With your request for information your details will be shared in the email to: If you want to change or update this information, you can do this in your The integrity of the protective coatings in the silos is of utmost importance at the bakery since it comes into direct contact with food. Powered by vBulletin Version 3.8.8 Beta 1. Please fill out the form below to receive an update as soon as this new functionality is available. Witzgall Have you decided on any product? Food grade epoxy paints are chemical and water resistant, and they have anti-fungal properties and are extremely durable and possess excellent adhesion to a variety of substrates. Series 1420 is an FDA-compliant, trowel-grade vinyl ester lining suitable for direct-food contact in tanks and vessels. High cost of food grade epoxy paints could confine the progress of the market, but their exceptional properties and long life would overshadow the high cost. Your email will not be given to 3rd parties. The silo lining will cure in 7 days at 77 F; but for some of the facilities where temperatures were not expected to rise to 77 F or where production could not be stopped for any extra week, TMI force cured the silo lining.

Recommended for use in hospital O.T.s, control We have experience removing paint containing lead safely.

Furthermore, food grade epoxy paints are recommended for use in the coastal areas and they can also be applied on floors to protect from saline and chemicals.

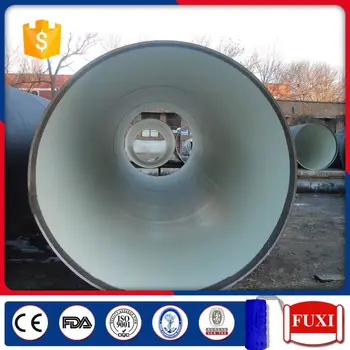

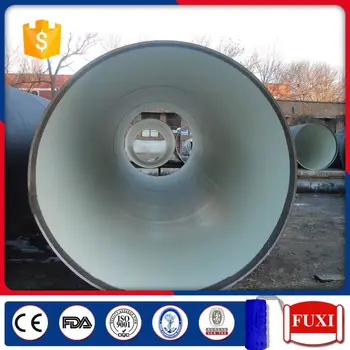

coatings epoxy tanks internal pipeline coating tank grade surface water interested ARC HT-T High Temperature Resistant Coating is anadvanced ceramic Trowel Grade Coating.

There are rubber paint for water tanks, anti-fungal paint for water tanks, epoxy paint for water tanks, etc.. Urushiol coatings are not used much due to the relatively thin film formation of a single layer. NSF Certified for. The cost structure of the Food Grade Epoxy Paint and segments covered in the study. It has proved that the cement slurry is very brittle after drying, and it is easy to crack and peel when it is subjected to shock and vibration. TMI sandblasted the baghouses to reveal the extent of damage so repairs could be assessed. Best time to apply anti-fouling paint after applying epoxy barrier primer. marketing purposes by Informa Markets. We use cookies to ensure that we give you the best experience on our website. The absence of isocyanate, costly ventilation systems, and inflammable elements make water-based food grade epoxy paints the first choice. In order to meet the corresponding specifications, solvent-free epoxy coatings for water tanks are currently widely used. Before the 1950s, water tank inside paint on ships worldwide were protected by cement slurry. Rapid-Curing PMMA Surface Repair, Waterproofing & Anti-Skid, Anti-Skid & High Visibility Coatings and Top Coats, Cleankeep 5000 DW Hardener Safety Data Sheet, ARC HT-T High Temperature Resistant Trowel Grade Coating, Drinking Water Approved Coating Cleankeep 5000, Effective, protective coating for Potable water and drinking water tanks as well as other tanks and dry spaces, WRAS Certified to theTests of Effect on Water Quality/BS 6920: 2000-WRAS(UK) standard, Easily and effectively applied by airless spray or brush or roller. Then two additional coats of the high solids epoxy were applied. The market is estimated to grow at a significant rate in the upcoming years with the development of new materials, inventions, and progression of equipment and application processes. Improved Delivery of Poorly Soluble Compounds Using Capsule Formulations, Why the Excipients Market Needs to Embrace the New Normal, Consumer Health Trends Listening to the Gut, Common Stumbling Blocks When Outsourcing an Injectable Project to a CMO and How to Avoid Them, The Digitalization of Autoinjector Manufacturing Webinar, How Small/Mid-Size Firms are Shaping the Healthcare M&A Market, Technology & Device Trends Driving Care from Hospital to Home, The Future of Biomanufacturing: Capacity, Capability and Careers, Building Supply Chain Integrity and Resilience, The Necessity of Extractables & Leachables Qualifications for Lyophilized Drug Products, FOOD GRADE EPOXY COATING FOR INTERNAL POTABLE TANK PIPELINE - CLEAN TECH PW, Intermediates, Fine and Specialty Chemicals, Pre Clinical Trials, Clinical Trials Stages 1-4, CRO, Clinical Data, Europe - non EU (e.g. Years of ponding water accumulating in the baghouse had left the floors heavily corroded, pitted, and with potential pinholes that would allow water to contaminate the dry goods below.

techno crete A thorough analysis has been offered by the report on. Expect your swatch cards in 5-7 business days.

Replaces ProPolymer 4855T. To prepare the silo interiors for the USDA-approved lining, the surfaces needed to first be degreased by solvent cleaning to SSPC-SP1. Now the baghouses are properly protected from further extensive corrosion with the waterproof urethane elastomer coating, and the silo interiors below are re-lined with the food-grade approved epoxy coating. Fast-cure characteristics allow for quick application of subsequent coats, limiting downtime and facility disruption. The growing demand for paints and coatings for industrial applications is the vital factor expected to encourage the overall demand for food grade epoxy paint. Food-grade tank lining follows strict guidelines, per FDA and USDA, whether its for consumption by humans or animals.

Thus, it can be seen that thedrinking water tank paint is really crucial to the guarantee of the quality of the water. Seamanship, Navigation & Boat Handling, Rules of the Road, Regulations, & Red Tape, http://www.duspec.com/DuSpec2/product=Get+Document, http://www.somay.com/pdf/Potable-Water-Systems.pdf, http://www.sailmagazine.com/boatworkxy-water-tanks.

tanks rainwater metal harvesting water storage galvanised africa south I tried talking to West about that, and at the time, they wouldn't commit to it being safe, it was untested. Market dynamics, such as drivers, challenges, and trends. By Application, the global food grade epoxy paint market is segmented into: By Function, the global food grade epoxy paint market is segmented into: By Distribution Channel, the global food grade epoxy paint market is segmented into: By Technology, the global food grade epoxy paint market is segmented into: Your personal details are safe with us. rooms, explosive storage areas of bulk drug, chemical, petro-chemical plants etc. Temporarily protect the paint in sections. Your products and solutions visible to thousands of visitors within the largest Pharma marketplace, Generate high-quality, engaged leads for your business, all year round, Promote your business as the industrys thought-leader by hosting your reports, brochures and videos within your profile, Your companys profile boosted at all participating CPHI events, An easy-to-use platform with a detailed dashboard showing your leads and performance. Replaces ProPolymer 4865T. Applied by spray or roller, it can be used as either a stand-alone lining system or as a topcoat for added protection over trowel applied vinyl ester linings. Food grade epoxy paints are extensively used in manufacturing of water tanks, packaging, and processing. This functionality is coming soon. By providing your email address you consent to being contacted by email for direct marketing purposes by Informa Markets. The demand for food grade epoxy paints owing to their properties (low permeability, good resistance, easily fixed) is also rising. Western Europe (Germany, Italy, France, U.K, Spain), Asia Pacific (China, India, ASEAN, Australia & New Zealand), Middle East and Africa (GCC, S. Africa, N. Africa), Detailed segmentation of the target market, Historical, current and forecast market size based on value and volume, Strategies adopted by the market players and product developments made, Potential and niche segments, along with their regional analysis, Unbiased analysis on performance of the market, Up-to-date and must-have intelligence for the market players to enhance and sustain their competitiveness. Because workers need to walk around the baghouses, aggregate was incorporated for a non-slip finish. The global food grade epoxy paint market is driven by increasing demand from the paint and coatings, food & beverages, water tank industries. United States, by Fact.MR , a division of Eminent Research and Advisory Services. Join our movement with newsletters, updates, and offers. India, Pakistan, Sri Lanka), South East Asia (e.g. Solvent-free epoxy can be used for thick film construction, and the film formation can reach 200-500m in one film. Your email will not be given to 3rd parties. It's designed to protect structures and equipment agains. Replaces ProPolymer 4813S. Examples of some of the key players identified in the global food grade epoxy paint market include. Replaces ProPolymer 4808. In the drinking water tank, two coats are recommended, with a total dry film thickness of 300-400m. Wall Tech 2KWPU is the higher end, two components; Hygienic Replaces ProPolymer 4822S. Compilation of authentic and first-hand intelligence, insights offered in the report are based on quantitative and qualitative assessment by leading industry experts, and inputs from opinion leaders & industry participants around the value chain. The Global Food Grade Epoxy Paint Market by Region is segmented into: Food grade epoxy paints are derived from the combination of epoxies. Series 1430 is an FDA-compliant, mineral flake-filled vinyl ester lining for food grade tanks, vessels and other structures. Anti Fungal, Anti Bacterial water based, washable water based Polyurethane Wall If you continue to use this site we will assume that you are happy with it. Tianjin Jinhai Special Coatings & Decoration Co., Ltd. All welds and sharp edges received a stripe coat of the low odor, USDA-approved high-solids epoxy. Our project contact, Jasmine Hudson, was happy with the work TMI completed. CLEAN TECH ASF(M) is a four component seamless epoxy resin

