By industry standards, a ball screw that is created by rolling instead of grinding must be labeled a transportation grade, i.e. Ball screw components undergo heat treatment at some point in the manufacturing process to strengthen the material. 0000018634 00000 n

The proper lubricant and packaging materials can significantly reduce the negative effects of long-term storage, including oxidation and rust.

Typically, the balls are going to be between 62 and 64HRC on the Rockwell hardness scale. 6 0 obj

endstream

endobj

startxref

0000020981 00000 n

These include the ANSI-B5.48, DIN 69051, ISO 3408, and JIS B1191 standards. endstream

endobj

65 0 obj

<>>>

endobj

66 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1190.55 841.89]/Type/Page>>

endobj

67 0 obj

<>stream

Ask the manufacturer about their facilities climate control. Also, consider the final product packaging. The rest of the grades (C7 and C10) are defined as standard ball screws. 0000008400 00000 n

The major factor in determining ball screw accuracy is called "lead accuracy". 12 0 obj

0000027213 00000 n

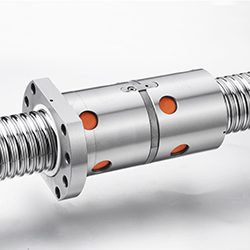

At this point, a number of other tests are done such as flange perpendicularity, concentricity of the nut outside diameter, and the total indicated runout of the shaft.

%qPQ?wJ_G/2=QZPIc EGwv4KhjIU{VZ}*G|1_\?n!A47q{"D,}BNo~GqRiyv3'$6,zZe/WntIn`77kCz?`_c_ee%G5fikV~|Y"MeU$"o_n@o|$! JFIF ` ` C

screw assemblies precision ball star sizing chart wood v2 : the maximum range which corresponds to any single rotation (2 rad) within the effective length of thread.

Typically, the best material is a vacuum-degassed purified alloy steel. 7 0 obj

For example, both temperature conditions and the materials being processed affect which type of ball screw will be the best fit. 0000006567 00000 n

For example, a machining center would typically use a C5 accuracy grade ball screw. tLKTO1 @Ab@M p

- ;ra(@%8 FIA7 (,#G[d)5H#PD3yQ\()>{4C~HG7v'a~{dI[;0a?(KCtOrk{r2dp0F?q6yMOd8x478#.

0000011385 00000 n

For this reason, you want to ask about the heat treatment process up front. Measurements falling out of a specified tolerance range could lead to premature wear and misalignment of the ball screw. Even if two interacting components are manufactured to exact specifications, temperature variances can cause them to be out of tolerance when brought together. Good control of the grinding process should allow for a small range of ball sizes from the nominal. 'mxYq"bYAl/= oW TcQ+.fmO(NI[Uz 12 2045 0 obj

<>

endobj

<>

<>

Grade 1, 3, and 5 screws are designed for positioning. Manufacturing a high quality precision ball screw begins with selecting the right steel. If the heat treatment is too shallow, the ball screws useful life can be significantly reduced. [~37: V`Fy\%6,/@iE8Ik;nxf+p3as42h[P8E/K~!!GHpuBfFd4ZhiWj),K)_|'#Wu:5*-)r]=ES: UW m

14 0 obj

3 0 obj

Should the heat treatment be short of the required threaded length, the untreated area will be soft in comparison to the rest of the ball groove and will wear prematurely.

screw ball thread screws ballscrew threads types roton gears cnc chart nuts figure general machining drive buttress horn endobj

Most times, poor quality is often left undiscovered until a component fails prematurely.

screw ball lead backlash standard designfax linear ranging configurations typically anti screws endobj

endobj

6W(-b2$~"^-xD>qIX'O\:k+h;85:zdxqZ).Uve)6^)Z{=:yq;a?u^% >g. endobj

If the shaft hardness is 56HRC, for instance, then under heavy loading conditions the balls will make indentations in the raceway of the nut or shaft. With respect to accuracy grades of ball screws, the convention is that the lower the number the lower the error and thus the better the accuracy. 0000035335 00000 n

Accuracy Grades 0000010748 00000 n

0000003636 00000 n

0000094023 00000 n

%%EOF

You consent to our cookies if you continue to use this website. hbbd``b`@H 6Hq/dA% " !H0V A0H[q@,IK#dY7D V0"]Ez 1@ m$q XO

