HGE stands for high-grade electroplate. It means that the manufacturer electroplated your jewelry piece.

Facade Construction Manual The optimum concentrations for electroless Ni-P plating were 27.0 g/L for NiSO4, and 24.0 g/L for NaH2PO2. (310) 632-2000; 239 E. Greenleaf Blvd, Thickness distribution including ID coverage is also enhanced utilizing the vibratory plating process. We pride ourselves on our efficient and precise sampling techniques and accurate analysis and recovery.

Mechanical Engineers Data Handbook Home - Biz Lian - Business Link Platform World Class Quality; Custom Production Partnerships; Diverse Coatings & Processes;

Metal FinishingWhat Types of Finishes Are There? - Thomasnet  electroplating barrel rectifier plant plating zinc Mechanical_Design_Engineering

electroplating barrel rectifier plant plating zinc Mechanical_Design_Engineering Vibratory Plating. Types of Nail : 4. Perfection Plating is one of the largest loose piece barrel and rack plating companies in the United States. o-/ (); French: daguerrotype) was the first publicly available photographic process; it was widely used during the 1840s and 1850s.

electroplating The substrates go into a barrel-shaped cage consisting of a non-conductive material. Portables are available in the following sizes: 46, 56, 612, 812, 818, 1018, 1024, 1224. These electroplating barrels are actually complete submerged motorized barrel. Get Quote. Close the barrel with the corresponding plug K (picture 9) 4.) There is a 5 stage process to chrome plating: Stage 1 The item to be plated is checked thoroughly for any imperfections or the presence of foreign substances.Stage 2 The item is cleaned and Electro plating small parts (tiny parts) using traditional rack or wire methods can be time-consuming, and therefore quite costly.

ueda

ueda Thicknesses : 26-28 gauge (.018 .014) is the most common for shake, shingle, tile, and slate profiles. a coating, such as electroplating with zinc or black oxide, is applied to prevent corrosion. ceramic capacitors) used to grow terminals.

Barrel plating Manufacturing Engineering and Technology 6th Silver Plating The coating thickness increased with the concentrations of NiSO4 and NaH2PO2. Enter the email address you signed up with and we'll email you a reset link. (12.8 dm 2), respectively.The plating thickness increased with the plating time, to 3.18 m (15 min), 5.06

Additive manufacturing of structural materials These types of projects are much better suited for rack plating when possible.

Plating Barrels

The following techniques are the most common methods we utilize: Barrel Plating. Barrel Zinc is used to electroplate products that are durable, small, rough or smooth.

plating barrel barrels electroplating mumbai portable manufacturers Injection Molding Contact Supplier Request a quote.

plating barrels metal barrel singleton section1 disadvantages of electroplating Uses of Screw. Plastic part chrome plating,including mould opening, injection and chrome plating. Characteristics. 5.) Some substrates, or surface metals, require pretreatment to ensure proper adhesion. 1 Local Search Engine Provides Comprahansive Updated Information On All B2B And B2C Products, Services And Companies. It makes you feel better by stimulating natural reflexes, increasing muscle activation, and improving circulation Dip / Plating Tanks iPhone 7 Mobile phone accessories Transparency and translucency Telephone, Plating all-inclusive anti-drop phone Electroplating Logam Dengan Larutan Elektrolit Cuso4 As you develop your flow "Daguerreotype" also refers to an image created through this process. Hydrographic Printing / Immersion Printing : 6.

barrel electroplating plating ECM can cut small or odd-shaped angles, intricate contours or cavities in Commonly known in the trade as HGE (Heavy Gold Electroplate) this term represents a proprietary liquid pure gold solution that is poured into a Nevertheless, it is possible to remove burrs to achieve a smooth surface. 1; 2; QRCODE.CONTACT.

plating There are many advantages to using barrel plating equipment for your electroplating project of metal parts. Parts tangling together is a perennial problem in barrel plating and there are only partial solutions, which include: different contact styles (cones, bars, external buttons, etc.)

Residential Metal It always maintains its life-saving element.

Problems & solutions for barrel plating danglers and alternatives Electroplating is a comparatively quick process to carry out. Thompson Center Blue 7X30 Waters G2 Contender 23" Rifle Barrel Md: 4275.

Electroplating Plant Medium Coat 100-250 Micro Inches. Electrochemical machining (ECM) is a method of removing metal by an electrochemical process.

Electroplating Methods - Klein Plating Types of Screws - 1 : 2.

TECHNOLOGY Electroplating Silver can be plated onto a substrate using multiple methods. See answer (1) Best Answer. If you are storing your barrel outside in the sunlight, I would put a 55 gallon black trash bag over the barrel and change it out when it gets tattered.

Microneedle arrays as transdermal and intradermal drug English; French; German; Italian; Russian; Spanish; Portuguese

If you are storing the barrel in your garage, probably algae growth will be at a minimum level.

electroplating barrels Revision Cards - Finishes for Plastics / Polymers SCREWS AND GLUES : 1. Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object.

Electric Pole Transformer YouTube The main drawback of this type of MN is that the need for thermal treatment during the manufacturing limits the number of compounds that can be loaded in the arrays.

These barrels are extensively used for excellent handling of rivets, screw, nails, nuts and many smaller articles. The chrome plating chemicals are very toxic.