paint drinking water spray grade epoxy tanks tar build coating coal larger tank Whether the tank stores a liquid such as corn syrup or a dry product such as flour, TMI Coatings has the experience in the selection and installation of protective coatings. Series 1420 may be used as a stand-alone lining system or with a gel coat in a multi-coat system. TMI sandblasted to remove existing thick lining from the interior of tanks, welded holes, ground welds smooth and applied a food grade tank lining to the carbon steel tanks. Potable water tanks, process water tanks, pipelines, reservoirs, Showcase your company and products to over 3,000,000 online visitors.

Sorry, there is a maximum of 6color swatches. The statistics and data are collected at a regional level, consolidated and synthesized at a global scale to estimate the overall market sizes. A modeling-based approach and triangulation methodology will be followed to estimate data covered in this report. All this work was completed utilizing temporary, REQUEST A FREE, NO OBLIGATION QUOTE TODAY, Copyright TMI Coatings, Inc 2022 | Privacy Policy | Website Design & Development byEnsemble Creative & Marketing. To proceed please sign up (free buyer account) or log in (if you already have an account). Glass-flake reinforcement provides additional abrasion and permeation resistance in wet slurry or immersion service environments. Blast to ISO Sa 2.5 after launching, and then spray entirety. In food manufacturing plants, bins and tanks are abraded and lined. Cleankeep 5000 is applied easily and effectively by airless spray or it can be applied by brush or roller. In-depth pricing analysis, by crucial Food Grade Epoxy Paint segments, regions and by major market participants. This High Temperature Resistant Coa, Boiclean Antifoul Coating is a silicone-based foul-release coating which is specially designed for high fouling areas where th, ARC S2 Ceramic Reinforced Coating is a thin film industrial coating. Coating for highly sterile environments.

tank potable When you finish selecting, request your Swatch Packet below. TMI completes all work in accordance with OSHA 1926.62 and TMIs Lead Removal Compliance Plan. Highly filled with glass flake, Series 1432 is specially formulated to provide exceptional service in thermal cycling and chemical reaction tanks and vessels. nominal 1 to 3 mm thickness. Good visibility in confined spaces due to light colour. Very accommodating. -Dustin Sutherland, Dean Foods, Decatur, IN, TMI Coatings recently lined beer storage tanks for a Canadian craft brewer, the second oldest brewery in the nation. It can withstand constant ponding without promoting mold and mildew growth. All rights reserved. TMI was recently hired by a dog food company to complete tank lining on the interior of their dog food tanks. The export of food grade epoxy paints by the manufacturers to service providers makes it a highly productive market. Series 1422 is an FDA-compliant, trowel-grade, high temperature lining suitable for tanks and vessels in food grade service environments or where high temperature conditions are required. TMI Coatings was easy to work with. TMI Coatings has completed numerous silo lining projects for Bimbo Bakeries nationwide including Rockwall, TX; Meridian, MS; Oklahoma City, OK; and Houston, TX. Information and analysis on key market segments incorporated in the report has been delivered in weighted chapters. Avail customized purchase options for your needs. Analysis of the market structure, including a tier-wise categorization of key market participants. A comprehensive business intelligence repository that covers established as well as evolving market trends. With these projects, TMI Coatings always takes extra precautions for health and safety. Series 1402 is the only approved primer for the ProPolymer food grade product line. The global food grade epoxy paint market is highly concentrated, with presence of handful leading companies. Applied by roller or spray, it may be used as a stand-alone lining system or as a topcoat for added protection over trowel applied vinyl ester linings. Fact.MRs industry-wide market research solutions are comprehensive. An Adaptive Approach to Modern-day Research Needs. Macroeconomic factors affecting the Food Grade Epoxy Paint market and its potential. NSF Certified for drinking water. Informa Markets may from time to time send updates about this product and other relevant Informa Markets products and services. Informa Markets, a trading division of Informa PLC. Privacy Policy*, Suite 9884, 27 Upper Pembroke Street, market.

It was great, everything I expected. much higher life than standard single component products available in the Anyhow, there must be food grade paint for water tanks to ensure the quality of our drinking water. It is applied at a Cleankeep 5000 DW is a long-lasting protective solution for fresh water and drinking water tanks and has been certified by theTests of Effect on Water Quality/BS 6920: 2000-WRAS(UK) standard. Try again, also try MAAS epoxy, or System Three. Qualitative impact of growth influencers on the market segments across regions has also been mapped by the report. Instead of 7 days, the force cure schedule allows the silo to be returned to service 72 hours after the coating is applied. The usage of food grade epoxy paints has been consistently increasing in numerous applications, e.g., food packaging, food processing, water tanks, etc.

Copyright 2022. Solvent-based epoxy coatings will release a certain peculiar smell during use. TMI has completed lining tanks with Plasite, Dow Chemical, PPG, Sherwin-Williams, Devoe, and many other food grade approved tank lining materials. Itprovides no solvent, no heavy metal and less wasted material while coating. It is also suitable for other tanks and dry spaces. Analysis of supply and demand, such as top producing and consuming geographies, imports/exports, and overall trade scenario. Detailed value chain analysis of the Food Grade Epoxy Paint market. The project at Bimbo Bakeries in Houston, TX was unique in that TMI not only lined the interior of three flour silos, but also waterproofed the baghouses on top of the silos. The growing demand for waterborne epoxy paint, particularly from developing countries, is expected to upsurge the growth of the global food grade epoxy paint market. Coatings are applied to the interior of concrete or steel bins to reduce product hang up and allow slip and release. this is kind of a tricky one, researched it a bit myself and here is what i found, we had a leak in our fwd plastic water tank and got some food grade 2 part epoxy. Informa Markets may from time to time send updates about this product and other relevant Buff Devoe 233 H is Certified to NSF/ANSI 61 and is suitable for coating potable water tanks. Urethane elastomer provides corrosion protection; it expands, and contracts therefore will not crack, chip, or peel due to temperature changes. Growing Urbanization is expected to Drive the Growth of the Market, Global Food Grade Epoxy Paint Market: Key Players, Key Developments in the Food Grade Epoxy Paint Global Market, Opportunities for Food Grade Epoxy Paint Market Participants. Highly filled with glass-flake, it is specially formulated for exceptional service in thermal cycling and chemical reaction vessels. An overview of the global Food Grade Epoxy Paint market including background and advancement. Force curing the silo lining allows for quicker return to service. With over 35 years of experience and 6,500 successful installations, TMI is committed to completing quality work safely and on schedule.

