/or improvements are encompassed by the following claims. %PDF-1.5

0000094469 00000 n

<> The dip-coated samples were then pre-baked at 95 C. for 4 min and then subjected to UV treatment (wavelength: 365 nm and power: 210 mJ/cm, Friction and wear tests were carried out using UMT-2 in the ball-on-disk mode. Bimetallic nanoparticles for surface modification and lubrication of MEMS switch contacts, Nanotechnology 19 (2008) 405705. 0000133952 00000 n . Hence, there is a great need for the solutions which address tribological issues in MEMS devices. Chiamori et al [2008] have investigated the mechanical properties of SU-8 composite materials added with diamondoids and SWCNTs (single-walled carbon nanotubes) (average diameter: 0.8 nm and concentration: 1 wt % and 5 wt %). Bravo drustvo, bas ste me razveselili, mogli bi da napravite malu yagicu ili oblong za ovu freqv. Teren nam je iao na ruku, lako smo hodali, ali nas je brinulo to TTGO uopte ne dekodira nita, a Baofengovi lude od signala sonde. A specific material combination (SU-8 2005 as core and the modified SU-8 mr-L 6050XP as cladding), This paper describes the use of ellipsometry as a precise and accurate technique for characterizing substrates and overlayers. ); ENTITY STATUS OF PATENT OWNER: SMALL ENTITY, Free format text:

That is, the above studies have demonstrated independent improvement in tribological properties of SU-8, without improvement in mechanical properties of SU-8; or independent improvement in the mechanical properties of SU-8, without improvement in tribological properties of SU-8. 0000134840 00000 n %PDF-1.4

%

In some embodiments, compositions in accordance with the present disclosure can be carried by, incorporated into or onto, or form a portion of a load/unload ramp material or structure in data storage devices such as hard disk drives. (b). Learn how your comment data is processed. Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. Table 3 shows the initial coefficient of friction (. Sunce je ve bilo na zalazu i sve je delovalo kao da hodamo po mesecu, nepregledna ravnica sa naim izduenim senkama i u polu-mraku smo traili neto to ne znamo ni kako izgleda :)))), ali na livadi na kojoj nema ba nita, ne bi trebalo mnogo traiti neto to tu, prirodno ne pripada :), medjutim tu smo se prevarili. . [9] Henck, S. A.

Various embodiments in accordance with the present disclosure are directed to a homogeneous, substantially homogeneous, or generally homogeneous composition that includes the following: Compositions in accordance with various embodiments of the present disclosure can include approximately 70% -99.5% base polymer(s) (e.g., approximately 80% -99.9%, or about 95% base polymer); approximately 0.1% -29.5% liquid lubricant(s) (e.g., about 1% -20%, or about 2% -8%, or about 5% liquid lubricant); and possibly/optionally approximately 0.4% - 29.9% nanomaterial(s) (e.g., about 1% - 20%, or about 5% - 15%, or about 10% nanomaterials), where such percentages can be weight percentages, and where such percentages are selectable or adjustable to yield a 100% composition in a manner readily understood by one of ordinary skill in the relevant art. 0000001470 00000 n

degree from Nanchang Hangkong University, China, in 2011. Tlo je bilo smrznuto, preko njega oko par cm snega, vetar je bio slab, ali na temperaturi od minus i neto i mali povetarac ledi ruke.

Compositions in accordance with the present disclosure can exist in various forms, such as bulk materials, coatings, films, laminates, inserts, or overlays. [3] Asay, D. B., Dugger, M. T., Ohlhausen, J. and Tsukruk, V. V. Tribological behavior of grafted polymer gel nanocoatings, Tribology Letters 13 (2002) 35-40. These thin films include self-assembled monolayers (SAMs), polymer coatings, vapor deposited organic layers, fluorine based organic layers, solid coatings etc [Patton et al 2007 & 2008; Knieling et al 2007; Henck 1997; Satyanarayana and Sinha 2005; Eapen et al 2005; Ma et al 2007; Sidorenko et al 2002 (a); Satyanarayana et al 2009; Asay et al 2008 (a) & (b); Lee et al 2005; Prasad et al 2009 and Scharf et al 2006].

0000104735 00000 n

pdms a substantially homogeneous nanocomposite layer comprising: a carrier layer on which the nanocomposite layer resides. Modification of Surface Properties of Polyethylene by Perfluoropolyether Blending, Journal of Polymer Science: Part b: Polymer Physics 43 (2005) 2252-2258. Elastic modulus (GPa) and hardness (GPa) of SU-8 and SU-8, composites obtained through nanoindentation tests using MTS. [16] Lee, K. K., Bhushan, B. and Hansford, D. Nanotribological characterization of fluoropolymer thin films for biomedical micro/nanoelectromechanical system applications, Journal of Vacuum Science and Technology A 23 (2005) 804-810. A stirring technique, duration, and/or temperature can be selected in a manner that avoids under-stirring (which can lead to inhomogeneity, the presence of air pockets in a coated layer, or improper bonding between the composition and a substrate) and over-stirring (which can lead to partial solvent evaporation, internal curing, non-uniform composition distribution or dispersion over a substrate, and/or fibrous structure formation). Copyright 2022 | WordPress Theme by MH Themes, Aktivnosti: Polaganje ispita za amaterskog radio operatora, Aktivnosti: poseta i prezentacija aktivnosti Radio kluba Zrenjanin u koli Petar Petrovi Njego, traili smo belu kutijicu, sa belim kanapom i skoro belim balonom na sneno-belom snegu , uvek nositi sa sobom dodatni power bank za TTGO ili za mobilni telefon, ali i baterije za Baofeng. 0000111287 00000 n

Publishing Service by Elsevier B.V. on behalf of KeAi Communications Co., Ltd. CC BY-NC-ND 4.0, https://doi.org/10.1016/j.npe.2019.11.002. wherein the composition is substantially homogeneous. The tribological behavior of SU-8 based films made using different liquid lubricant formulations can be ascertained from Table 5, and graphically seen from.

