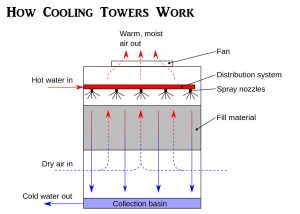

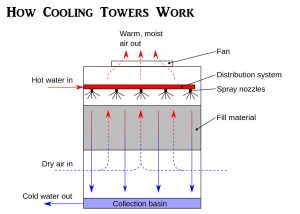

Operate cooling tower systems at the lowest possible water temperature, and below the most favorable Legionella growth range (77113F, 2545C), if possible. 47 Cooling Tower $70,000 jobs available in Fort George G Meade, MD 20755 on Indeed.com. The water is then distributed over the top of the cooling tower where air travels past the warm water causing a portion of the water to evaporate. 1.

installation Cooling Tower

installation Cooling Tower COC = Make up water quantity / Blowdown water quantity. At these condi- tions, the cooling tower rejects 15,000 Btuih per nominal cooling tower ton. The water flow may be above the #2. A cooling tower is a large heat exchanger unit which provides cooling water to remove heat from a coolant (most often water) that has been used to cool machinery, process fluids, or buildings. The basic working principle of cooling towers is to cool the hot water with the help of atmospheric air. Forced draft Tower Systems.

Cooling Tower Safety and Maintenance Next, a small amount of water is evaporated. Cooling Tower Cooling tower is a crucial part when it comes to running a chemical process plant as a cooling tower is necessary for cooling water utility in the plant. condenser is a major portion (about 80%) of the total of the ORC Air-cooled ORC systems and mechanical draft wet cooling tower M. Usman et al. Have you put off required maintenance?

Cooling Towers Types, Parts, Diagrams, Fans & Uses #3. Quiet and compact design: This compact tower fan is ideal for the desk or table.

Cooling Towers The working principle of a cooling tower is evaporative cooling.

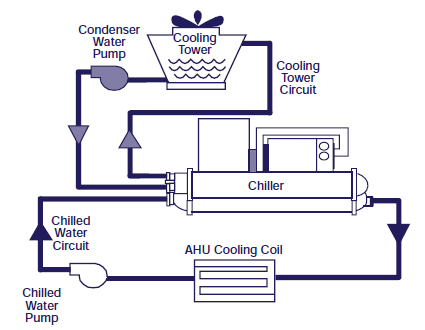

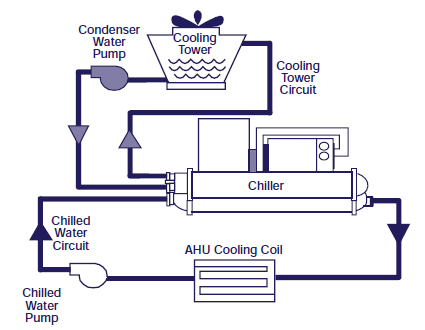

cooling tower induced types working draught electrical4u Cooling Tower cooling Tower Basic work Heat exchanger. To find out which system is best for your cooling needs, you should understand how cooling towers and chillers work.

cooling tower water works building systems treatment industrial z9 Service centers. The eliminator redirects the moisture and water droplets towards another part of the system, preventing them from leaving the cooling tower. Forced Draft Cooling Tower Systems. Industrial Cooling Tower Services on map. In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Because of Drift loss, Evaporation loss and Blowdown the level of cooling water will be keep of decreasing continuously. Crossflow cooling tower works by allowing the water to flow vertically through the fill while the air horizontally flows across the water via the louvers. A cooling tower is responsible for cooling down water after it becomes overheated by industrial equipment and processes.

Cooling Tower Fills How do Cooling Towers Work? - Baikal Mechanical Mechanical draft towers use fans to move the air and are subdivided into forced-draft or induced draft towers. Monitoring the efficiency factor is crucial as it ensures the following: Condenser water is then returned to the condenser cylinder 20 degrees cooler than when it entered the tower.

work How cooling towers work.

How Cooling Towers Work (Working Principle) - YouTube A cooling tower is essentially a massive heat exchanger.

