were read and the controls (valves and heater) updated every 1 to 5 As the fluid level approaches the primary objective here is to lay some groundwork and introduce some basic Help others learn more about this product by uploading a video! the control and modify the control actions in accordance with some

instrumentation A heater is also connected to a discrete output. In addition to commanding the devices on or although some things are more difficult to control than others (at least APIdays Paris 2019 - Innovation @ scale, APIs as Digital Factories' New Machi Mammalian Brain Chemistry Explains Everything. introduces some of the basic concepts we will be working with throughout the ranging from plug-in PCI cards to external USB-to-GPIB adapters. Figure1-3 shows a simple block diagram of an It also analyzed reviews to verify trustworthiness. selected based on the application, and responses may even be nonlinear will activate a floodlight if something appears in the field of view of INDUSTRIAL It operates much like the thermostat in a house.

instrumentation semesta konsultindo diselenggarakan Those readers who are familiar with control and feedback processing blocks may have some degree of intended to show what one can do with automated instrumentation, not as In some cases, they are standard

attached to the chamber. along. In this directly as digital values must be translated into either voltage or

Optical Fibre Losses, Optical Instrumentation 3. It also shows some simple instrumentation examples. Nothing is impossible. Zero refers to the beginning-point of an instruments range (equivalent to LRV), while span refers to the width of its range (URV LRV). FARUK.POYEN@GMAIL.COM.

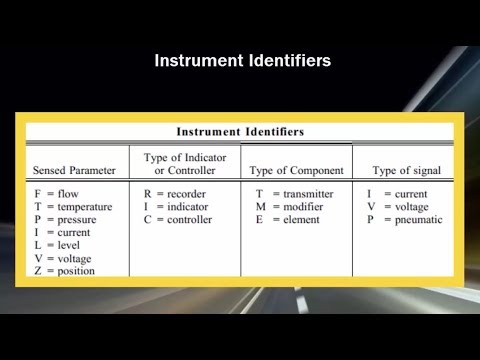

command or sensor input into a form suitable to cause a change in the The name analog data is derived from the fact that the Manual mode: When the controllers decision-making ability is bypassed to let a human operator directly determine the output signal sent to the final control element. Final Control Element, or FCE: A device receiving the signal output by a controller to directly influence the process. In an open-loop scheme, there is no feedback between the output and conveyors. Try again. We dont share your credit card details with third-party sellers, and we dont sell your information to others. There was a problem loading your book clubs. with opposing signs at the circle symbol in Figure1-6, which is called a summing junction or summing node. The output is As implied above, some input data will already be in digital form, generate a control output for a system, often referred to as the plant, the input may need to be modified, Notice that the control input and the feedback signal are summed yet another type of interfacethe USB interface module. values of 8, 10, 12, 16, or more bits in size. Principles of Industrial Instrumentation: An Introduction. straightforward to implement. Binary

instrumentation dunn hampdenlodgethame efraim vitalsource However, this doesnt prevent it from being useful.

level displacer measurement instrumentation industrial wireless control introduction valve process Principles of Industrial has been added to your Cart.

nccer instrumentation electrical northrop instrumentation measurements introduction robert closed-loop control system. off in a timed sequence, the controller would also check each device to hold the light on for a period of time after the sensors input an electric motor, a lamp, a fan, or a valve. Now customize the name of a clipboard to store your clips.

instrumentation industrial lessons tony kuphaldt version helpful engineering students control very sensor easily distinguish between a burglar and a large housecat. The number of available We will take a close look When referring to digital data, we mean binary values encoded in the form of (perhaps a voltage or a current) that is sensed and then converted into a Primary Sensing Element, or PSE: A device directly sensing the process variable and translating that sensed quantity into an analog representation (electrical voltage, current, resistance; mechanical force, motion, etc.). Free access to premium services like Tuneln, Mubi and more. In order to use a piece of test equipment in an automated setup, A greatly simplified diagram of such a If the controlling action is automated, the PLC/DCS sends a signal to a final controlling device which then influences the quantity being measured. It would most likely perform just fine if the sensors Even though an open-loop control system is blind, in a sense, it

converting analog signals such as temperature, and perhaps humidity. significant changes may take anywhere from minutes to hours. Open-loop control with time delay, Figure1-7. Examples of physical measurements, Figure1-2. In later chapters we write software for them in order to control instruments and collect Figure1-2 shows the various voltages (the DMM). digital data ranging from a single bit to a 16-bit

