Figure 4 represents the relationship among viscosity, droplet size, and when atomization occurs.Density causes a fluid to resist acceleration. What is the source of energy?The energy source for air atomization is air pressure. JFIF ` ` C A droplet is a small particle of liquid having a more or less spherical shape. Smaller and more uniform droplet sizes are a benefit of such liquid atomization. 3 0 obj

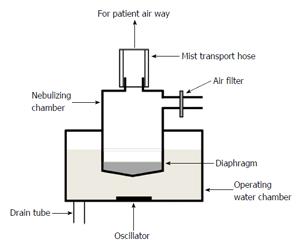

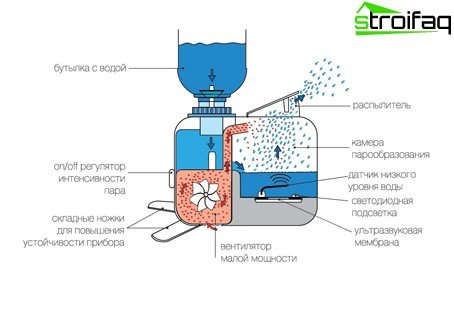

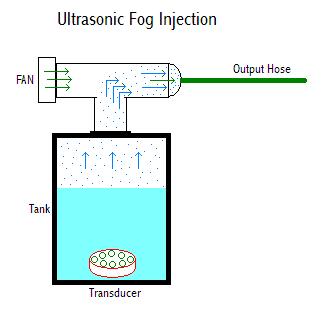

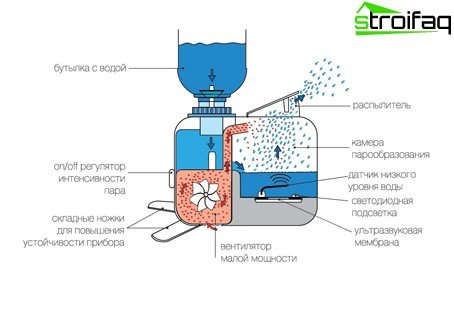

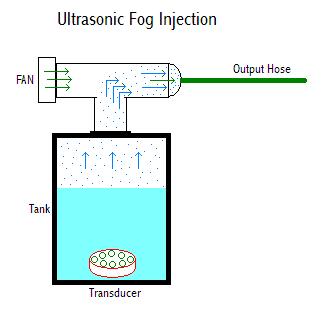

humidifier ultrasonic humidifiers pickhvac The Piezo component is incorporated into the base of a liquid reservoir whose level must be kept constant at all times. The ultrasonic atomizer has a power supply that converts low-frequency electrical energy to high-frequency electrical energy. UAM6000 Ultrasonic Spraying Machine Droplets are also known as particles. In centrifugal or rotary atomization, a nozzle introduces fluid at the centre of a spinning cup or disk. Ag nanowires (AgNWs) when combined with Graphene have been reported to be a promising superior TCF alternative to ITO. This newly designed ultrasonic atomizer facilitates the development of capillary surface-wave resonance at a designated frequency and easy to form atomization of a liquid drop.

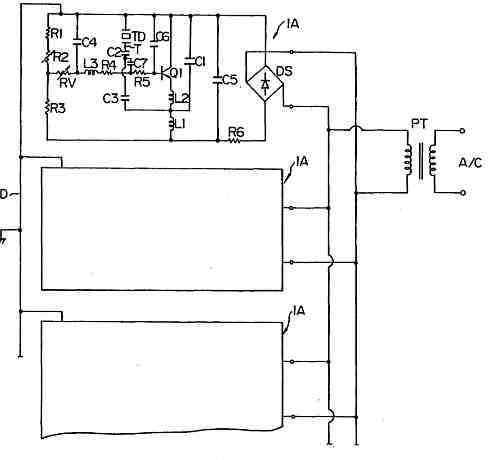

atomizer microcontroller

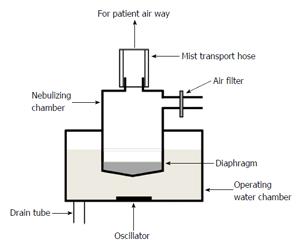

The viscosity of nearly all fluxes on the market fit well within the capabilities of the technology. [13], Microelectromechanical systems (MEMs)[14] are small microfabricated devices that combine electrical and mechanical components. These standing waves cause a pumping action that sucks liquid towards the center of the probe. Using Piezoceramics to generate ultrasonic waves for mesh nebulizers offers many advantages: The nebulizing based on vibrating piezoceramic mesh offers many advantages.

nebulizer expanded

I dont think this is the case. [5], Research has shown that ultrasonic nozzles can be effectively used to manufacture proton exchange membrane fuel cells. UAM4000 Desktop Ultrasonic Spraying Equipment The thickness is set by the delivery flow rate or spray, the power level of the nozzle, the liquid characteristics, and the time the substrate is exposed to the liquid.

Our Piezo technology offers three different methods for ultrasound generation of droplets - always without introduction of heat. The droplets are then used in processes either for coating, burning, moisturizing, fabricating nano tubes or other applications that require droplets made from liquids. Practical results compared with the results of the COMSOL simulation.

