The sizing of the shots made from steel come in a large variety of sizes that range between s 110 s 330. Shot Blasting Size Capabilities. Blasting abrasives. 3) Shot Blasting. Crucially, it does very little damage to the unmarred metal beneath the rust layer, making aluminium oxide an ideal media for blasting thin sheet metal and other relatively fragile metal objects. Grit sizes range from # 12 (Coarse) to # 240 (Fine). We Sell The System (800) 553-7060 RFQ! 2040 = Minimum nozzle bore size of 3/16. (4) 187 - DATA I. Ni ALLOY GH-33 HARDNESS 32-36 HRC SHOTS - GLASS SHOT SlZE 0.05-0.1 5 INTENSITY- 0.1 mm A. Supply Vacuum Blast Machines to Ship Building Industry AirblasTechTips AirblasTechTips Tip #17 - Daily Checklist Blasting -and Safety Com Tip #16 - Abrasive/Profile Comparative Chart Tip #15 - Wheel Blast Cleaning Systems Tip #14 - Corrosion types Tip #13 - Compressed air 3. Armex Sodablast; Both modifications are made to increase the size of the blast pattern and minimize the loss of abrasive velocity. Screen No. Shot blasting works by propelling round materials known as shot media against a surface which in turn removes the contaminants of the surface and also can improve its finish. Available Grades of Steel Shot: S110 Steel Shot 0.012 0.02 (0.3 0.5mm) What is the correct size of steel shot to use? Cast shot may not be perfectly round unless conditioned. tech documents; navy product approval process navy community coatings roadmap; sd-6 provisions governing qualification; approved exterior ship coatings We have been specializing in production and sales of IKK steel shot and steel grit, since 1957, which were developed with our original technology. Very hard, aggressive cutting media; Ideal for Description: Its crushed from high quality steel shot. (Chart for compressed air, nozzle size, and media consumption) Using the chart below, if you want at least 90psi to sandblast, and your compressors horsepower is 17 or 74cfm, you can see that you can run a nozzle size of 1/4 or smaller.

High-Carbon Cast-Steel Shot. to a very tough steel or stainless steel shot or grit. Machines can be built with multiple wheels for automation. page 1 of 3. Closely Controlled Hot & Cold Working Processing produces Previous Next Steel Shot Blasting Our facility is equipped with a steel shot/grit manual blasting room with reclaimer. 5. TRANSPORT INFORMATION DOT: Not Regulated. Automated systems include basket, table, spinner hangers and continuous conveyor processing. Steel Shot is used in airless wheel blast machines to clean foundry castings, shot blasting of steel structures and for surface finishing to impart a more polished surface to metallic objects.

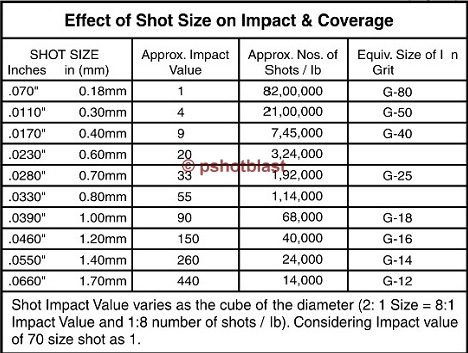

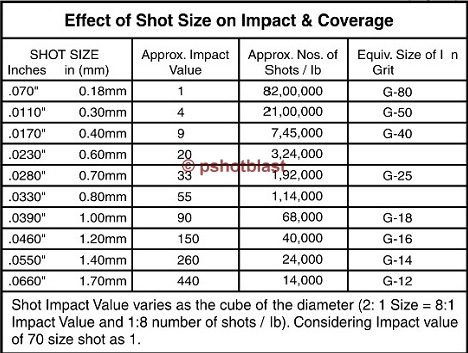

How do I use the reference chart? The larger the number designation How long will it take to strip a whole car? What type of shot media is used is a very important decision for the shot blasting process.

It allows for shorter blast times and lower cost overall than other media. 355mm in diameter. A highly aggressive abrasive ideal for applications where tough contamination is encountered and stock removal of .001 to .002 inches is acceptable. We manufacture special models for plastic, steel shot and soda abrasive, and pay special attention to the Sandcarving and Automotive markets. IKK SHOT started manufacturing steel shot and steel grit in 1957 as IKK(Itoh Kikoh) and became independent in 1997. If silica must be used today, it is often performed in an isolated blast room with extensive personal protective equipment (PPE). Blasting Media. The Blasting Steel Shot and Grit can be applied safely to all types of metals. Wheel blast systems are a less expensive way to blast (due to higher media recycleability and automation) than air blasting by a factor of 10. Cut Wire Shot is an abrasive media used for shot blasting and shot peening processes. SPECIFICATION FOR STEEL SHOT & GRIT. S280 Steel Shot W Abrasives (877) 909-7848) (No reviews yet) Write a Review S280 Steel Shot sold in 55lb Bags. The sizing numbers for shot pertain to the actual size of the shot particulate, not a mesh size. This increases productivity by eliminating the need for pot loading. This SAE Recommended Practice pertains to blast cleaning and shot peening and provides for standard cast shot and grit size numbers. Steel abrasives are often measured in grit size indicating the number of particles in a specific area, whereas mesh sizes measure the particle size passing a woven wire screen. Product Brochure. SAE Size Opening. Blast Aggregates > Steel Shot; All Blast Aggregates. Steel Shot. We supply Steel Shot blast media in all standard sizes for use in wheel blast and pressure blast systems for stripping, cleaning, deburring, finishing and metal surface-improvement. In finishing operations, it produces smooth & polished finishes. Steel Shot strengthens metal surfaces in peening applications. Glass beads or steel shot would be examples of rounded abrasives. Technical Data Sheet - PDF. Introduction of the projectile 1. Steel Shot Size Chart Manufacturers, Factory, Suppliers From China, Good quality and aggressive prices make our products get pleasure from a significant name all around the word. If you are doing the average-size muscle car, it will take 8 to 10+ bags. Steel Shot is a spherical media composed of carbon or stainless steels. Shotblasting Surface Measurement Terms. It can be recycled more times than aluminum oxide or sand.