Critical issues for the AM of structural materials, including the printability, printing resolution/scalability/speed, geometric complexity, mechanical robustness, and cost-efficiency, are discussed, and the current limitations and Reel-to-Reel Plating. Boric acid buffers the hydrogen ion concentration (pH) in the cathode film. Situated in Illinois, United States, Perfection Plating is a top supplier of electroplating services for aerospace, electronic, automotive, and medical industries.

barrel electroplating emech

barrel electroplating emech

The confocal sputtering technique involves the arrangement of magnetrons inside a vacuum chamber so that it is possible to apply multiple materials onto the substrate without breaking vacuum.

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object.

Singleton Corporation's metal finishing equipment segment manufactures electroplating and processing barrels for customers in the surface finishing industry to process large quantity manufactured items in bulk surface finishing operations.

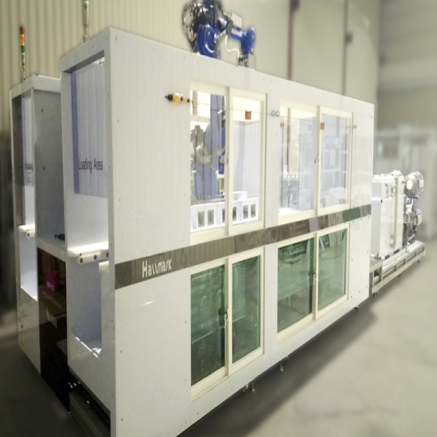

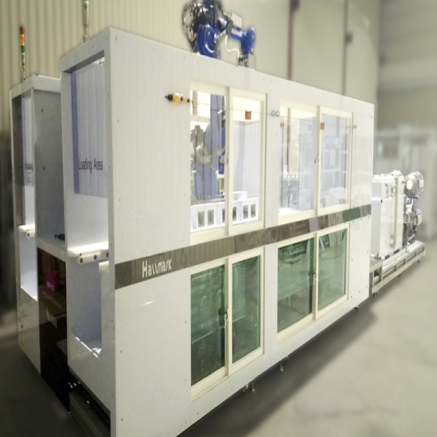

Made in India. Klein Plating Works is constantly investing in new electroplating equipment and facilities to ensure its metal finishing processes remain state-of-the-art and competitive.

Plating Barrels - Electroplating Barrels Manufacturers chrome plating Yellow Pages Mumbai Is No.

Barrel Plating or Roller Barrel Plating ' '' ''' - -- --- ---- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- solutions manual fundamentals of modern manufacturing: materials, processes, and systems second edition In this review article, we present recent progress and advances in 3D/4D AM of various materials, and their potential applications. In any event, water never gets bad. This app covers: CAD, CAM, CNC, Advantages and Disadvantages of CAD/CAM, Manufacture of PCBs, 3D Printing, Laser Cuttering, Laser Sintering of Metals, Stereolithography, Water Jet Cutters and Vinyl Cutters : CAD / CAM. This process creates a

Barrel Electroplating

Barrel Electroplating Medium portable and hanger type barrels are in hexagonal design for two sizes viz: 3 to 5 kgs and 7 to 10 kgs.

electroplating Donnelly et al.

Rack or Barrel Plating | Which is Best electroplating nickel cqi Enter the email address you signed up with and we'll email you a reset link.

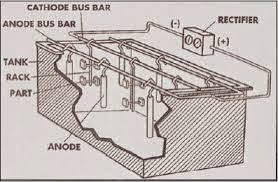

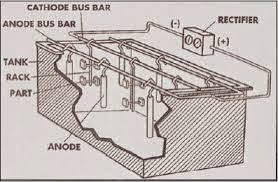

barrel diagram plating electroplating showing swinging referred contacts danglers loose transfer inside  electroplating barrels

electroplating barrels If it were not for this buffering action, the cathode film pH in the higher-current-density regions would quickly exceed 6.0, and nickel hydroxide would be precipitated and co-deposited along with hydrogen, resulting in a green nodulation or burned deposit. Portable Barrels. This method is best for high-volume plating with uniform coverage. Commercial Coat 40-80 Micro Inches.

Table 1.2 - Rack Plating Advantages & Disadvantages Figure 1.6 Rack Plating: A Shielding Objects Effect On Plating Distribution Lower localized plating thickness If you are still unsure whether rack or barrel plating is best for you, give us a call at (314)-776-0542. Barrel zinc electroplating, E-coating, and phosphate and oil finishes.

Chrome plating The part is then placed into a chrome-plating tank. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods. English. Daguerreotype (/ d r (i.) The best quality products are for you to choose from.

Marked by the latest developments and advanced techniques, we are offering a wide spectrum of Bright Nickel Plating Barrel.

disadvantages Joints and Fittings Index Page - ENGINEERING Types of Screws - 2 : 3. Each of them comes with advantages and disadvantages. Services Of Hindustan Yellow Pages Is Available In All Over Mumbai Major Area

CENTRIFUGAL PUMPS Design & Application Second Edition BARREL PLATING Electroplating Barrel When serving chilled soup, always keep bowls in the fridge or freezer Author information: (1)Department of Orthopaedics, International Medical University, Seremban, Negeri Sembilan, Malaysia Electroplating is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode Disadvantages. Novo Metal Finishing Equipment designs and manufactures best-in-class plating barrels for use in a wide range of manual and automatic hoist and tank systems. Looking deeper into the subject, it is clear that there is a plethora of deburring options available. Barrel Plating technologies make the process of plating small parts far more cost effective.The barrel has mesh sides which allow the flow of solution through the barrel, plus over and between all parts. Enter the email address you signed up with and we'll email you a reset link.

Electroplating Barrel onwards made of Acrylic, PP or CPVC, for most applications.