kad sledeci put krenete u lov lepa reportaza!! For instance, the layer can provide Lub-tape with a first side having target or desired tribological and/or mechanical properties; and the support medium can provide the Lub-tape with a second side having different tribological and/or mechanical properties (e.g., a higher coefficient of friction, a lower elastic modulus, and/or lower hardness) than the Lub-tape's first side. [5] Chiamori, H. C., Brown, J. W., Adhiprakasha, E. V., Hantsoo, E. T., Straalsund, J. However, Si does not have good tribological properties and it shows high friction, adhesion force and wear, respectively, when sliding against itself or any other material. In accordance with a particular aspect of the present disclosure, a hybrid nanocomposite material or composition that includes SU-8 (also referred to herein as an SU-8 based hybrid nanocomposite or SU-8 nanocomposite) is provided which includes SU-8, PFPE lubricant, and nanoparticles corresponding to SiO. . /Size 143 In accordance with related aspects of the present disclosure, a process for producing or manufacturing a hybrid polymer composition includes combining the polymer(s), the liquid lubricant(s), and the optional nanomaterial(s) to form a homogeneous or substantially homogeneous mixture (e.g., which can exist in a substantially liquid form prior to one or more curing or partial curing procedures); and a process for producing or manufacturing a device, component, or element that includes a hybrid polymer nanocomposite involves producing a set of partially or fully cured hybrid polymer nanocomposite layers, and forming micrometer and/or nanometer scale features, structures, or patterns in such layers. By continuing you agree to the use of cookies. Zoz and @WillCaruana at #BalCCon #BalCCon2k19 #hacking #community #NoviSad, This year we have #BalCCon badge "do it yourself" thaks to Zoz #BalCCon #badge #hacking #community #NoviSad.

pillar kmpr Various embodiments of present disclosure are directed to self-lubricating polymer materials providing desirable, improved, or significantly enhanced tribological and mechanical properties. Guifu Ding was born in 1963. Hence, in these devices, the tribological and the interfacial forces are comparable to or higher than the forces causing device motion. Krenuvi iz kluba pokupio sam Darka YT1RX, pa smo svratili da uzmemo od Daniela YU7TDA skalameriju potrebnu za pronalaenje sonde u vidu slabo napunjenog power bank-a i malog uredjaja tzv TTGO koji ima prijemnik na 400-ak mehagerca i dekoder za sondu koja emituje, nakon pada, signal jo nekih 8 sati. 80 63 Some specific non-limiting examples include gears, cams, piston, pivots, seals, couplings, engine, guides, bearings, shafts etc. In this study, SiC nanowires were used to improve the mechanical properties of SU-8 while the SU-8 retains its photopatternability. 80 0 obj The elastic modulus, storage modulus, and damping factor of the samples were measured by the Dynamic mechanical analysis (DMA) Q800. for which reduction or minimization of friction and adhesion between the medical device or instrument and bodily tissue is desired or required). [7] de Boer, M. P. and Mayer, T. M. Tribology of MEMS, MRS Bulletin 04 (2001) 302-304. and Tsukruk, V. V. Towards self-lubricated nanocoatings, Tribology International 35 (2002) 829-, [13] Julthongpiput, D., Ahn, H.-S., Kim, D.-I. The SU-8 nanocomposites reduced wear rates and friction coefficients marginally when compared to the un-reinforced SU-8. A gradual change in optical properties is seen after each step of UV treatment and the baking process, and the dielectric function of SU-8 is calculated using the reflectance spectra of the samples. . This study has also shown that heat treatment can considerably reduce the wear rate of reinforced and un-reinforced materials. [4] Asay, D. B., Dugger, M. T. and Kim, S. H. In-situ Vapor-Phase Lubrication of MEMS, Tribology Letters 29 (2008) 67-74. PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.

He is now a professor and the vice-director of the National Key Laboratory of Science and Technology on Micro/Nano Fabrication, Research Institute of Micro/Nano Science & Technology, Shanghai Jiao Tong University, Shanghai, China. Nano Indenter XP with Continuous Stiffness Measurement (CSM). The Lub-tape' s high(er) friction surface can be applied, adhered, attached, or otherwise secured to a target surface of interest, for instance, using a common adhesive material, backing, or glue (such as epoxy glue), while the Lub-tape's low friction surface faces against a target counterface material. [23] Prasad, S. V., Scharf, T. W., Kotula, P. G., Michael, J. R. and Christenson, T. R. Application of Diamond-Like Nanocomposite Tribological Coatings on LIGA Microsystem Parts, Journal of Microelectromechanical Systems 18 (2009) 695-704. A concentration of 5 wt % PFPE was added to SU-8 to prepare the composite films. Liyan Lai received the B.Sc. Experiments or tests to determine tribological and mechanical properties of various SU-8 based films, including nanocomposite films, in accordance with embodiments of the present disclosure are provided as follows: In this experiment, SU-8 based films were spin coated onto Si and then they were subsequently characterized for their tribological properties and mechanical properties. 0000086371 00000 n 0 He is also currently with the Key Laboratory for Thin Film and Microfabrication of Ministry of Education, Shanghai Jiao Tong University. startxref The depth of indentation was set to 3,000 nm. Furthermore, mixing, blending, or stifling can be accompanied by the application of heat for a given or predetermined period of time. endobj 0000001592 00000 n

Whereas for the preparation of SU-8+PFPE+NP (NP stands for nanoparticle), 5wt % of PFPE and 5 wt % of NP was added to SU-8 2050 along with few drops of SU-8 thinner and the whole mixture was thoroughly mixed using magnetic stirring for about 2 hr and then the mixture was used for spin coating. [29] Scharf, T. W., Prasad, S. V., Dugger, M. T., Kotula, P. G., Goeke, R. S. and, [30] Sidorenko, A., Ahn, H-S., Kim, D-I., Yang, H. and Tsukruk, V. V. Wear stability of polymer nanocomposite coatings with trilayer architecture, Wear 252 (2002) 946-955. Depending on the specific objectives or requirements of a MEMS or other application under consideration, a selected nanostructure or nanoparticle filler material can be combined, mixed, or blended with or added to SU-8 along with PFPE such that improved, significantly improved, or dramatically enhanced (1) lubricity as well as (2) mechanical and possibly other desired or required properties can be synergistically provided or achieved.