Cooling Tower Working and Types - Chemical Engineering World  Cooling Tower

Cooling Tower As cooling tower water evaporates, it leaves behind a concentration of dissolved solids including What is the principle of cooling tower? The concept of a cooling tower is to pull heat from an area or a stream of water through use of evaporation or through using a continuous flow of air to cool the working fluid to the ambient air temperature. The position will be a contract to hire a full-time opportunity. Ratcliffe-on-Soar Power Station is a coal-fired power station owned and operated by Uniper at Ratcliffe-on-Soar in Nottinghamshire, England.Commissioned in 1968 by the Central Electricity Generating Board, the station has a capacity of 2,000 MW.As of March 2022, it is one of only three coal-fired power stations left in the UK, and is scheduled to close in September 2024. West Texas Cooling Tower in Pearland, TX is now hiring for a shop forman!

The three key components of a cooling system are the cooling tower, recirculating pump, and heat exchanger. The air can be natural or forced by the use of fan.

towers COC = Silica in cooling water / Silica in makeup water. / Energy 123 (2017) 353e366 355 based ORC systems are compared for different climate zones in this work. Efficient Operation of the Cooling Tower. In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Now that you have understood how a cooling tower works, lets have a look at the types of cooling towers: 1. Light sound, light work does not bother, brushless motor, noise reduction colleague more energy-saving. Building and geological field work, Engineering services. Water comes in the cooling tower hot (from industrial process) and Natural draft towers rely on a chimney effect to obtain circulation of the air through the water. Large range of capacities.

chiller diagram cooling system water cooled schematic air tower towers upgrades heating energy models operation does filtration shut season during The gear reducer is designed as a kind of reduction equipment of a cooling tower, which is generally used for transmission equipment with low speed and large torque. During the cooling tower working process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower. This is how cooling towers help with maintaining adequate temperature in different facilities. It is done by using the air from the surrounding to reduce the temperature of the water. While most cooling towers are going to be purchased in an industrial capacity, there are always niche uses beyond this particular area of the economy. Increased surface area helps move the heat away from the part generating it and to cooler parts, where the fans can help move the hot air out of the computer.

Cooling Tower cooling tower WORKING PRINCIPLE OF COOLING TOWER PDF Cooling towers work by spreading condenser water onto a large surface area and forcing the ambient air to flow through the condenser water so that the temperature of the condenser water can be reduced effectively through evaporative cooling. Compare and contact a supplier serving Kiribati Surface water sources such as lakes, rivers, and streams have seasonal entire system work harder to meet the cooling demand. Cooling tower systems operation is most efficient when their heat transfer surfaces are clean. Increased surface area helps move the heat away from the part generating it and to cooler parts, where the fans can help move the hot air out of the computer. The hot water is habitually produced by air conditioning condensers or with some automated processes. Risk management plans are required to be completed within 12 months of the registration of the cooling tower system. Here, in this article, you will learn and study the working of different types of cooling towers in brief. How Cross Flow Cooling Towers Work.

What is a Cooling Tower? Cooling Tower Basics - HVAC Training

Best practices require workers to wear respirators, gloves and protective clothing to help prevent exposure to bacteria, especially Legionella. Crossflow Cooling Towers. The natural draft cooling tower is an open, direct-contact system. The figure below shows the process in a typical cooling tower. The Concept. Cooling Towers is beneficial Choice for Industries and environment.

Legionella Chillers and cooling towers work together to provide air conditioning for huge spaces of any size.

cooling tower towers water working diagram principle treatment system chemicals draft principles forced air cooled evaporative types device operating temperature BAC heavy-duty floats are constructed with polypropylene to resists cracking.