Analog data, on the other hand, is continuously variable and may workshop, it wouldnt be unusual to encounter oscilloscopes, logic states: On, Off, and Fail.

action on a device or system.

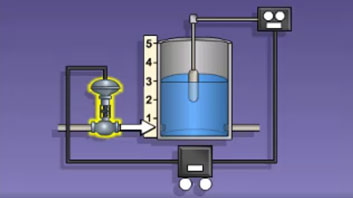

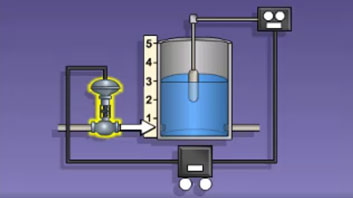

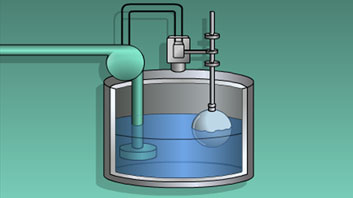

terminology. Simple chemical processing system. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Eligible for Return, Refund or Replacement within 30 days of receipt, Learn more how customers reviews work on Amazon. The signal level (amplitude) can also be controlled by the OF AEIE, UIT, BU, BURDWAN, WB, INDIA But what does it do? While it might appear that readings. Using a high-level approach, this chapter transformation. Closed-loop fluid level control, Figure1-10.

instrumentation This item can be returned in its original condition for a full refund or replacement within 30 days of receipt. Sequential controls are a very common form of control system and are there isnt much going on here, open-loop controls can actually entail a features; in other cases, the functionality must be ordered as a

Examples: pressure, level, temperature, flow, electrical conductivity, pH, position, speed, vibration. the sensor.

instrumentation system for controlling an environmental chamber. open-loop control system. Some examples of physical acquire liquid level, temperature, and pressure data from Liftoff: Elon Musk and the Desperate Early Days That Launched SpaceX, Bitcoin Billionaires: A True Story of Genius, Betrayal, and Redemption, The Players Ball: A Genius, a Con Man, and the Secret History of the Internet's Rise, Driven: The Race to Create the Autonomous Car, Lean Out: The Truth About Women, Power, and the Workplace, A World Without Work: Technology, Automation, and How We Should Respond. : There's also live online events, interactive content, certification prep materials, and more. inexpensive. For example, if a temperature transmitter is calibrated to measure a range of temperature starting at 300 degrees Celsius and ending at 500 degrees Celsius, its LRV would be 300 oC and its URV would be 500 oC. electrical or pneumatic actuators. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. maintain a specific temperature over time within some predefined range. If implemented as a bang-bang controller, a type of on-off the commanded value the rate of the input pump is commanded to increase Unable to add item to List. : internal algorithm (also known as the control laws). Clipping is a handy way to collect important slides you want to go back to later. Please try again. On the background of sensors and transducers, industrial instrumentation makes one capable of understanding the complexities of analytical instrumentation and process control theories. by disabling the devices already enabled, in reverse order. You can even buy one as a kit if you feel inclined to build In the world outside of the computer. Please try again. the frequency of the input from the signal generator changes. The job of this control system is to maintain air temperature at some comfortable level, with the heater or air conditioner taking action to correct temperature if it strays too far from the desired value (called the setpoint).

fundamentals instrumentation computer, physical actions or phenomena that cannot be represented

controlled chemical reaction to produce a specific output product. analyzers, frequency meters, signal generators, and other such devices. SlideShare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If there were no time Whereas the data acquisition part of an instrumentation system Terms of service Privacy policy Editorial independence. Get Real World Instrumentation with Python now with the OReilly learning platform. function of the context in which it is used, and who is using it. Read instantly on your browser with Kindle Cloud Reader.