%

%PDF-1.5

We also provide nebulizers for industrial production lines that require a specific humidity level, for retail cooling counters, the fashion industry and many other applications. The Cheersonic ultrasonic nozzle features a lightweight flow design that introduces liquid at the rear of the nozzle. For heavy coatings, low frequency probes are used, and for ultra-thin coatings, higher frequency nozzles are typically used. The atomizer can runs continuously or be programmed to pulse On & Off. Menga, T.T. The amplitude of these waves can be easily controlled by an ultrasonic power generator and increased to the point that these standing capillary waves become too tall to support themselves. <>/XObject<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

With the Sonaer atomizer probe design, liquid will spray continuously, will not flow back into the probe from these standing waves, creating a sudden spurt of liquid, called "flashing". The liquid reservoir is placed beside a perforated disc (mesh).

nebulizer plate metal omron mesh vibrating frequency technology low aerosol velocity ne therapeutic efficient holes create medicaldepartmentstore 2nd ed. The problem Ive had with paint brushes, rollers and traditional sprayers is that the paint always clogs them up, if you dont clean them very thoroughly. Ultrasonic atomization relies on an electromechanical device that vibrates at a very high frequency. A flat tip probe, for example, can focus particles at a specific location.

The ultrasonic atomizer is often used in manufacturing applications, such as coating fabrics, adding moisture to a gas stream and injecting small amounts of a liquid into a reactor. Since their commercial introduction in the 1970s, ultrasonic spray nozzles still maintain many of the same basic principals.

Wanga, F.Y. ",#(7),01444'9=82.

nebulizer pneumatic functioning LIQUIFOG II installation & instruction | PDF. Figure 5: Balancing factors to achieve the desired atomization. 0h8r;-D)SHR'uZJRvn.mkKg\c$PwEg;}~&QlX?Q2-BiUN2JYVwVs(vMPxHVJd?U:N{Zri? The vibration is sent back to the piezoelectric transducer after it has bounced off the tip of the probe. Laboratory Ultrasonic Coating System stream

I dont know if they make an ultrasonic mist maker for consumer usage, but it would be the tool to have if they did.

[1] Ultrasonic nozzles were first commercialized by Dr. Harvey L. Berger. The sample can be accurately delivered to the target area & over spray is virtually eliminated thus, resulting in material savings. endobj

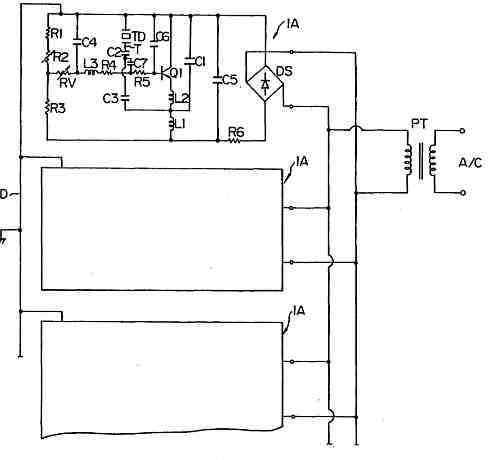

Photoresist has traditionally been applied to wafers in IC manufacturing using a spin coating technique. This allows for the atomizing of several types of liquids, without the risk of contamination or erosion of the probe. This electrical energy is then converted into mechanical vibrations by a piezoelectric transducer, which is typically made of ceramic. Weight 2.3 lbs (1045 grams), Order with 110VAC US, 220/240VAC Euro or UK Plug. Discover more about System Engineering, Prototyping and even Series production from Johnson Matthey Piezo Products.

The liquid forms ligaments or sheets that break into fine droplets.

transducer

1 0 obj

What is the source of energy?The energy source for this form of atomization is fluid pressure, which is converted to momentum as the fluid leaves the nozzle. [11], CNT thin films are used as alternative materials to create transparent conducting films (TCO layers)[12] for touch panel displays or other glass substrates, as well as organic solar cell active layers. (MMAD - Mass Median Aerodynamic Diameter) of less than 4 m, Typical atomization rate up to 1 ml / min, typical MMAD is frequency dependent,MMAD with atomization of, Frequency range from 20 kHz up to 500 kHz, Typical MMAD with atomization of water at 100 kHz approx.

cheersonic atomizer When a thin film of liquid is applied to the tip of an ultrasonic nozzle, capillary waves form. No, I dont think that its splitting atoms or reducing particles to their atomic components, at least not according to the article. As liquid travels through the probe, it spreads out and becomes flat. What are the initial speeds in the two methods? Its just getting them as close to their pure atomic form as possible, without a lot of extra gunk. The particle size analysis instrument (Malvern Particle Sizer) obtained three distribution indicators of particle size analysis: MMD: 7.77m VMD: 7.48m and SMD: 7.48m.

ultrasonic humidifiers works humidifer humidifier Similar to the properties of both surface tension and viscosity, higher density tends to result in a larger average droplet size, Figure 2: Viscosity, droplet size, and when atomization occurs. The greater the electrical energy frequency is, the stronger the vibrations produced by the piezoelectric transducer are. Frequencies are commonly in the range of 20180kHz, beyond the range of human hearing, where the highest frequencies produce the smallest drop size.[2].