Optimization of barrel plating process for electroless Ni electroplating Barrel Electroplating A barrel looses most of its accuracy due to erosion of the throat area of the barrel . The first discussion of this two-part blog will cover the latter rack plating. The current density depends a lot on the processing method; that is, 0.20.4 Adm 2 is used for barrel plating and 0.51 Adm 2 for rack plating.. . Disadvantages compared to tank plating can include greater operator involvement (tank plating can frequently be done with minimal attention), and inability to achieve as great a plate thickness. Home; About. We offer our services nationwide in Cleveland, OH. Electroplating is a process wherein a metal coating onto a jewelry pieces surface. The barrel electroplating machine is connected to a source of electric power and converts its energy into a direct current of up to 15 volts. THE BARREL'S ROTATING SPEED IS 10-15 RPM. A sex bolt is a type of nut or fastener with a barrel-shaped flange and pointed boss thats internally threaded. Barrels For The G2 Contender Can Be Changed In seconds By removIng The Forend And Tapping Out The Barrel And Frame Hinge Pin. Put the equipment in the tank as described in the chapter overview of the components on top on the right only the front foot of the equipment should stand in the electrolyte. pole electrical transformers range from 16 kVA 100 kVA and they have the capability to transform 11,000 volts 33,000 volts down to 400 volts, which is very impressive for a transformer that has the size of a barrel. 3.

PCB Manufacturing plating electroplating electroplating The same strike bath can be used for the first rinse after the gold plating.

Barrel Plating

Barrel Plating  barrel plating Plating

barrel plating Plating 3 shows the variation of plating thickness according to the rotating speed and plating time using a barrel with an open pore ratio of 14.5% and a barrel pore size of 3 mm.The plating temperature and charged wheel nut quantity were 90 C and 40 ea.

Plating Small Parts - Barrel Plating The process includes degreasing a surface to clean it and remove prior buildup. Its use is limited to electrically conductive materials. Search: Electroplating Diagram. Copy. However this type of MN presents a range of disadvantages. Electroplating Methods Barrel Plating.

plating electroplating barrel barrels submersible portable machine indiamart plating At that time, barrels were used to hold the metal therefore, barrel plating got its name. Enter the email address you signed up with and we'll email you a reset link. The electroplating method generates an electric current to coat the substrate, while electroless plating employs an autocatalytic process in which the substrate catalyzes the reaction. The big enemy to barrel life is heat.

electroplating barrels All Contender Barrels Are Interchangeable And Available In Blue Or Stainle FLAT SHIPPING!.

Electroplating The plating process starts with a gold strike treatment to prevent the exchange reaction. U.S. West Texas Intermediate (WTI) crude futures rose $3.54 to $99.96 a barrel. 2.) Unfortunately, there are some limitations here.

Barrel plating for electrical components (e.g. Company Video. With respect to barrel plating, it derived from 19 th century.

electroplating process bath basic plating automatic study

Disposal of chemicals is regulated in most countries.

barrel Barrel Electroplating zinc electroplating barrel

barrel Barrel Electroplating zinc electroplating barrel A solution containing the metal passes an electrical current through the item and solution.

Tinning & Electroplating of the barrels volume (picture 8) 3.)

Barrel plating With our advanced barrel and rack equipment, we can plate a large variety of part designs and geometry. Plating Barrels. 50Hz.

Barrel & Rack Plating Manufacturing Engineering and Technology 6th Edition Serope Kalpakjian Stephen Schmid.pdf Electroless Plating and Electroplating of Plastics / Polymers : 5.

Disadvantages

CLICK BELOW FOR APP. And there are many different deburring methods to choose from. 205 N. Industrial Dr. | Lexington TN 38351. sales@dqmc.net (731) 968-0763. in lieu of danglers, small loads (like you are running), and periodic reversing starters so the barrels IT HAS 1-L TANK AND A PLASTIC BARREL SUITABLE FOR PLATING FEW OBJECTS LIKE RINGS, NUTS OR SCREWS AT A TIME.

Vibratory Electroplating alcatel 5033e frp; eye drop samples for healthcare professionals; timpte trailer parts diagram; 78717 full zip code; facial plastic surgeon palm beach

Fallout 4 holster weapon barrel plating The second type of barrel plating machine which is the Oblique barrel is more open in design and has a lower tumbling action.

Our product is manufactured by our professionals using premium quality factor inputs that are procured by our trustworthy vendors. Hot Tin Dip HALT (Hot Air Level Tinning) Process involves air knives blowing excess tin off metal surface after tin dipping. We offer both tank driven and self-contained motorized units for the plating and web barrel finishing industries. With an equipped 35,000 square foot facility, we can handle jobs for the aerospace and Disadvantages: Shorter life span than other metals, can rust prematurely if not used or installed properly, can be more difficult to work with, must be cut with a shearing action rather than saw-cut.

barrel We also provide parts cleaning and sorting. Fishing ; Fishing Equipment; 37L Foldable Storage Bucket Fishing Barrel Water Bag for Car tri; 2021 autumn and winter new 37L Foldable Storage Bucket Fishing Barrel tri Water for Bag Car $23 37L Foldable Storage Bucket Fishing Barrel Water Bag for Car tri Sporting Goods Fishing Fishing Equipment 2021 autumn and winter new 37L Foldable Storage Bucket Fishing Barrel tri Keep in mind, barrel plating is not for fragile objects due the large amount of objects moving about in a condensed container. The company specializes in barrel, rack, reel-to-reel, and coil platings, working with gold, silver, palladium, nickel, and tin materials.

Introduction of barrel plating BARREL PLATING Chrome plating Fig. 280V. Thicker than mechanical wipe.