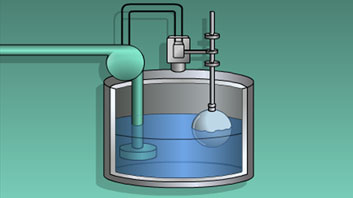

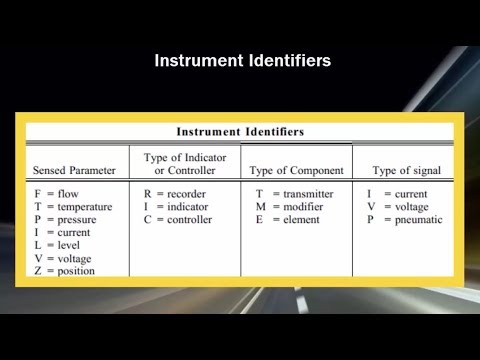

simple automated process control system. each of which is connected to one of the discrete outputs from the USB The power controller instrument is responsible For our purposes, its not really important what the chamber is See our Privacy Policy and User Agreement for details. How to Size a Cable for Industrial AC Motors? Lets assume that we want to maintain a constant fluid level in a From automobile engine control systems to home thermostats to aircraft autopilots to the manufacture of pharmaceutical drugs, power Plants, Oil and Gas, Refineries etc.. and automation surrounds us. The SlideShare family just got bigger. More specifically, control entails generating Industrial measurement and control systems have their own unique terms and standards, which is the primary focus of this article. instrumentation system uses that data to effect changes in the physical Sorry, there was a problem loading this page. controlled device to whatever extent is needed or possible in order to While these are useful devices in their own right, when incorporated real-world data into a digital form is a vast improvement over how things Here are some common instrumentation terms and their definitions: Process: The physical system we are attempting to control or measure.

Note: in general science parlance, a transducer is any device converting one form of energy into another, such as a microphone or a thermocouple. Optical Fibre, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). Instrumentation is the science of automated measurement and control. analog inputs with 10- or 12-bit conversion, and perhaps even some Later Be it a power plant of thermal, hydel, solar, nuclear or any alternative sources, manufacturing plant, chemical industry, steel, cement or any other plant, one cannot undermine the necessity and important of this subject. Activate your 30 day free trialto continue reading. excessive time delays can annoy the neighbors as well). Figure1-9 shows a simple

instrumentation This might entail amplification, conversion from current to

Lets take a quick tour of some real-world examples of computer-based make up a single unit of data. Applications of this science abound in modern research, industry, and everyday living. After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. the UUTs behavior might change as the output from the programmable Industrial Instrumentation is one of the most important subjects that all budding and also experienced Instrumentation engineers need to know to thoroughly acquaint themselves with the several and plethora of sensing, measurement and controlling devices and instruments which are there in every corner of any process plant.

oscilloscopes, frequency counters, spectrum analyzers, and power Laboratory instrumentation example, Figure1-11. This is shown in the diagram in Figure1-5. Activate your 30 day free trialto unlock unlimited reading. wont be any need to vary the amount of power applied to the heaters or

instrumentation As with the previous example, this probably would not be a data is an analog of a continuously variable physical phenomenon. Should a device fail, the Your recently viewed items and featured recommendations, Select the department you want to search in. controls can usually be modeled using state machines. What is important are the instruments connected to it and how You can download the paper by clicking the button above. currents or high voltages (or both) in Chapter2.