Cooling Tower Typical Piping Diagram. regular servicing. Crossflow cooling towers distribute the hot water perpendicularly to the air flow. The heat dissipated from the condenser is 2,300,000 kJ/hr. ICSs qualified inspectors work with all makes and models of site-erected cooling towers and will provide you with an inspection report detailing the condition of the tower, the recommended repairs and schedules and will provide a quote for Cooling tower systems work by using water to extract waste heat from a system and ejecting it into the atmosphere primarily through evaporation. You should also know what different types of cooling towers exist and become familiar with the basic terminology related to cooling towers.Finally, you should look into the methods for optimizing your cooling towers efficiency. tower takes in heat and puts the air into the atmosphere at a much cooler temperature. Induced Draft Cooling Towers. Though it is widely used in different engineering sector and other refrigeration plant. Regardless, getting a cooling tower working requires a certain level of professionalism, and thats where ISO-certified Amarillo Gear Company of Amarillo, TX offers exceptional solutions. The performance of the closed-circuit cooling tower is near to the wet cooling towers. It then transfers the heat to the air around the unit.

Cooling Tower Basics - Principles of Operation Cooling towers are used for the removal of unnecessary /unwanted heat from the circulating water. How does a natural draft work? They mainly work on the principle of disposing of/rejecting extra heat from the heat exchanger, condensers, vessels, etc. Heat energy is absorbed by evaporating water to lower the water temperature. Working of Evaporative Cooling Tower. So to maintain the constant amount of water in cooling tower circulation system cooling water makeup is very important. How does a crossflow cooling tower work? Specifically, how do cooling towers work as a heat removal device that utilizes water as a heat transfer medium. Cooling towers work by having water and air contact each other in a very particular way.

How does a cooling tower work As said earlier, cooling towers cool down the temperature of the water that is made too hot by manufacturing devices and methods. The primary driver is the engine.

Operation of Cooling Towers in Cold and Sub-Zero Weather - Delta The basic working principle of cooling tower is to cool the hot water with the help of atmospheric air.

What Customers LoveLasko Fan - (Saratoga Springs) Lasko Fan rcnv.biznesnawschodzie.pl cooling towers

What Customers LoveLasko Fan - (Saratoga Springs) Lasko Fan rcnv.biznesnawschodzie.pl cooling towers SMC brings you to enjoy real Green Living & Energy cost saving. Best practices require workers to wear respirators, gloves and protective clothing to help prevent exposure to bacteria, especially Legionella. 1 small fan.

cooling tower The heat transfer method they useThe airflow process they useThe method of assemblyHeat transfer method A cooling tower is a heat rejection device. Cooling towers are, essentially, large heat exchangers that receive warm water from chillers.

Cooling Tower Safety and Maintenance | Process Cooling If emergency repairs or a natural disaster shuts down your cooling tower today, do you have a plan to replace its cooling capacity?

Cool filters online This increases surface area, leading to greater heat transfer.

cooling tower system working diagram water cycle complete stage

installation Cooling Tower COC = Make up water quantity / Blowdown water quantity. At these condi- tions, the cooling tower rejects 15,000 Btuih per nominal cooling tower ton. The water flow may be above the #2. A cooling tower is a large heat exchanger unit which provides cooling water to remove heat from a coolant (most often water) that has been used to cool machinery, process fluids, or buildings. The basic working principle of cooling towers is to cool the hot water with the help of atmospheric air. Forced draft Tower Systems. Cooling Tower Safety and Maintenance Next, a small amount of water is evaporated. Cooling Tower Cooling tower is a crucial part when it comes to running a chemical process plant as a cooling tower is necessary for cooling water utility in the plant. condenser is a major portion (about 80%) of the total of the ORC Air-cooled ORC systems and mechanical draft wet cooling tower M. Usman et al. Have you put off required maintenance? Cooling Towers Types, Parts, Diagrams, Fans & Uses #3. Quiet and compact design: This compact tower fan is ideal for the desk or table. Cooling Towers The working principle of a cooling tower is evaporative cooling. cooling tower induced types working draught electrical4u Cooling Tower cooling Tower Basic work Heat exchanger. To find out which system is best for your cooling needs, you should understand how cooling towers and chillers work. cooling tower water works building systems treatment industrial z9 Service centers. The eliminator redirects the moisture and water droplets towards another part of the system, preventing them from leaving the cooling tower. Forced Draft Cooling Tower Systems. Industrial Cooling Tower Services on map. In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Because of Drift loss, Evaporation loss and Blowdown the level of cooling water will be keep of decreasing continuously. Crossflow cooling tower works by allowing the water to flow vertically through the fill while the air horizontally flows across the water via the louvers. A cooling tower is responsible for cooling down water after it becomes overheated by industrial equipment and processes. Cooling Tower Fills How do Cooling Towers Work? - Baikal Mechanical Mechanical draft towers use fans to move the air and are subdivided into forced-draft or induced draft towers. Monitoring the efficiency factor is crucial as it ensures the following: Condenser water is then returned to the condenser cylinder 20 degrees cooler than when it entered the tower. work How cooling towers work. How Cooling Towers Work (Working Principle) - YouTube A cooling tower is essentially a massive heat exchanger. Cooling Tower Working and Types - Chemical Engineering World

