These layers consist of a cotton core, a glass filter core, and three activated carbon filter core layers. DIGITAL VS. STANDARD MOTORS: The types of motors (blowers) used in these systems varies but they fall into two categories: standard brush motors and digital motors. A waterjet cutter is a powerful industrial tool that uses a very focused high-pressure stream of water (and sometimes an abrasive substance like natural sand) to cut through a wide variety of materials. The first carbon dioxide (C02) laser was invented in 1963 by Kumar Patel, and just two years later, the first Western Engineering Research Center (in Buffalo, USA) was the first to employ a laser as a cutting device, using a laser to drill holes in diamond dies. To be effective, air must remain in the charcoal for an extended time.

There are a number of filtration manufacturers in the U.S. and around the world. Running the wrong cycle rating can and will damage equipment.

LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well. Use collapsible tabs for more detailed information that will help customers make a purchasing decision. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable.

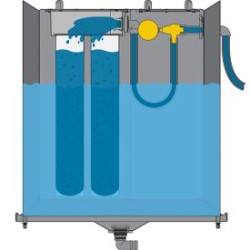

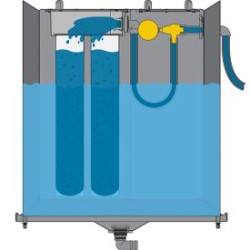

Find more information on them here. In the U.S., we generally refer to airflow in CFM (cubic feet per minute). NOISE: Filtration devices include a motor and they are pulling a lot of air. Prices and offers are subject to change. These cant be trapped in ordinary paper filters. We recommend checking the filters on a bi-weekly basisto monitor debris build-up. This feature is also helpful when running multiple lasers through a single filtration system as the volume of CFM will need to be changed when multiple lasers are running vs. reduced when only one laser is running. The larger the laser, the more exhaust it will require. Illustration courtesy of BOFA Americas, Inc. Obviously, these gases and particles cant be exhausted into a work environment because of the potentially deadly consequences. A system that meets your needs and has affordable filters will save a lot of money over the lifespan of the system. Laser marking and coding of packaging and products with traceable information such as barcodes, batch codes and sell by dates. Without an adequate filtration system, using a laser would be impossible. To learn more, visit their website at www.cmu.edu/ehs. Most of us, however, should be happy with 40 lbs. Adapt Laser specializes in providing the highest-quality laser cleaning systems available.

MULTIPLE VOLTAGE CAPABILITY: Most places in the U.S. will provide 110-120 volts and 220-240 volts of power supply, and most people will run their lasers and filtration systems at 110-120 volts. Many engravers who work with lasers are fortunate to be able to vent their lasers to the outside. Buy the system that will meet your needs both now and in the future. Selecting one model over another can be difficult. This device is responsible for removing the really tiny particles from the air stream. All Rights Reserved. The smaller the particle the system is capable of catching, the better. Optional: 2, 3 or 4" diameter, Optional 10" or 12" discharge collars for venting to the exterior, Suction hose: 12 feet (3.6m) of flexible hose & clamps. Searching out a unit that doesnt have features you dont need might help keep the cost down but be careful since, as you eliminate features, you might be making your system more difficult to use or service. In the most basic terms, all filtration systems work the same way.

For me, cutting acrylic is the worst. The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. Johnson Plastics Plus has four great options for double-sided adhesive Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece. United Kingdom This gives the charcoal time to actually absorb the odors and other hazardous fumes.

Unfortunately, we dont. Thank you to all at CTR for collaborating with Cross to build us a bespoke machine. There are many models, features, options and sizes.

To underrate a laser means the filtration either isnt going to be adequate or the filters are going to require more frequent replacement. Without a way to accurately read this, you will likely run the system too slow, which doesnt let it do its job, or too fast, which shortens the life of the HEPA filter. Most of Europe is 220 volts and most lasers and filtration systems offer both standard voltages, but if there is any chance you might take your equipment on a sightseeing tour of the world, or the area where you live struggles to maintain consistent voltages, it is nice to have an automated voltage selector on your filtration system that can detect the actual voltage (not just what it is supposed to be) and adjust accordingly. To determine this, add the number of amps listed for your laser(s) and for the filtration system. Coding for Climate Webinars (CanCode 3.0). T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. The quiet and compact Advantage 350 is ideal for use in light duty laser marking applications, including schools, sign making workshops and small scale industrial environments. The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. Although you might think of this as just a convenience, it is also a safety feature that ensures the operator never forgets to turn it on and endanger their health. This seems to be pretty consistent across the industry but it is important to consider. If you have attended a tradeshow where working lasers are displayed, you have probably noticed they all have filtration systems connected to their lasers. Box 318 Brighton, MI 48116-0318 In Europe, however, this isnt the case, so an indoor ventless filtration system is required for most lasers. This means it can be broken down into components and shipped using regular UPS. {{product.adhesive===''?'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}. Opinions vary as to which is the best design. The air quality control people, for the most part, have left engraving shops untouched by strict regulations. Call us toll free 1-800-626-0664 for help with your product selection.