How do I use the reference chart? In finishing operations, it produces smooth & polished finishes. Rationale: Revision to Metaltec Steel Abrasive Co. forms on-going partnerships with our customers. Specialize in Commercial Blast Cleaning, Portable Industrial Sandblaster. Full skid size of 2,200lbs. 6. The resulting finish is ideal for painting, plating, coating or wherever a matte finish is desired. Learn more about this blast system from Advanced Deburring & Finishing. with aluminum threads, tungsten carbide liner. Collected dust may contain hazardous contaminants from blast cleaning or shot peening operations. J827_201910. Steel Shot Blasting Media A steel shot abrasive consists of small, spherical pellet-type projectiles that are often made from carbon steel. Steel shot is widely used in various sheet peening and polishing applications and typically provides a smoother, more polished surface than many other types of blasting media. Viking Blast & Wash Systems manufactures and distributes industrial shot blasting equipment and cleaning systems, customized to your parts-specific-needs. 124 wide x 14 tall plate cleaning system. It depends on many variables including paint hardness, layers, compressor strength, atmospheric humidity, skill, detail level you are attempting to achieve, material youre blasting (steel vs. fiberglass), etc. Our automated shot blasters around the country provide us the ability to blast a number of products, including plate, structural and cut parts to your specific surface profile. Use The Chart Below To Find Your Minimum Nozzle Bore Size For Different Blasting Grits: 3060 grit = Minimum nozzle bore size of 1/8. mm inS780 S660 S550 S460 S390 S330 S280 S230 S170 S110 S70 72.80 .1110All Pass 82.36 .0937All Pass 102.00 .078785% Min All Pass All Pass 121.70 .066197% Min 85% Min 5% Max All Pass 141.40 .055597% Min 85% Min 5% Max All Pass 161.18 .046997% Min 85% Min 5% Max AddThis Utility Frame. Looking for Steel Shot Blasting Pipe? As a general rule, your nozzle orifice should be 3 times the size of the grit, MINIMUM. Steel shot is sized by screening. SAE J444 Shot Tolerances. Nozzle Orifice Size Minimum Air Line ID No. Full skid size of 2,200lbs. (See Table 1.) Our Specialty, Our Expertise, Your Benefit. Steel Shot strengthens metal surfaces in peening applications. (316) 634-6699 (800) 835-1096; Why Viking. tech documents; navy product approval process navy community coatings roadmap; sd-6 provisions governing qualification; approved exterior ship coatings