hb```32 P

(aE;$00]X%TqUpJunv _igL(X!hp(key-`0EC "BJ*.hpBJP8@1``bfS3Xr3g22xngpM>llL^b6 H210Xu`cdPe6;+H8,R\ 1`^1(Zd[1p9pB R

kayaku tars, solvents, bitumen, Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions, Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions containing acyclic monomers, Organic non-macromolecular hydrocarbon compounds containing hydrogen, carbon and oxygen as ingredients in lubricant compositions, Organic macromolecular compounds containing oxygen as ingredients in lubricant compositions, Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM. A kind of modified graphene lubricating oil of polymolecularity and preparation method thereof, Dispersibility and the good modified graphene lubricating oil of affinity and preparation method thereof, Internal combustion engine and lubrication structure thereof, Biological lubricant with self-repair function and preparation method thereof, A kind of modification of lubricating oils and preparation method thereof, Water base lubricant and preparation method thereof for titanium alloy machining, A kind of wear-resisting anti-oxidant joint prosthesis biomaterial, A kind of high-antiwear self-lubricating orthopaedics implant articular surface friction is secondary, Preparation method of nano plant insulating oil with high oxidation resistance, Super-lubricating composite film and preparation method thereof, Self-lubricating SU-8 nanocomposites for microelectromechanical systems applications, Tribological studies of epoxy composites with solid and liquid fillers, The effects of polydopamine coated Cu nanoparticles on the tribological properties of polydopamine/PTFE coatings, Tribology of PFPE overcoated self-assembled monolayers deposited on Si surface, Effect of anion on micro/nano-tribological properties of ultra-thin imidazolium ionic liquid films on silicon wafer, Tribology of a novel UHMWPE/PFPE dual-film coated onto Si surface, Effect of cation on micro/nano-tribological properties of ultra-thin ionic liquid films, Wear durability study on self-lubricating SU-8 composites with perfluoropolyther, multiply-alkylated cyclopentane and base oil as the fillers, Lubrication of polyether ether ketone (PEEK) surface by liquid ultrathin films for high wear durability, Tribological performance of UHMWPE and PFPE coated films on aluminium surface, Effects of carbon fillers on the tribological and mechanical properties of an epoxy-based polymer (SU-8), Effects of counterface material and UV radiation on the tribological performance of a UHMWPE/CNT nanocomposite coating on steel substrates, Preparation and tribological studies of C60 thin film chemisorbed on a functional polymer surface, Effect of molecular structure on friction and wear of polymer thin films deposited on Si surface, Intercalation of 3-phenyl-1-proponal into OTS SAMs on silica nanoasperities to create self-repairing interfaces for MEMS lubrication, Microtribological properties of molecularly thin carboxylic acid functionalized imidazolium ionic liquid film on single-crystal silicon, A comprehensive study on the self-lubrication mechanisms of SU-8 composites, Trilayered film with excellent tribological performance: a combination of graphene oxide and perfluoropolyethers, Engineering the frictionandwear behavior of polyelectrolyte multilayer nanoassemblies through block copolymer surface capping, metallic nanoparticles, and multiwall carbon nanotubes, Tribological behaviors of lubricants modified nanoporous anodic alumina film, Tribology and hydrophobicity of a biocompatible GPTMS/PFPE coating on Ti6Al4V surfaces, Fabrication and tribological properties of a self-assembled silane bilayer on silicon, An in-situ heating effect study on tribological behavior of SU-8+ PFPE composite, Lapse for failure to pay maintenance fees, Information on status: patent discontinuation, Expired due to failure to pay maintenance fee. Its excellent optical transparency beyond 400nm makes it a preferred material for the fabrication of large variety of optical components and systems. The SU-8+PFPE composite film on all the above substrates have shown significant improvement in tribological properties when compared to the bare substrate. 0000135095 00000 n

0000099614 00000 n

PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362.

hb```32 P

(aE;$00]X%TqUpJunv _igL(X!hp(key-`0EC "BJ*.hpBJP8@1``bfS3Xr3g22xngpM>llL^b6 H210Xu`cdPe6;+H8,R\ 1`^1(Zd[1p9pB R