CTR will simply wheel in your laser machine and filter unit, link them up, and talk you through the simple process of using them. that we can directly apply to your sheet stock before it's shipped to you. Whilst it can be beneficial to understand some of the pitfalls that can occur when cutting certain types of plastics, it's important to relate the question to the exact device you're using and the plastic you're cutting. The amount of CFM a filtration system can develop is significant and should be matched carefully with the specifications of each laser.

In other parts of the world, it is rated by m3/h (cubic meters per hour). After systems are out in the field for a few years, developers at TEKA will take feedback from customers and incorporate it into their existing designs to better match changing customer needs. For our purposes, we will consider six companies that are well-known and involved in our industry. E: info@ctrfuture.co.uk Filtration units that weigh 100 lbs. Some of the really large systems, of course, use more and if you plan to run multiple lasers with the same filtration system or you are running an unusually large laser or cutting certain materials, you might want to consider finding a system with larger charcoal filters. Second, go with a major, well-known company in the industry, one that has service capabilities near you if possible. These coarse to extremely fine paper filters can trap particles as small as 0.001mm (many times smaller than a human hair). Down-flow filtration systems generally use a pleated filter made of paper, glass fiber, etc., to catch the big particles and serve as a first stage of filtration. Forms, TECH One feature which might be nice but is certainly not mandatory for most of us is the ability to place a small air compressor (for air assist) inside the filtration cabinet just to get it out of the way and perhaps reduce some of the noise. IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. (BOFA says their carbon filter can capture 99.997% down to 3 microns and 95% down to 1 micron.). of activated charcoal. Lasers can expel some pretty deadly gases and particles when engraving and cutting certain materials. Brush motors, like we have all used for 100+ years, are less expensive but they have something called brushes that brush up against the armature to transfer electricity. Our systems come in both handheld and automated options making them versatile for different applications and surface preparation. The idea to sell fume extraction systems in conjunction with our lasers came from the filter units themselves, as we wanted the ability to pair our top of the line laser cleaning systems with fume extractors of equal caliber. The activated charcoal actually absorbs the odors. For the best experience on our site, be sure to turn on Javascript in your browser. For this feature to be effective, it is important to have a device that displays what the actual amount of airflow is in real time. OSHA, the Occupational, Safety and Health Administration, has identified over 200 such agents that can cause asthma and even cancer. My best advice is first, take your time and talk to company representatives but also their customers.

'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}, {{adhesive.label.replace('+',`+${adhesivePrice(adhesive.price,product.sku,product.uom)}`)}}, Credit Application & Tax Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation. TEKAs high-quality filtration systems paired with their reliability in performance soon proved to be a perfect match for our state-of-the-art laser cleaning systems. The AIRDOCK from PAT Technology Systems, Inc. is completely modular, allowing you to change the configuration to fit your needs at any given time. PRE-FILTERS: As the name suggests, these filters are first in line. Website Design and Programming by Freetimers, Laser Cutters for Schools and Universities. The fume filtration units are constructed of corrosion resistant stainless steel, and are mounted on four castors for increased mobility. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. Click here for more health and safety information. Noise is measured in dBs (decibels). | a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. The first stage removes the largest particles.

That means the blower isnt exhausting all of the odor (odor is actually caused by super-fine particles in the air). Finally, take the time, energy and money necessary to maintain your system properly. To do that, lets consider the various features offered by some of the leading companies. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. (45 kg) of chemical filtration media, Motor(s): 3 X 1.0 kW High Speed Turbine, UL & CSA Listed, Dimensions: 16"W x 25"D x 30"H / 406mm x 635mm x 760mm, Filter Sequence: Multi layered knock-out pad (1 / inlet) (F166-125), 2 x Pleated pre-filter, 30% ASHRAE rated (F071), 2 x 2 Medical grade HEPA filter 99.97% (F074), 2 x 8 Chemical filter (AG097), Optional lnlets: 1.5, 2, 2.5, 3 or 4" diameter, Front door access to filters and the motor blower, Also available: articulated arms, hoods and ducting accessories, Dimensions: 24"W x 26"D x 71"H / 610mm x 660mm x 1800mm, Filtration: Pre-filters, Medical grade HEPA filters 99.97%, Chemical filter, up to 200 lbs / 90kg, lnlets: 6 standard. (23 kg) of chemical filtration media, LaserBlue gel seal guarantees ZERO FILTER BYPASS, Dual high speed turbine for high suction, pressure and airflow, Dimensions: 12"W x 15"D x 24"H / 304mm x 381mm x 762mm, Filter Sequence: Multi layered knock-out pad (F166-125), Pleated pre-filter, 30% ASHRAE rated (F071), 2 Medical grade HEPA filter 99.97% (F074), 8 Chemical filter (AG097), Optional lnlets: 2, 3 or 4" diameter.