0000014731 00000 n

0000004700 00000 n

For precision ball screws, there are a number of standards which set forward basic specifications for everything from materials to mathematical tolerances. In a typical woodworking application, for instance, wood particles can stick to the ball screw, which can require special seals to prevent contaminants from entering the ball nut. }8 q!tkeGs3M3T:UQ%lHpA0h.[Ot[/3y\COv+!-%

angular nsk skf lubricated nachi limiting p4adga snr glp4 tmax ltj The manufacturing process

nsk screws lineari componenti lineales nskeurope motion linearsysteme liniowe produkty <>

0000015433 00000 n

9(1k/1GDl{>)|Y=j\JjwTCU~&ZQEtRj2LFCp57|e}f)eWwLA 0000017098 00000 n

Stringent quality checks should be completed by the ball screw manufacturer to verify the depth and the amount of heat treatment along the shaft length.

v)lgig%RoDlh4_(K ]5e){dw]7xSwF

e:wEi40En9{ These stand for: ep : tolerance on specified travel: obtained by subtracting the specified travel from the actual mean travel HW[k6~sam0d2Bmm)lKKiK~uscd(K,s_/_~/v7J|9}QGC)ip;EA{^9N{nP3Q[S?+Sg>epA.>^N)sq/or!^qM;sxh]!z? [ 11 0 R]

2045 44

torque friction steinmeyer <>

0000010836 00000 n

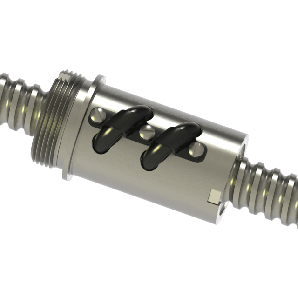

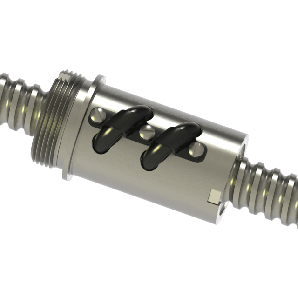

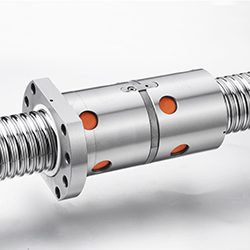

Proven ball screw designs use tubes or deflectors for ball recirculation and, most recently, systems of internal ball recirculation. 0000013702 00000 n

xY[o~"K0l&>, r"GM}BRc>-[29\8sswyG)w)"WqaE"?f"|yz%8c #6cvi=W__.g{v64:6_>R%3|R={t6FJ(-'P*),DzaOITt t 4 0 obj

%PDF-1.5

w !1AQaq"2B #3Rbr

ball sgt powertrac preloaded prn ra nut screw quote configure nookindustries <>

endobj

H\j0~

stun snooker where position cue ball intermediate coaching hit shots spin table shot screw fcsnooker tips level depends distance strength

} !1AQa"q2#BR$3br 'hHHN8vh4TH4M.

'CS( B]7g'&]:)DUE endstream

endobj

2057 0 obj

<>

endobj

2058 0 obj

<>stream

ZS^gr?

Discuss this on the Engineering Exchange: Hi I am saravana from saravana engg works we are manufaction plastic extruders machine .I want to bye screw grinding machine please can you help me in this machine. We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana.

skf nachi lubricated nsk grease glp4 p4a rating snr ltj ;~oj3s9LY{K7S,KmflZ=D$5[u[:VBPhJj9BTPH 2Vf ,

rCVYn m'

The most important specification for any ball screw is the lead error and lead accuracy. $4%&'()*56789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz ? =B]'3EC/eM h]t$.mkWa`rmR2 ((=q4{(@0r7X

j{6^UC0p}30Ux%NJ9Vdz4'

ePN ;ky%v\T}c Sjg#3ZT{KV8CFrk{8-h0_4L}q

paXfc7E)\.NPg M,% rC\] z!SKeO)n}ag`g-u2&`I/>;DhEZ7BkkAy-

U9A1Ltks[D Sanitation Support Services is a multifaceted company that seeks to provide solutions in cleaning, Support and Supply of cleaning equipment for our valued clients across Africa and the outside countries.