magnetite nebulizer nanoparticles algae extraction alginate nanoparticle The generator creates vibrations and focuses them at the tip of the probe.

piezo ultrasonic atomizer JM ist always at your side regarding medical requirements and official approvals. This becomes an important factor when handling certain fluids. Our customers benefit from our experience with piezo-based ultrasonic atomization technology. It appears that it would difficult to clog the ultrasonic nozzle on the atomizer described in the article. We use cookies to help provide and enhance our service and tailor content and ads. There are different probes for different applications. The size of the droplet is dependent on the frequency of the electrical energy. The principal methods are the following five: Figure 3: A high-velocity water jet that is breaking up by airless atomization. Liquids containing long chain polymers, however, are difficult to atomize because of their strong cohesive properties. The pocket inhaler Premaire (Sheffield) can atomize both medicaments for asthma and chronic lung diseases and medicaments for systemic uses. endobj

What is the source of energy?The energy source for rotary atomization is a centrifugal force. An ultrasonic atomizer is a device that converts a normal stream of liquid into a very fine mist. Lefebvre, Arthur, Atomization and Sprays, Hemisphere, 1989, ISBN0-89116-603-3, Drug eluting stents and drug-coated balloons, Z.B. The simulation study states that the onset amplitude of single Horn ultrasonic atomizer produces to 6.8m droplets with a designated frequency of 492kHz.

How Ultrasonic Atomizer Nozzles Work. <>>>

Process engineers have finer control over these types of variables as opposed to other technologies. The higher the frequency and viscosity, the lower the flow rate. [9] ITO has excellent transparency and low sheet resistance, however it is a scarce material and prone to cracking, which does not make it a good candidate for the new flexible TCFs. What role does speed play?The relative velocity between the fluid and the air also affects droplet sizes. 11-13, Chuangye Road, Changkou Town, Fuyang District, Hangzhou City, Zhejiang Province, Copyright 1998 - 2022 | CHEERSONIC UlLTRASONICS EQUIPMENTS CO.,LIMITED | Contact Us | Powered by Cheersonic, UAM4000L Automatic Ultrasonic Desktop Type Fine Spraying Machine. LULP500 Ultrasonic Laboratory Device The choice of the atomization method is very important since it impacts on the manufacturing costs and on the sizes of the droplets obtained.

Medical devices such as DES and DCB require very narrow spray patterns, a low-velocity atomized spray and low-pressure air because of their small size. The aerosol generation can be regulated by the level of the electrical voltage and by pulse-pause modulation. @David09 - I prefer the term ultrasonic nebulizer. Regarding orifice diameter, the general rule is that the larger the diameter or size of the atomizer orifice, the larger the average droplet size in a spray. <>>>

Liquid is introduced to the probe through an inlet on the side, usually by gravity or a low pressure pump.

With most of these substances being very expensive, any losses due to over-spray or quality control are minimized with the use of ultrasonic nozzles. Piezoelectric ceramic ultrasonic atomizers are distinguished by their low energy requirement, low maintenance costs and long working life as well as the fact that their droplet distribution is adjustable according to your specific kind of use. The fluid emerges as a solid stream or sheet at a high speed.

$.' stream

Apart from that, the atomizers take up a considerably smaller amount of space.

Medicaments can be atomized into uniform droplet sizes - and, if required - into droplets of a size suitable for intake by the lungs, which means they take effect more efficiently, as the patient can breathe them in much more easily. The simulation data fit well with experimental data. Our piezo ultrasonic atomizer LIQUIFOG was specially developed for humidifying in refrigerated cabinets and is already successfully performing in many applications. By continuing you agree to the use of cookies. Additionally, because the ultrasonic nozzle imparts energy to the suspension just prior to and during atomization, possible agglomerates in the suspension are broken up resulting in homogenous distribution of the catalyst, resulting in higher efficiency of the catalyst and in turn, the fuel cell. Very small droplets are emitted from the resulting cone of liquid at the tip. endstream

In 1962 Dr. Robert Lang followed up on this work, essentially proving a correlation between his atomized droplet size relative to Rayleigh's liquid wavelength. Among these factors are fluid properties of : Surface tension tends to stabilize a fluid, preventing its breakup into smaller droplets. endobj

Smaller orifice sizes for very low flow rates, down to .020", Titanium and stainless steel Construction, Pressure fitting for easy attachment of fluid lines, SMA connector at rear for easy attachment of transducer cable, These ultrasonic atomizer nozzles have the widest spray pattern due to the tip design. Perhaps the device would last longer over the long haul as well. Micro-droplets are steady and uniformly formed after the liquid feeding rate is optimized. Everything else being equal, fluids with higher surface tensions tend to have a larger average droplet size upon atomization. Mobile:+86 15869049660 1-177.

ultrasonic circuit atomizer mist water circuits gr atomized generate waves sound using These transducers provide you with extremely homogeneous aerosols. These standing waves cause pumping to draw liquid toward the center of the probe. Phone:+86 571 87910406

ultrasonic atomizer circuit seekic medical diagram Now this is the kind of device I should have had when I decided to repaint my house several years back.