A HEPA filter can handle particles down to 1 micron. The temptation to buy based on cost, however, is a poor one. Actually, the venting of smoke and other combustion fumes is increasingly being banned in many localities not to mention a source of complaints from neighbors. No returns accepted on this item. This means you will probably need a separate circuit that is dedicated to run your filtration system. For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy? You want to be sure those are protected. If this filter does its job, it will greatly extend the life of the other filters in the system. See the sidebar accompanying this article for a list and contact information. the item is considered a custom product and is not returnable. If you are going to run your system 24/7, the difference in cost is certainly merited but for normal use, the need to replace brushes probably will never happen so it is an option that you can justify either way. Copyright 2020 Selecting a system that removes as much particulate as possible in the first stage, either by gravity or by filter, is one way to greatly extend the life of the other more expensive filters. It puts out less RF, runs quieter and cooler, and should last longer without attention, but you will have to decide if the difference in cost is worth it to you. or more (the charcoal filter weighs 40 lbs by itself). By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. Keeping the environment and operators safe when using our systems was extremely important and the number one thing we kept in mind when searching for a fume extraction system supplier. Here, ventless filtration systems are a necessity. Most filtration systems create 55-65 dBs of noise.

Reducing the airflow reduces air noise and extends the life of the filter media. Johnson Plastics Plus is located in the United States of America. And the good news is A good filtration system can last decades when given the proper care. Most systems are designed to run on both but check to be sure. Most of us dont have shipping docks so heavy deliveries must be carefully scheduled. Although the cellphone concept might be overkill for most of us, it is helpful to have some diagnostic ability with these systems. One is the ability to filter volatile organic compounds (VOCs). We call it the LASER BLUE GEL. Products shipped direct to you factory fresh. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. Applied Adhesive The XL-300 filter cores should be replaced on average after60-80 hours of use, however, this is just a guideline. SHIPPING: Most filtrations systems adequate for our industry are heavyat least 100-200 lbs. A special range of filters are available for cutting thicker metals with MicroStep machines - please contact us for details. The Filtration System consists of a 5 layer filter core to intercept airborne particles, absorb gases and odors and purify air output. And {{cart.summary_count - 3}} other items in your cart Add {{price(remainder)}} to qualify for free shipping*, You qualify for

There are a number of filtration manufacturers in the U.S. and around the world. Running the wrong cycle rating can and will damage equipment.

There are a number of filtration manufacturers in the U.S. and around the world. Running the wrong cycle rating can and will damage equipment.  LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well. Use collapsible tabs for more detailed information that will help customers make a purchasing decision. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable.

LASER INTERFACE: Some units come with an electrical interface that connects with your laser so when you turn on your laser, the filtration device activates as well. Use collapsible tabs for more detailed information that will help customers make a purchasing decision. When added to the noise of one or more lasers, and perhaps a rotary engraver or two, the noise level can be uncomfortable.  Find more information on them here. In the U.S., we generally refer to airflow in CFM (cubic feet per minute). NOISE: Filtration devices include a motor and they are pulling a lot of air. Prices and offers are subject to change. These cant be trapped in ordinary paper filters. We recommend checking the filters on a bi-weekly basisto monitor debris build-up. This feature is also helpful when running multiple lasers through a single filtration system as the volume of CFM will need to be changed when multiple lasers are running vs. reduced when only one laser is running. The larger the laser, the more exhaust it will require. Illustration courtesy of BOFA Americas, Inc. Obviously, these gases and particles cant be exhausted into a work environment because of the potentially deadly consequences. A system that meets your needs and has affordable filters will save a lot of money over the lifespan of the system. Laser marking and coding of packaging and products with traceable information such as barcodes, batch codes and sell by dates. Without an adequate filtration system, using a laser would be impossible. To learn more, visit their website at www.cmu.edu/ehs. Most of us, however, should be happy with 40 lbs. Adapt Laser specializes in providing the highest-quality laser cleaning systems available.