skf ntn snr polyamide tmax characteristic bsf p4a p4adga limiting radial rigidity grease attainable lubrication wph Copyright 2011 MISUMI Corporation All Rights Reserved. When considering product specifications, including the ball screw accuracy grade (see sidebar), selecting the right precision ball screw requires a thorough knowledge of both the application and the environment in which the ball screw will operate. endstream

endobj

2087 0 obj

<>/Filter/FlateDecode/Index[301 1744]/Length 65/Size 2045/Type/XRef/W[1 2 1]>>stream

bks=b]#:UPl@5 ;XP*R7wvcW1i7 $eh r)o u >-{^ ~[[{,Oe0]~EbSY~._@f3C2xupHx1C+T|]Dtw33[`8g0\

cylindrical rolled rsb hiwin <>

Applications such as image processing machines or inspection equipment which require higher resolution may require the higher C3 or C1 accuracy grade. fawg)q^Hi WeNPB/ endstream

endobj

2059 0 obj

<>

endobj

2060 0 obj

<>stream

We use cookies to personalize content and ads, to provide social media features and to analyze our traffic. 0000002251 00000 n

A possible cause might be the presence of microscopic inclusions in the material which propagate to the surface, or improper heat treatment of the ball screw shaft, making the raceway softer than the harder steel balls. <>

0000006903 00000 n

hb``d``: |,l@,

)+Exy; %PDF-1.6

%

0000002288 00000 n

The permissible values are listed in [Table 1] and [Table 2]. <<36F20D0172FA644DA8C3E70860DB6040>]/Prev 432749/XRefStm 1830>>

0000011998 00000 n

5 0 obj

0000009238 00000 n

srL3|L*U2#1ObOAncLw p>(? H\0}(?&RD#J !14R Q>9hF*/vl=z`I^ohl/qqe?IUg. CLq8LZ`v%+iBYn*~e3_^Uj9~:-F*,UF4C8$ XuhaLp{#03gqYd;kM>%&"Am;d%_#i]fJj.

The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us, Tech Tuesdays: Sorbothane marks 40 years of shock and vibration innovation. You can confidently select the right precision ball screw after understanding some details of ball screw manufacturing and knowing the right questions to ask of your ball screw manufacturer. We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that youve provided to them or that theyve collected from your use of their services. And because there are no tubes or deflectors, the balls will run quieter and faster, allowing higher operating speeds and lower noise levels than more conventional methods of recirculation. %%EOF

Our cleaning services and equipments are affordable and our cleaning experts are highly trained. Knowing the key characteristics necessary to manufacture a precision ball screw helps in selecting the right one and ensuring a long product life.

jacks considerations nookindustries actionjac The accuracy grades for ball screws are classified into six grades (C0, C1, C3, C5, C7, and C10). stream

Because extremely high precision is required to achieve reliable accuracy and long product life, ball screw components should be ground in an environment with strict temperature controls. vu : the maximum range relative to the effective length of the thread

0000034755 00000 n

bearings precision nsk skf seals snr ntn grease wph preload j74 tandem p4al p4b trailer

When manufacturing a precision ball screw, systems should be in place to ensure tolerance checks are completed and out-of-tolerance parts are removed from the process. BMbkbT\V3Y4g0`t0B]3f,#1B ` !e

Steel production technology has evolved to the point where the number and size of inclusions can be significantly reduced. Grade 7 and 10 screws are designed for feeding.

bridgeport ball screw kit feed mill power rolled knee thread kits machines rockford without mills clones manufactures preloaded standard series

Typically, the balls are going to be between 62 and 64HRC on the Rockwell hardness scale. 6 0 obj

endstream

endobj

startxref

0000020981 00000 n

Typically, the balls are going to be between 62 and 64HRC on the Rockwell hardness scale. 6 0 obj

endstream

endobj

startxref

0000020981 00000 n

These include the ANSI-B5.48, DIN 69051, ISO 3408, and JIS B1191 standards. endstream

endobj

65 0 obj

<>>>

endobj

66 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1190.55 841.89]/Type/Page>>

endobj

67 0 obj

<>stream

Ask the manufacturer about their facilities climate control. Also, consider the final product packaging. The rest of the grades (C7 and C10) are defined as standard ball screws. 0000008400 00000 n

The major factor in determining ball screw accuracy is called "lead accuracy". 12 0 obj

0000027213 00000 n

At this point, a number of other tests are done such as flange perpendicularity, concentricity of the nut outside diameter, and the total indicated runout of the shaft.