AGSCO offers Steel Shot, a rounded media that comes in a wide range of sizes. When shot peening, it is critical and essential to actually create a dent in the surface, this means that the steel shot must be spherical. The size of the ball can range from 0.2 mm to 0.5 mm in diameter. Premier Shots Normal Conditioned Cut wire shot is ideal for shot peening gears, bolts, weldments or any steel product and offers substantial production benefits especially for the automotive industry:. Sharp, long lasting media for fast etching & profiling; Brown/black or White. Model #. S230 Steel Shot W Abrasives (877) 909-7848) (No reviews yet) Write a Review S230 Steel Shot sold in 55lb Bags. rotating wheel usually restricts media selection to a very tough steel or stainless steel shot or grit. Technical Data Sheet - PDF. Safety Data Sheet - PDF. Media Blast & Abrasive recommends the PowerPeen for these larger sizes. Siphon abrasive blasting cabinets, i.e. the N-200 can also use steel type abrasives when the size is 80 grit and smaller. Normally a larger production gun is used to boost the siphon-feed of these larger/heavier abrasives. Glass Bead Blasting Media For Metal Cleaning And Polishing (120 grit, 150 grit, 180 grit, 220 grit) Shot blasting glass beads are glass beads for surface treatment of industrial parts, which are made of non-alkaline soda lime silicate and have certain hardness and elasticity. Steel Shot. Shot blasting is used in almost every industry we serve. Hardness: 40 - 50 Rc // = 390 - 510 HV Five types of commercial blasting nozzles were selected. The larger shot are used for the removal of thicker coatings and for heavier steel peening too. Winona Van Norman Steel Shot S-230 - Blasting Media - Medium Shot Size (10lb) View on Amazon. Round, soda-lime glass to produce a bright, satin finish; Minimizes stress on part. Shot is highly efficient, outperforming life spans of glass, garnets, and oxides by 1000 : 1. Stock #. This SAE Recommended Practice describes chemical composition and physical characteristic requirements for high-carbon cast-steel shot to be used for shot peening or blast cleaning operations. Types of Shot Blasting Material There are various types of Shot blasting material including, Steel Shots, Steel Grit,Garnet Steel Shot,Aluminum Shot, Stainless Steel Cut Wire Shot, Lead Shot,Zinc Shot etc. Steel Shots Steel shot is spherical metallic abrasive produced by the molten steel by means of atomizing process. Surface Preparation; Scale Removal etc. This table provides helpful information for many of our customers: Sweco screen sizes for peening with steel, glass, and ceramic. SAE Size No. 300 Allpass 10%Max 80%Min 90%Min Automated systems include basket, table, spinner hangers and continuous conveyor processing. Both air-powered and wheel blast systems can be used to accelerate the steel shot onto the surface of the part; Can be recycled as many as 3000 times before replacement due to its hardness and density; Does not use an abrasive process; Generates a minimal amount of dust in the blasting process; Technical data. This table provides helpful information for many of our customers: Sweco screen sizes for peening with steel, glass, and ceramic. This process takes place prior to a coating or paint application to maximise the adherence potential and corrosion control. Shot blasting is often confused with grit blasting, but they are actually used for very different purposes. This chart is estimated and based upon use of a long venturi nozzle, SSPC-6 commercial blast specification. REGULATORY INFORMATION N/A S.A.E. 2. The mass of a shot particle is its volume multi- Each material can use different sized shot and each size can have many different hardness numbers/ratings. HANDLING AND STORAGE HANDLING: Avoid contact with eyes. Blastrite is the market leader in the South African market with regards to the production and supply of granular abrasives to the surface preparation industry, whether blasting or painting. Dust and contaminants are removed by an air wash separator and are removed to a dedicated Blastrac dust collector. The resulting angular particles were screened to range sizes G10, G12, G14, G16, G18, G25, G40, G50, G80, G120 as described in SAE J444. Use silicon carbide for toughest jobs. Products Offered: Abrasives, metal abrasives, steel abrasives, blasting medias, steel grit, steel shot. The coated specimens were blast cleaned to a White Metal finish (SSPC-SP 5 or Sa 3) with Introduction Shot Blasting is a surface treatment process using high stream of abrasive material. SAE Specifications for Cast Steel Shot. Sandblasting media was versatile and worked well on an array of structures like bridges and ships. Steel shot is round and grit is angular. 2. Winona Van Norman Steel Shot S-550 - Blasting Media - Large Shot Size (50lb) Winona Van Norman Steel Shot S-550 - Blasting Media - Large Shot Size (15lb) Winona Van Norman Steel Shot S-170 - Blasting Media - Fine Shot Size (10lb) MSDS - STEEL SHOT & GRIT Page 3 of 4 7. Specifications for peening shot and beads include type or shape, media size, and grading system. 2. Industries: Automotive Automotive. Silica-free, 100% recycled glass; Efficient, economical stripping. Pick steel grit or steel shot for special finishes. We are an industry leader of value-added services supporting a vast customer base of end use markets. To check the roughness of steel surfaces which have been blast cleaned to cleanliness grades SA 2.5 and SA 3 before painting. View Similar Products. Minerals and Abrasives. For more aggressive finishes a full range of SAE cast steel grit sizes are also available. Abrasive delivery method: o By Compressed Air. 35% Larger blast pattern 1-1/4 NPM thread, 1 entry, steel jacket. AddThis Utility Frame. Used widely in airless shot blasting and shot peening applications, shot will impact a surface with considerable energy performing a variety of critical processes. Size Chart. The criteria used for selecting the type of shot blasting system depends on the size and shape of the parts, the condition of the surface to be cleaned, final surface finish specification and overall process required. As a quality-conscious producer, IKK SHOT is proud of its achievement in establishing its credibility of the IKK brand Founded in 1981, Metaltec Steel Abrasive Company is the only American steel shot producer to succeed in the manufacturing of low carbon, Bainite cast steel shot. Use in a well-ventilated area. Cut wire shot and rounded or preconditioned products are usually made of metals such as steel. 9.2 AI Score This Score is known as Artificial Intelligence, which is capable of simulating human intelligence expressed through programmed machines. Different materials used for this process includes steel, iron, glass beads and ceramics. Lower numbers mean larger, coarser particles, while higher numbers mean the particles are more fine. J444_201710. Provides recommended top and on-size screens for a variety of media used in abrasive grit blasting and shot peening. Since 1972. We supply Steel Shot blast media in all standard sizes for use in wheel blast and pressure blast systems for stripping, cleaning, deburring, finishing and metal surface-improvement. Here are some of the most common sandblasting media available: Steel shot and grit: When you need to do heavy-duty work, steel shot and grit is an excellent choice. Steel shot is not as hard as cast iron shot, but is much more durable. size in mm 2.80mm 2.40mm 2.00mm 1.70mm 1.40mm 1.18mm 1.00mm 0.850mm 0.710mm 0.600mm 0.500mm 0.425mm 0.355mm 0.180mm S - 70 SS - 180 0.180 S - 110 SS - 300 0. This material is made from steel and comes in several varieties of hardness, size and shape. The hardness is generally 40~50HRC. 1200 fps lead #8 shot gets .70" of gel penetration at 50.1 yards with .56 lbs of energy at 50.1 yards. Review our buying guide to find the right model for your application. 100 psi 420 mph 100% 95 psi 400 mph 93% Get the most current version of Adobe Acrobat Reader . Shotblasting of steel plate, profiles, construction, and fabrications is a process to clean, descale, provide a specified surface profile and edge break as a surface preparation. Nozzle No. Cleaning, peening Al. Grinding, steel shot blast CSP-3 Thin Film 4-10 mils Acid Etching (not recommended) Grinding Steel Shot Blast CSP 3-4 High-Build 10-40 mils Steel Shot Blast CSP 3-4 Scarifying Self-Leveling 50mils-1/8 inch SteelShotBlast CSP 4-5 Scarifying Needle Scaling High/Ultra high Pressure Water Jetting 40,000 psi Polymer Overlay 3 3/16" (5.0mm) 1" (25.0mm) Steel Shot 8-200 280 8.0 - high 200+ low mfd. Crushed Glass - Garnet - Chilled Iron - Steel Grit - Steel Shot - Ceramic Beads - Stainless Steel Shot Note - Figures may vary depending on raw materials and manufacturing processes used. Steel Shot Blasting Blasting with steel shot and steel grit increases productivity. Types of Anchor Patterns and Surface Profiles. (29.8 K) Adobe PDF. Longer Life; High Quality Raw Materials unlike others, we never use scrap steel! 16/20, 1240 = Minimum nozzle bore size of 1/4. We offer Stainless steel shot blasting for a equal finish to sand blasting. In the past, silica sand was one of the most common abrasives used. (29.8 K) Adobe PDF. Blasting Media Comparison Chart Aluminum Oxide Crushed Glass Grit Glass Beads Silicon Carbide Plastic Abrasives Blasting Media. This type of shot is used in all applications where the desired effect is for mass and maximum bounce as well as for shot peening. It is mainly used for peening, deburring, and texturing metals and concrete.

According to different requirement, do the heat treatment to control hardness to standard GP, GL, GH. Available Grades: S70 0.0070 0.0165 (0.180 0.425mm) 1350 fps steel #6 shot gets .70" of gel penetration at 40.2 yards with .96 lbs of energy at 40.2 yards. Mechanical force is used to propel blast media such as sand, sponge or glass beads at the surface to be cleaned to remove contaminants such as paint ,rust, corrosive layer etc.