Find more information on them here. In the U.S., we generally refer to airflow in CFM (cubic feet per minute). NOISE: Filtration devices include a motor and they are pulling a lot of air. Prices and offers are subject to change. These cant be trapped in ordinary paper filters. We recommend checking the filters on a bi-weekly basisto monitor debris build-up. This feature is also helpful when running multiple lasers through a single filtration system as the volume of CFM will need to be changed when multiple lasers are running vs. reduced when only one laser is running. The larger the laser, the more exhaust it will require. Illustration courtesy of BOFA Americas, Inc. Obviously, these gases and particles cant be exhausted into a work environment because of the potentially deadly consequences. A system that meets your needs and has affordable filters will save a lot of money over the lifespan of the system. Laser marking and coding of packaging and products with traceable information such as barcodes, batch codes and sell by dates. Without an adequate filtration system, using a laser would be impossible. To learn more, visit their website at www.cmu.edu/ehs. Most of us, however, should be happy with 40 lbs. Adapt Laser specializes in providing the highest-quality laser cleaning systems available.  MULTIPLE VOLTAGE CAPABILITY: Most places in the U.S. will provide 110-120 volts and 220-240 volts of power supply, and most people will run their lasers and filtration systems at 110-120 volts. Many engravers who work with lasers are fortunate to be able to vent their lasers to the outside. Buy the system that will meet your needs both now and in the future. Selecting one model over another can be difficult. This device is responsible for removing the really tiny particles from the air stream. All Rights Reserved. The smaller the particle the system is capable of catching, the better. Optional: 2, 3 or 4" diameter, Optional 10" or 12" discharge collars for venting to the exterior, Suction hose: 12 feet (3.6m) of flexible hose & clamps. Searching out a unit that doesnt have features you dont need might help keep the cost down but be careful since, as you eliminate features, you might be making your system more difficult to use or service. In the most basic terms, all filtration systems work the same way.

MULTIPLE VOLTAGE CAPABILITY: Most places in the U.S. will provide 110-120 volts and 220-240 volts of power supply, and most people will run their lasers and filtration systems at 110-120 volts. Many engravers who work with lasers are fortunate to be able to vent their lasers to the outside. Buy the system that will meet your needs both now and in the future. Selecting one model over another can be difficult. This device is responsible for removing the really tiny particles from the air stream. All Rights Reserved. The smaller the particle the system is capable of catching, the better. Optional: 2, 3 or 4" diameter, Optional 10" or 12" discharge collars for venting to the exterior, Suction hose: 12 feet (3.6m) of flexible hose & clamps. Searching out a unit that doesnt have features you dont need might help keep the cost down but be careful since, as you eliminate features, you might be making your system more difficult to use or service. In the most basic terms, all filtration systems work the same way.  For me, cutting acrylic is the worst. The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. Johnson Plastics Plus has four great options for double-sided adhesive Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece. United Kingdom This gives the charcoal time to actually absorb the odors and other hazardous fumes.

For me, cutting acrylic is the worst. The XL-300 Filtration System is easy to set up and maintain in settings where external ventilation is not an option. Johnson Plastics Plus has four great options for double-sided adhesive Some Universal Laser Systems lasers like the VLS2.30 are available with a custom laser fume filtration system stacked beneath the laser, making a single piece. United Kingdom This gives the charcoal time to actually absorb the odors and other hazardous fumes.  Unfortunately, we dont. Thank you to all at CTR for collaborating with Cross to build us a bespoke machine. There are many models, features, options and sizes.

Unfortunately, we dont. Thank you to all at CTR for collaborating with Cross to build us a bespoke machine. There are many models, features, options and sizes.  To underrate a laser means the filtration either isnt going to be adequate or the filters are going to require more frequent replacement. Without a way to accurately read this, you will likely run the system too slow, which doesnt let it do its job, or too fast, which shortens the life of the HEPA filter. Most of Europe is 220 volts and most lasers and filtration systems offer both standard voltages, but if there is any chance you might take your equipment on a sightseeing tour of the world, or the area where you live struggles to maintain consistent voltages, it is nice to have an automated voltage selector on your filtration system that can detect the actual voltage (not just what it is supposed to be) and adjust accordingly. To determine this, add the number of amps listed for your laser(s) and for the filtration system. Coding for Climate Webinars (CanCode 3.0). T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. The quiet and compact Advantage 350 is ideal for use in light duty laser marking applications, including schools, sign making workshops and small scale industrial environments. The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. Although you might think of this as just a convenience, it is also a safety feature that ensures the operator never forgets to turn it on and endanger their health. This seems to be pretty consistent across the industry but it is important to consider. If you have attended a tradeshow where working lasers are displayed, you have probably noticed they all have filtration systems connected to their lasers. Box 318 Brighton, MI 48116-0318 In Europe, however, this isnt the case, so an indoor ventless filtration system is required for most lasers. This means it can be broken down into components and shipped using regular UPS. {{product.adhesive===''?'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}. Opinions vary as to which is the best design. The air quality control people, for the most part, have left engraving shops untouched by strict regulations. Call us toll free 1-800-626-0664 for help with your product selection.