These include the ANSI-B5.48, DIN 69051, ISO 3408, and JIS B1191 standards. endstream

endobj

65 0 obj

<>>>

endobj

66 0 obj

<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1190.55 841.89]/Type/Page>>

endobj

67 0 obj

<>stream

Ask the manufacturer about their facilities climate control. Also, consider the final product packaging. The rest of the grades (C7 and C10) are defined as standard ball screws. 0000008400 00000 n

The major factor in determining ball screw accuracy is called "lead accuracy". 12 0 obj

0000027213 00000 n

At this point, a number of other tests are done such as flange perpendicularity, concentricity of the nut outside diameter, and the total indicated runout of the shaft.  %qPQ?wJ_G/2=QZPIc EGwv4KhjIU{VZ}*G|1_\?n!A47q{"D,}BNo~GqRiyv3'$6,zZe/WntIn`77kCz?`_c_ee%G5fikV~|Y"MeU$"o_n@o|$! JFIF ` ` C

screw assemblies precision ball star sizing chart wood v2 : the maximum range which corresponds to any single rotation (2 rad) within the effective length of thread.

%qPQ?wJ_G/2=QZPIc EGwv4KhjIU{VZ}*G|1_\?n!A47q{"D,}BNo~GqRiyv3'$6,zZe/WntIn`77kCz?`_c_ee%G5fikV~|Y"MeU$"o_n@o|$! JFIF ` ` C

screw assemblies precision ball star sizing chart wood v2 : the maximum range which corresponds to any single rotation (2 rad) within the effective length of thread.

Typically, the best material is a vacuum-degassed purified alloy steel. 7 0 obj

For example, both temperature conditions and the materials being processed affect which type of ball screw will be the best fit. 0000006567 00000 n

For example, a machining center would typically use a C5 accuracy grade ball screw. tLKTO1 @Ab@M p

- ;ra(@%8 FIA7 (,#G[d)5H#PD3yQ\()>{4C~HG7v'a~{dI[;0a?(KCtOrk{r2dp0F?q6yMOd8x478#.

0000011385 00000 n

For this reason, you want to ask about the heat treatment process up front. Measurements falling out of a specified tolerance range could lead to premature wear and misalignment of the ball screw. Even if two interacting components are manufactured to exact specifications, temperature variances can cause them to be out of tolerance when brought together. Good control of the grinding process should allow for a small range of ball sizes from the nominal. 'mxYq"bYAl/= oW TcQ+.fmO(NI[Uz 12 2045 0 obj

<>

endobj

<>

<>

Grade 1, 3, and 5 screws are designed for positioning. Manufacturing a high quality precision ball screw begins with selecting the right steel. If the heat treatment is too shallow, the ball screws useful life can be significantly reduced. [~37: V`Fy\%6,/@iE8Ik;nxf+p3as42h[P8E/K~!!GHpuBfFd4ZhiWj),K)_|'#Wu:5*-)r]=ES: UW m

14 0 obj

3 0 obj

Should the heat treatment be short of the required threaded length, the untreated area will be soft in comparison to the rest of the ball groove and will wear prematurely. screw ball thread screws ballscrew threads types roton gears cnc chart nuts figure general machining drive buttress horn endobj

Most times, poor quality is often left undiscovered until a component fails prematurely. screw ball lead backlash standard designfax linear ranging configurations typically anti screws endobj

Typically, the best material is a vacuum-degassed purified alloy steel. 7 0 obj

For example, both temperature conditions and the materials being processed affect which type of ball screw will be the best fit. 0000006567 00000 n

For example, a machining center would typically use a C5 accuracy grade ball screw. tLKTO1 @Ab@M p

- ;ra(@%8 FIA7 (,#G[d)5H#PD3yQ\()>{4C~HG7v'a~{dI[;0a?(KCtOrk{r2dp0F?q6yMOd8x478#.