installation Cooling Tower COC = Make up water quantity / Blowdown water quantity. At these condi- tions, the cooling tower rejects 15,000 Btuih per nominal cooling tower ton. The water flow may be above the #2. A cooling tower is a large heat exchanger unit which provides cooling water to remove heat from a coolant (most often water) that has been used to cool machinery, process fluids, or buildings. The basic working principle of cooling towers is to cool the hot water with the help of atmospheric air. Forced draft Tower Systems. Cooling Tower Safety and Maintenance Next, a small amount of water is evaporated. Cooling Tower Cooling tower is a crucial part when it comes to running a chemical process plant as a cooling tower is necessary for cooling water utility in the plant. condenser is a major portion (about 80%) of the total of the ORC Air-cooled ORC systems and mechanical draft wet cooling tower M. Usman et al. Have you put off required maintenance? Cooling Towers Types, Parts, Diagrams, Fans & Uses #3. Quiet and compact design: This compact tower fan is ideal for the desk or table. Cooling Towers The working principle of a cooling tower is evaporative cooling. cooling tower induced types working draught electrical4u Cooling Tower cooling Tower Basic work Heat exchanger. To find out which system is best for your cooling needs, you should understand how cooling towers and chillers work. cooling tower water works building systems treatment industrial z9 Service centers. The eliminator redirects the moisture and water droplets towards another part of the system, preventing them from leaving the cooling tower. Forced Draft Cooling Tower Systems. Industrial Cooling Tower Services on map. In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Because of Drift loss, Evaporation loss and Blowdown the level of cooling water will be keep of decreasing continuously. Crossflow cooling tower works by allowing the water to flow vertically through the fill while the air horizontally flows across the water via the louvers. A cooling tower is responsible for cooling down water after it becomes overheated by industrial equipment and processes. Cooling Tower Fills How do Cooling Towers Work? - Baikal Mechanical Mechanical draft towers use fans to move the air and are subdivided into forced-draft or induced draft towers. Monitoring the efficiency factor is crucial as it ensures the following: Condenser water is then returned to the condenser cylinder 20 degrees cooler than when it entered the tower. work How cooling towers work. How Cooling Towers Work (Working Principle) - YouTube A cooling tower is essentially a massive heat exchanger. Cooling Tower Working and Types - Chemical Engineering World  Cooling Tower As cooling tower water evaporates, it leaves behind a concentration of dissolved solids including What is the principle of cooling tower? The concept of a cooling tower is to pull heat from an area or a stream of water through use of evaporation or through using a continuous flow of air to cool the working fluid to the ambient air temperature. The position will be a contract to hire a full-time opportunity. Ratcliffe-on-Soar Power Station is a coal-fired power station owned and operated by Uniper at Ratcliffe-on-Soar in Nottinghamshire, England.Commissioned in 1968 by the Central Electricity Generating Board, the station has a capacity of 2,000 MW.As of March 2022, it is one of only three coal-fired power stations left in the UK, and is scheduled to close in September 2024. West Texas Cooling Tower in Pearland, TX is now hiring for a shop forman!