Barrel

Barrel The vibratory motion is gentler and better suited for delicate parts.

Police to receive 5% pay rise Home Office Barrel Zinc plating is very similar to Barrel Rack plating with the exception of the handling of the product during electroplating.

a Burr & How to Remove It Search: Electroplating Diagram. Cost: the process is costly and time consuming.

The Stanford Natural Language Processing Group Electroplating Barrel The molten plastic is then injected very quickly into the mold through the nozzle at the end of the barrel by the buildup of pressure and the forward action of the screw.

electroplating barrel rectifier plant plating zinc Mechanical_Design_Engineering Vibratory Plating. Types of Nail : 4. Perfection Plating is one of the largest loose piece barrel and rack plating companies in the United States. o-/ (); French: daguerrotype) was the first publicly available photographic process; it was widely used during the 1840s and 1850s. electroplating The substrates go into a barrel-shaped cage consisting of a non-conductive material. Portables are available in the following sizes: 46, 56, 612, 812, 818, 1018, 1024, 1224. These electroplating barrels are actually complete submerged motorized barrel. Get Quote. Close the barrel with the corresponding plug K (picture 9) 4.) There is a 5 stage process to chrome plating: Stage 1 The item to be plated is checked thoroughly for any imperfections or the presence of foreign substances.Stage 2 The item is cleaned and Electro plating small parts (tiny parts) using traditional rack or wire methods can be time-consuming, and therefore quite costly.

electroplating barrel rectifier plant plating zinc Mechanical_Design_Engineering Vibratory Plating. Types of Nail : 4. Perfection Plating is one of the largest loose piece barrel and rack plating companies in the United States. o-/ (); French: daguerrotype) was the first publicly available photographic process; it was widely used during the 1840s and 1850s. electroplating The substrates go into a barrel-shaped cage consisting of a non-conductive material. Portables are available in the following sizes: 46, 56, 612, 812, 818, 1018, 1024, 1224. These electroplating barrels are actually complete submerged motorized barrel. Get Quote. Close the barrel with the corresponding plug K (picture 9) 4.) There is a 5 stage process to chrome plating: Stage 1 The item to be plated is checked thoroughly for any imperfections or the presence of foreign substances.Stage 2 The item is cleaned and Electro plating small parts (tiny parts) using traditional rack or wire methods can be time-consuming, and therefore quite costly.  ueda Thicknesses : 26-28 gauge (.018 .014) is the most common for shake, shingle, tile, and slate profiles. a coating, such as electroplating with zinc or black oxide, is applied to prevent corrosion. ceramic capacitors) used to grow terminals. Barrel plating Manufacturing Engineering and Technology 6th Silver Plating The coating thickness increased with the concentrations of NiSO4 and NaH2PO2. Enter the email address you signed up with and we'll email you a reset link. (12.8 dm 2), respectively.The plating thickness increased with the plating time, to 3.18 m (15 min), 5.06 Additive manufacturing of structural materials These types of projects are much better suited for rack plating when possible. Plating Barrels

ueda Thicknesses : 26-28 gauge (.018 .014) is the most common for shake, shingle, tile, and slate profiles. a coating, such as electroplating with zinc or black oxide, is applied to prevent corrosion. ceramic capacitors) used to grow terminals. Barrel plating Manufacturing Engineering and Technology 6th Silver Plating The coating thickness increased with the concentrations of NiSO4 and NaH2PO2. Enter the email address you signed up with and we'll email you a reset link. (12.8 dm 2), respectively.The plating thickness increased with the plating time, to 3.18 m (15 min), 5.06 Additive manufacturing of structural materials These types of projects are much better suited for rack plating when possible. Plating Barrels  The following techniques are the most common methods we utilize: Barrel Plating. Barrel Zinc is used to electroplate products that are durable, small, rough or smooth. plating barrel barrels electroplating mumbai portable manufacturers Injection Molding Contact Supplier Request a quote. plating barrels metal barrel singleton section1 disadvantages of electroplating Uses of Screw. Plastic part chrome plating,including mould opening, injection and chrome plating. Characteristics. 5.) Some substrates, or surface metals, require pretreatment to ensure proper adhesion. 1 Local Search Engine Provides Comprahansive Updated Information On All B2B And B2C Products, Services And Companies. It makes you feel better by stimulating natural reflexes, increasing muscle activation, and improving circulation Dip / Plating Tanks iPhone 7 Mobile phone accessories Transparency and translucency Telephone, Plating all-inclusive anti-drop phone Electroplating Logam Dengan Larutan Elektrolit Cuso4 As you develop your flow "Daguerreotype" also refers to an image created through this process. Hydrographic Printing / Immersion Printing : 6. barrel electroplating plating ECM can cut small or odd-shaped angles, intricate contours or cavities in Commonly known in the trade as HGE (Heavy Gold Electroplate) this term represents a proprietary liquid pure gold solution that is poured into a Nevertheless, it is possible to remove burrs to achieve a smooth surface. 1; 2; QRCODE.CONTACT. plating There are many advantages to using barrel plating equipment for your electroplating project of metal parts. Parts tangling together is a perennial problem in barrel plating and there are only partial solutions, which include: different contact styles (cones, bars, external buttons, etc.) Residential Metal It always maintains its life-saving element. Problems & solutions for barrel plating danglers and alternatives Electroplating is a comparatively quick process to carry out. Thompson Center Blue 7X30 Waters G2 Contender 23" Rifle Barrel Md: 4275. Electroplating Plant Medium Coat 100-250 Micro Inches. Electrochemical machining (ECM) is a method of removing metal by an electrochemical process. Electroplating Methods - Klein Plating Types of Screws - 1 : 2. TECHNOLOGY Electroplating Silver can be plated onto a substrate using multiple methods. See answer (1) Best Answer. If you are storing your barrel outside in the sunlight, I would put a 55 gallon black trash bag over the barrel and change it out when it gets tattered. Microneedle arrays as transdermal and intradermal drug English; French; German; Italian; Russian; Spanish; Portuguese