To underrate a laser means the filtration either isnt going to be adequate or the filters are going to require more frequent replacement. Without a way to accurately read this, you will likely run the system too slow, which doesnt let it do its job, or too fast, which shortens the life of the HEPA filter. Most of Europe is 220 volts and most lasers and filtration systems offer both standard voltages, but if there is any chance you might take your equipment on a sightseeing tour of the world, or the area where you live struggles to maintain consistent voltages, it is nice to have an automated voltage selector on your filtration system that can detect the actual voltage (not just what it is supposed to be) and adjust accordingly. To determine this, add the number of amps listed for your laser(s) and for the filtration system. Coding for Climate Webinars (CanCode 3.0). T: 0844 800 4727 or 01604 675 417, 2022 CTR Lasers 2022 Freetimers for Web Programming & CMS Website Design and Programming by Freetimers, Case Study; Bespoke Laser Machine for Major UK Car Manufacturer. The quiet and compact Advantage 350 is ideal for use in light duty laser marking applications, including schools, sign making workshops and small scale industrial environments. The Filtrabox Expand series laser fume extractor from PAT Technology Systems, Inc. pulls fumes from the laser and purifies the air using three independent filters. Although you might think of this as just a convenience, it is also a safety feature that ensures the operator never forgets to turn it on and endanger their health. This seems to be pretty consistent across the industry but it is important to consider. If you have attended a tradeshow where working lasers are displayed, you have probably noticed they all have filtration systems connected to their lasers. Box 318 Brighton, MI 48116-0318 In Europe, however, this isnt the case, so an indoor ventless filtration system is required for most lasers. This means it can be broken down into components and shipped using regular UPS. {{product.adhesive===''?'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}. Opinions vary as to which is the best design. The air quality control people, for the most part, have left engraving shops untouched by strict regulations. Call us toll free 1-800-626-0664 for help with your product selection.  CTR will simply wheel in your laser machine and filter unit, link them up, and talk you through the simple process of using them. that we can directly apply to your sheet stock before it's shipped to you. Whilst it can be beneficial to understand some of the pitfalls that can occur when cutting certain types of plastics, it's important to relate the question to the exact device you're using and the plastic you're cutting. The amount of CFM a filtration system can develop is significant and should be matched carefully with the specifications of each laser.

CTR will simply wheel in your laser machine and filter unit, link them up, and talk you through the simple process of using them. that we can directly apply to your sheet stock before it's shipped to you. Whilst it can be beneficial to understand some of the pitfalls that can occur when cutting certain types of plastics, it's important to relate the question to the exact device you're using and the plastic you're cutting. The amount of CFM a filtration system can develop is significant and should be matched carefully with the specifications of each laser.  In other parts of the world, it is rated by m3/h (cubic meters per hour). After systems are out in the field for a few years, developers at TEKA will take feedback from customers and incorporate it into their existing designs to better match changing customer needs. For our purposes, we will consider six companies that are well-known and involved in our industry. E: info@ctrfuture.co.uk Filtration units that weigh 100 lbs. Some of the really large systems, of course, use more and if you plan to run multiple lasers with the same filtration system or you are running an unusually large laser or cutting certain materials, you might want to consider finding a system with larger charcoal filters. Second, go with a major, well-known company in the industry, one that has service capabilities near you if possible. These coarse to extremely fine paper filters can trap particles as small as 0.001mm (many times smaller than a human hair). Down-flow filtration systems generally use a pleated filter made of paper, glass fiber, etc., to catch the big particles and serve as a first stage of filtration. Forms, TECH One feature which might be nice but is certainly not mandatory for most of us is the ability to place a small air compressor (for air assist) inside the filtration cabinet just to get it out of the way and perhaps reduce some of the noise. IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. (BOFA says their carbon filter can capture 99.997% down to 3 microns and 95% down to 1 micron.). of activated charcoal. Lasers can expel some pretty deadly gases and particles when engraving and cutting certain materials. Brush motors, like we have all used for 100+ years, are less expensive but they have something called brushes that brush up against the armature to transfer electricity. Our systems come in both handheld and automated options making them versatile for different applications and surface preparation. The idea to sell fume extraction systems in conjunction with our lasers came from the filter units themselves, as we wanted the ability to pair our top of the line laser cleaning systems with fume extractors of equal caliber. The activated charcoal actually absorbs the odors. For the best experience on our site, be sure to turn on Javascript in your browser. For this feature to be effective, it is important to have a device that displays what the actual amount of airflow is in real time. OSHA, the Occupational, Safety and Health Administration, has identified over 200 such agents that can cause asthma and even cancer. My best advice is first, take your time and talk to company representatives but also their customers.