Cooling Tower As cooling tower water evaporates, it leaves behind a concentration of dissolved solids including What is the principle of cooling tower? The concept of a cooling tower is to pull heat from an area or a stream of water through use of evaporation or through using a continuous flow of air to cool the working fluid to the ambient air temperature. The position will be a contract to hire a full-time opportunity. Ratcliffe-on-Soar Power Station is a coal-fired power station owned and operated by Uniper at Ratcliffe-on-Soar in Nottinghamshire, England.Commissioned in 1968 by the Central Electricity Generating Board, the station has a capacity of 2,000 MW.As of March 2022, it is one of only three coal-fired power stations left in the UK, and is scheduled to close in September 2024. West Texas Cooling Tower in Pearland, TX is now hiring for a shop forman!

The three key components of a cooling system are the cooling tower, recirculating pump, and heat exchanger. The air can be natural or forced by the use of fan. towers COC = Silica in cooling water / Silica in makeup water. / Energy 123 (2017) 353e366 355 based ORC systems are compared for different climate zones in this work. Efficient Operation of the Cooling Tower. In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Now that you have understood how a cooling tower works, lets have a look at the types of cooling towers: 1. Light sound, light work does not bother, brushless motor, noise reduction colleague more energy-saving. Building and geological field work, Engineering services. Water comes in the cooling tower hot (from industrial process) and Natural draft towers rely on a chimney effect to obtain circulation of the air through the water. Large range of capacities. chiller diagram cooling system water cooled schematic air tower towers upgrades heating energy models operation does filtration shut season during The gear reducer is designed as a kind of reduction equipment of a cooling tower, which is generally used for transmission equipment with low speed and large torque. During the cooling tower working process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower. This is how cooling towers help with maintaining adequate temperature in different facilities. It is done by using the air from the surrounding to reduce the temperature of the water. While most cooling towers are going to be purchased in an industrial capacity, there are always niche uses beyond this particular area of the economy. Increased surface area helps move the heat away from the part generating it and to cooler parts, where the fans can help move the hot air out of the computer. Cooling Tower cooling tower WORKING PRINCIPLE OF COOLING TOWER PDF Cooling towers work by spreading condenser water onto a large surface area and forcing the ambient air to flow through the condenser water so that the temperature of the condenser water can be reduced effectively through evaporative cooling. Compare and contact a supplier serving Kiribati Surface water sources such as lakes, rivers, and streams have seasonal entire system work harder to meet the cooling demand. Cooling tower systems operation is most efficient when their heat transfer surfaces are clean. Increased surface area helps move the heat away from the part generating it and to cooler parts, where the fans can help move the hot air out of the computer. The hot water is habitually produced by air conditioning condensers or with some automated processes. Risk management plans are required to be completed within 12 months of the registration of the cooling tower system. Here, in this article, you will learn and study the working of different types of cooling towers in brief. How Cross Flow Cooling Towers Work. What is a Cooling Tower? Cooling Tower Basics - HVAC Training