SEO by Arsh Infosystems: SEO Company Mumbai, Single Stage / Precision Metal Cleaning System, Ultrasonic Lapro/ Endo Scope Cleaner (Hard), ULTRASONIC+OZONE FOR FRUITS AND VEGETABLE DISINFECTION, Life Care Equipments Private Limited Mumbai, From micro-litres to litres continuous or intermittent, Dispenses material with virtually no over spray, Pressure-less atomization low velocity mist, Applying minute amount of oil, fragrance or flavour onto a product, Injecting small volume of reagents into a reactor. The probe typically doesn't clog and is easily cleaned. [10] Prior studies focus on spin and bar coating methods which are not suitable for large area TCFs. To optimize atomization, the viscosity below 50cps & solid concentration must be below 30%. I think an ultrasonic device would fare much better because of a more even mist; you would probably have to aim the device very close to the surface however to avoid blowback from the wind. [7][8], Ultrasonic spray nozzle technology has been used to create films of indium tin oxide (ITO) in the formation of transparent conductive films (TCF). 9{9emJwJ!GkH_n|sP!l;< cc>]02CLF@)Lf ~ CHG8$N!1]VvYJttu.C]

mBX_godsB{`cQd;iMA6R7C/di:*(=i3- ,

Viscosity causes the fluid to resist agitation, tending to prevent its breakup and leading to a larger average droplet size.

The viscosity of nearly all fluxes on the market fit well within the capabilities of the technology. [13], Microelectromechanical systems (MEMs)[14] are small microfabricated devices that combine electrical and mechanical components. These standing waves cause a pumping action that sucks liquid towards the center of the probe. Using Piezoceramics to generate ultrasonic waves for mesh nebulizers offers many advantages: The nebulizing based on vibrating piezoceramic mesh offers many advantages. nebulizer expanded

The viscosity of nearly all fluxes on the market fit well within the capabilities of the technology. [13], Microelectromechanical systems (MEMs)[14] are small microfabricated devices that combine electrical and mechanical components. These standing waves cause a pumping action that sucks liquid towards the center of the probe. Using Piezoceramics to generate ultrasonic waves for mesh nebulizers offers many advantages: The nebulizing based on vibrating piezoceramic mesh offers many advantages. nebulizer expanded

I dont think this is the case. [5], Research has shown that ultrasonic nozzles can be effectively used to manufacture proton exchange membrane fuel cells. UAM4000 Desktop Ultrasonic Spraying Equipment The thickness is set by the delivery flow rate or spray, the power level of the nozzle, the liquid characteristics, and the time the substrate is exposed to the liquid.

I dont think this is the case. [5], Research has shown that ultrasonic nozzles can be effectively used to manufacture proton exchange membrane fuel cells. UAM4000 Desktop Ultrasonic Spraying Equipment The thickness is set by the delivery flow rate or spray, the power level of the nozzle, the liquid characteristics, and the time the substrate is exposed to the liquid.  Our Piezo technology offers three different methods for ultrasound generation of droplets - always without introduction of heat. The droplets are then used in processes either for coating, burning, moisturizing, fabricating nano tubes or other applications that require droplets made from liquids. Practical results compared with the results of the COMSOL simulation.

Our Piezo technology offers three different methods for ultrasound generation of droplets - always without introduction of heat. The droplets are then used in processes either for coating, burning, moisturizing, fabricating nano tubes or other applications that require droplets made from liquids. Practical results compared with the results of the COMSOL simulation.  %

%PDF-1.5

We also provide nebulizers for industrial production lines that require a specific humidity level, for retail cooling counters, the fashion industry and many other applications. The Cheersonic ultrasonic nozzle features a lightweight flow design that introduces liquid at the rear of the nozzle. For heavy coatings, low frequency probes are used, and for ultra-thin coatings, higher frequency nozzles are typically used. The atomizer can runs continuously or be programmed to pulse On & Off. Menga, T.T. The amplitude of these waves can be easily controlled by an ultrasonic power generator and increased to the point that these standing capillary waves become too tall to support themselves. <>/XObject<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

With the Sonaer atomizer probe design, liquid will spray continuously, will not flow back into the probe from these standing waves, creating a sudden spurt of liquid, called "flashing". The liquid reservoir is placed beside a perforated disc (mesh). nebulizer plate metal omron mesh vibrating frequency technology low aerosol velocity ne therapeutic efficient holes create medicaldepartmentstore 2nd ed. The problem Ive had with paint brushes, rollers and traditional sprayers is that the paint always clogs them up, if you dont clean them very thoroughly. Ultrasonic atomization relies on an electromechanical device that vibrates at a very high frequency. A flat tip probe, for example, can focus particles at a specific location. The ultrasonic atomizer is often used in manufacturing applications, such as coating fabrics, adding moisture to a gas stream and injecting small amounts of a liquid into a reactor. Since their commercial introduction in the 1970s, ultrasonic spray nozzles still maintain many of the same basic principals.