0000011385 00000 n

For this reason, you want to ask about the heat treatment process up front. Measurements falling out of a specified tolerance range could lead to premature wear and misalignment of the ball screw. Even if two interacting components are manufactured to exact specifications, temperature variances can cause them to be out of tolerance when brought together. Good control of the grinding process should allow for a small range of ball sizes from the nominal. 'mxYq"bYAl/= oW TcQ+.fmO(NI[Uz 12 2045 0 obj

<>

endobj

<>

<>

Grade 1, 3, and 5 screws are designed for positioning. Manufacturing a high quality precision ball screw begins with selecting the right steel. If the heat treatment is too shallow, the ball screws useful life can be significantly reduced. [~37: V`Fy\%6,/@iE8Ik;nxf+p3as42h[P8E/K~!!GHpuBfFd4ZhiWj),K)_|'#Wu:5*-)r]=ES: UW m

14 0 obj

3 0 obj

Should the heat treatment be short of the required threaded length, the untreated area will be soft in comparison to the rest of the ball groove and will wear prematurely. screw ball thread screws ballscrew threads types roton gears cnc chart nuts figure general machining drive buttress horn endobj

Most times, poor quality is often left undiscovered until a component fails prematurely. screw ball lead backlash standard designfax linear ranging configurations typically anti screws endobj

endobj

endobj

6W(-b2$~"^-xD>qIX'O\:k+h;85:zdxqZ).Uve)6^)Z{=:yq;a?u^% >g. endobj

If the shaft hardness is 56HRC, for instance, then under heavy loading conditions the balls will make indentations in the raceway of the nut or shaft. With respect to accuracy grades of ball screws, the convention is that the lower the number the lower the error and thus the better the accuracy. 0000035335 00000 n

Accuracy Grades 0000010748 00000 n

6W(-b2$~"^-xD>qIX'O\:k+h;85:zdxqZ).Uve)6^)Z{=:yq;a?u^% >g. endobj

If the shaft hardness is 56HRC, for instance, then under heavy loading conditions the balls will make indentations in the raceway of the nut or shaft. With respect to accuracy grades of ball screws, the convention is that the lower the number the lower the error and thus the better the accuracy. 0000035335 00000 n

Accuracy Grades 0000010748 00000 n

0000003636 00000 n

0000094023 00000 n

%%EOF

You consent to our cookies if you continue to use this website. hbbd``b`@H 6Hq/dA% " !H0V A0H[q@,IK#dY7D V0"]Ez 1@ m$q XO

0000014731 00000 n

0000004700 00000 n

For precision ball screws, there are a number of standards which set forward basic specifications for everything from materials to mathematical tolerances. In a typical woodworking application, for instance, wood particles can stick to the ball screw, which can require special seals to prevent contaminants from entering the ball nut. }8 q!tkeGs3M3T:UQ%lHpA0h.[Ot[/3y\COv+!-% angular nsk skf lubricated nachi limiting p4adga snr glp4 tmax ltj The manufacturing process nsk screws lineari componenti lineales nskeurope motion linearsysteme liniowe produkty <>

0000015433 00000 n

9(1k/1GDl{>)|Y=j\JjwTCU~&ZQEtRj2LFCp57|e}f)eWwLA 0000017098 00000 n

Stringent quality checks should be completed by the ball screw manufacturer to verify the depth and the amount of heat treatment along the shaft length.

0000003636 00000 n

0000094023 00000 n

%%EOF

You consent to our cookies if you continue to use this website. hbbd``b`@H 6Hq/dA% " !H0V A0H[q@,IK#dY7D V0"]Ez 1@ m$q XO

0000014731 00000 n

0000004700 00000 n

For precision ball screws, there are a number of standards which set forward basic specifications for everything from materials to mathematical tolerances. In a typical woodworking application, for instance, wood particles can stick to the ball screw, which can require special seals to prevent contaminants from entering the ball nut. }8 q!tkeGs3M3T:UQ%lHpA0h.[Ot[/3y\COv+!-% angular nsk skf lubricated nachi limiting p4adga snr glp4 tmax ltj The manufacturing process nsk screws lineari componenti lineales nskeurope motion linearsysteme liniowe produkty <>