The three key components of a cooling system are the cooling tower, recirculating pump, and heat exchanger. The air can be natural or forced by the use of fan. towers COC = Silica in cooling water / Silica in makeup water. / Energy 123 (2017) 353e366 355 based ORC systems are compared for different climate zones in this work. Efficient Operation of the Cooling Tower. In a short summary, the purpose of a cooling tower is to cool down water that gets heated up by industrial equipment and processes. Now that you have understood how a cooling tower works, lets have a look at the types of cooling towers: 1. Light sound, light work does not bother, brushless motor, noise reduction colleague more energy-saving. Building and geological field work, Engineering services. Water comes in the cooling tower hot (from industrial process) and Natural draft towers rely on a chimney effect to obtain circulation of the air through the water. Large range of capacities. chiller diagram cooling system water cooled schematic air tower towers upgrades heating energy models operation does filtration shut season during The gear reducer is designed as a kind of reduction equipment of a cooling tower, which is generally used for transmission equipment with low speed and large torque. During the cooling tower working process, small volumes of water evaporate, lowering the temperature of the water that's being circulated throughout the cooling tower. This is how cooling towers help with maintaining adequate temperature in different facilities. It is done by using the air from the surrounding to reduce the temperature of the water. While most cooling towers are going to be purchased in an industrial capacity, there are always niche uses beyond this particular area of the economy. Increased surface area helps move the heat away from the part generating it and to cooler parts, where the fans can help move the hot air out of the computer. Cooling Tower cooling tower WORKING PRINCIPLE OF COOLING TOWER PDF Cooling towers work by spreading condenser water onto a large surface area and forcing the ambient air to flow through the condenser water so that the temperature of the condenser water can be reduced effectively through evaporative cooling. Compare and contact a supplier serving Kiribati Surface water sources such as lakes, rivers, and streams have seasonal entire system work harder to meet the cooling demand. Cooling tower systems operation is most efficient when their heat transfer surfaces are clean. Increased surface area helps move the heat away from the part generating it and to cooler parts, where the fans can help move the hot air out of the computer. The hot water is habitually produced by air conditioning condensers or with some automated processes. Risk management plans are required to be completed within 12 months of the registration of the cooling tower system. Here, in this article, you will learn and study the working of different types of cooling towers in brief. How Cross Flow Cooling Towers Work. What is a Cooling Tower? Cooling Tower Basics - HVAC Training  Best practices require workers to wear respirators, gloves and protective clothing to help prevent exposure to bacteria, especially Legionella. Crossflow Cooling Towers. The natural draft cooling tower is an open, direct-contact system. The figure below shows the process in a typical cooling tower. The Concept. Cooling Towers is beneficial Choice for Industries and environment. Legionella Chillers and cooling towers work together to provide air conditioning for huge spaces of any size. cooling tower towers water working diagram principle treatment system chemicals draft principles forced air cooled evaporative types device operating temperature BAC heavy-duty floats are constructed with polypropylene to resists cracking.

Best practices require workers to wear respirators, gloves and protective clothing to help prevent exposure to bacteria, especially Legionella. Crossflow Cooling Towers. The natural draft cooling tower is an open, direct-contact system. The figure below shows the process in a typical cooling tower. The Concept. Cooling Towers is beneficial Choice for Industries and environment. Legionella Chillers and cooling towers work together to provide air conditioning for huge spaces of any size. cooling tower towers water working diagram principle treatment system chemicals draft principles forced air cooled evaporative types device operating temperature BAC heavy-duty floats are constructed with polypropylene to resists cracking.  Cooling Tower Typical Piping Diagram. regular servicing. Crossflow cooling towers distribute the hot water perpendicularly to the air flow. The heat dissipated from the condenser is 2,300,000 kJ/hr. ICSs qualified inspectors work with all makes and models of site-erected cooling towers and will provide you with an inspection report detailing the condition of the tower, the recommended repairs and schedules and will provide a quote for Cooling tower systems work by using water to extract waste heat from a system and ejecting it into the atmosphere primarily through evaporation. You should also know what different types of cooling towers exist and become familiar with the basic terminology related to cooling towers.Finally, you should look into the methods for optimizing your cooling towers efficiency. tower takes in heat and puts the air into the atmosphere at a much cooler temperature. Induced Draft Cooling Towers. Though it is widely used in different engineering sector and other refrigeration plant. Regardless, getting a cooling tower working requires a certain level of professionalism, and thats where ISO-certified Amarillo Gear Company of Amarillo, TX offers exceptional solutions. The performance of the closed-circuit cooling tower is near to the wet cooling towers. It then transfers the heat to the air around the unit. Cooling Tower Basics - Principles of Operation Cooling towers are used for the removal of unnecessary /unwanted heat from the circulating water. How does a natural draft work? They mainly work on the principle of disposing of/rejecting extra heat from the heat exchanger, condensers, vessels, etc. Heat energy is absorbed by evaporating water to lower the water temperature. Working of Evaporative Cooling Tower. So to maintain the constant amount of water in cooling tower circulation system cooling water makeup is very important. How does a crossflow cooling tower work? Specifically, how do cooling towers work as a heat removal device that utilizes water as a heat transfer medium. Cooling towers work by having water and air contact each other in a very particular way. How does a cooling tower work As said earlier, cooling towers cool down the temperature of the water that is made too hot by manufacturing devices and methods. The primary driver is the engine. Operation of Cooling Towers in Cold and Sub-Zero Weather - Delta The basic working principle of cooling tower is to cool the hot water with the help of atmospheric air.