High-Carbon Cast-Steel Shot. to a very tough steel or stainless steel shot or grit. Machines can be built with multiple wheels for automation. page 1 of 3. Closely Controlled Hot & Cold Working Processing produces Previous Next Steel Shot Blasting Our facility is equipped with a steel shot/grit manual blasting room with reclaimer. 5. TRANSPORT INFORMATION DOT: Not Regulated. Automated systems include basket, table, spinner hangers and continuous conveyor processing. Steel Shot is used in airless wheel blast machines to clean foundry castings, shot blasting of steel structures and for surface finishing to impart a more polished surface to metallic objects.

High-Carbon Cast-Steel Shot. to a very tough steel or stainless steel shot or grit. Machines can be built with multiple wheels for automation. page 1 of 3. Closely Controlled Hot & Cold Working Processing produces Previous Next Steel Shot Blasting Our facility is equipped with a steel shot/grit manual blasting room with reclaimer. 5. TRANSPORT INFORMATION DOT: Not Regulated. Automated systems include basket, table, spinner hangers and continuous conveyor processing. Steel Shot is used in airless wheel blast machines to clean foundry castings, shot blasting of steel structures and for surface finishing to impart a more polished surface to metallic objects.  How do I use the reference chart? The larger the number designation How long will it take to strip a whole car? What type of shot media is used is a very important decision for the shot blasting process.

How do I use the reference chart? The larger the number designation How long will it take to strip a whole car? What type of shot media is used is a very important decision for the shot blasting process.  It allows for shorter blast times and lower cost overall than other media. 355mm in diameter. A highly aggressive abrasive ideal for applications where tough contamination is encountered and stock removal of .001 to .002 inches is acceptable. We manufacture special models for plastic, steel shot and soda abrasive, and pay special attention to the Sandcarving and Automotive markets. IKK SHOT started manufacturing steel shot and steel grit in 1957 as IKK(Itoh Kikoh) and became independent in 1997. If silica must be used today, it is often performed in an isolated blast room with extensive personal protective equipment (PPE). Blasting Media. The Blasting Steel Shot and Grit can be applied safely to all types of metals. Wheel blast systems are a less expensive way to blast (due to higher media recycleability and automation) than air blasting by a factor of 10. Cut Wire Shot is an abrasive media used for shot blasting and shot peening processes. SPECIFICATION FOR STEEL SHOT & GRIT. S280 Steel Shot W Abrasives (877) 909-7848) (No reviews yet) Write a Review S280 Steel Shot sold in 55lb Bags. The sizing numbers for shot pertain to the actual size of the shot particulate, not a mesh size. This increases productivity by eliminating the need for pot loading. This SAE Recommended Practice pertains to blast cleaning and shot peening and provides for standard cast shot and grit size numbers. Steel abrasives are often measured in grit size indicating the number of particles in a specific area, whereas mesh sizes measure the particle size passing a woven wire screen. Product Brochure. SAE Size Opening. Blast Aggregates > Steel Shot; All Blast Aggregates. Steel Shot. We supply Steel Shot blast media in all standard sizes for use in wheel blast and pressure blast systems for stripping, cleaning, deburring, finishing and metal surface-improvement. In finishing operations, it produces smooth & polished finishes. Steel Shot strengthens metal surfaces in peening applications. Glass beads or steel shot would be examples of rounded abrasives. Technical Data Sheet - PDF. Introduction of the projectile 1. Steel Shot Size Chart Manufacturers, Factory, Suppliers From China, Good quality and aggressive prices make our products get pleasure from a significant name all around the word. If you are doing the average-size muscle car, it will take 8 to 10+ bags. Steel Shot is a spherical media composed of carbon or stainless steels. Shotblasting Surface Measurement Terms. It can be recycled more times than aluminum oxide or sand.