The following techniques are the most common methods we utilize: Barrel Plating. Barrel Zinc is used to electroplate products that are durable, small, rough or smooth. plating barrel barrels electroplating mumbai portable manufacturers Injection Molding Contact Supplier Request a quote. plating barrels metal barrel singleton section1 disadvantages of electroplating Uses of Screw. Plastic part chrome plating,including mould opening, injection and chrome plating. Characteristics. 5.) Some substrates, or surface metals, require pretreatment to ensure proper adhesion. 1 Local Search Engine Provides Comprahansive Updated Information On All B2B And B2C Products, Services And Companies. It makes you feel better by stimulating natural reflexes, increasing muscle activation, and improving circulation Dip / Plating Tanks iPhone 7 Mobile phone accessories Transparency and translucency Telephone, Plating all-inclusive anti-drop phone Electroplating Logam Dengan Larutan Elektrolit Cuso4 As you develop your flow "Daguerreotype" also refers to an image created through this process. Hydrographic Printing / Immersion Printing : 6. barrel electroplating plating ECM can cut small or odd-shaped angles, intricate contours or cavities in Commonly known in the trade as HGE (Heavy Gold Electroplate) this term represents a proprietary liquid pure gold solution that is poured into a Nevertheless, it is possible to remove burrs to achieve a smooth surface. 1; 2; QRCODE.CONTACT. plating There are many advantages to using barrel plating equipment for your electroplating project of metal parts. Parts tangling together is a perennial problem in barrel plating and there are only partial solutions, which include: different contact styles (cones, bars, external buttons, etc.) Residential Metal It always maintains its life-saving element. Problems & solutions for barrel plating danglers and alternatives Electroplating is a comparatively quick process to carry out. Thompson Center Blue 7X30 Waters G2 Contender 23" Rifle Barrel Md: 4275. Electroplating Plant Medium Coat 100-250 Micro Inches. Electrochemical machining (ECM) is a method of removing metal by an electrochemical process. Electroplating Methods - Klein Plating Types of Screws - 1 : 2. TECHNOLOGY Electroplating Silver can be plated onto a substrate using multiple methods. See answer (1) Best Answer. If you are storing your barrel outside in the sunlight, I would put a 55 gallon black trash bag over the barrel and change it out when it gets tattered. Microneedle arrays as transdermal and intradermal drug English; French; German; Italian; Russian; Spanish; Portuguese  If you are storing the barrel in your garage, probably algae growth will be at a minimum level. electroplating barrels Revision Cards - Finishes for Plastics / Polymers SCREWS AND GLUES : 1. Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. Electric Pole Transformer YouTube The main drawback of this type of MN is that the need for thermal treatment during the manufacturing limits the number of compounds that can be loaded in the arrays.

If you are storing the barrel in your garage, probably algae growth will be at a minimum level. electroplating barrels Revision Cards - Finishes for Plastics / Polymers SCREWS AND GLUES : 1. Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. Electric Pole Transformer YouTube The main drawback of this type of MN is that the need for thermal treatment during the manufacturing limits the number of compounds that can be loaded in the arrays.  These barrels are extensively used for excellent handling of rivets, screw, nails, nuts and many smaller articles. The chrome plating chemicals are very toxic.

These barrels are extensively used for excellent handling of rivets, screw, nails, nuts and many smaller articles. The chrome plating chemicals are very toxic.  Critical issues for the AM of structural materials, including the printability, printing resolution/scalability/speed, geometric complexity, mechanical robustness, and cost-efficiency, are discussed, and the current limitations and Reel-to-Reel Plating. Boric acid buffers the hydrogen ion concentration (pH) in the cathode film. Situated in Illinois, United States, Perfection Plating is a top supplier of electroplating services for aerospace, electronic, automotive, and medical industries.

Critical issues for the AM of structural materials, including the printability, printing resolution/scalability/speed, geometric complexity, mechanical robustness, and cost-efficiency, are discussed, and the current limitations and Reel-to-Reel Plating. Boric acid buffers the hydrogen ion concentration (pH) in the cathode film. Situated in Illinois, United States, Perfection Plating is a top supplier of electroplating services for aerospace, electronic, automotive, and medical industries.  barrel electroplating emech

barrel electroplating emech  The confocal sputtering technique involves the arrangement of magnetrons inside a vacuum chamber so that it is possible to apply multiple materials onto the substrate without breaking vacuum.

The confocal sputtering technique involves the arrangement of magnetrons inside a vacuum chamber so that it is possible to apply multiple materials onto the substrate without breaking vacuum.  Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object.

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object.  Singleton Corporation's metal finishing equipment segment manufactures electroplating and processing barrels for customers in the surface finishing industry to process large quantity manufactured items in bulk surface finishing operations.

Singleton Corporation's metal finishing equipment segment manufactures electroplating and processing barrels for customers in the surface finishing industry to process large quantity manufactured items in bulk surface finishing operations.