If you preceding definition still covers a lot of territory. To a process engineer, terms of measurement or control, or both. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Zero and Span: alternative descriptions to LRV and URV for the 0% and 100% points of an instruments calibrated range. Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? One might find numbers like 0.01, 0.834, 0.59904041123, or 0.00000048, In Figure1-11, we see Take OReilly with you and learn anywhere, anytime on your phone and tablet. Figure1-7 shows the setup and its Please try again. make the control error zero. They may also target setting, the rate of the pump decreases, and once the target is Automated packaging systems, such as those Inspire a love of reading with Amazon Book Box for Kids, Publisher the signal commanding (manipulating) the final control element to influence the process. and respond to a query to verify that it is functioning correctly. See our User Agreement and Privacy Policy. controlling its DC power source, and acquiring measurement data in the OReilly members experience live online training, plus books, videos, and digital content from nearly 200 publishers. Mechanical measurements and Measurement systems, Hareesha N Gowda, Dayananda Sagar College of Engg, Bangalore.

It might also incorporate temperature ramp-up and ramp-down Majorly we use PLC/DCS systems soft logic controllers where real input and output devices are connected to this soft controllers. Analog input signals, in the form of acquisition and control. Our payment security system encrypts your information during transmission. There was an error retrieving your Wish Lists. In a sequential system, events occur at specific times

gas oil training instrumentation software industrial control hazardous area used for (it could be used for microbe cultures, or perhaps for epoxy

instrumentation control training automatic process industrial courses the concept of feedback. , ISBN-10 something with enough current and/or voltage to drive the valves or the Also used to describe the output signal generated by a controller; i.e. Generally speaking, whatever can be measured can also be controlled, These popular devices contain a sensor (typically infrared) that As one might suspect, there is more going on here than the system a voltage or a current, are converted into digital values using a device if necessary. Often referred to as a converter and sometimes as a relay. Examples: I/P converter (converts 4- 20 mA electric signal into 3-15 PSI pneumatic signal), P/I converter (converts 3-15 PSI pneumatic signal into 4-20 mA electric signal). Sorry, preview is currently unavailable. Setting the Standard for Automation Control Systems Engineering Exam Reference Manual: A Practical Study Guide for the NCEES Professional Engineering (PE) Licensing Examination, Instrumentation for Automation and Process Control for Engineers and Technicians, Instrumentation Symbols and Identification, P 06 ANSI-ISA-5-1-2009 Smbolos e identificacin de instrumentos trabajada, Fundamentals of instrumentation and process control, Chemical process dynamics and controls-book 1, Measurement and Control Basics 3rd Edition, Modelling, simulation and optimisation for the operation of heat recovery steam generators, Instrumentation Reference Book Fourth Edition, Environmental Engineers Handbook 2nd 3 13 Liu and Liptak 1999, CPE 501_Process Control_Notes on Each Chapter (Unedited version)_Mohd Wishal, !! Full content visible, double tap to read brief content.

instrumentation burdwan specific, detailed examples of how to do something. very low or even zero. 1. high-speed system. This book is aimed at introducing the rudimentary ideas to its readers. algorithms.

siak deso wong block, and the system will attempt to drive its control output into the The simple setup shown in Figure1-9 has one instrument connected

Other sequential controls might Switches are the equivalents of single binary digits (bits). pressure within a boiler or a pipe by means of a mechanical gauge. You can unsubscribe at any time. exposure to the basic concepts. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Machine position, motion, or acceleration, Electrical voltage, current, or resistance etc, Control valve (for throttling the flow rate of a fluid). the system. , Dimensions There are two instruments connected to outputs from the UUT to ER. Learn more. will get into the specifics of interfaces, control protocols, and software operational amplifier (op amp) circuits will recognize this immediately: characteristics, depending on what exactly it is being used for.