In other parts of the world, it is rated by m3/h (cubic meters per hour). After systems are out in the field for a few years, developers at TEKA will take feedback from customers and incorporate it into their existing designs to better match changing customer needs. For our purposes, we will consider six companies that are well-known and involved in our industry. E: info@ctrfuture.co.uk Filtration units that weigh 100 lbs. Some of the really large systems, of course, use more and if you plan to run multiple lasers with the same filtration system or you are running an unusually large laser or cutting certain materials, you might want to consider finding a system with larger charcoal filters. Second, go with a major, well-known company in the industry, one that has service capabilities near you if possible. These coarse to extremely fine paper filters can trap particles as small as 0.001mm (many times smaller than a human hair). Down-flow filtration systems generally use a pleated filter made of paper, glass fiber, etc., to catch the big particles and serve as a first stage of filtration. Forms, TECH One feature which might be nice but is certainly not mandatory for most of us is the ability to place a small air compressor (for air assist) inside the filtration cabinet just to get it out of the way and perhaps reduce some of the noise. IMPORTANT:Please be aware that venting to the atmosphere will not remove any harmful particles from fumes that may be created by laser cutting/engraving a material. (BOFA says their carbon filter can capture 99.997% down to 3 microns and 95% down to 1 micron.). of activated charcoal. Lasers can expel some pretty deadly gases and particles when engraving and cutting certain materials. Brush motors, like we have all used for 100+ years, are less expensive but they have something called brushes that brush up against the armature to transfer electricity. Our systems come in both handheld and automated options making them versatile for different applications and surface preparation. The idea to sell fume extraction systems in conjunction with our lasers came from the filter units themselves, as we wanted the ability to pair our top of the line laser cleaning systems with fume extractors of equal caliber. The activated charcoal actually absorbs the odors. For the best experience on our site, be sure to turn on Javascript in your browser. For this feature to be effective, it is important to have a device that displays what the actual amount of airflow is in real time. OSHA, the Occupational, Safety and Health Administration, has identified over 200 such agents that can cause asthma and even cancer. My best advice is first, take your time and talk to company representatives but also their customers.  'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}, {{adhesive.label.replace('+',`+${adhesivePrice(adhesive.price,product.sku,product.uom)}`)}}, Credit Application & Tax Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation. TEKAs high-quality filtration systems paired with their reliability in performance soon proved to be a perfect match for our state-of-the-art laser cleaning systems. The AIRDOCK from PAT Technology Systems, Inc. is completely modular, allowing you to change the configuration to fit your needs at any given time. PRE-FILTERS: As the name suggests, these filters are first in line. Website Design and Programming by Freetimers, Laser Cutters for Schools and Universities. The fume filtration units are constructed of corrosion resistant stainless steel, and are mounted on four castors for increased mobility. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. Click here for more health and safety information. Noise is measured in dBs (decibels). | a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. The first stage removes the largest particles.