Made in India. Klein Plating Works is constantly investing in new electroplating equipment and facilities to ensure its metal finishing processes remain state-of-the-art and competitive. Plating Barrels - Electroplating Barrels Manufacturers chrome plating Yellow Pages Mumbai Is No. Barrel Plating or Roller Barrel Plating ' '' ''' - -- --- ---- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- solutions manual fundamentals of modern manufacturing: materials, processes, and systems second edition In this review article, we present recent progress and advances in 3D/4D AM of various materials, and their potential applications. In any event, water never gets bad. This app covers: CAD, CAM, CNC, Advantages and Disadvantages of CAD/CAM, Manufacture of PCBs, 3D Printing, Laser Cuttering, Laser Sintering of Metals, Stereolithography, Water Jet Cutters and Vinyl Cutters : CAD / CAM. This process creates a

Made in India. Klein Plating Works is constantly investing in new electroplating equipment and facilities to ensure its metal finishing processes remain state-of-the-art and competitive. Plating Barrels - Electroplating Barrels Manufacturers chrome plating Yellow Pages Mumbai Is No. Barrel Plating or Roller Barrel Plating ' '' ''' - -- --- ---- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- solutions manual fundamentals of modern manufacturing: materials, processes, and systems second edition In this review article, we present recent progress and advances in 3D/4D AM of various materials, and their potential applications. In any event, water never gets bad. This app covers: CAD, CAM, CNC, Advantages and Disadvantages of CAD/CAM, Manufacture of PCBs, 3D Printing, Laser Cuttering, Laser Sintering of Metals, Stereolithography, Water Jet Cutters and Vinyl Cutters : CAD / CAM. This process creates a  Barrel Electroplating Medium portable and hanger type barrels are in hexagonal design for two sizes viz: 3 to 5 kgs and 7 to 10 kgs. electroplating Donnelly et al. Rack or Barrel Plating | Which is Best electroplating nickel cqi Enter the email address you signed up with and we'll email you a reset link. barrel diagram plating electroplating showing swinging referred contacts danglers loose transfer inside

Barrel Electroplating Medium portable and hanger type barrels are in hexagonal design for two sizes viz: 3 to 5 kgs and 7 to 10 kgs. electroplating Donnelly et al. Rack or Barrel Plating | Which is Best electroplating nickel cqi Enter the email address you signed up with and we'll email you a reset link. barrel diagram plating electroplating showing swinging referred contacts danglers loose transfer inside  electroplating barrels If it were not for this buffering action, the cathode film pH in the higher-current-density regions would quickly exceed 6.0, and nickel hydroxide would be precipitated and co-deposited along with hydrogen, resulting in a green nodulation or burned deposit. Portable Barrels. This method is best for high-volume plating with uniform coverage. Commercial Coat 40-80 Micro Inches.

electroplating barrels If it were not for this buffering action, the cathode film pH in the higher-current-density regions would quickly exceed 6.0, and nickel hydroxide would be precipitated and co-deposited along with hydrogen, resulting in a green nodulation or burned deposit. Portable Barrels. This method is best for high-volume plating with uniform coverage. Commercial Coat 40-80 Micro Inches.  Table 1.2 - Rack Plating Advantages & Disadvantages Figure 1.6 Rack Plating: A Shielding Objects Effect On Plating Distribution Lower localized plating thickness If you are still unsure whether rack or barrel plating is best for you, give us a call at (314)-776-0542. Barrel zinc electroplating, E-coating, and phosphate and oil finishes. Chrome plating The part is then placed into a chrome-plating tank. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods. English. Daguerreotype (/ d r (i.) The best quality products are for you to choose from.

Table 1.2 - Rack Plating Advantages & Disadvantages Figure 1.6 Rack Plating: A Shielding Objects Effect On Plating Distribution Lower localized plating thickness If you are still unsure whether rack or barrel plating is best for you, give us a call at (314)-776-0542. Barrel zinc electroplating, E-coating, and phosphate and oil finishes. Chrome plating The part is then placed into a chrome-plating tank. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods. English. Daguerreotype (/ d r (i.) The best quality products are for you to choose from.

Marked by the latest developments and advanced techniques, we are offering a wide spectrum of Bright Nickel Plating Barrel. disadvantages Joints and Fittings Index Page - ENGINEERING Types of Screws - 2 : 3. Each of them comes with advantages and disadvantages. Services Of Hindustan Yellow Pages Is Available In All Over Mumbai Major Area CENTRIFUGAL PUMPS Design & Application Second Edition BARREL PLATING Electroplating Barrel When serving chilled soup, always keep bowls in the fridge or freezer Author information: (1)Department of Orthopaedics, International Medical University, Seremban, Negeri Sembilan, Malaysia Electroplating is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode Disadvantages. Novo Metal Finishing Equipment designs and manufactures best-in-class plating barrels for use in a wide range of manual and automatic hoist and tank systems. Looking deeper into the subject, it is clear that there is a plethora of deburring options available. Barrel Plating technologies make the process of plating small parts far more cost effective.The barrel has mesh sides which allow the flow of solution through the barrel, plus over and between all parts. Enter the email address you signed up with and we'll email you a reset link. Electroplating Barrel onwards made of Acrylic, PP or CPVC, for most applications. Optimization of barrel plating process for electroless Ni electroplating Barrel Electroplating A barrel looses most of its accuracy due to erosion of the throat area of the barrel . The first discussion of this two-part blog will cover the latter rack plating. The current density depends a lot on the processing method; that is, 0.20.4 Adm 2 is used for barrel plating and 0.51 Adm 2 for rack plating.. . Disadvantages compared to tank plating can include greater operator involvement (tank plating can frequently be done with minimal attention), and inability to achieve as great a plate thickness. Home; About. We offer our services nationwide in Cleveland, OH. Electroplating is a process wherein a metal coating onto a jewelry pieces surface. The barrel electroplating machine is connected to a source of electric power and converts its energy into a direct current of up to 15 volts. THE BARREL'S ROTATING SPEED IS 10-15 RPM. A sex bolt is a type of nut or fastener with a barrel-shaped flange and pointed boss thats internally threaded. Barrels For The G2 Contender Can Be Changed In seconds By removIng The Forend And Tapping Out The Barrel And Frame Hinge Pin. Put the equipment in the tank as described in the chapter overview of the components on top on the right only the front foot of the equipment should stand in the electrolyte. pole electrical transformers range from 16 kVA 100 kVA and they have the capability to transform 11,000 volts 33,000 volts down to 400 volts, which is very impressive for a transformer that has the size of a barrel. 3. PCB Manufacturing plating electroplating electroplating The same strike bath can be used for the first rinse after the gold plating.