It allows for shorter blast times and lower cost overall than other media. 355mm in diameter. A highly aggressive abrasive ideal for applications where tough contamination is encountered and stock removal of .001 to .002 inches is acceptable. We manufacture special models for plastic, steel shot and soda abrasive, and pay special attention to the Sandcarving and Automotive markets. IKK SHOT started manufacturing steel shot and steel grit in 1957 as IKK(Itoh Kikoh) and became independent in 1997. If silica must be used today, it is often performed in an isolated blast room with extensive personal protective equipment (PPE). Blasting Media. The Blasting Steel Shot and Grit can be applied safely to all types of metals. Wheel blast systems are a less expensive way to blast (due to higher media recycleability and automation) than air blasting by a factor of 10. Cut Wire Shot is an abrasive media used for shot blasting and shot peening processes. SPECIFICATION FOR STEEL SHOT & GRIT. S280 Steel Shot W Abrasives (877) 909-7848) (No reviews yet) Write a Review S280 Steel Shot sold in 55lb Bags. The sizing numbers for shot pertain to the actual size of the shot particulate, not a mesh size. This increases productivity by eliminating the need for pot loading. This SAE Recommended Practice pertains to blast cleaning and shot peening and provides for standard cast shot and grit size numbers. Steel abrasives are often measured in grit size indicating the number of particles in a specific area, whereas mesh sizes measure the particle size passing a woven wire screen. Product Brochure. SAE Size Opening. Blast Aggregates > Steel Shot; All Blast Aggregates. Steel Shot. We supply Steel Shot blast media in all standard sizes for use in wheel blast and pressure blast systems for stripping, cleaning, deburring, finishing and metal surface-improvement. In finishing operations, it produces smooth & polished finishes. Steel Shot strengthens metal surfaces in peening applications. Glass beads or steel shot would be examples of rounded abrasives. Technical Data Sheet - PDF. Introduction of the projectile 1. Steel Shot Size Chart Manufacturers, Factory, Suppliers From China, Good quality and aggressive prices make our products get pleasure from a significant name all around the word. If you are doing the average-size muscle car, it will take 8 to 10+ bags. Steel Shot is a spherical media composed of carbon or stainless steels. Shotblasting Surface Measurement Terms. It can be recycled more times than aluminum oxide or sand.  How do I use the reference chart? In finishing operations, it produces smooth & polished finishes. Rationale: Revision to Metaltec Steel Abrasive Co. forms on-going partnerships with our customers. Specialize in Commercial Blast Cleaning, Portable Industrial Sandblaster. Full skid size of 2,200lbs. 6. The resulting finish is ideal for painting, plating, coating or wherever a matte finish is desired. Learn more about this blast system from Advanced Deburring & Finishing. with aluminum threads, tungsten carbide liner. Collected dust may contain hazardous contaminants from blast cleaning or shot peening operations. J827_201910. Steel Shot Blasting Media A steel shot abrasive consists of small, spherical pellet-type projectiles that are often made from carbon steel. Steel shot is widely used in various sheet peening and polishing applications and typically provides a smoother, more polished surface than many other types of blasting media. Viking Blast & Wash Systems manufactures and distributes industrial shot blasting equipment and cleaning systems, customized to your parts-specific-needs. 124 wide x 14 tall plate cleaning system. It depends on many variables including paint hardness, layers, compressor strength, atmospheric humidity, skill, detail level you are attempting to achieve, material youre blasting (steel vs. fiberglass), etc. Our automated shot blasters around the country provide us the ability to blast a number of products, including plate, structural and cut parts to your specific surface profile. Use The Chart Below To Find Your Minimum Nozzle Bore Size For Different Blasting Grits: 3060 grit = Minimum nozzle bore size of 1/8. mm inS780 S660 S550 S460 S390 S330 S280 S230 S170 S110 S70 72.80 .1110All Pass 82.36 .0937All Pass 102.00 .078785% Min All Pass All Pass 121.70 .066197% Min 85% Min 5% Max All Pass 141.40 .055597% Min 85% Min 5% Max All Pass 161.18 .046997% Min 85% Min 5% Max AddThis Utility Frame. Looking for Steel Shot Blasting Pipe? As a general rule, your nozzle orifice should be 3 times the size of the grit, MINIMUM. Steel shot is sized by screening. SAE J444 Shot Tolerances. Nozzle Orifice Size Minimum Air Line ID No. Full skid size of 2,200lbs. (See Table 1.) Our Specialty, Our Expertise, Your Benefit. Steel Shot strengthens metal surfaces in peening applications. (316) 634-6699 (800) 835-1096; Why Viking. tech documents; navy product approval process navy community coatings roadmap; sd-6 provisions governing qualification; approved exterior ship coatings