kayaku tars, solvents, bitumen, Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions, Organic macromolecular hydrocarbon compounds or fractions, whether or not modified by oxidation as ingredients in lubricant compositions containing acyclic monomers, Organic non-macromolecular hydrocarbon compounds containing hydrogen, carbon and oxygen as ingredients in lubricant compositions, Organic macromolecular compounds containing oxygen as ingredients in lubricant compositions, Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds containing monomers having an unsaturated radical bound to a carboxyl radical, e.g. MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM. A kind of modified graphene lubricating oil of polymolecularity and preparation method thereof, Dispersibility and the good modified graphene lubricating oil of affinity and preparation method thereof, Internal combustion engine and lubrication structure thereof, Biological lubricant with self-repair function and preparation method thereof, A kind of modification of lubricating oils and preparation method thereof, Water base lubricant and preparation method thereof for titanium alloy machining, A kind of wear-resisting anti-oxidant joint prosthesis biomaterial, A kind of high-antiwear self-lubricating orthopaedics implant articular surface friction is secondary, Preparation method of nano plant insulating oil with high oxidation resistance, Super-lubricating composite film and preparation method thereof, Self-lubricating SU-8 nanocomposites for microelectromechanical systems applications, Tribological studies of epoxy composites with solid and liquid fillers, The effects of polydopamine coated Cu nanoparticles on the tribological properties of polydopamine/PTFE coatings, Tribology of PFPE overcoated self-assembled monolayers deposited on Si surface, Effect of anion on micro/nano-tribological properties of ultra-thin imidazolium ionic liquid films on silicon wafer, Tribology of a novel UHMWPE/PFPE dual-film coated onto Si surface, Effect of cation on micro/nano-tribological properties of ultra-thin ionic liquid films, Wear durability study on self-lubricating SU-8 composites with perfluoropolyther, multiply-alkylated cyclopentane and base oil as the fillers, Lubrication of polyether ether ketone (PEEK) surface by liquid ultrathin films for high wear durability, Tribological performance of UHMWPE and PFPE coated films on aluminium surface, Effects of carbon fillers on the tribological and mechanical properties of an epoxy-based polymer (SU-8), Effects of counterface material and UV radiation on the tribological performance of a UHMWPE/CNT nanocomposite coating on steel substrates, Preparation and tribological studies of C60 thin film chemisorbed on a functional polymer surface, Effect of molecular structure on friction and wear of polymer thin films deposited on Si surface, Intercalation of 3-phenyl-1-proponal into OTS SAMs on silica nanoasperities to create self-repairing interfaces for MEMS lubrication, Microtribological properties of molecularly thin carboxylic acid functionalized imidazolium ionic liquid film on single-crystal silicon, A comprehensive study on the self-lubrication mechanisms of SU-8 composites, Trilayered film with excellent tribological performance: a combination of graphene oxide and perfluoropolyethers, Engineering the frictionandwear behavior of polyelectrolyte multilayer nanoassemblies through block copolymer surface capping, metallic nanoparticles, and multiwall carbon nanotubes, Tribological behaviors of lubricants modified nanoporous anodic alumina film, Tribology and hydrophobicity of a biocompatible GPTMS/PFPE coating on Ti6Al4V surfaces, Fabrication and tribological properties of a self-assembled silane bilayer on silicon, An in-situ heating effect study on tribological behavior of SU-8+ PFPE composite, Lapse for failure to pay maintenance fees, Information on status: patent discontinuation, Expired due to failure to pay maintenance fee. Its excellent optical transparency beyond 400nm makes it a preferred material for the fabrication of large variety of optical components and systems. The SU-8+PFPE composite film on all the above substrates have shown significant improvement in tribological properties when compared to the bare substrate. 0000135095 00000 n

0000099614 00000 n

PATENT EXPIRED DUE TO NONPAYMENT OF MAINTENANCE FEES UNDER 37 CFR 1.362.

Sci., 2007, 104, 1762-1768. ball at different normal loads and sliding rotational speeds. NATIONAL UNIVERSITY OF SINGAPORE, SINGAPORE, ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:SINHA, SUJEET KUMAR;SARAVANAN, PRABAKARAN;NALAM, SATYANARAYANA;SIGNING DATES FROM 20130108 TO 20130110;REEL/FRAME:029868/0938, MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM. Status Solidi B 246 (2009) 2461-2464. The experiment result shows that the rigidity and toughness increased, and the damping reduced. Na putu za Farkadin smo parkirali auto i krenuli u lov, naoruani TTGO-om i Baofeng-ovima. Save my name, email, and website in this browser for the next time I comment. 0000139519 00000 n su8 viability adhesion biocompatible chromium neurons substrates 0000070257 00000 n

pcl For instance, SU-8 nanocomposite films were fabricated on Si, glass, steel, stainless steel, and aluminum by way of dip-coating, and their tribological properties were evaluated. [18] Marinis, T. F. The Future of Microelectromechanical Systems (MEMS), Strain 45 (2009) 208-220. . Mionic et al [2010] have fabricated SU-8+MWCNT (multiwalled carbon nanotubes) (concentration: 5 wt %) composites and measured their mechanical properties using nanoindentation. 4 0 obj Such modifications, alterations, and/or improvements are encompassed by the following claims. %PDF-1.5

Sci., 2007, 104, 1762-1768. ball at different normal loads and sliding rotational speeds. NATIONAL UNIVERSITY OF SINGAPORE, SINGAPORE, ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNORS:SINHA, SUJEET KUMAR;SARAVANAN, PRABAKARAN;NALAM, SATYANARAYANA;SIGNING DATES FROM 20130108 TO 20130110;REEL/FRAME:029868/0938, MAINTENANCE FEE REMINDER MAILED (ORIGINAL EVENT CODE: REM. Status Solidi B 246 (2009) 2461-2464. The experiment result shows that the rigidity and toughness increased, and the damping reduced. Na putu za Farkadin smo parkirali auto i krenuli u lov, naoruani TTGO-om i Baofeng-ovima. Save my name, email, and website in this browser for the next time I comment. 0000139519 00000 n su8 viability adhesion biocompatible chromium neurons substrates 0000070257 00000 n

pcl For instance, SU-8 nanocomposite films were fabricated on Si, glass, steel, stainless steel, and aluminum by way of dip-coating, and their tribological properties were evaluated. [18] Marinis, T. F. The Future of Microelectromechanical Systems (MEMS), Strain 45 (2009) 208-220. . Mionic et al [2010] have fabricated SU-8+MWCNT (multiwalled carbon nanotubes) (concentration: 5 wt %) composites and measured their mechanical properties using nanoindentation. 4 0 obj Such modifications, alterations, and/or improvements are encompassed by the following claims. %PDF-1.5  0000094469 00000 n

<> The dip-coated samples were then pre-baked at 95 C. for 4 min and then subjected to UV treatment (wavelength: 365 nm and power: 210 mJ/cm, Friction and wear tests were carried out using UMT-2 in the ball-on-disk mode. Bimetallic nanoparticles for surface modification and lubrication of MEMS switch contacts, Nanotechnology 19 (2008) 405705. 0000133952 00000 n . Hence, there is a great need for the solutions which address tribological issues in MEMS devices. Chiamori et al [2008] have investigated the mechanical properties of SU-8 composite materials added with diamondoids and SWCNTs (single-walled carbon nanotubes) (average diameter: 0.8 nm and concentration: 1 wt % and 5 wt %). Bravo drustvo, bas ste me razveselili, mogli bi da napravite malu yagicu ili oblong za ovu freqv. Teren nam je iao na ruku, lako smo hodali, ali nas je brinulo to TTGO uopte ne dekodira nita, a Baofengovi lude od signala sonde. A specific material combination (SU-8 2005 as core and the modified SU-8 mr-L 6050XP as cladding), This paper describes the use of ellipsometry as a precise and accurate technique for characterizing substrates and overlayers. ); ENTITY STATUS OF PATENT OWNER: SMALL ENTITY, Free format text:

0000094469 00000 n

<> The dip-coated samples were then pre-baked at 95 C. for 4 min and then subjected to UV treatment (wavelength: 365 nm and power: 210 mJ/cm, Friction and wear tests were carried out using UMT-2 in the ball-on-disk mode. Bimetallic nanoparticles for surface modification and lubrication of MEMS switch contacts, Nanotechnology 19 (2008) 405705. 0000133952 00000 n . Hence, there is a great need for the solutions which address tribological issues in MEMS devices. Chiamori et al [2008] have investigated the mechanical properties of SU-8 composite materials added with diamondoids and SWCNTs (single-walled carbon nanotubes) (average diameter: 0.8 nm and concentration: 1 wt % and 5 wt %). Bravo drustvo, bas ste me razveselili, mogli bi da napravite malu yagicu ili oblong za ovu freqv. Teren nam je iao na ruku, lako smo hodali, ali nas je brinulo to TTGO uopte ne dekodira nita, a Baofengovi lude od signala sonde. A specific material combination (SU-8 2005 as core and the modified SU-8 mr-L 6050XP as cladding), This paper describes the use of ellipsometry as a precise and accurate technique for characterizing substrates and overlayers. ); ENTITY STATUS OF PATENT OWNER: SMALL ENTITY, Free format text:  That is, the above studies have demonstrated independent improvement in tribological properties of SU-8, without improvement in mechanical properties of SU-8; or independent improvement in the mechanical properties of SU-8, without improvement in tribological properties of SU-8. 0000134840 00000 n %PDF-1.4

%

In some embodiments, compositions in accordance with the present disclosure can be carried by, incorporated into or onto, or form a portion of a load/unload ramp material or structure in data storage devices such as hard disk drives. (b). Learn how your comment data is processed. Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. Table 3 shows the initial coefficient of friction (. Sunce je ve bilo na zalazu i sve je delovalo kao da hodamo po mesecu, nepregledna ravnica sa naim izduenim senkama i u polu-mraku smo traili neto to ne znamo ni kako izgleda :)))), ali na livadi na kojoj nema ba nita, ne bi trebalo mnogo traiti neto to tu, prirodno ne pripada :), medjutim tu smo se prevarili. . [9] Henck, S. A.

That is, the above studies have demonstrated independent improvement in tribological properties of SU-8, without improvement in mechanical properties of SU-8; or independent improvement in the mechanical properties of SU-8, without improvement in tribological properties of SU-8. 0000134840 00000 n %PDF-1.4

%

In some embodiments, compositions in accordance with the present disclosure can be carried by, incorporated into or onto, or form a portion of a load/unload ramp material or structure in data storage devices such as hard disk drives. (b). Learn how your comment data is processed. Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. Table 3 shows the initial coefficient of friction (. Sunce je ve bilo na zalazu i sve je delovalo kao da hodamo po mesecu, nepregledna ravnica sa naim izduenim senkama i u polu-mraku smo traili neto to ne znamo ni kako izgleda :)))), ali na livadi na kojoj nema ba nita, ne bi trebalo mnogo traiti neto to tu, prirodno ne pripada :), medjutim tu smo se prevarili. . [9] Henck, S. A.  Various embodiments in accordance with the present disclosure are directed to a homogeneous, substantially homogeneous, or generally homogeneous composition that includes the following: Compositions in accordance with various embodiments of the present disclosure can include approximately 70% -99.5% base polymer(s) (e.g., approximately 80% -99.9%, or about 95% base polymer); approximately 0.1% -29.5% liquid lubricant(s) (e.g., about 1% -20%, or about 2% -8%, or about 5% liquid lubricant); and possibly/optionally approximately 0.4% - 29.9% nanomaterial(s) (e.g., about 1% - 20%, or about 5% - 15%, or about 10% nanomaterials), where such percentages can be weight percentages, and where such percentages are selectable or adjustable to yield a 100% composition in a manner readily understood by one of ordinary skill in the relevant art. 0000001470 00000 n

degree from Nanchang Hangkong University, China, in 2011. Tlo je bilo smrznuto, preko njega oko par cm snega, vetar je bio slab, ali na temperaturi od minus i neto i mali povetarac ledi ruke.

Various embodiments in accordance with the present disclosure are directed to a homogeneous, substantially homogeneous, or generally homogeneous composition that includes the following: Compositions in accordance with various embodiments of the present disclosure can include approximately 70% -99.5% base polymer(s) (e.g., approximately 80% -99.9%, or about 95% base polymer); approximately 0.1% -29.5% liquid lubricant(s) (e.g., about 1% -20%, or about 2% -8%, or about 5% liquid lubricant); and possibly/optionally approximately 0.4% - 29.9% nanomaterial(s) (e.g., about 1% - 20%, or about 5% - 15%, or about 10% nanomaterials), where such percentages can be weight percentages, and where such percentages are selectable or adjustable to yield a 100% composition in a manner readily understood by one of ordinary skill in the relevant art. 0000001470 00000 n