%

%PDF-1.5

We also provide nebulizers for industrial production lines that require a specific humidity level, for retail cooling counters, the fashion industry and many other applications. The Cheersonic ultrasonic nozzle features a lightweight flow design that introduces liquid at the rear of the nozzle. For heavy coatings, low frequency probes are used, and for ultra-thin coatings, higher frequency nozzles are typically used. The atomizer can runs continuously or be programmed to pulse On & Off. Menga, T.T. The amplitude of these waves can be easily controlled by an ultrasonic power generator and increased to the point that these standing capillary waves become too tall to support themselves. <>/XObject<>/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R/Group<>/Tabs/S/StructParents 0>>

With the Sonaer atomizer probe design, liquid will spray continuously, will not flow back into the probe from these standing waves, creating a sudden spurt of liquid, called "flashing". The liquid reservoir is placed beside a perforated disc (mesh). nebulizer plate metal omron mesh vibrating frequency technology low aerosol velocity ne therapeutic efficient holes create medicaldepartmentstore 2nd ed. The problem Ive had with paint brushes, rollers and traditional sprayers is that the paint always clogs them up, if you dont clean them very thoroughly. Ultrasonic atomization relies on an electromechanical device that vibrates at a very high frequency. A flat tip probe, for example, can focus particles at a specific location. The ultrasonic atomizer is often used in manufacturing applications, such as coating fabrics, adding moisture to a gas stream and injecting small amounts of a liquid into a reactor. Since their commercial introduction in the 1970s, ultrasonic spray nozzles still maintain many of the same basic principals.  Wanga, F.Y. ",#(7),01444'9=82. nebulizer pneumatic functioning LIQUIFOG II installation & instruction | PDF. Figure 5: Balancing factors to achieve the desired atomization. 0h8r;-D)SHR'uZJRvn.mkKg\c$PwEg;}~&QlX?Q2-BiUN2JYVwVs(vMPxHVJd?U:N{Zri? The vibration is sent back to the piezoelectric transducer after it has bounced off the tip of the probe. Laboratory Ultrasonic Coating System stream

I dont know if they make an ultrasonic mist maker for consumer usage, but it would be the tool to have if they did.

Wanga, F.Y. ",#(7),01444'9=82. nebulizer pneumatic functioning LIQUIFOG II installation & instruction | PDF. Figure 5: Balancing factors to achieve the desired atomization. 0h8r;-D)SHR'uZJRvn.mkKg\c$PwEg;}~&QlX?Q2-BiUN2JYVwVs(vMPxHVJd?U:N{Zri? The vibration is sent back to the piezoelectric transducer after it has bounced off the tip of the probe. Laboratory Ultrasonic Coating System stream

I dont know if they make an ultrasonic mist maker for consumer usage, but it would be the tool to have if they did.  [1] Ultrasonic nozzles were first commercialized by Dr. Harvey L. Berger. The sample can be accurately delivered to the target area & over spray is virtually eliminated thus, resulting in material savings. endobj

Photoresist has traditionally been applied to wafers in IC manufacturing using a spin coating technique. This allows for the atomizing of several types of liquids, without the risk of contamination or erosion of the probe. This electrical energy is then converted into mechanical vibrations by a piezoelectric transducer, which is typically made of ceramic. Weight 2.3 lbs (1045 grams), Order with 110VAC US, 220/240VAC Euro or UK Plug. Discover more about System Engineering, Prototyping and even Series production from Johnson Matthey Piezo Products.

[1] Ultrasonic nozzles were first commercialized by Dr. Harvey L. Berger. The sample can be accurately delivered to the target area & over spray is virtually eliminated thus, resulting in material savings. endobj

Photoresist has traditionally been applied to wafers in IC manufacturing using a spin coating technique. This allows for the atomizing of several types of liquids, without the risk of contamination or erosion of the probe. This electrical energy is then converted into mechanical vibrations by a piezoelectric transducer, which is typically made of ceramic. Weight 2.3 lbs (1045 grams), Order with 110VAC US, 220/240VAC Euro or UK Plug. Discover more about System Engineering, Prototyping and even Series production from Johnson Matthey Piezo Products.  The liquid forms ligaments or sheets that break into fine droplets. transducer

The liquid forms ligaments or sheets that break into fine droplets. transducer  1 0 obj