How do I use the reference chart? In finishing operations, it produces smooth & polished finishes. Rationale: Revision to Metaltec Steel Abrasive Co. forms on-going partnerships with our customers. Specialize in Commercial Blast Cleaning, Portable Industrial Sandblaster. Full skid size of 2,200lbs. 6. The resulting finish is ideal for painting, plating, coating or wherever a matte finish is desired. Learn more about this blast system from Advanced Deburring & Finishing. with aluminum threads, tungsten carbide liner. Collected dust may contain hazardous contaminants from blast cleaning or shot peening operations. J827_201910. Steel Shot Blasting Media A steel shot abrasive consists of small, spherical pellet-type projectiles that are often made from carbon steel. Steel shot is widely used in various sheet peening and polishing applications and typically provides a smoother, more polished surface than many other types of blasting media. Viking Blast & Wash Systems manufactures and distributes industrial shot blasting equipment and cleaning systems, customized to your parts-specific-needs. 124 wide x 14 tall plate cleaning system. It depends on many variables including paint hardness, layers, compressor strength, atmospheric humidity, skill, detail level you are attempting to achieve, material youre blasting (steel vs. fiberglass), etc. Our automated shot blasters around the country provide us the ability to blast a number of products, including plate, structural and cut parts to your specific surface profile. Use The Chart Below To Find Your Minimum Nozzle Bore Size For Different Blasting Grits: 3060 grit = Minimum nozzle bore size of 1/8. mm inS780 S660 S550 S460 S390 S330 S280 S230 S170 S110 S70 72.80 .1110All Pass 82.36 .0937All Pass 102.00 .078785% Min All Pass All Pass 121.70 .066197% Min 85% Min 5% Max All Pass 141.40 .055597% Min 85% Min 5% Max All Pass 161.18 .046997% Min 85% Min 5% Max AddThis Utility Frame. Looking for Steel Shot Blasting Pipe? As a general rule, your nozzle orifice should be 3 times the size of the grit, MINIMUM. Steel shot is sized by screening. SAE J444 Shot Tolerances. Nozzle Orifice Size Minimum Air Line ID No. Full skid size of 2,200lbs. (See Table 1.) Our Specialty, Our Expertise, Your Benefit. Steel Shot strengthens metal surfaces in peening applications. (316) 634-6699 (800) 835-1096; Why Viking. tech documents; navy product approval process navy community coatings roadmap; sd-6 provisions governing qualification; approved exterior ship coatings  AGSCO offers Steel Shot, a rounded media that comes in a wide range of sizes. When shot peening, it is critical and essential to actually create a dent in the surface, this means that the steel shot must be spherical. The size of the ball can range from 0.2 mm to 0.5 mm in diameter. Premier Shots Normal Conditioned Cut wire shot is ideal for shot peening gears, bolts, weldments or any steel product and offers substantial production benefits especially for the automotive industry:. Sharp, long lasting media for fast etching & profiling; Brown/black or White. Model #. S230 Steel Shot W Abrasives (877) 909-7848) (No reviews yet) Write a Review S230 Steel Shot sold in 55lb Bags. rotating wheel usually restricts media selection to a very tough steel or stainless steel shot or grit. Technical Data Sheet - PDF. Safety Data Sheet - PDF. Media Blast & Abrasive recommends the PowerPeen for these larger sizes. Siphon abrasive blasting cabinets, i.e. the N-200 can also use steel type abrasives when the size is 80 grit and smaller. Normally a larger production gun is used to boost the siphon-feed of these larger/heavier abrasives. Glass Bead Blasting Media For Metal Cleaning And Polishing (120 grit, 150 grit, 180 grit, 220 grit) Shot blasting glass beads are glass beads for surface treatment of industrial parts, which are made of non-alkaline soda lime silicate and have certain hardness and elasticity. Steel Shot. Shot blasting is used in almost every industry we serve. Hardness: 40 - 50 Rc // = 390 - 510 HV Five types of commercial blasting nozzles were selected. The larger shot are used for the removal of thicker coatings and for heavier steel peening too. Winona Van Norman Steel Shot S-230 - Blasting Media - Medium Shot Size (10lb) View on Amazon. Round, soda-lime glass to produce a bright, satin finish; Minimizes stress on part. Shot is highly efficient, outperforming life spans of glass, garnets, and oxides by 1000 : 1. Stock #. This SAE Recommended Practice describes chemical composition and physical characteristic requirements for high-carbon cast-steel shot to be used for shot peening or blast cleaning operations. Types of Shot Blasting Material There are various types of Shot blasting material including, Steel Shots, Steel Grit,Garnet Steel Shot,Aluminum Shot, Stainless Steel Cut Wire Shot, Lead Shot,Zinc Shot etc. Steel Shots Steel shot is spherical metallic abrasive produced by the molten steel by means of atomizing process. Surface Preparation; Scale Removal etc. This table provides helpful information for many of our customers: Sweco screen sizes for peening with steel, glass, and ceramic. SAE Size No. 300 Allpass 10%Max 80%Min 90%Min Automated systems include basket, table, spinner hangers and continuous conveyor processing. Both air-powered and wheel blast systems can be used to accelerate the steel shot onto the surface of the part; Can be recycled as many as 3000 times before replacement due to its hardness and density; Does not use an abrasive process; Generates a minimal amount of dust in the blasting process; Technical data. This table provides helpful information for many of our customers: Sweco screen sizes for peening with steel, glass, and ceramic. This process takes place prior to a coating or paint application to maximise the adherence potential and corrosion control. Shot blasting is often confused with grit blasting, but they are actually used for very different purposes. This chart is estimated and based upon use of a long venturi nozzle, SSPC-6 commercial blast