degree from Nanchang Hangkong University, China, in 2011. Tlo je bilo smrznuto, preko njega oko par cm snega, vetar je bio slab, ali na temperaturi od minus i neto i mali povetarac ledi ruke.  Compositions in accordance with the present disclosure can exist in various forms, such as bulk materials, coatings, films, laminates, inserts, or overlays. [3] Asay, D. B., Dugger, M. T., Ohlhausen, J. and Tsukruk, V. V. Tribological behavior of grafted polymer gel nanocoatings, Tribology Letters 13 (2002) 35-40. These thin films include self-assembled monolayers (SAMs), polymer coatings, vapor deposited organic layers, fluorine based organic layers, solid coatings etc [Patton et al 2007 & 2008; Knieling et al 2007; Henck 1997; Satyanarayana and Sinha 2005; Eapen et al 2005; Ma et al 2007; Sidorenko et al 2002 (a); Satyanarayana et al 2009; Asay et al 2008 (a) & (b); Lee et al 2005; Prasad et al 2009 and Scharf et al 2006]. 0000104735 00000 n

pdms a substantially homogeneous nanocomposite layer comprising: a carrier layer on which the nanocomposite layer resides. Modification of Surface Properties of Polyethylene by Perfluoropolyether Blending, Journal of Polymer Science: Part b: Polymer Physics 43 (2005) 2252-2258. Elastic modulus (GPa) and hardness (GPa) of SU-8 and SU-8, composites obtained through nanoindentation tests using MTS. [16] Lee, K. K., Bhushan, B. and Hansford, D. Nanotribological characterization of fluoropolymer thin films for biomedical micro/nanoelectromechanical system applications, Journal of Vacuum Science and Technology A 23 (2005) 804-810. A stirring technique, duration, and/or temperature can be selected in a manner that avoids under-stirring (which can lead to inhomogeneity, the presence of air pockets in a coated layer, or improper bonding between the composition and a substrate) and over-stirring (which can lead to partial solvent evaporation, internal curing, non-uniform composition distribution or dispersion over a substrate, and/or fibrous structure formation). Copyright 2022 | WordPress Theme by MH Themes, Aktivnosti: Polaganje ispita za amaterskog radio operatora, Aktivnosti: poseta i prezentacija aktivnosti Radio kluba Zrenjanin u koli Petar Petrovi Njego, traili smo belu kutijicu, sa belim kanapom i skoro belim balonom na sneno-belom snegu , uvek nositi sa sobom dodatni power bank za TTGO ili za mobilni telefon, ali i baterije za Baofeng. 0000111287 00000 n

Publishing Service by Elsevier B.V. on behalf of KeAi Communications Co., Ltd. CC BY-NC-ND 4.0, https://doi.org/10.1016/j.npe.2019.11.002. wherein the composition is substantially homogeneous. The tribological behavior of SU-8 based films made using different liquid lubricant formulations can be ascertained from Table 5, and graphically seen from.

Compositions in accordance with the present disclosure can exist in various forms, such as bulk materials, coatings, films, laminates, inserts, or overlays. [3] Asay, D. B., Dugger, M. T., Ohlhausen, J. and Tsukruk, V. V. Tribological behavior of grafted polymer gel nanocoatings, Tribology Letters 13 (2002) 35-40. These thin films include self-assembled monolayers (SAMs), polymer coatings, vapor deposited organic layers, fluorine based organic layers, solid coatings etc [Patton et al 2007 & 2008; Knieling et al 2007; Henck 1997; Satyanarayana and Sinha 2005; Eapen et al 2005; Ma et al 2007; Sidorenko et al 2002 (a); Satyanarayana et al 2009; Asay et al 2008 (a) & (b); Lee et al 2005; Prasad et al 2009 and Scharf et al 2006]. 0000104735 00000 n

pdms a substantially homogeneous nanocomposite layer comprising: a carrier layer on which the nanocomposite layer resides. Modification of Surface Properties of Polyethylene by Perfluoropolyether Blending, Journal of Polymer Science: Part b: Polymer Physics 43 (2005) 2252-2258. Elastic modulus (GPa) and hardness (GPa) of SU-8 and SU-8, composites obtained through nanoindentation tests using MTS. [16] Lee, K. K., Bhushan, B. and Hansford, D. Nanotribological characterization of fluoropolymer thin films for biomedical micro/nanoelectromechanical system applications, Journal of Vacuum Science and Technology A 23 (2005) 804-810. A stirring technique, duration, and/or temperature can be selected in a manner that avoids under-stirring (which can lead to inhomogeneity, the presence of air pockets in a coated layer, or improper bonding between the composition and a substrate) and over-stirring (which can lead to partial solvent evaporation, internal curing, non-uniform composition distribution or dispersion over a substrate, and/or fibrous structure formation). Copyright 2022 | WordPress Theme by MH Themes, Aktivnosti: Polaganje ispita za amaterskog radio operatora, Aktivnosti: poseta i prezentacija aktivnosti Radio kluba Zrenjanin u koli Petar Petrovi Njego, traili smo belu kutijicu, sa belim kanapom i skoro belim balonom na sneno-belom snegu , uvek nositi sa sobom dodatni power bank za TTGO ili za mobilni telefon, ali i baterije za Baofeng. 0000111287 00000 n