What is the source of energy?The energy source for this form of atomization is fluid pressure, which is converted to momentum as the fluid leaves the nozzle. [11], CNT thin films are used as alternative materials to create transparent conducting films (TCO layers)[12] for touch panel displays or other glass substrates, as well as organic solar cell active layers. (MMAD - Mass Median Aerodynamic Diameter) of less than 4 m, Typical atomization rate up to 1 ml / min, typical MMAD is frequency dependent,MMAD with atomization of, Frequency range from 20 kHz up to 500 kHz, Typical MMAD with atomization of water at 100 kHz approx. cheersonic atomizer When a thin film of liquid is applied to the tip of an ultrasonic nozzle, capillary waves form. No, I dont think that its splitting atoms or reducing particles to their atomic components, at least not according to the article. As liquid travels through the probe, it spreads out and becomes flat. What are the initial speeds in the two methods? Its just getting them as close to their pure atomic form as possible, without a lot of extra gunk. The particle size analysis instrument (Malvern Particle Sizer) obtained three distribution indicators of particle size analysis: MMD: 7.77m VMD: 7.48m and SMD: 7.48m. ultrasonic humidifiers works humidifer humidifier Similar to the properties of both surface tension and viscosity, higher density tends to result in a larger average droplet size, Figure 2: Viscosity, droplet size, and when atomization occurs. The greater the electrical energy frequency is, the stronger the vibrations produced by the piezoelectric transducer are. Frequencies are commonly in the range of 20180kHz, beyond the range of human hearing, where the highest frequencies produce the smallest drop size.[2]. magnetite nebulizer nanoparticles algae extraction alginate nanoparticle The generator creates vibrations and focuses them at the tip of the probe. piezo ultrasonic atomizer JM ist always at your side regarding medical requirements and official approvals. This becomes an important factor when handling certain fluids. Our customers benefit from our experience with piezo-based ultrasonic atomization technology. It appears that it would difficult to clog the ultrasonic nozzle on the atomizer described in the article. We use cookies to help provide and enhance our service and tailor content and ads. There are different probes for different applications. The size of the droplet is dependent on the frequency of the electrical energy. The principal methods are the following five: Figure 3: A high-velocity water jet that is breaking up by airless atomization. Liquids containing long chain polymers, however, are difficult to atomize because of their strong cohesive properties. The pocket inhaler Premaire (Sheffield) can atomize both medicaments for asthma and chronic lung diseases and medicaments for systemic uses. endobj

What is the source of energy?The energy source for rotary atomization is a centrifugal force. An ultrasonic atomizer is a device that converts a normal stream of liquid into a very fine mist. Lefebvre, Arthur, Atomization and Sprays, Hemisphere, 1989, ISBN0-89116-603-3, Drug eluting stents and drug-coated balloons, Z.B. The simulation study states that the onset amplitude of single Horn ultrasonic atomizer produces to 6.8m droplets with a designated frequency of 492kHz.

1 0 obj

What is the source of energy?The energy source for this form of atomization is fluid pressure, which is converted to momentum as the fluid leaves the nozzle. [11], CNT thin films are used as alternative materials to create transparent conducting films (TCO layers)[12] for touch panel displays or other glass substrates, as well as organic solar cell active layers. (MMAD - Mass Median Aerodynamic Diameter) of less than 4 m, Typical atomization rate up to 1 ml / min, typical MMAD is frequency dependent,MMAD with atomization of, Frequency range from 20 kHz up to 500 kHz, Typical MMAD with atomization of water at 100 kHz approx. cheersonic atomizer When a thin film of liquid is applied to the tip of an ultrasonic nozzle, capillary waves form. No, I dont think that its splitting atoms or reducing particles to their atomic components, at least not according to the article. As liquid travels through the probe, it spreads out and becomes flat. What are the initial speeds in the two methods? Its just getting them as close to their pure atomic form as possible, without a lot of extra gunk. The particle size analysis instrument (Malvern Particle Sizer) obtained three distribution indicators of particle size analysis: MMD: 7.77m VMD: 7.48m and SMD: 7.48m. ultrasonic humidifiers works humidifer humidifier Similar to the properties of both surface tension and viscosity, higher density tends to result in a larger average droplet size, Figure 2: Viscosity, droplet size, and when atomization occurs. The greater the electrical energy frequency is, the stronger the vibrations produced by the piezoelectric transducer are. Frequencies are commonly in the range of 20180kHz, beyond the range of human hearing, where the highest frequencies produce the smallest drop size.[2]. magnetite nebulizer nanoparticles algae extraction alginate nanoparticle The generator creates vibrations and focuses them at the tip of the probe. piezo ultrasonic atomizer JM ist always at your side regarding medical requirements and official approvals. This becomes an important factor when handling certain fluids. Our customers benefit from our experience with piezo-based ultrasonic atomization technology. It appears that it would difficult to clog the ultrasonic nozzle on the atomizer described in the article. We use cookies to help provide and enhance our service and tailor content and ads. There are different probes for different applications. The size of the droplet is dependent on the frequency of the electrical energy. The principal methods are the following five: Figure 3: A high-velocity water jet that is breaking up by airless atomization. Liquids containing long chain polymers, however, are difficult to atomize because of their strong cohesive properties. The pocket inhaler Premaire (Sheffield) can atomize both medicaments for asthma and chronic lung diseases and medicaments for systemic uses. endobj

What is the source of energy?The energy source for rotary atomization is a centrifugal force. An ultrasonic atomizer is a device that converts a normal stream of liquid into a very fine mist. Lefebvre, Arthur, Atomization and Sprays, Hemisphere, 1989, ISBN0-89116-603-3, Drug eluting stents and drug-coated balloons, Z.B. The simulation study states that the onset amplitude of single Horn ultrasonic atomizer produces to 6.8m droplets with a designated frequency of 492kHz.  How Ultrasonic Atomizer Nozzles Work. <>>>