'None':adhesiveOptions[product.adhesive].label.replace('+',`+${adhesivePrice(adhesiveOptions[product.adhesive].price,product.sku,product.uom)}`)}}, {{adhesive.label.replace('+',`+${adhesivePrice(adhesive.price,product.sku,product.uom)}`)}}, Credit Application & Tax Of even greater concern to laser engraving and cutting businesses is breathing these fumes in a location with no exterior ventilation. TEKAs high-quality filtration systems paired with their reliability in performance soon proved to be a perfect match for our state-of-the-art laser cleaning systems. The AIRDOCK from PAT Technology Systems, Inc. is completely modular, allowing you to change the configuration to fit your needs at any given time. PRE-FILTERS: As the name suggests, these filters are first in line. Website Design and Programming by Freetimers, Laser Cutters for Schools and Universities. The fume filtration units are constructed of corrosion resistant stainless steel, and are mounted on four castors for increased mobility. Like us onFacebook, connect with us onLinkedIn, and subscribe to us onYouTube, Adapt Laser To Exhibit At Warrior East 2022, Safety Tip: Designate A Laser Safety Officer, Adapt Laser Hosts Summer Internship Opportunity, HEPA filters are 99.99% effective at capturing particles as small as 0.3 micrometers, ULPA filters are 99.9995% effective and capture particles as small as .12 micrometers. Click here for more health and safety information. Noise is measured in dBs (decibels). | a backdraft eliminator or louvre vent to ensure that the wind, rain and elements do not blow back through the ventillation hole and affect the laser machine. The first stage removes the largest particles.  That means the blower isnt exhausting all of the odor (odor is actually caused by super-fine particles in the air). Finally, take the time, energy and money necessary to maintain your system properly. To do that, lets consider the various features offered by some of the leading companies. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. (45 kg) of chemical filtration media, Motor(s): 3 X 1.0 kW High Speed Turbine, UL & CSA Listed, Dimensions: 16"W x 25"D x 30"H / 406mm x 635mm x 760mm, Filter Sequence: Multi layered knock-out pad (1 / inlet) (F166-125), 2 x Pleated pre-filter, 30% ASHRAE rated (F071), 2 x 2 Medical grade HEPA filter 99.97% (F074), 2 x 8 Chemical filter (AG097), Optional lnlets: 1.5, 2, 2.5, 3 or 4" diameter, Front door access to filters and the motor blower, Also available: articulated arms, hoods and ducting accessories, Dimensions: 24"W x 26"D x 71"H / 610mm x 660mm x 1800mm, Filtration: Pre-filters, Medical grade HEPA filters 99.97%, Chemical filter, up to 200 lbs / 90kg, lnlets: 6 standard. (23 kg) of chemical filtration media, LaserBlue gel seal guarantees ZERO FILTER BYPASS, Dual high speed turbine for high suction, pressure and airflow, Dimensions: 12"W x 15"D x 24"H / 304mm x 381mm x 762mm, Filter Sequence: Multi layered knock-out pad (F166-125), Pleated pre-filter, 30% ASHRAE rated (F071), 2 Medical grade HEPA filter 99.97% (F074), 8 Chemical filter (AG097), Optional lnlets: 2, 3 or 4" diameter.

That means the blower isnt exhausting all of the odor (odor is actually caused by super-fine particles in the air). Finally, take the time, energy and money necessary to maintain your system properly. To do that, lets consider the various features offered by some of the leading companies. Warranties wont cover filters, but there is also a fairly expensive blower motor and some electronics in these devices. (45 kg) of chemical filtration media, Motor(s): 3 X 1.0 kW High Speed Turbine, UL & CSA Listed, Dimensions: 16"W x 25"D x 30"H / 406mm x 635mm x 760mm, Filter Sequence: Multi layered knock-out pad (1 / inlet) (F166-125), 2 x Pleated pre-filter, 30% ASHRAE rated (F071), 2 x 2 Medical grade HEPA filter 99.97% (F074), 2 x 8 Chemical filter (AG097), Optional lnlets: 1.5, 2, 2.5, 3 or 4" diameter, Front door access to filters and the motor blower, Also available: articulated arms, hoods and ducting accessories, Dimensions: 24"W x 26"D x 71"H / 610mm x 660mm x 1800mm, Filtration: Pre-filters, Medical grade HEPA filters 99.97%, Chemical filter, up to 200 lbs / 90kg, lnlets: 6 standard. (23 kg) of chemical filtration media, LaserBlue gel seal guarantees ZERO FILTER BYPASS, Dual high speed turbine for high suction, pressure and airflow, Dimensions: 12"W x 15"D x 24"H / 304mm x 381mm x 762mm, Filter Sequence: Multi layered knock-out pad (F166-125), Pleated pre-filter, 30% ASHRAE rated (F071), 2 Medical grade HEPA filter 99.97% (F074), 8 Chemical filter (AG097), Optional lnlets: 2, 3 or 4" diameter.  A HEPA filter can handle particles down to 1 micron. The temptation to buy based on cost, however, is a poor one. Actually, the venting of smoke and other combustion fumes is increasingly being banned in many localities not to mention a source of complaints from neighbors. No returns accepted on this item. This means you will probably need a separate circuit that is dedicated to run your filtration system. For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy? You want to be sure those are protected. If this filter does its job, it will greatly extend the life of the other filters in the system. See the sidebar accompanying this article for a list and contact information. the item is considered a custom product and is not returnable. If you are going to run your system 24/7, the difference in cost is certainly merited but for normal use, the need to replace brushes probably will never happen so it is an option that you can justify either way. Copyright 2020 Selecting a system that removes as much particulate as possible in the first stage, either by gravity or by filter, is one way to greatly extend the life of the other more expensive filters. It puts out less RF, runs quieter and cooler, and should last longer without attention, but you will have to decide if the difference in cost is worth it to you. or more (the charcoal filter weighs 40 lbs by itself). By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. Keeping the environment and operators safe when using our systems was extremely important and the number one thing we kept in mind when searching for a fume extraction system supplier. Here, ventless filtration systems are a necessity. Most filtration systems create 55-65 dBs of noise.