specification. REGULATORY INFORMATION N/A S.A.E. 2. The mass of a shot particle is its volume multi- Each material can use different sized shot and each size can have many different hardness numbers/ratings. HANDLING AND STORAGE HANDLING: Avoid contact with eyes. Blastrite is the market leader in the South African market with regards to the production and supply of granular abrasives to the surface preparation industry, whether blasting or painting. Dust and contaminants are removed by an air wash separator and are removed to a dedicated Blastrac dust collector. The resulting angular particles were screened to range sizes G10, G12, G14, G16, G18, G25, G40, G50, G80, G120 as described in SAE J444. Use silicon carbide for toughest jobs. Products Offered: Abrasives, metal abrasives, steel abrasives, blasting medias, steel grit, steel shot. The coated specimens were blast cleaned to a White Metal finish (SSPC-SP 5 or Sa 3) with Introduction Shot Blasting is a surface treatment process using high stream of abrasive material. SAE Specifications for Cast Steel Shot. Sandblasting media was versatile and worked well on an array of structures like bridges and ships. Steel shot is round and grit is angular. 2. Winona Van Norman Steel Shot S-550 - Blasting Media - Large Shot Size (50lb) Winona Van Norman Steel Shot S-550 - Blasting Media - Large Shot Size (15lb) Winona Van Norman Steel Shot S-170 - Blasting Media - Fine Shot Size (10lb) MSDS - STEEL SHOT & GRIT Page 3 of 4 7. Specifications for peening shot and beads include type or shape, media size, and grading system. 2. Industries: Automotive Automotive. Silica-free, 100% recycled glass; Efficient, economical stripping. Pick steel grit or steel shot for special finishes. We are an industry leader of value-added services supporting a vast customer base of end use markets. To check the roughness of steel surfaces which have been blast cleaned to cleanliness grades SA 2.5 and SA 3 before painting. View Similar Products. Minerals and Abrasives. For more aggressive finishes a full range of SAE cast steel grit sizes are also available. Abrasive delivery method: o By Compressed Air. 35% Larger blast pattern 1-1/4 NPM thread, 1 entry, steel jacket. AddThis Utility Frame. Used widely in airless shot blasting and shot peening applications, shot will impact a surface with considerable energy performing a variety of critical processes. Size Chart. The criteria used for selecting the type of shot blasting system depends on the size and shape of the parts, the condition of the surface to be cleaned, final surface finish specification and overall process required. As a quality-conscious producer, IKK SHOT is proud of its achievement in establishing its credibility of the IKK brand Founded in 1981, Metaltec Steel Abrasive Company is the only American steel shot producer to succeed in the manufacturing of low carbon, Bainite cast steel shot. Use in a well-ventilated area. Cut wire shot and rounded or preconditioned products are usually made of metals such as steel. 9.2 AI Score This Score is known as Artificial Intelligence, which is capable of simulating human intelligence expressed through programmed machines. Different materials used for this process includes steel, iron, glass beads and ceramics. Lower numbers mean larger, coarser particles, while higher numbers mean the particles are more fine. J444_201710. Provides recommended top and on-size screens for a variety of media used in abrasive grit blasting and shot peening. Since 1972. We supply Steel Shot blast media in all standard sizes for use in wheel blast and pressure blast systems for stripping, cleaning, deburring, finishing and metal surface-improvement. Here are some of the most common sandblasting media available: Steel shot and grit: When you need to do heavy-duty work, steel shot and grit is an excellent choice. Steel shot is not as hard as cast iron shot, but is much more durable. size in mm 2.80mm 2.40mm 2.00mm 1.70mm 1.40mm 1.18mm 1.00mm 0.850mm 0.710mm 0.600mm 0.500mm 0.425mm 0.355mm 0.180mm S - 70 SS - 180 0.180 S - 110 SS - 300 0. This material is made from steel and comes in several varieties of hardness, size and shape. The hardness is generally 40~50HRC. 1200 fps lead #8 shot gets .70" of gel penetration at 50.1 yards with .56 lbs of energy at 50.1 yards. Review our buying guide to find the right model for your application. 100 psi 420 mph 100% 95 psi 400 mph 93% Get the most current version of Adobe Acrobat Reader . Shotblasting of steel plate, profiles, construction, and fabrications is a process to clean, descale, provide a specified surface profile and edge break as a surface preparation. Nozzle No. Cleaning, peening Al. Grinding, steel shot blast CSP-3 Thin Film 4-10 mils Acid Etching (not recommended) Grinding Steel Shot Blast CSP 3-4 High-Build 10-40 mils Steel Shot Blast CSP 3-4 Scarifying Self-Leveling 50mils-1/8 inch SteelShotBlast CSP 4-5 Scarifying Needle Scaling High/Ultra high Pressure Water Jetting 40,000 psi Polymer Overlay 3 3/16" (5.0mm) 1" (25.0mm) Steel Shot 8-200 280 8.0 - high 200+ low mfd. Crushed Glass - Garnet - Chilled Iron - Steel Grit - Steel Shot - Ceramic Beads - Stainless Steel Shot Note - Figures may vary depending on raw materials and manufacturing processes used. Steel Shot Blasting Blasting with steel shot and steel grit increases productivity. Types of Anchor Patterns and Surface Profiles. (29.8 K) Adobe PDF. Longer Life; High Quality Raw Materials unlike others, we never use scrap steel! 16/20, 1240 = Minimum nozzle bore size of 1/4. We offer Stainless steel shot blasting for a equal finish to sand blasting. In the past, silica sand was one of the most common abrasives used. (29.8 K) Adobe PDF. Blasting Media Comparison Chart Aluminum Oxide Crushed Glass Grit Glass Beads Silicon Carbide Plastic Abrasives Blasting Media. This type of shot is used in all applications where the desired effect is for mass and maximum bounce as well as for shot peening. It is mainly used for peening, deburring, and texturing metals and concrete.