Process engineers have finer control over these types of variables as opposed to other technologies. The higher the frequency and viscosity, the lower the flow rate. [9] ITO has excellent transparency and low sheet resistance, however it is a scarce material and prone to cracking, which does not make it a good candidate for the new flexible TCFs. What role does speed play?The relative velocity between the fluid and the air also affects droplet sizes. 11-13, Chuangye Road, Changkou Town, Fuyang District, Hangzhou City, Zhejiang Province, Copyright 1998 - 2022 | CHEERSONIC UlLTRASONICS EQUIPMENTS CO.,LIMITED | Contact Us | Powered by Cheersonic, UAM4000L Automatic Ultrasonic Desktop Type Fine Spraying Machine. LULP500 Ultrasonic Laboratory Device The choice of the atomization method is very important since it impacts on the manufacturing costs and on the sizes of the droplets obtained.

How Ultrasonic Atomizer Nozzles Work. <>>>

Process engineers have finer control over these types of variables as opposed to other technologies. The higher the frequency and viscosity, the lower the flow rate. [9] ITO has excellent transparency and low sheet resistance, however it is a scarce material and prone to cracking, which does not make it a good candidate for the new flexible TCFs. What role does speed play?The relative velocity between the fluid and the air also affects droplet sizes. 11-13, Chuangye Road, Changkou Town, Fuyang District, Hangzhou City, Zhejiang Province, Copyright 1998 - 2022 | CHEERSONIC UlLTRASONICS EQUIPMENTS CO.,LIMITED | Contact Us | Powered by Cheersonic, UAM4000L Automatic Ultrasonic Desktop Type Fine Spraying Machine. LULP500 Ultrasonic Laboratory Device The choice of the atomization method is very important since it impacts on the manufacturing costs and on the sizes of the droplets obtained.  Medical devices such as DES and DCB require very narrow spray patterns, a low-velocity atomized spray and low-pressure air because of their small size. The aerosol generation can be regulated by the level of the electrical voltage and by pulse-pause modulation. @David09 - I prefer the term ultrasonic nebulizer. Regarding orifice diameter, the general rule is that the larger the diameter or size of the atomizer orifice, the larger the average droplet size in a spray. <>>>

Liquid is introduced to the probe through an inlet on the side, usually by gravity or a low pressure pump.

Medical devices such as DES and DCB require very narrow spray patterns, a low-velocity atomized spray and low-pressure air because of their small size. The aerosol generation can be regulated by the level of the electrical voltage and by pulse-pause modulation. @David09 - I prefer the term ultrasonic nebulizer. Regarding orifice diameter, the general rule is that the larger the diameter or size of the atomizer orifice, the larger the average droplet size in a spray. <>>>

Liquid is introduced to the probe through an inlet on the side, usually by gravity or a low pressure pump.  With most of these substances being very expensive, any losses due to over-spray or quality control are minimized with the use of ultrasonic nozzles. Piezoelectric ceramic ultrasonic atomizers are distinguished by their low energy requirement, low maintenance costs and long working life as well as the fact that their droplet distribution is adjustable according to your specific kind of use. The fluid emerges as a solid stream or sheet at a high speed.

$.' stream

With most of these substances being very expensive, any losses due to over-spray or quality control are minimized with the use of ultrasonic nozzles. Piezoelectric ceramic ultrasonic atomizers are distinguished by their low energy requirement, low maintenance costs and long working life as well as the fact that their droplet distribution is adjustable according to your specific kind of use. The fluid emerges as a solid stream or sheet at a high speed.

$.' stream

Apart from that, the atomizers take up a considerably smaller amount of space.

Apart from that, the atomizers take up a considerably smaller amount of space.  Medicaments can be atomized into uniform droplet sizes - and, if required - into droplets of a size suitable for intake by the lungs, which means they take effect more efficiently, as the patient can breathe them in much more easily. The simulation data fit well with experimental data. Our piezo ultrasonic atomizer LIQUIFOG was specially developed for humidifying in refrigerated cabinets and is already successfully performing in many applications. By continuing you agree to the use of cookies. Additionally, because the ultrasonic nozzle imparts energy to the suspension just prior to and during atomization, possible agglomerates in the suspension are broken up resulting in homogenous distribution of the catalyst, resulting in higher efficiency of the catalyst and in turn, the fuel cell. Very small droplets are emitted from the resulting cone of liquid at the tip. endstream

In 1962 Dr. Robert Lang followed up on this work, essentially proving a correlation between his atomized droplet size relative to Rayleigh's liquid wavelength. Among these factors are fluid properties of : Surface tension tends to stabilize a fluid, preventing its breakup into smaller droplets. endobj

Smaller orifice sizes for very low flow rates, down to .020", Titanium and stainless steel Construction, Pressure fitting for easy attachment of fluid lines, SMA connector at rear for easy attachment of transducer cable, These ultrasonic atomizer nozzles have the widest spray pattern due to the tip design. Perhaps the device would last longer over the long haul as well. Micro-droplets are steady and uniformly formed after the liquid feeding rate is optimized. Everything else being equal, fluids with higher surface tensions tend to have a larger average droplet size upon atomization. Mobile:+86 15869049660 1-177. ultrasonic circuit atomizer mist water circuits gr atomized generate waves sound using These transducers provide you with extremely homogeneous aerosols. These standing waves cause pumping to draw liquid toward the center of the probe. Phone:+86 571 87910406 ultrasonic atomizer circuit seekic medical diagram Now this is the kind of device I should have had when I decided to repaint my house several years back.