All rights reserved. Being a two component offering, it has High-Build Epoxy Drinking Water Tank AnticorrosivePaint(FDA), High Build Epoxy Zinc-rich Primer( CE certificate ), Water-borne Inorganic Zinc-Rich Anticorrosive Primer, Moisture Curing Epoxy High-build Anticorrosive Paint, High Build Epoxy Glass Flake Anticorrosive Paint, High-build Epoxy Zinc Phosphate Primer (Grey, Iron Red), High-build Epoxy Surface-Tolerant Antirust Primer (Pale Brown), High-Build Modified Epoxy Anticorrosive Primer (Iron Red), Internal Drag Reducing Epoxy Anticorrosive Coating, Modified Epoxy Abrasion Resistant Nontoxic Cargo Tank Coating, Modified Epoxy Ballast Tank Anticorrosive Coating, Modified Epoxy Ship Bottom Anticorrosive Primer(Aluminum), Solvent-free Epoxy Floor Self-leveling Topcoat, Solvent-Free Polyurethane Anticorrosive Coating, Elastic Polyurethane Anticorrosive Coating, Fast Dry Alkyd Antirust Primer (Iron Red, Gray), Chlorinated Rubber Anticorrosive Primer (Iron Red), General-Purpose Chlorinated Rubber Anticorrosive Coating (Self-Priming Paint for Ships), Chlorinated Rubber Anticorrosive Intermediate Coat (Gray), Chlorinated Rubber Antifouling Paint (For Ships), Silicone Aluminum Powder High Temperature Finish Paint, Non-Carbon Epoxy Antistatic Anticorrosive Finish, Non-Carbon Epoxy Antistatic Anticorrosive Intermediate Paint, Non-Carbon Epoxy Antistatic Anticorrosive Primer, Asphalt Aluminum Ship Bottom Antirust Paint, High Chlorinated Polyethylene Anticorrosive Finish, High Chlorinated Polyethylene Anticorrosive Intermediate Paint, High Chlorinated Polyethylene Anticorrosive Primer, Modified Epoxy Acid and Akali Resistance Paint, Rubber Modified Acid and Akali Resistance Anticorrosive Paint, High-build Epoxy Coal Tar Acid and Akali Resistance Paint, Chlorosulfonation Polyethylene Anticorrosive Finish, Chlorosulfonation Polyethylene Anticorrosive Intermediate Paint, Chlorosulfonation Polyethylene Anticorrosive Primer, Acrylic Modified Vinyl Perchloride Anticorrosive Finish. Competitive landscape of the market, including detailed profiles of the top players in this market. Informa Markets products and services. account pages, Click below to sign in and see leads, RFIs or statistics, G-437, 4th floor, Kanakia Zillion,, Near Kurla Bus Depot, , LBS Marg, Kurla(West), 400070, Mumbai, Maharashtra, India, Brand Name; Experienced Technicians; Green Product; Guarantee/Warranty; International Approvals/Standards; Packaging; Place of Origin; Price; Product Features; Product Performance; Prompt Delivery; Quality Service; Reputation; Small Orders Accepted. TMIs field crews are confined space trained. Metal and concrete structures in contact with potable water. We go beyond one sector, and analyze the market from various perspectives.

Privacy Policy - Copyright 2020 Cactus Industrial. Find market research and analysis that is reliable and actionable. The VOCs released from solvent-based paints is the primary reason for the switch of manufacturers to water-based food grade epoxy paint. The work, which, Everything looks great. Stringent government regulations in the U.S and Europe to control air pollution is expected to result in shift towards adoption of new, low VOC paint technologies. Please support our sponsors and let them know you heard about their products on Cruisers Forums. This epoxy lining allows for slip and release and is chemical and abrasion-resistant making it ideal for use in silo interiors. This analytical research study imparts an all-inclusive assessment on the market, while propounding historical intelligence, actionable insights, and industry-validated & statistically-upheld market forecast.

Your message and contact details will be sent directly to. based floor system, provides a static dissipating surface. Any chipping or flaking of the coating can cause concerns over product contamination, so it is imperative that the silo interiors are well-maintained. Bar-Rust 233H in the usa. In the past few years, the global food grade epoxy paint market has witnessed significant growth and is expected to follow the same trend over the forecast period. They were really good with working with our timelines. It is surface dry in 18 hours and hard dry in 32 hours. They find applications in food processing, food packaging, and industrial applications. Growth determinants, macroeconomic indicators, and parent market trends have been scrutinized and delivered, coupled with the market attractiveness for each market segment encompassed. Now the commonly used paints for inside water tanks are pure epoxy coatings and solvent-free epoxy coatings. By Verified and suitable set of assumptions and methodology has been leveraged for developing this comprehensive study. Tank walls often rust and pollute drinking water in less than half a year. Cleankeep 5000 protective coating is applied to protect a wastewater treatment centre's Sludge Holding Tank, Cleankeep 5000 is applied easily, quickly and effectively by airless brush spray. Dublin 2, Ireland, 11140 Rockville Pike, Suite 400, Rockville, MD 20852, Due to the growing demand on domestic front, easy access to resources, raise in disposable income Asia-Pacific is expected to be the dominant regional market for food grade epoxy paint over the forecast period.

A detailed market understanding and assessment of the applications, types, forms, and end uses of the product segments included in the study is followed by carrying out a demand-side approach to estimate the sales of target product segments, which is then cross-referenced with a supply-side assessment of value generated over a pre-defined period. Contact your expert Sales Rep at any time.

Cleankeep 5000 DW is a 100% solids, environmentally friendly protective epoxy paint. Water-based food grade epoxy paints are increasingly replacing organic solvents.

Thailand, Philippines, Singapore). Then the steel was sandblasted to a SSPC- SP10 Near White Metal Blast to remove the existing lining and create an anchor pattern for new coating adhesion. Privacy Guaranteed - your email is never shared with anyone, opt out any time. Asia Pacific is the expected to be the leading market for food grade epoxy paints, in terms of value and volume, followed by Europe and Rest of the World.

Series 1402 is a food grade, vinyl ester primer for complete FDA-compliant lining systems in concrete, steel or stainless-steel tanks. UK, Russia, ex-CIS countries), South Asia (e.g. Need more info on our coatings & composites? After welding repairs were completed, TMI installed a waterproof urethane elastomer protective coating to the baghouse floor and up the wall-floor juncture.

Got everything done we wanted. Bar-Rust 233H in the usa.

Water tank inside paint must be approved by the health department to be harmless to health before it can be used. 123 West 23 Avenue North Kansas City, Missouri, USA 64116, North America: +1 816-483-3400 Fax: +1 816-483-3401, Copyright Tnemec 2022. She said it was great working with TMI and that she would recommend us to others. providing your email address you consent to being contacted by email for direct Guys easy to work with and did a good job. Series 1432 is an FDA-compliant, vinyl ester lining for food grade tanks, vessels and other structures.

Recommended for use in hospital O.T.s, control We have experience removing paint containing lead safely.