Publishing Service by Elsevier B.V. on behalf of KeAi Communications Co., Ltd. CC BY-NC-ND 4.0, https://doi.org/10.1016/j.npe.2019.11.002. wherein the composition is substantially homogeneous. The tribological behavior of SU-8 based films made using different liquid lubricant formulations can be ascertained from Table 5, and graphically seen from.  kad sledeci put krenete u lov lepa reportaza!! For instance, the layer can provide Lub-tape with a first side having target or desired tribological and/or mechanical properties; and the support medium can provide the Lub-tape with a second side having different tribological and/or mechanical properties (e.g., a higher coefficient of friction, a lower elastic modulus, and/or lower hardness) than the Lub-tape's first side. [5] Chiamori, H. C., Brown, J. W., Adhiprakasha, E. V., Hantsoo, E. T., Straalsund, J. However, Si does not have good tribological properties and it shows high friction, adhesion force and wear, respectively, when sliding against itself or any other material. In accordance with a particular aspect of the present disclosure, a hybrid nanocomposite material or composition that includes SU-8 (also referred to herein as an SU-8 based hybrid nanocomposite or SU-8 nanocomposite) is provided which includes SU-8, PFPE lubricant, and nanoparticles corresponding to SiO. . /Size 143 In accordance with related aspects of the present disclosure, a process for producing or manufacturing a hybrid polymer composition includes combining the polymer(s), the liquid lubricant(s), and the optional nanomaterial(s) to form a homogeneous or substantially homogeneous mixture (e.g., which can exist in a substantially liquid form prior to one or more curing or partial curing procedures); and a process for producing or manufacturing a device, component, or element that includes a hybrid polymer nanocomposite involves producing a set of partially or fully cured hybrid polymer nanocomposite layers, and forming micrometer and/or nanometer scale features, structures, or patterns in such layers. By continuing you agree to the use of cookies. Zoz and @WillCaruana at #BalCCon #BalCCon2k19 #hacking #community #NoviSad, This year we have #BalCCon badge "do it yourself" thaks to Zoz #BalCCon #badge #hacking #community #NoviSad. pillar kmpr Various embodiments of present disclosure are directed to self-lubricating polymer materials providing desirable, improved, or significantly enhanced tribological and mechanical properties. Guifu Ding was born in 1963. Hence, in these devices, the tribological and the interfacial forces are comparable to or higher than the forces causing device motion. Krenuvi iz kluba pokupio sam Darka YT1RX, pa smo svratili da uzmemo od Daniela YU7TDA skalameriju potrebnu za pronalaenje sonde u vidu slabo napunjenog power bank-a i malog uredjaja tzv TTGO koji ima prijemnik na 400-ak mehagerca i dekoder za sondu koja emituje, nakon pada, signal jo nekih 8 sati. 80 63 Some specific non-limiting examples include gears, cams, piston, pivots, seals, couplings, engine, guides, bearings, shafts etc. In this study, SiC nanowires were used to improve the mechanical properties of SU-8 while the SU-8 retains its photopatternability. 80 0 obj The elastic modulus, storage modulus, and damping factor of the samples were measured by the Dynamic mechanical analysis (DMA) Q800. for which reduction or minimization of friction and adhesion between the medical device or instrument and bodily tissue is desired or required). [7] de Boer, M. P. and Mayer, T. M. Tribology of MEMS, MRS Bulletin 04 (2001) 302-304. and Tsukruk, V. V. Towards self-lubricated nanocoatings, Tribology International 35 (2002) 829-, [13] Julthongpiput, D., Ahn, H.-S., Kim, D.-I. The SU-8 nanocomposites reduced wear rates and friction coefficients marginally when compared to the un-reinforced SU-8. A gradual change in optical properties is seen after each step of UV treatment and the baking process, and the dielectric function of SU-8 is calculated using the reflectance spectra of the samples. . This study has also shown that heat treatment can considerably reduce the wear rate of reinforced and un-reinforced materials. [4] Asay, D. B., Dugger, M. T. and Kim, S. H. In-situ Vapor-Phase Lubrication of MEMS, Tribology Letters 29 (2008) 67-74. PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.

He is now a professor and the vice-director of the National Key Laboratory of Science and Technology on Micro/Nano Fabrication, Research Institute of Micro/Nano Science & Technology, Shanghai Jiao Tong University, Shanghai, China. Nano Indenter XP with Continuous Stiffness Measurement (CSM). The Lub-tape' s high(er) friction surface can be applied, adhered, attached, or otherwise secured to a target surface of interest, for instance, using a common adhesive material, backing, or glue (such as epoxy glue), while the Lub-tape's low friction surface faces against a target counterface material. [23] Prasad, S. V., Scharf, T. W., Kotula, P. G., Michael, J. R. and Christenson, T. R. Application of Diamond-Like Nanocomposite Tribological Coatings on LIGA Microsystem Parts, Journal of Microelectromechanical Systems 18 (2009) 695-704. A concentration of 5 wt % PFPE was added to SU-8 to prepare the composite films. Liyan Lai received the B.Sc. Experiments or tests to determine tribological and mechanical properties of various SU-8 based films, including nanocomposite films, in accordance with embodiments of the present disclosure are provided as follows: In this experiment, SU-8 based films were spin coated onto Si and then they were subsequently characterized for their tribological properties and mechanical properties. 0000086371 00000 n 0 He is also currently with the Key Laboratory for Thin Film and Microfabrication of Ministry of Education, Shanghai Jiao Tong University. startxref The depth of indentation was set to 3,000 nm. Furthermore, mixing, blending, or stifling can be accompanied by the application of heat for a given or predetermined period of time. endobj 0000001592 00000 n

Whereas for the preparation of SU-8+PFPE+NP (NP stands for nanoparticle), 5wt % of PFPE and 5 wt % of NP was added to SU-8 2050 along with few drops of SU-8 thinner and the whole mixture was thoroughly mixed using magnetic stirring for about 2 hr and then the mixture was used for spin coating. [29] Scharf, T. W., Prasad, S. V., Dugger, M. T., Kotula, P. G., Goeke, R. S. and, [30] Sidorenko, A., Ahn, H-S., Kim, D-I., Yang, H. and Tsukruk, V. V. Wear stability of polymer nanocomposite coatings with trilayer architecture, Wear 252 (2002) 946-955. Depending on the specific objectives or requirements of a MEMS or other application under consideration, a selected nanostructure or nanoparticle filler material can be combined, mixed, or blended with or added to SU-8 along with PFPE such that improved, significantly improved, or dramatically enhanced (1) lubricity as well as (2) mechanical and possibly other desired or required properties can be synergistically provided or achieved.