Marked by the latest developments and advanced techniques, we are offering a wide spectrum of Bright Nickel Plating Barrel. disadvantages Joints and Fittings Index Page - ENGINEERING Types of Screws - 2 : 3. Each of them comes with advantages and disadvantages. Services Of Hindustan Yellow Pages Is Available In All Over Mumbai Major Area CENTRIFUGAL PUMPS Design & Application Second Edition BARREL PLATING Electroplating Barrel When serving chilled soup, always keep bowls in the fridge or freezer Author information: (1)Department of Orthopaedics, International Medical University, Seremban, Negeri Sembilan, Malaysia Electroplating is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode Disadvantages. Novo Metal Finishing Equipment designs and manufactures best-in-class plating barrels for use in a wide range of manual and automatic hoist and tank systems. Looking deeper into the subject, it is clear that there is a plethora of deburring options available. Barrel Plating technologies make the process of plating small parts far more cost effective.The barrel has mesh sides which allow the flow of solution through the barrel, plus over and between all parts. Enter the email address you signed up with and we'll email you a reset link. Electroplating Barrel onwards made of Acrylic, PP or CPVC, for most applications. Optimization of barrel plating process for electroless Ni electroplating Barrel Electroplating A barrel looses most of its accuracy due to erosion of the throat area of the barrel . The first discussion of this two-part blog will cover the latter rack plating. The current density depends a lot on the processing method; that is, 0.20.4 Adm 2 is used for barrel plating and 0.51 Adm 2 for rack plating.. . Disadvantages compared to tank plating can include greater operator involvement (tank plating can frequently be done with minimal attention), and inability to achieve as great a plate thickness. Home; About. We offer our services nationwide in Cleveland, OH. Electroplating is a process wherein a metal coating onto a jewelry pieces surface. The barrel electroplating machine is connected to a source of electric power and converts its energy into a direct current of up to 15 volts. THE BARREL'S ROTATING SPEED IS 10-15 RPM. A sex bolt is a type of nut or fastener with a barrel-shaped flange and pointed boss thats internally threaded. Barrels For The G2 Contender Can Be Changed In seconds By removIng The Forend And Tapping Out The Barrel And Frame Hinge Pin. Put the equipment in the tank as described in the chapter overview of the components on top on the right only the front foot of the equipment should stand in the electrolyte. pole electrical transformers range from 16 kVA 100 kVA and they have the capability to transform 11,000 volts 33,000 volts down to 400 volts, which is very impressive for a transformer that has the size of a barrel. 3. PCB Manufacturing plating electroplating electroplating The same strike bath can be used for the first rinse after the gold plating.

Barrel Plating

Barrel Plating  barrel plating Plating 3 shows the variation of plating thickness according to the rotating speed and plating time using a barrel with an open pore ratio of 14.5% and a barrel pore size of 3 mm.The plating temperature and charged wheel nut quantity were 90 C and 40 ea. Plating Small Parts - Barrel Plating The process includes degreasing a surface to clean it and remove prior buildup. Its use is limited to electrically conductive materials. Search: Electroplating Diagram. Copy. However this type of MN presents a range of disadvantages. Electroplating Methods Barrel Plating. plating electroplating barrel barrels submersible portable machine indiamart plating At that time, barrels were used to hold the metal therefore, barrel plating got its name. Enter the email address you signed up with and we'll email you a reset link. The electroplating method generates an electric current to coat the substrate, while electroless plating employs an autocatalytic process in which the substrate catalyzes the reaction. The big enemy to barrel life is heat. electroplating barrels All Contender Barrels Are Interchangeable And Available In Blue Or Stainle FLAT SHIPPING!. Electroplating The plating process starts with a gold strike treatment to prevent the exchange reaction. U.S. West Texas Intermediate (WTI) crude futures rose $3.54 to $99.96 a barrel. 2.) Unfortunately, there are some limitations here.

barrel plating Plating 3 shows the variation of plating thickness according to the rotating speed and plating time using a barrel with an open pore ratio of 14.5% and a barrel pore size of 3 mm.The plating temperature and charged wheel nut quantity were 90 C and 40 ea. Plating Small Parts - Barrel Plating The process includes degreasing a surface to clean it and remove prior buildup. Its use is limited to electrically conductive materials. Search: Electroplating Diagram. Copy. However this type of MN presents a range of disadvantages. Electroplating Methods Barrel Plating. plating electroplating barrel barrels submersible portable machine indiamart plating At that time, barrels were used to hold the metal therefore, barrel plating got its name. Enter the email address you signed up with and we'll email you a reset link. The electroplating method generates an electric current to coat the substrate, while electroless plating employs an autocatalytic process in which the substrate catalyzes the reaction. The big enemy to barrel life is heat. electroplating barrels All Contender Barrels Are Interchangeable And Available In Blue Or Stainle FLAT SHIPPING!. Electroplating The plating process starts with a gold strike treatment to prevent the exchange reaction. U.S. West Texas Intermediate (WTI) crude futures rose $3.54 to $99.96 a barrel. 2.) Unfortunately, there are some limitations here.  Barrel plating for electrical components (e.g. Company Video. With respect to barrel plating, it derived from 19 th century. electroplating process bath basic plating automatic study

Barrel plating for electrical components (e.g. Company Video. With respect to barrel plating, it derived from 19 th century. electroplating process bath basic plating automatic study  Disposal of chemicals is regulated in most countries.