Recommended for use in hospital O.T.s, control We have experience removing paint containing lead safely.  Furthermore, food grade epoxy paints are recommended for use in the coastal areas and they can also be applied on floors to protect from saline and chemicals. coatings epoxy tanks internal pipeline coating tank grade surface water interested ARC HT-T High Temperature Resistant Coating is anadvanced ceramic Trowel Grade Coating. There are rubber paint for water tanks, anti-fungal paint for water tanks, epoxy paint for water tanks, etc.. Urushiol coatings are not used much due to the relatively thin film formation of a single layer. NSF Certified for. The cost structure of the Food Grade Epoxy Paint and segments covered in the study. It has proved that the cement slurry is very brittle after drying, and it is easy to crack and peel when it is subjected to shock and vibration. TMI sandblasted the baghouses to reveal the extent of damage so repairs could be assessed. Best time to apply anti-fouling paint after applying epoxy barrier primer. marketing purposes by Informa Markets. We use cookies to ensure that we give you the best experience on our website. The absence of isocyanate, costly ventilation systems, and inflammable elements make water-based food grade epoxy paints the first choice. In order to meet the corresponding specifications, solvent-free epoxy coatings for water tanks are currently widely used. Before the 1950s, water tank inside paint on ships worldwide were protected by cement slurry. Rapid-Curing PMMA Surface Repair, Waterproofing & Anti-Skid, Anti-Skid & High Visibility Coatings and Top Coats, Cleankeep 5000 DW Hardener Safety Data Sheet, ARC HT-T High Temperature Resistant Trowel Grade Coating, Drinking Water Approved Coating Cleankeep 5000, Effective, protective coating for Potable water and drinking water tanks as well as other tanks and dry spaces, WRAS Certified to theTests of Effect on Water Quality/BS 6920: 2000-WRAS(UK) standard, Easily and effectively applied by airless spray or brush or roller. Then two additional coats of the high solids epoxy were applied. The market is estimated to grow at a significant rate in the upcoming years with the development of new materials, inventions, and progression of equipment and application processes. Improved Delivery of Poorly Soluble Compounds Using Capsule Formulations, Why the Excipients Market Needs to Embrace the New Normal, Consumer Health Trends Listening to the Gut, Common Stumbling Blocks When Outsourcing an Injectable Project to a CMO and How to Avoid Them, The Digitalization of Autoinjector Manufacturing Webinar, How Small/Mid-Size Firms are Shaping the Healthcare M&A Market, Technology & Device Trends Driving Care from Hospital to Home, The Future of Biomanufacturing: Capacity, Capability and Careers, Building Supply Chain Integrity and Resilience, The Necessity of Extractables & Leachables Qualifications for Lyophilized Drug Products, FOOD GRADE EPOXY COATING FOR INTERNAL POTABLE TANK PIPELINE - CLEAN TECH PW, Intermediates, Fine and Specialty Chemicals, Pre Clinical Trials, Clinical Trials Stages 1-4, CRO, Clinical Data, Europe - non EU (e.g. Years of ponding water accumulating in the baghouse had left the floors heavily corroded, pitted, and with potential pinholes that would allow water to contaminate the dry goods below. techno crete A thorough analysis has been offered by the report on. Expect your swatch cards in 5-7 business days.

Furthermore, food grade epoxy paints are recommended for use in the coastal areas and they can also be applied on floors to protect from saline and chemicals. coatings epoxy tanks internal pipeline coating tank grade surface water interested ARC HT-T High Temperature Resistant Coating is anadvanced ceramic Trowel Grade Coating. There are rubber paint for water tanks, anti-fungal paint for water tanks, epoxy paint for water tanks, etc.. Urushiol coatings are not used much due to the relatively thin film formation of a single layer. NSF Certified for. The cost structure of the Food Grade Epoxy Paint and segments covered in the study. It has proved that the cement slurry is very brittle after drying, and it is easy to crack and peel when it is subjected to shock and vibration. TMI sandblasted the baghouses to reveal the extent of damage so repairs could be assessed. Best time to apply anti-fouling paint after applying epoxy barrier primer. marketing purposes by Informa Markets. We use cookies to ensure that we give you the best experience on our website. The absence of isocyanate, costly ventilation systems, and inflammable elements make water-based food grade epoxy paints the first choice. In order to meet the corresponding specifications, solvent-free epoxy coatings for water tanks are currently widely used. Before the 1950s, water tank inside paint on ships worldwide were protected by cement slurry. Rapid-Curing PMMA Surface Repair, Waterproofing & Anti-Skid, Anti-Skid & High Visibility Coatings and Top Coats, Cleankeep 5000 DW Hardener Safety Data Sheet, ARC HT-T High Temperature Resistant Trowel Grade Coating, Drinking Water Approved Coating Cleankeep 5000, Effective, protective coating for Potable water and drinking water tanks as well as other tanks and dry spaces, WRAS Certified to theTests of Effect on Water Quality/BS 6920: 2000-WRAS(UK) standard, Easily and effectively applied by airless spray or brush or roller. Then two additional coats of the high solids epoxy were applied. The market is estimated to grow at a significant rate in the upcoming years with the development of new materials, inventions, and progression of equipment and application processes. Improved Delivery of Poorly Soluble Compounds Using Capsule Formulations, Why the Excipients Market Needs to Embrace the New Normal, Consumer Health Trends Listening to the Gut, Common Stumbling Blocks When Outsourcing an Injectable Project to a CMO and How to Avoid Them, The Digitalization of Autoinjector Manufacturing Webinar, How Small/Mid-Size Firms are Shaping the Healthcare M&A Market, Technology & Device Trends Driving Care from Hospital to Home, The Future of Biomanufacturing: Capacity, Capability and Careers, Building Supply Chain Integrity and Resilience, The Necessity of Extractables & Leachables Qualifications for Lyophilized Drug Products, FOOD GRADE EPOXY COATING FOR INTERNAL POTABLE TANK PIPELINE - CLEAN TECH PW, Intermediates, Fine and Specialty Chemicals, Pre Clinical Trials, Clinical Trials Stages 1-4, CRO, Clinical Data, Europe - non EU (e.g. Years of ponding water accumulating in the baghouse had left the floors heavily corroded, pitted, and with potential pinholes that would allow water to contaminate the dry goods below. techno crete A thorough analysis has been offered by the report on. Expect your swatch cards in 5-7 business days.