A HEPA filter can handle particles down to 1 micron. The temptation to buy based on cost, however, is a poor one. Actually, the venting of smoke and other combustion fumes is increasingly being banned in many localities not to mention a source of complaints from neighbors. No returns accepted on this item. This means you will probably need a separate circuit that is dedicated to run your filtration system. For over 40 years, laser cutters have improved in terms of speed, performance and quality, but what about accuracy? You want to be sure those are protected. If this filter does its job, it will greatly extend the life of the other filters in the system. See the sidebar accompanying this article for a list and contact information. the item is considered a custom product and is not returnable. If you are going to run your system 24/7, the difference in cost is certainly merited but for normal use, the need to replace brushes probably will never happen so it is an option that you can justify either way. Copyright 2020 Selecting a system that removes as much particulate as possible in the first stage, either by gravity or by filter, is one way to greatly extend the life of the other more expensive filters. It puts out less RF, runs quieter and cooler, and should last longer without attention, but you will have to decide if the difference in cost is worth it to you. or more (the charcoal filter weighs 40 lbs by itself). By the late 1960s, gas laser cutting was being used to cut through metal with ease and accuracy, something that CO2 lasers originally hadn't been capable of. Keeping the environment and operators safe when using our systems was extremely important and the number one thing we kept in mind when searching for a fume extraction system supplier. Here, ventless filtration systems are a necessity. Most filtration systems create 55-65 dBs of noise.  Reducing the airflow reduces air noise and extends the life of the filter media. Johnson Plastics Plus is located in the United States of America. And the good news is A good filtration system can last decades when given the proper care. Most systems are designed to run on both but check to be sure. Most of us dont have shipping docks so heavy deliveries must be carefully scheduled. Although the cellphone concept might be overkill for most of us, it is helpful to have some diagnostic ability with these systems. One is the ability to filter volatile organic compounds (VOCs). We call it the LASER BLUE GEL. Products shipped direct to you factory fresh. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. Applied Adhesive The XL-300 filter cores should be replaced on average after60-80 hours of use, however, this is just a guideline. SHIPPING: Most filtrations systems adequate for our industry are heavyat least 100-200 lbs. A special range of filters are available for cutting thicker metals with MicroStep machines - please contact us for details. The Filtration System consists of a 5 layer filter core to intercept airborne particles, absorb gases and odors and purify air output. And {{cart.summary_count - 3}} other items in your cart Add {{price(remainder)}} to qualify for free shipping*, You qualify for

Reducing the airflow reduces air noise and extends the life of the filter media. Johnson Plastics Plus is located in the United States of America. And the good news is A good filtration system can last decades when given the proper care. Most systems are designed to run on both but check to be sure. Most of us dont have shipping docks so heavy deliveries must be carefully scheduled. Although the cellphone concept might be overkill for most of us, it is helpful to have some diagnostic ability with these systems. One is the ability to filter volatile organic compounds (VOCs). We call it the LASER BLUE GEL. Products shipped direct to you factory fresh. For example, over time weve found that the LFE 401 works really well with mid power and high power cleaning lasers, as its fairly high capacity while still being a compact system. Applied Adhesive The XL-300 filter cores should be replaced on average after60-80 hours of use, however, this is just a guideline. SHIPPING: Most filtrations systems adequate for our industry are heavyat least 100-200 lbs. A special range of filters are available for cutting thicker metals with MicroStep machines - please contact us for details. The Filtration System consists of a 5 layer filter core to intercept airborne particles, absorb gases and odors and purify air output. And {{cart.summary_count - 3}} other items in your cart Add {{price(remainder)}} to qualify for free shipping*, You qualify for