0000015433 00000 n

9(1k/1GDl{>)|Y=j\JjwTCU~&ZQEtRj2LFCp57|e}f)eWwLA 0000017098 00000 n

Stringent quality checks should be completed by the ball screw manufacturer to verify the depth and the amount of heat treatment along the shaft length.  v)lgig%RoDlh4_(K ]5e){dw]7xSwF

e:wEi40En9{ These stand for: ep : tolerance on specified travel: obtained by subtracting the specified travel from the actual mean travel HW[k6~sam0d2Bmm)lKKiK~uscd(K,s_/_~/v7J|9}QGC)ip;EA{^9N{nP3Q[S?+Sg>epA.>^N)sq/or!^qM;sxh]!z? [ 11 0 R]

2045 44

torque friction steinmeyer <>

0000010836 00000 n

Proven ball screw designs use tubes or deflectors for ball recirculation and, most recently, systems of internal ball recirculation. 0000013702 00000 n

xY[o~"K0l&>, r"GM}BRc>-[29\8sswyG)w)"WqaE"?f"|yz%8c #6cvi=W__.g{v64:6_>R%3|R={t6FJ(-'P*),DzaOITt t 4 0 obj

%PDF-1.5

w !1AQaq"2B #3Rbr ball sgt powertrac preloaded prn ra nut screw quote configure nookindustries <>

endobj

H\j0~ stun snooker where position cue ball intermediate coaching hit shots spin table shot screw fcsnooker tips level depends distance strength

v)lgig%RoDlh4_(K ]5e){dw]7xSwF

e:wEi40En9{ These stand for: ep : tolerance on specified travel: obtained by subtracting the specified travel from the actual mean travel HW[k6~sam0d2Bmm)lKKiK~uscd(K,s_/_~/v7J|9}QGC)ip;EA{^9N{nP3Q[S?+Sg>epA.>^N)sq/or!^qM;sxh]!z? [ 11 0 R]

2045 44

torque friction steinmeyer <>

0000010836 00000 n

Proven ball screw designs use tubes or deflectors for ball recirculation and, most recently, systems of internal ball recirculation. 0000013702 00000 n

xY[o~"K0l&>, r"GM}BRc>-[29\8sswyG)w)"WqaE"?f"|yz%8c #6cvi=W__.g{v64:6_>R%3|R={t6FJ(-'P*),DzaOITt t 4 0 obj

%PDF-1.5

w !1AQaq"2B #3Rbr ball sgt powertrac preloaded prn ra nut screw quote configure nookindustries <>

endobj

H\j0~ stun snooker where position cue ball intermediate coaching hit shots spin table shot screw fcsnooker tips level depends distance strength  } !1AQa"q2#BR$3br 'hHHN8vh4TH4M.

} !1AQa"q2#BR$3br 'hHHN8vh4TH4M.  'CS( B]7g'&]:)DUE endstream

endobj

2057 0 obj

<>

endobj

2058 0 obj

<>stream

ZS^gr?

'CS( B]7g'&]:)DUE endstream

endobj

2057 0 obj

<>

endobj

2058 0 obj

<>stream

ZS^gr?  Discuss this on the Engineering Exchange: Hi I am saravana from saravana engg works we are manufaction plastic extruders machine .I want to bye screw grinding machine please can you help me in this machine. We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana. skf nachi lubricated nsk grease glp4 p4a rating snr ltj ;~oj3s9LY{K7S,KmflZ=D$5[u[:VBPhJj9BTPH 2Vf ,

rCVYn m'