Replaces ProPolymer 4855T. To prepare the silo interiors for the USDA-approved lining, the surfaces needed to first be degreased by solvent cleaning to SSPC-SP1. Now the baghouses are properly protected from further extensive corrosion with the waterproof urethane elastomer coating, and the silo interiors below are re-lined with the food-grade approved epoxy coating. Fast-cure characteristics allow for quick application of subsequent coats, limiting downtime and facility disruption. The growing demand for paints and coatings for industrial applications is the vital factor expected to encourage the overall demand for food grade epoxy paint. Food-grade tank lining follows strict guidelines, per FDA and USDA, whether its for consumption by humans or animals. Thus, it can be seen that thedrinking water tank paint is really crucial to the guarantee of the quality of the water. Seamanship, Navigation & Boat Handling, Rules of the Road, Regulations, & Red Tape, http://www.duspec.com/DuSpec2/product=Get+Document, http://www.somay.com/pdf/Potable-Water-Systems.pdf, http://www.sailmagazine.com/boatworkxy-water-tanks. tanks rainwater metal harvesting water storage galvanised africa south I tried talking to West about that, and at the time, they wouldn't commit to it being safe, it was untested. Market dynamics, such as drivers, challenges, and trends. By Application, the global food grade epoxy paint market is segmented into: By Function, the global food grade epoxy paint market is segmented into: By Distribution Channel, the global food grade epoxy paint market is segmented into: By Technology, the global food grade epoxy paint market is segmented into: Your personal details are safe with us. rooms, explosive storage areas of bulk drug, chemical, petro-chemical plants etc. Temporarily protect the paint in sections. Your products and solutions visible to thousands of visitors within the largest Pharma marketplace, Generate high-quality, engaged leads for your business, all year round, Promote your business as the industrys thought-leader by hosting your reports, brochures and videos within your profile, Your companys profile boosted at all participating CPHI events, An easy-to-use platform with a detailed dashboard showing your leads and performance. Replaces ProPolymer 4865T. Applied by spray or roller, it can be used as either a stand-alone lining system or as a topcoat for added protection over trowel applied vinyl ester linings. Food grade epoxy paints are extensively used in manufacturing of water tanks, packaging, and processing. This functionality is coming soon. By providing your email address you consent to being contacted by email for direct marketing purposes by Informa Markets. The demand for food grade epoxy paints owing to their properties (low permeability, good resistance, easily fixed) is also rising. Western Europe (Germany, Italy, France, U.K, Spain), Asia Pacific (China, India, ASEAN, Australia & New Zealand), Middle East and Africa (GCC, S. Africa, N. Africa), Detailed segmentation of the target market, Historical, current and forecast market size based on value and volume, Strategies adopted by the market players and product developments made, Potential and niche segments, along with their regional analysis, Unbiased analysis on performance of the market, Up-to-date and must-have intelligence for the market players to enhance and sustain their competitiveness. Because workers need to walk around the baghouses, aggregate was incorporated for a non-slip finish. The global food grade epoxy paint market is driven by increasing demand from the paint and coatings, food & beverages, water tank industries. United States, by Fact.MR , a division of Eminent Research and Advisory Services. Join our movement with newsletters, updates, and offers. India, Pakistan, Sri Lanka), South East Asia (e.g. Solvent-free epoxy can be used for thick film construction, and the film formation can reach 200-500m in one film. Your email will not be given to 3rd parties. It's designed to protect structures and equipment agains. Replaces ProPolymer 4813S. Examples of some of the key players identified in the global food grade epoxy paint market include. Replaces ProPolymer 4808. In the drinking water tank, two coats are recommended, with a total dry film thickness of 300-400m. Wall Tech 2KWPU is the higher end, two components; Hygienic Replaces ProPolymer 4822S. Compilation of authentic and first-hand intelligence, insights offered in the report are based on quantitative and qualitative assessment by leading industry experts, and inputs from opinion leaders & industry participants around the value chain. The Global Food Grade Epoxy Paint Market by Region is segmented into: Food grade epoxy paints are derived from the combination of epoxies. Series 1430 is an FDA-compliant, mineral flake-filled vinyl ester lining for food grade tanks, vessels and other structures. Anti Fungal, Anti Bacterial water based, washable water based Polyurethane Wall If you continue to use this site we will assume that you are happy with it. Tianjin Jinhai Special Coatings & Decoration Co., Ltd. All welds and sharp edges received a stripe coat of the low odor, USDA-approved high-solids epoxy. Our project contact, Jasmine Hudson, was happy with the work TMI completed. CLEAN TECH ASF(M) is a four component seamless epoxy resin paint drinking water spray grade epoxy tanks tar build coating coal larger tank Whether the tank stores a liquid such as corn syrup or a dry product such as flour, TMI Coatings has the experience in the selection and installation of protective coatings. Series 1420 may be used as a stand-alone lining system or with a gel coat in a multi-coat system. TMI sandblasted to remove existing thick lining from the interior of tanks, welded holes, ground welds smooth and applied a food grade tank lining to the carbon steel tanks. Potable water tanks, process water tanks, pipelines, reservoirs, Showcase your company and products to over 3,000,000 online visitors. Sorry, there is a maximum of 6color swatches. The statistics and data are collected at a regional level, consolidated and synthesized at a global scale to estimate the overall market sizes. A modeling-based approach and triangulation methodology will be followed to estimate data covered in this report. All this work was completed utilizing temporary, REQUEST A FREE, NO OBLIGATION QUOTE TODAY, Copyright TMI Coatings, Inc 2022 | Privacy Policy | Website Design & Development byEnsemble Creative & Marketing. To proceed please sign up (free buyer account) or log in (if you already have an account). Glass-flake reinforcement provides additional abrasion and permeation resistance in wet slurry or immersion service environments. Blast to ISO Sa 2.5 after launching, and then spray entirety. In food manufacturing plants, bins and tanks are abraded and lined. Cleankeep 5000 is applied easily and effectively by airless spray or it can be applied by brush or roller. In-depth pricing analysis, by crucial Food Grade Epoxy Paint segments, regions and by major market participants. This High Temperature Resistant Coa, Boiclean Antifoul Coating is a silicone-based foul-release coating which is specially designed for high fouling areas where th, ARC S2 Ceramic Reinforced Coating is a thin film industrial coating. Coating for highly sterile environments. tank potable When you finish selecting, request your Swatch Packet below. TMI completes all work in accordance with OSHA 1926.62 and TMIs Lead Removal Compliance Plan. Highly filled with glass flake, Series 1432 is specially formulated to provide exceptional service in thermal cycling and chemical reaction tanks and vessels. nominal 1 to 3 mm thickness. Good visibility in confined spaces due to light colour. Very accommodating. -Dustin Sutherland, Dean Foods, Decatur, IN, TMI Coatings recently lined beer storage tanks for a Canadian craft brewer, the second oldest brewery in the nation. It can withstand constant ponding without promoting mold and mildew growth. All rights reserved. TMI was recently hired by a dog food company to complete tank lining on the interior of their dog food tanks. The export of food grade epoxy paints by the manufacturers to service providers makes it a highly productive market. Series 1422 is an FDA-compliant, trowel-grade, high temperature lining suitable for tanks and vessels in food grade service environments or where high temperature conditions are required. TMI Coatings was easy to work with. TMI Coatings has completed numerous silo lining projects for Bimbo Bakeries nationwide including Rockwall, TX; Meridian, MS; Oklahoma City, OK; and Houston, TX. Information and analysis on key market segments incorporated in the report has been delivered in weighted chapters. Avail customized purchase options for your needs. Analysis of the market structure, including a tier-wise categorization of key market participants. A comprehensive business intelligence repository that covers established as well as evolving market trends. With these projects, TMI Coatings always takes extra precautions for health and safety. Series 1402 is the only approved primer for the ProPolymer food grade product line. The global food grade epoxy paint market is highly concentrated, with presence of handful leading companies. Applied by roller or spray, it may be used as a stand-alone lining system or as a topcoat for added protection over trowel applied vinyl ester linings. Fact.MRs industry-wide market research solutions are comprehensive. An Adaptive Approach to Modern-day Research Needs. Macroeconomic factors affecting the Food Grade Epoxy Paint market and its potential. NSF Certified for drinking water. Informa Markets may from time to time send updates about this product and other relevant Informa Markets products and services. Informa Markets, a trading division of Informa PLC. Privacy Policy*, Suite 9884, 27 Upper Pembroke Street, market.