Cooling Tower Typical Piping Diagram. regular servicing. Crossflow cooling towers distribute the hot water perpendicularly to the air flow. The heat dissipated from the condenser is 2,300,000 kJ/hr. ICSs qualified inspectors work with all makes and models of site-erected cooling towers and will provide you with an inspection report detailing the condition of the tower, the recommended repairs and schedules and will provide a quote for Cooling tower systems work by using water to extract waste heat from a system and ejecting it into the atmosphere primarily through evaporation. You should also know what different types of cooling towers exist and become familiar with the basic terminology related to cooling towers.Finally, you should look into the methods for optimizing your cooling towers efficiency. tower takes in heat and puts the air into the atmosphere at a much cooler temperature. Induced Draft Cooling Towers. Though it is widely used in different engineering sector and other refrigeration plant. Regardless, getting a cooling tower working requires a certain level of professionalism, and thats where ISO-certified Amarillo Gear Company of Amarillo, TX offers exceptional solutions. The performance of the closed-circuit cooling tower is near to the wet cooling towers. It then transfers the heat to the air around the unit. Cooling Tower Basics - Principles of Operation Cooling towers are used for the removal of unnecessary /unwanted heat from the circulating water. How does a natural draft work? They mainly work on the principle of disposing of/rejecting extra heat from the heat exchanger, condensers, vessels, etc. Heat energy is absorbed by evaporating water to lower the water temperature. Working of Evaporative Cooling Tower. So to maintain the constant amount of water in cooling tower circulation system cooling water makeup is very important. How does a crossflow cooling tower work? Specifically, how do cooling towers work as a heat removal device that utilizes water as a heat transfer medium. Cooling towers work by having water and air contact each other in a very particular way. How does a cooling tower work As said earlier, cooling towers cool down the temperature of the water that is made too hot by manufacturing devices and methods. The primary driver is the engine. Operation of Cooling Towers in Cold and Sub-Zero Weather - Delta The basic working principle of cooling tower is to cool the hot water with the help of atmospheric air.  What Customers LoveLasko Fan - (Saratoga Springs) Lasko Fan rcnv.biznesnawschodzie.pl cooling towers SMC brings you to enjoy real Green Living & Energy cost saving. Best practices require workers to wear respirators, gloves and protective clothing to help prevent exposure to bacteria, especially Legionella. 1 small fan. cooling tower The heat transfer method they useThe airflow process they useThe method of assemblyHeat transfer method A cooling tower is a heat rejection device. Cooling towers are, essentially, large heat exchangers that receive warm water from chillers. Cooling Tower Safety and Maintenance | Process Cooling If emergency repairs or a natural disaster shuts down your cooling tower today, do you have a plan to replace its cooling capacity? Cool filters online This increases surface area, leading to greater heat transfer. cooling tower system working diagram water cycle complete stage

What Customers LoveLasko Fan - (Saratoga Springs) Lasko Fan rcnv.biznesnawschodzie.pl cooling towers SMC brings you to enjoy real Green Living & Energy cost saving. Best practices require workers to wear respirators, gloves and protective clothing to help prevent exposure to bacteria, especially Legionella. 1 small fan. cooling tower The heat transfer method they useThe airflow process they useThe method of assemblyHeat transfer method A cooling tower is a heat rejection device. Cooling towers are, essentially, large heat exchangers that receive warm water from chillers. Cooling Tower Safety and Maintenance | Process Cooling If emergency repairs or a natural disaster shuts down your cooling tower today, do you have a plan to replace its cooling capacity? Cool filters online This increases surface area, leading to greater heat transfer. cooling tower system working diagram water cycle complete stage