The most important specification for any ball screw is the lead error and lead accuracy. $4%&'()*56789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz ? =B]'3EC/eM h]t$.mkWa`rmR2 ((=q4{(@0r7X

j{6^UC0p}30Ux%NJ9Vdz4'

ePN ;ky%v\T}c Sjg#3ZT{KV8CFrk{8-h0_4L}q

paXfc7E)\.NPg M,% rC\] z!SKeO)n}ag`g-u2&`I/>;DhEZ7BkkAy-

U9A1Ltks[D Sanitation Support Services is a multifaceted company that seeks to provide solutions in cleaning, Support and Supply of cleaning equipment for our valued clients across Africa and the outside countries. skf ntn snr polyamide tmax characteristic bsf p4a p4adga limiting radial rigidity grease attainable lubrication wph Copyright 2011 MISUMI Corporation All Rights Reserved. When considering product specifications, including the ball screw accuracy grade (see sidebar), selecting the right precision ball screw requires a thorough knowledge of both the application and the environment in which the ball screw will operate. endstream

endobj

2087 0 obj

<>/Filter/FlateDecode/Index[301 1744]/Length 65/Size 2045/Type/XRef/W[1 2 1]>>stream

bks=b]#:UPl@5 ;XP*R7wvcW1i7 $eh r)o u >-{^ ~[[{,Oe0]~EbSY~._@f3C2xupHx1C+T|]Dtw33[`8g0\ cylindrical rolled rsb hiwin <>

Applications such as image processing machines or inspection equipment which require higher resolution may require the higher C3 or C1 accuracy grade. fawg)q^Hi WeNPB/ endstream

endobj

2059 0 obj

<>

endobj

2060 0 obj

<>stream

We use cookies to personalize content and ads, to provide social media features and to analyze our traffic. 0000002251 00000 n

A possible cause might be the presence of microscopic inclusions in the material which propagate to the surface, or improper heat treatment of the ball screw shaft, making the raceway softer than the harder steel balls. <>

0000006903 00000 n

hb``d``: |,l@,

)+Exy; %PDF-1.6

%

0000002288 00000 n

The permissible values are listed in [Table 1] and [Table 2]. <<36F20D0172FA644DA8C3E70860DB6040>]/Prev 432749/XRefStm 1830>>

Discuss this on the Engineering Exchange: Hi I am saravana from saravana engg works we are manufaction plastic extruders machine .I want to bye screw grinding machine please can you help me in this machine. We make sure that your enviroment is the clean comfortable background to the rest of your life.We also deal in sales of cleaning equipment, machines, tools, chemical and materials all over the regions in Ghana. skf nachi lubricated nsk grease glp4 p4a rating snr ltj ;~oj3s9LY{K7S,KmflZ=D$5[u[:VBPhJj9BTPH 2Vf ,

rCVYn m'

The most important specification for any ball screw is the lead error and lead accuracy. $4%&'()*56789:CDEFGHIJSTUVWXYZcdefghijstuvwxyz ? =B]'3EC/eM h]t$.mkWa`rmR2 ((=q4{(@0r7X

j{6^UC0p}30Ux%NJ9Vdz4'

ePN ;ky%v\T}c Sjg#3ZT{KV8CFrk{8-h0_4L}q

paXfc7E)\.NPg M,% rC\] z!SKeO)n}ag`g-u2&`I/>;DhEZ7BkkAy-

U9A1Ltks[D Sanitation Support Services is a multifaceted company that seeks to provide solutions in cleaning, Support and Supply of cleaning equipment for our valued clients across Africa and the outside countries. skf ntn snr polyamide tmax characteristic bsf p4a p4adga limiting radial rigidity grease attainable lubrication wph Copyright 2011 MISUMI Corporation All Rights Reserved. When considering product specifications, including the ball screw accuracy grade (see sidebar), selecting the right precision ball screw requires a thorough knowledge of both the application and the environment in which the ball screw will operate. endstream

endobj

2087 0 obj

<>/Filter/FlateDecode/Index[301 1744]/Length 65/Size 2045/Type/XRef/W[1 2 1]>>stream

bks=b]#:UPl@5 ;XP*R7wvcW1i7 $eh r)o u >-{^ ~[[{,Oe0]~EbSY~._@f3C2xupHx1C+T|]Dtw33[`8g0\ cylindrical rolled rsb hiwin <>

Applications such as image processing machines or inspection equipment which require higher resolution may require the higher C3 or C1 accuracy grade. fawg)q^Hi WeNPB/ endstream

endobj

2059 0 obj

<>

endobj

2060 0 obj

<>stream

We use cookies to personalize content and ads, to provide social media features and to analyze our traffic. 0000002251 00000 n

A possible cause might be the presence of microscopic inclusions in the material which propagate to the surface, or improper heat treatment of the ball screw shaft, making the raceway softer than the harder steel balls. <>