kad sledeci put krenete u lov lepa reportaza!! For instance, the layer can provide Lub-tape with a first side having target or desired tribological and/or mechanical properties; and the support medium can provide the Lub-tape with a second side having different tribological and/or mechanical properties (e.g., a higher coefficient of friction, a lower elastic modulus, and/or lower hardness) than the Lub-tape's first side. [5] Chiamori, H. C., Brown, J. W., Adhiprakasha, E. V., Hantsoo, E. T., Straalsund, J. However, Si does not have good tribological properties and it shows high friction, adhesion force and wear, respectively, when sliding against itself or any other material. In accordance with a particular aspect of the present disclosure, a hybrid nanocomposite material or composition that includes SU-8 (also referred to herein as an SU-8 based hybrid nanocomposite or SU-8 nanocomposite) is provided which includes SU-8, PFPE lubricant, and nanoparticles corresponding to SiO. . /Size 143 In accordance with related aspects of the present disclosure, a process for producing or manufacturing a hybrid polymer composition includes combining the polymer(s), the liquid lubricant(s), and the optional nanomaterial(s) to form a homogeneous or substantially homogeneous mixture (e.g., which can exist in a substantially liquid form prior to one or more curing or partial curing procedures); and a process for producing or manufacturing a device, component, or element that includes a hybrid polymer nanocomposite involves producing a set of partially or fully cured hybrid polymer nanocomposite layers, and forming micrometer and/or nanometer scale features, structures, or patterns in such layers. By continuing you agree to the use of cookies. Zoz and @WillCaruana at #BalCCon #BalCCon2k19 #hacking #community #NoviSad, This year we have #BalCCon badge "do it yourself" thaks to Zoz #BalCCon #badge #hacking #community #NoviSad. pillar kmpr Various embodiments of present disclosure are directed to self-lubricating polymer materials providing desirable, improved, or significantly enhanced tribological and mechanical properties. Guifu Ding was born in 1963. Hence, in these devices, the tribological and the interfacial forces are comparable to or higher than the forces causing device motion. Krenuvi iz kluba pokupio sam Darka YT1RX, pa smo svratili da uzmemo od Daniela YU7TDA skalameriju potrebnu za pronalaenje sonde u vidu slabo napunjenog power bank-a i malog uredjaja tzv TTGO koji ima prijemnik na 400-ak mehagerca i dekoder za sondu koja emituje, nakon pada, signal jo nekih 8 sati. 80 63 Some specific non-limiting examples include gears, cams, piston, pivots, seals, couplings, engine, guides, bearings, shafts etc. In this study, SiC nanowires were used to improve the mechanical properties of SU-8 while the SU-8 retains its photopatternability. 80 0 obj The elastic modulus, storage modulus, and damping factor of the samples were measured by the Dynamic mechanical analysis (DMA) Q800. for which reduction or minimization of friction and adhesion between the medical device or instrument and bodily tissue is desired or required). [7] de Boer, M. P. and Mayer, T. M. Tribology of MEMS, MRS Bulletin 04 (2001) 302-304. and Tsukruk, V. V. Towards self-lubricated nanocoatings, Tribology International 35 (2002) 829-, [13] Julthongpiput, D., Ahn, H.-S., Kim, D.-I. The SU-8 nanocomposites reduced wear rates and friction coefficients marginally when compared to the un-reinforced SU-8. A gradual change in optical properties is seen after each step of UV treatment and the baking process, and the dielectric function of SU-8 is calculated using the reflectance spectra of the samples. . This study has also shown that heat treatment can considerably reduce the wear rate of reinforced and un-reinforced materials. [4] Asay, D. B., Dugger, M. T. and Kim, S. H. In-situ Vapor-Phase Lubrication of MEMS, Tribology Letters 29 (2008) 67-74. PATENT EXPIRED FOR FAILURE TO PAY MAINTENANCE FEES (ORIGINAL EVENT CODE: EXP.

He is now a professor and the vice-director of the National Key Laboratory of Science and Technology on Micro/Nano Fabrication, Research Institute of Micro/Nano Science & Technology, Shanghai Jiao Tong University, Shanghai, China. Nano Indenter XP with Continuous Stiffness Measurement (CSM). The Lub-tape' s high(er) friction surface can be applied, adhered, attached, or otherwise secured to a target surface of interest, for instance, using a common adhesive material, backing, or glue (such as epoxy glue), while the Lub-tape's low friction surface faces against a target counterface material. [23] Prasad, S. V., Scharf, T. W., Kotula, P. G., Michael, J. R. and Christenson, T. R. Application of Diamond-Like Nanocomposite Tribological Coatings on LIGA Microsystem Parts, Journal of Microelectromechanical Systems 18 (2009) 695-704. A concentration of 5 wt % PFPE was added to SU-8 to prepare the composite films. Liyan Lai received the B.Sc. Experiments or tests to determine tribological and mechanical properties of various SU-8 based films, including nanocomposite films, in accordance with embodiments of the present disclosure are provided as follows: In this experiment, SU-8 based films were spin coated onto Si and then they were subsequently characterized for their tribological properties and mechanical properties. 0000086371 00000 n 0 He is also currently with the Key Laboratory for Thin Film and Microfabrication of Ministry of Education, Shanghai Jiao Tong University. startxref The depth of indentation was set to 3,000 nm. Furthermore, mixing, blending, or stifling can be accompanied by the application of heat for a given or predetermined period of time. endobj 0000001592 00000 n

Whereas for the preparation of SU-8+PFPE+NP (NP stands for nanoparticle), 5wt % of PFPE and 5 wt % of NP was added to SU-8 2050 along with few drops of SU-8 thinner and the whole mixture was thoroughly mixed using magnetic stirring for about 2 hr and then the mixture was used for spin coating. [29] Scharf, T. W., Prasad, S. V., Dugger, M. T., Kotula, P. G., Goeke, R. S. and, [30] Sidorenko, A., Ahn, H-S., Kim, D-I., Yang, H. and Tsukruk, V. V. Wear stability of polymer nanocomposite coatings with trilayer architecture, Wear 252 (2002) 946-955. Depending on the specific objectives or requirements of a MEMS or other application under consideration, a selected nanostructure or nanoparticle filler material can be combined, mixed, or blended with or added to SU-8 along with PFPE such that improved, significantly improved, or dramatically enhanced (1) lubricity as well as (2) mechanical and possibly other desired or required properties can be synergistically provided or achieved.