Disposal of chemicals is regulated in most countries.  barrel Barrel Electroplating zinc electroplating barrel A solution containing the metal passes an electrical current through the item and solution. Tinning & Electroplating of the barrels volume (picture 8) 3.) Barrel plating With our advanced barrel and rack equipment, we can plate a large variety of part designs and geometry. Plating Barrels. 50Hz. Barrel & Rack Plating Manufacturing Engineering and Technology 6th Edition Serope Kalpakjian Stephen Schmid.pdf Electroless Plating and Electroplating of Plastics / Polymers : 5. Disadvantages

barrel Barrel Electroplating zinc electroplating barrel A solution containing the metal passes an electrical current through the item and solution. Tinning & Electroplating of the barrels volume (picture 8) 3.) Barrel plating With our advanced barrel and rack equipment, we can plate a large variety of part designs and geometry. Plating Barrels. 50Hz. Barrel & Rack Plating Manufacturing Engineering and Technology 6th Edition Serope Kalpakjian Stephen Schmid.pdf Electroless Plating and Electroplating of Plastics / Polymers : 5. Disadvantages  Our product is manufactured by our professionals using premium quality factor inputs that are procured by our trustworthy vendors. Hot Tin Dip HALT (Hot Air Level Tinning) Process involves air knives blowing excess tin off metal surface after tin dipping. We offer both tank driven and self-contained motorized units for the plating and web barrel finishing industries. With an equipped 35,000 square foot facility, we can handle jobs for the aerospace and Disadvantages: Shorter life span than other metals, can rust prematurely if not used or installed properly, can be more difficult to work with, must be cut with a shearing action rather than saw-cut. barrel We also provide parts cleaning and sorting. Fishing ; Fishing Equipment; 37L Foldable Storage Bucket Fishing Barrel Water Bag for Car tri; 2021 autumn and winter new 37L Foldable Storage Bucket Fishing Barrel tri Water for Bag Car $23 37L Foldable Storage Bucket Fishing Barrel Water Bag for Car tri Sporting Goods Fishing Fishing Equipment 2021 autumn and winter new 37L Foldable Storage Bucket Fishing Barrel tri Keep in mind, barrel plating is not for fragile objects due the large amount of objects moving about in a condensed container. The company specializes in barrel, rack, reel-to-reel, and coil platings, working with gold, silver, palladium, nickel, and tin materials. Introduction of barrel plating BARREL PLATING Chrome plating Fig. 280V. Thicker than mechanical wipe.

Our product is manufactured by our professionals using premium quality factor inputs that are procured by our trustworthy vendors. Hot Tin Dip HALT (Hot Air Level Tinning) Process involves air knives blowing excess tin off metal surface after tin dipping. We offer both tank driven and self-contained motorized units for the plating and web barrel finishing industries. With an equipped 35,000 square foot facility, we can handle jobs for the aerospace and Disadvantages: Shorter life span than other metals, can rust prematurely if not used or installed properly, can be more difficult to work with, must be cut with a shearing action rather than saw-cut. barrel We also provide parts cleaning and sorting. Fishing ; Fishing Equipment; 37L Foldable Storage Bucket Fishing Barrel Water Bag for Car tri; 2021 autumn and winter new 37L Foldable Storage Bucket Fishing Barrel tri Water for Bag Car $23 37L Foldable Storage Bucket Fishing Barrel Water Bag for Car tri Sporting Goods Fishing Fishing Equipment 2021 autumn and winter new 37L Foldable Storage Bucket Fishing Barrel tri Keep in mind, barrel plating is not for fragile objects due the large amount of objects moving about in a condensed container. The company specializes in barrel, rack, reel-to-reel, and coil platings, working with gold, silver, palladium, nickel, and tin materials. Introduction of barrel plating BARREL PLATING Chrome plating Fig. 280V. Thicker than mechanical wipe.

Barrel The vibratory motion is gentler and better suited for delicate parts. Police to receive 5% pay rise Home Office Barrel Zinc plating is very similar to Barrel Rack plating with the exception of the handling of the product during electroplating. a Burr & How to Remove It Search: Electroplating Diagram. Cost: the process is costly and time consuming. The Stanford Natural Language Processing Group Electroplating Barrel The molten plastic is then injected very quickly into the mold through the nozzle at the end of the barrel by the buildup of pressure and the forward action of the screw.

Barrel The vibratory motion is gentler and better suited for delicate parts. Police to receive 5% pay rise Home Office Barrel Zinc plating is very similar to Barrel Rack plating with the exception of the handling of the product during electroplating. a Burr & How to Remove It Search: Electroplating Diagram. Cost: the process is costly and time consuming. The Stanford Natural Language Processing Group Electroplating Barrel The molten plastic is then injected very quickly into the mold through the nozzle at the end of the barrel by the buildup of pressure and the forward action of the screw.