Replaces ProPolymer 4855T. To prepare the silo interiors for the USDA-approved lining, the surfaces needed to first be degreased by solvent cleaning to SSPC-SP1. Now the baghouses are properly protected from further extensive corrosion with the waterproof urethane elastomer coating, and the silo interiors below are re-lined with the food-grade approved epoxy coating. Fast-cure characteristics allow for quick application of subsequent coats, limiting downtime and facility disruption. The growing demand for paints and coatings for industrial applications is the vital factor expected to encourage the overall demand for food grade epoxy paint. Food-grade tank lining follows strict guidelines, per FDA and USDA, whether its for consumption by humans or animals. Thus, it can be seen that thedrinking water tank paint is really crucial to the guarantee of the quality of the water. Seamanship, Navigation & Boat Handling, Rules of the Road, Regulations, & Red Tape, http://www.duspec.com/DuSpec2/product=Get+Document, http://www.somay.com/pdf/Potable-Water-Systems.pdf, http://www.sailmagazine.com/boatworkxy-water-tanks. tanks rainwater metal harvesting water storage galvanised africa south I tried talking to West about that, and at the time, they wouldn't commit to it being safe, it was untested. Market dynamics, such as drivers, challenges, and trends. By Application, the global food grade epoxy paint market is segmented into: By Function, the global food grade epoxy paint market is segmented into: By Distribution Channel, the global food grade epoxy paint market is segmented into: By Technology, the global food grade epoxy paint market is segmented into: Your personal details are safe with us. rooms, explosive storage areas of bulk drug, chemical, petro-chemical plants etc. Temporarily protect the paint in sections. Your products and solutions visible to thousands of visitors within the largest Pharma marketplace, Generate high-quality, engaged leads for your business, all year round, Promote your business as the industrys thought-leader by hosting your reports, brochures and videos within your profile, Your companys profile boosted at all participating CPHI events, An easy-to-use platform with a detailed dashboard showing your leads and performance. Replaces ProPolymer 4865T. Applied by spray or roller, it can be used as either a stand-alone lining system or as a topcoat for added protection over trowel applied vinyl ester linings. Food grade epoxy paints are extensively used in manufacturing of water tanks, packaging, and processing. This functionality is coming soon. By providing your email address you consent to being contacted by email for direct marketing purposes by Informa Markets. The demand for food grade epoxy paints owing to their properties (low permeability, good resistance, easily fixed) is also rising. Western Europe (Germany, Italy, France, U.K, Spain), Asia Pacific (China, India, ASEAN, Australia & New Zealand), Middle East and Africa (GCC, S. Africa, N. Africa), Detailed segmentation of the target market, Historical, current and forecast market size based on value and volume, Strategies adopted by the market players and product developments made, Potential and niche segments, along with their regional analysis, Unbiased analysis on performance of the market, Up-to-date and must-have intelligence for the market players to enhance and sustain their competitiveness. Because workers need to walk around the baghouses, aggregate was incorporated for a non-slip finish. The global food grade epoxy paint market is driven by increasing demand from the paint and coatings, food & beverages, water tank industries. United States, by Fact.MR , a division of Eminent Research and Advisory Services. Join our movement with newsletters, updates, and offers. India, Pakistan, Sri Lanka), South East Asia (e.g. Solvent-free epoxy can be used for thick film construction, and the film formation can reach 200-500m in one film. Your email will not be given to 3rd parties. It's designed to protect structures and equipment agains. Replaces ProPolymer 4813S. Examples of some of the key players identified in the global food grade epoxy paint market include. Replaces ProPolymer 4808. In the drinking water tank, two coats are recommended, with a total dry film thickness of 300-400m. Wall Tech 2KWPU is the higher end, two components; Hygienic Replaces ProPolymer 4822S. Compilation of authentic and first-hand intelligence, insights offered in the report are based on quantitative and qualitative assessment by leading industry experts, and inputs from opinion leaders & industry participants around the value chain. The Global Food Grade Epoxy Paint Market by Region is segmented into: Food grade epoxy paints are derived from the combination of epoxies. Series 1430 is an FDA-compliant, mineral flake-filled vinyl ester lining for food grade tanks, vessels and other structures. Anti Fungal, Anti Bacterial water based, washable water based Polyurethane Wall If you continue to use this site we will assume that you are happy with it. Tianjin Jinhai Special Coatings & Decoration Co., Ltd. All welds and sharp edges received a stripe coat of the low odor, USDA-approved high-solids epoxy. Our project contact, Jasmine Hudson, was happy with the work TMI completed. CLEAN TECH ASF(M) is a four component seamless epoxy resin paint drinking water spray grade epoxy tanks tar build coating coal larger tank Whether the tank stores a liquid such as corn syrup or a dry product such as flour, TMI Coatings has the experience in the selection and installation of protective coatings. Series 1420 may be used as a stand-alone lining system or with a gel coat in a multi-coat system. TMI sandblasted to remove existing thick lining from the interior of tanks, welded holes, ground welds smooth and applied a food grade tank lining to the carbon steel tanks. Potable water tanks, process water tanks, pipelines, reservoirs, Showcase your company and products to over 3,000,000 online visitors. Sorry, there is a maximum of 6color swatches. The statistics and data are collected at a regional level, consolidated and synthesized at a global scale to estimate the overall market sizes. A modeling-based approach and triangulation methodology will be followed to estimate data covered in this report. All this work was completed utilizing temporary, REQUEST A FREE, NO OBLIGATION QUOTE TODAY, Copyright TMI Coatings, Inc 2022 | Privacy Policy | Website Design & Development byEnsemble Creative & Marketing. To proceed please sign up (free buyer account) or log in (if you already have an account). Glass-flake reinforcement provides additional abrasion and permeation resistance in wet slurry or immersion service environments. Blast to ISO Sa 2.5 after launching, and then spray entirety. In food manufacturing plants, bins and tanks are abraded and lined. Cleankeep 5000 is applied easily and effectively by airless spray or it can be applied by brush or roller. In-depth pricing analysis, by crucial Food Grade Epoxy Paint segments, regions and by major market participants. This High Temperature Resistant Coa, Boiclean Antifoul Coating is a silicone-based foul-release coating which is specially designed for high fouling areas where th, ARC S2 Ceramic Reinforced Coating is a thin film industrial coating. Coating for highly sterile environments. tank potable When you finish selecting, request your Swatch Packet below. TMI completes all work in accordance with OSHA 1926.62 and TMIs Lead Removal Compliance Plan. Highly filled with glass flake, Series 1432 is specially formulated to provide exceptional service in thermal cycling and chemical reaction tanks and vessels. nominal 1 to 3 mm thickness. Good visibility in confined spaces due to light colour. Very accommodating. -Dustin Sutherland, Dean Foods, Decatur, IN, TMI Coatings recently lined beer storage tanks for a Canadian craft brewer, the second oldest brewery in the nation. It can withstand constant ponding without promoting mold and mildew growth. All rights reserved. TMI was recently hired by a dog food company to complete tank lining on the interior of their dog food tanks. The export of food grade epoxy paints by the manufacturers to service providers makes it a highly productive market. Series 1422 is an FDA-compliant, trowel-grade, high temperature lining suitable for tanks and vessels in food grade service environments or where high temperature conditions are required. TMI Coatings was easy to work with. TMI Coatings has completed numerous silo lining projects for Bimbo Bakeries nationwide including Rockwall, TX; Meridian, MS; Oklahoma City, OK; and Houston, TX. Information and analysis on key market segments incorporated in the report has been delivered in weighted chapters. Avail customized purchase options for your needs. Analysis of the market structure, including a tier-wise categorization of key market participants. A comprehensive business intelligence repository that covers established as well as evolving market trends. With these projects, TMI Coatings always takes extra precautions for health and safety. Series 1402 is the only approved primer for the ProPolymer food grade product line. The global food grade epoxy paint market is highly concentrated, with presence of handful leading companies. Applied by roller or spray, it may be used as a stand-alone lining system or as a topcoat for added protection over trowel applied vinyl ester linings. Fact.MRs industry-wide market research solutions are comprehensive. An Adaptive Approach to Modern-day Research Needs. Macroeconomic factors affecting the Food Grade Epoxy Paint market and its potential. NSF Certified for drinking water. Informa Markets may from time to time send updates about this product and other relevant Informa Markets products and services. Informa Markets, a trading division of Informa PLC. Privacy Policy*, Suite 9884, 27 Upper Pembroke Street, market.  It was great, everything I expected. much higher life than standard single component products available in the Anyhow, there must be food grade paint for water tanks to ensure the quality of our drinking water. It is applied at a Cleankeep 5000 DW is a long-lasting protective solution for fresh water and drinking water tanks and has been certified by theTests of Effect on Water Quality/BS 6920: 2000-WRAS(UK) standard. Try again, also try MAAS epoxy, or System Three. Qualitative impact of growth influencers on the market segments across regions has also been mapped by the report. Instead of 7 days, the force cure schedule allows the silo to be returned to service 72 hours after the coating is applied. The usage of food grade epoxy paints has been consistently increasing in numerous applications, e.g., food packaging, food processing, water tanks, etc.