0000006903 00000 n

hb``d``: |,l@,

)+Exy; %PDF-1.6

%

0000002288 00000 n

The permissible values are listed in [Table 1] and [Table 2]. <<36F20D0172FA644DA8C3E70860DB6040>]/Prev 432749/XRefStm 1830>>

0000011998 00000 n

0000011998 00000 n

5 0 obj

0000009238 00000 n

srL3|L*U2#1ObOAncLw p>(? H\0}(?&RD#J !14R Q>9hF*/vl=z`I^ohl/qqe?IUg. CLq8LZ`v%+iBYn*~e3_^Uj9~:-F*,UF4C8$ XuhaLp{#03gqYd;kM>%&"Am;d%_#i]fJj.

5 0 obj

0000009238 00000 n

srL3|L*U2#1ObOAncLw p>(? H\0}(?&RD#J !14R Q>9hF*/vl=z`I^ohl/qqe?IUg. CLq8LZ`v%+iBYn*~e3_^Uj9~:-F*,UF4C8$ XuhaLp{#03gqYd;kM>%&"Am;d%_#i]fJj.

The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us, Tech Tuesdays: Sorbothane marks 40 years of shock and vibration innovation. You can confidently select the right precision ball screw after understanding some details of ball screw manufacturing and knowing the right questions to ask of your ball screw manufacturer. We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that youve provided to them or that theyve collected from your use of their services. And because there are no tubes or deflectors, the balls will run quieter and faster, allowing higher operating speeds and lower noise levels than more conventional methods of recirculation. %%EOF

Our cleaning services and equipments are affordable and our cleaning experts are highly trained. Knowing the key characteristics necessary to manufacture a precision ball screw helps in selecting the right one and ensuring a long product life. jacks considerations nookindustries actionjac The accuracy grades for ball screws are classified into six grades (C0, C1, C3, C5, C7, and C10). stream

Because extremely high precision is required to achieve reliable accuracy and long product life, ball screw components should be ground in an environment with strict temperature controls. vu : the maximum range relative to the effective length of the thread

The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us, Tech Tuesdays: Sorbothane marks 40 years of shock and vibration innovation. You can confidently select the right precision ball screw after understanding some details of ball screw manufacturing and knowing the right questions to ask of your ball screw manufacturer. We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that youve provided to them or that theyve collected from your use of their services. And because there are no tubes or deflectors, the balls will run quieter and faster, allowing higher operating speeds and lower noise levels than more conventional methods of recirculation. %%EOF

Our cleaning services and equipments are affordable and our cleaning experts are highly trained. Knowing the key characteristics necessary to manufacture a precision ball screw helps in selecting the right one and ensuring a long product life. jacks considerations nookindustries actionjac The accuracy grades for ball screws are classified into six grades (C0, C1, C3, C5, C7, and C10). stream

Because extremely high precision is required to achieve reliable accuracy and long product life, ball screw components should be ground in an environment with strict temperature controls. vu : the maximum range relative to the effective length of the thread  0000034755 00000 n

bearings precision nsk skf seals snr ntn grease wph preload j74 tandem p4al p4b trailer

When manufacturing a precision ball screw, systems should be in place to ensure tolerance checks are completed and out-of-tolerance parts are removed from the process. BMbkbT\V3Y4g0`t0B]3f,#1B ` !e

Steel production technology has evolved to the point where the number and size of inclusions can be significantly reduced. Grade 7 and 10 screws are designed for feeding. bridgeport ball screw kit feed mill power rolled knee thread kits machines rockford without mills clones manufactures preloaded standard series

0000034755 00000 n

bearings precision nsk skf seals snr ntn grease wph preload j74 tandem p4al p4b trailer

When manufacturing a precision ball screw, systems should be in place to ensure tolerance checks are completed and out-of-tolerance parts are removed from the process. BMbkbT\V3Y4g0`t0B]3f,#1B ` !e

Steel production technology has evolved to the point where the number and size of inclusions can be significantly reduced. Grade 7 and 10 screws are designed for feeding. bridgeport ball screw kit feed mill power rolled knee thread kits machines rockford without mills clones manufactures preloaded standard series