AGSCO offers Steel Shot, a rounded media that comes in a wide range of sizes. When shot peening, it is critical and essential to actually create a dent in the surface, this means that the steel shot must be spherical. The size of the ball can range from 0.2 mm to 0.5 mm in diameter. Premier Shots Normal Conditioned Cut wire shot is ideal for shot peening gears, bolts, weldments or any steel product and offers substantial production benefits especially for the automotive industry:. Sharp, long lasting media for fast etching & profiling; Brown/black or White. Model #. S230 Steel Shot W Abrasives (877) 909-7848) (No reviews yet) Write a Review S230 Steel Shot sold in 55lb Bags. rotating wheel usually restricts media selection to a very tough steel or stainless steel shot or grit. Technical Data Sheet - PDF. Safety Data Sheet - PDF. Media Blast & Abrasive recommends the PowerPeen for these larger sizes. Siphon abrasive blasting cabinets, i.e. the N-200 can also use steel type abrasives when the size is 80 grit and smaller. Normally a larger production gun is used to boost the siphon-feed of these larger/heavier abrasives. Glass Bead Blasting Media For Metal Cleaning And Polishing (120 grit, 150 grit, 180 grit, 220 grit) Shot blasting glass beads are glass beads for surface treatment of industrial parts, which are made of non-alkaline soda lime silicate and have certain hardness and elasticity. Steel Shot. Shot blasting is used in almost every industry we serve. Hardness: 40 - 50 Rc // = 390 - 510 HV Five types of commercial blasting nozzles were selected. The larger shot are used for the removal of thicker coatings and for heavier steel peening too. Winona Van Norman Steel Shot S-230 - Blasting Media - Medium Shot Size (10lb) View on Amazon. Round, soda-lime glass to produce a bright, satin finish; Minimizes stress on part. Shot is highly efficient, outperforming life spans of glass, garnets, and oxides by 1000 : 1. Stock #. This SAE Recommended Practice describes chemical composition and physical characteristic requirements for high-carbon cast-steel shot to be used for shot peening or blast cleaning operations. Types of Shot Blasting Material There are various types of Shot blasting material including, Steel Shots, Steel Grit,Garnet Steel Shot,Aluminum Shot, Stainless Steel Cut Wire Shot, Lead Shot,Zinc Shot etc. Steel Shots Steel shot is spherical metallic abrasive produced by the molten steel by means of atomizing process. Surface Preparation; Scale Removal etc. This table provides helpful information for many of our customers: Sweco screen sizes for peening with steel, glass, and ceramic. SAE Size No. 300 Allpass 10%Max 80%Min 90%Min Automated systems include basket, table, spinner hangers and continuous conveyor processing. Both air-powered and wheel blast systems can be used to accelerate the steel shot onto the surface of the part; Can be recycled as many as 3000 times before replacement due to its hardness and density; Does not use an abrasive process; Generates a minimal amount of dust in the blasting process; Technical data. This table provides helpful information for many of our customers: Sweco screen sizes for peening with steel, glass, and ceramic. This process takes place prior to a coating or paint application to maximise the adherence potential and corrosion control. Shot blasting is often confused with grit blasting, but they are actually used for very different purposes. This chart is estimated and based upon use of a long venturi nozzle, SSPC-6 commercial blast specification. REGULATORY INFORMATION N/A S.A.E. 2. The mass of a shot particle is its volume multi- Each material can use different sized shot and each size can have many different hardness numbers/ratings. HANDLING AND STORAGE HANDLING: Avoid contact with eyes. Blastrite is the market leader in the South African market with regards to the production and supply of granular abrasives to the surface preparation industry, whether blasting or painting. Dust and contaminants are removed by an air wash separator and are removed to a dedicated Blastrac dust collector. The resulting angular particles were screened to range sizes G10, G12, G14, G16, G18, G25, G40, G50, G80, G120 as described in SAE J444. Use silicon carbide for toughest jobs. Products Offered: Abrasives, metal abrasives, steel abrasives, blasting medias, steel grit, steel shot. The coated specimens were blast cleaned to a White Metal finish (SSPC-SP 5 or Sa 3) with Introduction Shot Blasting is a surface treatment process using high stream of abrasive material. SAE Specifications for Cast Steel Shot. Sandblasting media was versatile and worked well on an array of structures like bridges and ships. Steel shot is round and grit is angular. 2. Winona Van Norman Steel Shot S-550 - Blasting Media - Large Shot Size (50lb) Winona Van Norman Steel Shot S-550 - Blasting Media - Large Shot Size (15lb) Winona Van Norman Steel Shot S-170 - Blasting Media - Fine Shot Size (10lb) MSDS - STEEL SHOT & GRIT Page 3 of 4 7. Specifications for peening shot and beads include type or shape, media size, and grading system. 2. Industries: Automotive Automotive. Silica-free, 100% recycled glass; Efficient, economical stripping. Pick steel grit or steel shot for special finishes. We are an industry leader of value-added services supporting a vast customer base of end use markets. To check the roughness of steel surfaces which have been blast cleaned to cleanliness grades SA 2.5 and SA 3 before painting. View Similar Products. Minerals and Abrasives. For more aggressive finishes a full range of SAE cast steel grit sizes are also available. Abrasive delivery method: o By Compressed Air. 35% Larger blast pattern 1-1/4 NPM thread, 1 entry, steel jacket. AddThis Utility Frame. Used widely in airless shot blasting and shot peening applications, shot will impact a surface with considerable energy performing a variety of critical processes. Size Chart. The criteria used for selecting the type of shot blasting system depends on the size and shape of the parts, the condition of the surface to be cleaned, final surface finish specification and overall process required. As a quality-conscious producer, IKK SHOT is proud of its achievement in establishing its credibility of the IKK brand Founded in 1981, Metaltec Steel Abrasive Company is the only American steel shot producer to succeed in the manufacturing of low carbon, Bainite cast steel shot. Use in a well-ventilated area. Cut wire shot and rounded or preconditioned products are usually made of metals such as steel. 9.2 AI Score This Score is known as Artificial Intelligence, which is capable of simulating human intelligence expressed through programmed machines. Different materials used for this process includes steel, iron, glass beads and ceramics. Lower numbers mean larger, coarser particles, while higher numbers mean the particles are more fine. J444_201710. Provides recommended top and on-size screens for a variety of media used in abrasive grit blasting and shot peening. Since 1972. We supply Steel Shot blast media in all standard sizes for use in wheel blast and pressure blast systems for stripping, cleaning, deburring, finishing and metal surface-improvement. Here are some of the most common sandblasting media available: Steel shot and grit: When you need to do heavy-duty work, steel shot and grit is an excellent choice. Steel shot is not as hard as cast iron shot, but is much more durable. size in mm 2.80mm 2.40mm 2.00mm 1.70mm 1.40mm 1.18mm 1.00mm 0.850mm 0.710mm 0.600mm 0.500mm 0.425mm 0.355mm 0.180mm S - 70 SS - 180 0.180 S - 110 SS - 300 0. This material is made from steel and comes in several varieties of hardness, size and shape. The hardness is generally 40~50HRC. 1200 fps lead #8 shot gets .70" of gel penetration at 50.1 yards with .56 lbs of energy at 50.1 yards. Review our buying guide to find the right model for your application. 100 psi 420 mph 100% 95 psi 400 mph 93% Get the most current version of Adobe Acrobat Reader . Shotblasting of steel plate, profiles, construction, and fabrications is a process to clean, descale, provide a specified surface profile and edge break as a surface preparation. Nozzle No. Cleaning, peening Al. Grinding, steel shot blast CSP-3 Thin Film 4-10 mils Acid Etching (not recommended) Grinding Steel Shot Blast CSP 3-4 High-Build 10-40 mils Steel Shot Blast CSP 3-4 Scarifying Self-Leveling 50mils-1/8 inch SteelShotBlast CSP 4-5 Scarifying Needle Scaling High/Ultra high Pressure Water Jetting 40,000 psi Polymer Overlay 3 3/16" (5.0mm) 1" (25.0mm) Steel Shot 8-200 280 8.0 - high 200+ low mfd. Crushed Glass - Garnet - Chilled Iron - Steel Grit - Steel Shot - Ceramic Beads - Stainless Steel Shot Note - Figures may vary depending on raw materials and manufacturing processes used. Steel Shot Blasting Blasting with steel shot and steel grit increases productivity. Types of Anchor Patterns and Surface Profiles. (29.8 K) Adobe PDF. Longer Life; High Quality Raw Materials unlike others, we never use scrap steel! 16/20, 1240 = Minimum nozzle bore size of 1/4. We offer Stainless steel shot blasting for a equal finish to sand blasting. In the past, silica sand was one of the most common abrasives used. (29.8 K) Adobe PDF. Blasting Media Comparison Chart Aluminum Oxide Crushed Glass Grit Glass Beads Silicon Carbide Plastic Abrasives Blasting Media. This type of shot is used in all applications where the desired effect is for mass and maximum bounce as well as for shot peening. It is mainly used for peening, deburring, and texturing metals and concrete.

According to different requirement, do the heat treatment to control hardness to standard GP, GL, GH. Available Grades: S70 0.0070 0.0165 (0.180 0.425mm) 1350 fps steel #6 shot gets .70" of gel penetration at 40.2 yards with .96 lbs of energy at 40.2 yards. Mechanical force is used to propel blast media such as sand, sponge or glass beads at the surface to be cleaned to remove contaminants such as paint ,rust, corrosive layer etc.

According to different requirement, do the heat treatment to control hardness to standard GP, GL, GH. Available Grades: S70 0.0070 0.0165 (0.180 0.425mm) 1350 fps steel #6 shot gets .70" of gel penetration at 40.2 yards with .96 lbs of energy at 40.2 yards. Mechanical force is used to propel blast media such as sand, sponge or glass beads at the surface to be cleaned to remove contaminants such as paint ,rust, corrosive layer etc.