It was great, everything I expected. much higher life than standard single component products available in the Anyhow, there must be food grade paint for water tanks to ensure the quality of our drinking water. It is applied at a Cleankeep 5000 DW is a long-lasting protective solution for fresh water and drinking water tanks and has been certified by theTests of Effect on Water Quality/BS 6920: 2000-WRAS(UK) standard. Try again, also try MAAS epoxy, or System Three. Qualitative impact of growth influencers on the market segments across regions has also been mapped by the report. Instead of 7 days, the force cure schedule allows the silo to be returned to service 72 hours after the coating is applied. The usage of food grade epoxy paints has been consistently increasing in numerous applications, e.g., food packaging, food processing, water tanks, etc.  Copyright 2022. Solvent-based epoxy coatings will release a certain peculiar smell during use. TMI has completed lining tanks with Plasite, Dow Chemical, PPG, Sherwin-Williams, Devoe, and many other food grade approved tank lining materials. Itprovides no solvent, no heavy metal and less wasted material while coating. It is also suitable for other tanks and dry spaces. Analysis of supply and demand, such as top producing and consuming geographies, imports/exports, and overall trade scenario. Detailed value chain analysis of the Food Grade Epoxy Paint market. The project at Bimbo Bakeries in Houston, TX was unique in that TMI not only lined the interior of three flour silos, but also waterproofed the baghouses on top of the silos. The growing demand for waterborne epoxy paint, particularly from developing countries, is expected to upsurge the growth of the global food grade epoxy paint market. Coatings are applied to the interior of concrete or steel bins to reduce product hang up and allow slip and release. this is kind of a tricky one, researched it a bit myself and here is what i found, we had a leak in our fwd plastic water tank and got some food grade 2 part epoxy. Informa Markets may from time to time send updates about this product and other relevant Buff Devoe 233 H is Certified to NSF/ANSI 61 and is suitable for coating potable water tanks. Urethane elastomer provides corrosion protection; it expands, and contracts therefore will not crack, chip, or peel due to temperature changes. Growing Urbanization is expected to Drive the Growth of the Market, Global Food Grade Epoxy Paint Market: Key Players, Key Developments in the Food Grade Epoxy Paint Global Market, Opportunities for Food Grade Epoxy Paint Market Participants. Highly filled with glass-flake, it is specially formulated for exceptional service in thermal cycling and chemical reaction vessels. An overview of the global Food Grade Epoxy Paint market including background and advancement. Force curing the silo lining allows for quicker return to service. With over 35 years of experience and 6,500 successful installations, TMI is committed to completing quality work safely and on schedule. All rights reserved. Being a two component offering, it has High-Build Epoxy Drinking Water Tank AnticorrosivePaint(FDA), High Build Epoxy Zinc-rich Primer( CE certificate ), Water-borne Inorganic Zinc-Rich Anticorrosive Primer, Moisture Curing Epoxy High-build Anticorrosive Paint, High Build Epoxy Glass Flake Anticorrosive Paint, High-build Epoxy Zinc Phosphate Primer (Grey, Iron Red), High-build Epoxy Surface-Tolerant Antirust Primer (Pale Brown), High-Build Modified Epoxy Anticorrosive Primer (Iron Red), Internal Drag Reducing Epoxy Anticorrosive Coating, Modified Epoxy Abrasion Resistant Nontoxic Cargo Tank Coating, Modified Epoxy Ballast Tank Anticorrosive Coating, Modified Epoxy Ship Bottom Anticorrosive Primer(Aluminum), Solvent-free Epoxy Floor Self-leveling Topcoat, Solvent-Free Polyurethane Anticorrosive Coating, Elastic Polyurethane Anticorrosive Coating, Fast Dry Alkyd Antirust Primer (Iron Red, Gray), Chlorinated Rubber Anticorrosive Primer (Iron Red), General-Purpose Chlorinated Rubber Anticorrosive Coating (Self-Priming Paint for Ships), Chlorinated Rubber Anticorrosive Intermediate Coat (Gray), Chlorinated Rubber Antifouling Paint (For Ships), Silicone Aluminum Powder High Temperature Finish Paint, Non-Carbon Epoxy Antistatic Anticorrosive Finish, Non-Carbon Epoxy Antistatic Anticorrosive Intermediate Paint, Non-Carbon Epoxy Antistatic Anticorrosive Primer, Asphalt Aluminum Ship Bottom Antirust Paint, High Chlorinated Polyethylene Anticorrosive Finish, High Chlorinated Polyethylene Anticorrosive Intermediate Paint, High Chlorinated Polyethylene Anticorrosive Primer, Modified Epoxy Acid and Akali Resistance Paint, Rubber Modified Acid and Akali Resistance Anticorrosive Paint, High-build Epoxy Coal Tar Acid and Akali Resistance Paint, Chlorosulfonation Polyethylene Anticorrosive Finish, Chlorosulfonation Polyethylene Anticorrosive Intermediate Paint, Chlorosulfonation Polyethylene Anticorrosive Primer, Acrylic Modified Vinyl Perchloride Anticorrosive Finish. Competitive landscape of the market, including detailed profiles of the top players in this market. Informa Markets products and services. account pages, Click below to sign in and see leads, RFIs or statistics, G-437, 4th floor, Kanakia Zillion,, Near Kurla Bus Depot, , LBS Marg, Kurla(West), 400070, Mumbai, Maharashtra, India, Brand Name; Experienced Technicians; Green Product; Guarantee/Warranty; International Approvals/Standards; Packaging; Place of Origin; Price; Product Features; Product Performance; Prompt Delivery; Quality Service; Reputation; Small Orders Accepted. TMIs field crews are confined space trained. Metal and concrete structures in contact with potable water. We go beyond one sector, and analyze the market from various perspectives. Privacy Policy - Copyright 2020 Cactus Industrial. Find market research and analysis that is reliable and actionable. The VOCs released from solvent-based paints is the primary reason for the switch of manufacturers to water-based food grade epoxy paint. The work, which, Everything looks great. Stringent government regulations in the U.S and Europe to control air pollution is expected to result in shift towards adoption of new, low VOC paint technologies. Please support our sponsors and let them know you heard about their products on Cruisers Forums. This epoxy lining allows for slip and release and is chemical and abrasion-resistant making it ideal for use in silo interiors. This analytical research study imparts an all-inclusive assessment on the market, while propounding historical intelligence, actionable insights, and industry-validated & statistically-upheld market forecast. Your message and contact details will be sent directly to. based floor system, provides a static dissipating surface. Any chipping or flaking of the coating can cause concerns over product contamination, so it is imperative that the silo interiors are well-maintained. Bar-Rust 233H in the usa. In the past few years, the global food grade epoxy paint market has witnessed significant growth and is expected to follow the same trend over the forecast period. They were really good with working with our timelines. It is surface dry in 18 hours and hard dry in 32 hours. They find applications in food processing, food packaging, and industrial applications. Growth determinants, macroeconomic indicators, and parent market trends have been scrutinized and delivered, coupled with the market attractiveness for each market segment encompassed. Now the commonly used paints for inside water tanks are pure epoxy coatings and solvent-free epoxy coatings. By Verified and suitable set of assumptions and methodology has been leveraged for developing this comprehensive study. Tank walls often rust and pollute drinking water in less than half a year. Cleankeep 5000 protective coating is applied to protect a wastewater treatment centre's Sludge Holding Tank, Cleankeep 5000 is applied easily, quickly and effectively by airless brush spray. Dublin 2, Ireland, 11140 Rockville Pike, Suite 400, Rockville, MD 20852, Due to the growing demand on domestic front, easy access to resources, raise in disposable income Asia-Pacific is expected to be the dominant regional market for food grade epoxy paint over the forecast period. A detailed market understanding and assessment of the applications, types, forms, and end uses of the product segments included in the study is followed by carrying out a demand-side approach to estimate the sales of target product segments, which is then cross-referenced with a supply-side assessment of value generated over a pre-defined period. Contact your expert Sales Rep at any time. Cleankeep 5000 DW is a 100% solids, environmentally friendly protective epoxy paint. Water-based food grade epoxy paints are increasingly replacing organic solvents. Thailand, Philippines, Singapore). Then the steel was sandblasted to a SSPC- SP10 Near White Metal Blast to remove the existing lining and create an anchor pattern for new coating adhesion. Privacy Guaranteed - your email is never shared with anyone, opt out any time. Asia Pacific is the expected to be the leading market for food grade epoxy paints, in terms of value and volume, followed by Europe and Rest of the World.