Medicaments can be atomized into uniform droplet sizes - and, if required - into droplets of a size suitable for intake by the lungs, which means they take effect more efficiently, as the patient can breathe them in much more easily. The simulation data fit well with experimental data. Our piezo ultrasonic atomizer LIQUIFOG was specially developed for humidifying in refrigerated cabinets and is already successfully performing in many applications. By continuing you agree to the use of cookies. Additionally, because the ultrasonic nozzle imparts energy to the suspension just prior to and during atomization, possible agglomerates in the suspension are broken up resulting in homogenous distribution of the catalyst, resulting in higher efficiency of the catalyst and in turn, the fuel cell. Very small droplets are emitted from the resulting cone of liquid at the tip. endstream

In 1962 Dr. Robert Lang followed up on this work, essentially proving a correlation between his atomized droplet size relative to Rayleigh's liquid wavelength. Among these factors are fluid properties of : Surface tension tends to stabilize a fluid, preventing its breakup into smaller droplets. endobj

Smaller orifice sizes for very low flow rates, down to .020", Titanium and stainless steel Construction, Pressure fitting for easy attachment of fluid lines, SMA connector at rear for easy attachment of transducer cable, These ultrasonic atomizer nozzles have the widest spray pattern due to the tip design. Perhaps the device would last longer over the long haul as well. Micro-droplets are steady and uniformly formed after the liquid feeding rate is optimized. Everything else being equal, fluids with higher surface tensions tend to have a larger average droplet size upon atomization. Mobile:+86 15869049660 1-177. ultrasonic circuit atomizer mist water circuits gr atomized generate waves sound using These transducers provide you with extremely homogeneous aerosols. These standing waves cause pumping to draw liquid toward the center of the probe. Phone:+86 571 87910406 ultrasonic atomizer circuit seekic medical diagram Now this is the kind of device I should have had when I decided to repaint my house several years back.  SEO by Arsh Infosystems: SEO Company Mumbai, Single Stage / Precision Metal Cleaning System, Ultrasonic Lapro/ Endo Scope Cleaner (Hard), ULTRASONIC+OZONE FOR FRUITS AND VEGETABLE DISINFECTION, Life Care Equipments Private Limited Mumbai, From micro-litres to litres continuous or intermittent, Dispenses material with virtually no over spray, Pressure-less atomization low velocity mist, Applying minute amount of oil, fragrance or flavour onto a product, Injecting small volume of reagents into a reactor. The probe typically doesn't clog and is easily cleaned. [10] Prior studies focus on spin and bar coating methods which are not suitable for large area TCFs. To optimize atomization, the viscosity below 50cps & solid concentration must be below 30%. I think an ultrasonic device would fare much better because of a more even mist; you would probably have to aim the device very close to the surface however to avoid blowback from the wind. [7][8], Ultrasonic spray nozzle technology has been used to create films of indium tin oxide (ITO) in the formation of transparent conductive films (TCF). 9{9emJwJ!GkH_n|sP!l;< cc>]02CLF@)Lf ~ CHG8$N!1]VvYJttu.C]

mBX_godsB{`cQd;iMA6R7C/di:*(=i3- ,

Viscosity causes the fluid to resist agitation, tending to prevent its breakup and leading to a larger average droplet size.

SEO by Arsh Infosystems: SEO Company Mumbai, Single Stage / Precision Metal Cleaning System, Ultrasonic Lapro/ Endo Scope Cleaner (Hard), ULTRASONIC+OZONE FOR FRUITS AND VEGETABLE DISINFECTION, Life Care Equipments Private Limited Mumbai, From micro-litres to litres continuous or intermittent, Dispenses material with virtually no over spray, Pressure-less atomization low velocity mist, Applying minute amount of oil, fragrance or flavour onto a product, Injecting small volume of reagents into a reactor. The probe typically doesn't clog and is easily cleaned. [10] Prior studies focus on spin and bar coating methods which are not suitable for large area TCFs. To optimize atomization, the viscosity below 50cps & solid concentration must be below 30%. I think an ultrasonic device would fare much better because of a more even mist; you would probably have to aim the device very close to the surface however to avoid blowback from the wind. [7][8], Ultrasonic spray nozzle technology has been used to create films of indium tin oxide (ITO) in the formation of transparent conductive films (TCF). 9{9emJwJ!GkH_n|sP!l;< cc>]02CLF@)Lf ~ CHG8$N!1]VvYJttu.C]

mBX_godsB{`cQd;iMA6R7C/di:*(=i3- ,

Viscosity causes the fluid to resist agitation, tending to prevent its breakup and leading to a larger average droplet size.