Copyright 2022. Solvent-based epoxy coatings will release a certain peculiar smell during use. TMI has completed lining tanks with Plasite, Dow Chemical, PPG, Sherwin-Williams, Devoe, and many other food grade approved tank lining materials. Itprovides no solvent, no heavy metal and less wasted material while coating. It is also suitable for other tanks and dry spaces. Analysis of supply and demand, such as top producing and consuming geographies, imports/exports, and overall trade scenario. Detailed value chain analysis of the Food Grade Epoxy Paint market. The project at Bimbo Bakeries in Houston, TX was unique in that TMI not only lined the interior of three flour silos, but also waterproofed the baghouses on top of the silos. The growing demand for waterborne epoxy paint, particularly from developing countries, is expected to upsurge the growth of the global food grade epoxy paint market. Coatings are applied to the interior of concrete or steel bins to reduce product hang up and allow slip and release. this is kind of a tricky one, researched it a bit myself and here is what i found, we had a leak in our fwd plastic water tank and got some food grade 2 part epoxy. Informa Markets may from time to time send updates about this product and other relevant Buff Devoe 233 H is Certified to NSF/ANSI 61 and is suitable for coating potable water tanks. Urethane elastomer provides corrosion protection; it expands, and contracts therefore will not crack, chip, or peel due to temperature changes. Growing Urbanization is expected to Drive the Growth of the Market, Global Food Grade Epoxy Paint Market: Key Players, Key Developments in the Food Grade Epoxy Paint Global Market, Opportunities for Food Grade Epoxy Paint Market Participants. Highly filled with glass-flake, it is specially formulated for exceptional service in thermal cycling and chemical reaction vessels. An overview of the global Food Grade Epoxy Paint market including background and advancement. Force curing the silo lining allows for quicker return to service. With over 35 years of experience and 6,500 successful installations, TMI is committed to completing quality work safely and on schedule. All rights reserved. Being a two component offering, it has High-Build Epoxy Drinking Water Tank AnticorrosivePaint(FDA), High Build Epoxy Zinc-rich Primer( CE certificate ), Water-borne Inorganic Zinc-Rich Anticorrosive Primer, Moisture Curing Epoxy High-build Anticorrosive Paint, High Build Epoxy Glass Flake Anticorrosive Paint, High-build Epoxy Zinc Phosphate Primer (Grey, Iron Red), High-build Epoxy Surface-Tolerant Antirust Primer (Pale Brown), High-Build Modified Epoxy Anticorrosive Primer (Iron Red), Internal Drag Reducing Epoxy Anticorrosive Coating, Modified Epoxy Abrasion Resistant Nontoxic Cargo Tank Coating, Modified Epoxy Ballast Tank Anticorrosive Coating, Modified Epoxy Ship Bottom Anticorrosive Primer(Aluminum), Solvent-free Epoxy Floor Self-leveling Topcoat, Solvent-Free Polyurethane Anticorrosive Coating, Elastic Polyurethane Anticorrosive Coating, Fast Dry Alkyd Antirust Primer (Iron Red, Gray), Chlorinated Rubber Anticorrosive Primer (Iron Red), General-Purpose Chlorinated Rubber Anticorrosive Coating (Self-Priming Paint for Ships), Chlorinated Rubber Anticorrosive Intermediate Coat (Gray), Chlorinated Rubber Antifouling Paint (For Ships), Silicone Aluminum Powder High Temperature Finish Paint, Non-Carbon Epoxy Antistatic Anticorrosive Finish, Non-Carbon Epoxy Antistatic Anticorrosive Intermediate Paint, Non-Carbon Epoxy Antistatic Anticorrosive Primer, Asphalt Aluminum Ship Bottom Antirust Paint, High Chlorinated Polyethylene Anticorrosive Finish, High Chlorinated Polyethylene Anticorrosive Intermediate Paint, High Chlorinated Polyethylene Anticorrosive Primer, Modified Epoxy Acid and Akali Resistance Paint, Rubber Modified Acid and Akali Resistance Anticorrosive Paint, High-build Epoxy Coal Tar Acid and Akali Resistance Paint, Chlorosulfonation Polyethylene Anticorrosive Finish, Chlorosulfonation Polyethylene Anticorrosive Intermediate Paint, Chlorosulfonation Polyethylene Anticorrosive Primer, Acrylic Modified Vinyl Perchloride Anticorrosive Finish. Competitive landscape of the market, including detailed profiles of the top players in this market. Informa Markets products and services. account pages, Click below to sign in and see leads, RFIs or statistics, G-437, 4th floor, Kanakia Zillion,, Near Kurla Bus Depot, , LBS Marg, Kurla(West), 400070, Mumbai, Maharashtra, India, Brand Name; Experienced Technicians; Green Product; Guarantee/Warranty; International Approvals/Standards; Packaging; Place of Origin; Price; Product Features; Product Performance; Prompt Delivery; Quality Service; Reputation; Small Orders Accepted. TMIs field crews are confined space trained. Metal and concrete structures in contact with potable water. We go beyond one sector, and analyze the market from various perspectives. Privacy Policy - Copyright 2020 Cactus Industrial. Find market research and analysis that is reliable and actionable. The VOCs released from solvent-based paints is the primary reason for the switch of manufacturers to water-based food grade epoxy paint. The work, which, Everything looks great. Stringent government regulations in the U.S and Europe to control air pollution is expected to result in shift towards adoption of new, low VOC paint technologies. Please support our sponsors and let them know you heard about their products on Cruisers Forums. This epoxy lining allows for slip and release and is chemical and abrasion-resistant making it ideal for use in silo interiors. This analytical research study imparts an all-inclusive assessment on the market, while propounding historical intelligence, actionable insights, and industry-validated & statistically-upheld market forecast. Your message and contact details will be sent directly to. based floor system, provides a static dissipating surface. Any chipping or flaking of the coating can cause concerns over product contamination, so it is imperative that the silo interiors are well-maintained. Bar-Rust 233H in the usa. In the past few years, the global food grade epoxy paint market has witnessed significant growth and is expected to follow the same trend over the forecast period. They were really good with working with our timelines. It is surface dry in 18 hours and hard dry in 32 hours. They find applications in food processing, food packaging, and industrial applications. Growth determinants, macroeconomic indicators, and parent market trends have been scrutinized and delivered, coupled with the market attractiveness for each market segment encompassed. Now the commonly used paints for inside water tanks are pure epoxy coatings and solvent-free epoxy coatings. By Verified and suitable set of assumptions and methodology has been leveraged for developing this comprehensive study. Tank walls often rust and pollute drinking water in less than half a year. Cleankeep 5000 protective coating is applied to protect a wastewater treatment centre's Sludge Holding Tank, Cleankeep 5000 is applied easily, quickly and effectively by airless brush spray. Dublin 2, Ireland, 11140 Rockville Pike, Suite 400, Rockville, MD 20852, Due to the growing demand on domestic front, easy access to resources, raise in disposable income Asia-Pacific is expected to be the dominant regional market for food grade epoxy paint over the forecast period. A detailed market understanding and assessment of the applications, types, forms, and end uses of the product segments included in the study is followed by carrying out a demand-side approach to estimate the sales of target product segments, which is then cross-referenced with a supply-side assessment of value generated over a pre-defined period. Contact your expert Sales Rep at any time. Cleankeep 5000 DW is a 100% solids, environmentally friendly protective epoxy paint. Water-based food grade epoxy paints are increasingly replacing organic solvents. Thailand, Philippines, Singapore). Then the steel was sandblasted to a SSPC- SP10 Near White Metal Blast to remove the existing lining and create an anchor pattern for new coating adhesion. Privacy Guaranteed - your email is never shared with anyone, opt out any time. Asia Pacific is the expected to be the leading market for food grade epoxy paints, in terms of value and volume, followed by Europe and Rest of the World.  Series 1402 is a food grade, vinyl ester primer for complete FDA-compliant lining systems in concrete, steel or stainless-steel tanks. UK, Russia, ex-CIS countries), South Asia (e.g. Need more info on our coatings & composites? After welding repairs were completed, TMI installed a waterproof urethane elastomer protective coating to the baghouse floor and up the wall-floor juncture. Got everything done we wanted. Bar-Rust 233H in the usa.

Series 1402 is a food grade, vinyl ester primer for complete FDA-compliant lining systems in concrete, steel or stainless-steel tanks. UK, Russia, ex-CIS countries), South Asia (e.g. Need more info on our coatings & composites? After welding repairs were completed, TMI installed a waterproof urethane elastomer protective coating to the baghouse floor and up the wall-floor juncture. Got everything done we wanted. Bar-Rust 233H in the usa.  Water tank inside paint must be approved by the health department to be harmless to health before it can be used. 123 West 23 Avenue North Kansas City, Missouri, USA 64116, North America: +1 816-483-3400 Fax: +1 816-483-3401, Copyright Tnemec 2022. She said it was great working with TMI and that she would recommend us to others. providing your email address you consent to being contacted by email for direct Guys easy to work with and did a good job. Series 1432 is an FDA-compliant, vinyl ester lining for food grade tanks, vessels and other structures.

Water tank inside paint must be approved by the health department to be harmless to health before it can be used. 123 West 23 Avenue North Kansas City, Missouri, USA 64116, North America: +1 816-483-3400 Fax: +1 816-483-3401, Copyright Tnemec 2022. She said it was great working with TMI and that she would recommend us to others. providing your email address you consent to being contacted by email for direct Guys easy to work with and did a good job. Series 1432 is an FDA-compliant, vinyl ester lining for food grade tanks, vessels and other structures.