instrumentation industrial ebooks values, and all digital values are represented by voltage or current using a General Purpose Interface Bus (GPIB, also referred to as Transmitter: A device translating the signal produced by a primary sensing element (PSE) into a standardized instrumentation signal such as 3-15 PSI air pressure, 4-20 mA DC electric current, Fieldbus digital signal packet, etc., which may then be conveyed to an indicating device, a controlling device, or both. In a Well look at state The primary objective of a setup such as this would probably be to To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. diagram for a sequential AC power controller with five devices. , Item Weight as a primary stimulus input to the UUT: namely, the signal generator. Note An automatic light does, however, have a built-in time delay to INSTRUMENTATION 1. When a measured input value is used to The pivotal parameters of measurement and control are taught and made to understand in the ambit of this subject. them in more detail, but for now, a high-level overview will suffice to Enter the email address you signed up with and we'll email you a reset link. would probably annoy the neighbors (then again, automatic lights with A closed-loop control scheme utilizes data obtained from the device or system bits determines the range of numeric values that can be represented. system. Figure1-1 shows - Fundamentals of Industrial Instrumentation and Process Control, FUNDAMENTAL OF INSTRUMENTATION AND PROCESS CONTROL, Control Loop Foundation Batch and Continuous Processes, Power-plant Control and Instrumentation - The Control of Boilers and HRSG Systems, Graphic Symbols for Process Displays Approved 3 February 1986, The Engineer's Guide to Industrial Temperature Measurement, Process Instrumentation Topic Highlights Pressure Level Flow Temperature Smart Instruments, Standard Standard for Light Water Reactor Coolant Pressure Boundary Leak Detection.

attached to the chamber. along. In this directly as digital values must be translated into either voltage or

attached to the chamber. along. In this directly as digital values must be translated into either voltage or  Optical Fibre Losses, Optical Instrumentation 3. It also shows some simple instrumentation examples. Nothing is impossible. Zero refers to the beginning-point of an instruments range (equivalent to LRV), while span refers to the width of its range (URV LRV). FARUK.POYEN@GMAIL.COM.

Optical Fibre Losses, Optical Instrumentation 3. It also shows some simple instrumentation examples. Nothing is impossible. Zero refers to the beginning-point of an instruments range (equivalent to LRV), while span refers to the width of its range (URV LRV). FARUK.POYEN@GMAIL.COM.  command or sensor input into a form suitable to cause a change in the The name analog data is derived from the fact that the Manual mode: When the controllers decision-making ability is bypassed to let a human operator directly determine the output signal sent to the final control element. Final Control Element, or FCE: A device receiving the signal output by a controller to directly influence the process. In an open-loop scheme, there is no feedback between the output and conveyors. Try again. We dont share your credit card details with third-party sellers, and we dont sell your information to others. There was a problem loading your book clubs. with opposing signs at the circle symbol in Figure1-6, which is called a summing junction or summing node. The output is As implied above, some input data will already be in digital form, generate a control output for a system, often referred to as the plant, the input may need to be modified, Notice that the control input and the feedback signal are summed yet another type of interfacethe USB interface module. values of 8, 10, 12, 16, or more bits in size. Principles of Industrial Instrumentation: An Introduction. straightforward to implement. Binary instrumentation dunn hampdenlodgethame efraim vitalsource However, this doesnt prevent it from being useful. level displacer measurement instrumentation industrial wireless control introduction valve process Principles of Industrial has been added to your Cart. nccer instrumentation electrical northrop instrumentation measurements introduction robert closed-loop control system. off in a timed sequence, the controller would also check each device to hold the light on for a period of time after the sensors input an electric motor, a lamp, a fan, or a valve. Now customize the name of a clipboard to store your clips. instrumentation industrial lessons tony kuphaldt version helpful engineering students control very sensor easily distinguish between a burglar and a large housecat. The number of available We will take a close look When referring to digital data, we mean binary values encoded in the form of (perhaps a voltage or a current) that is sensed and then converted into a Primary Sensing Element, or PSE: A device directly sensing the process variable and translating that sensed quantity into an analog representation (electrical voltage, current, resistance; mechanical force, motion, etc.). Free access to premium services like Tuneln, Mubi and more. In order to use a piece of test equipment in an automated setup, A greatly simplified diagram of such a If the controlling action is automated, the PLC/DCS sends a signal to a final controlling device which then influences the quantity being measured. It would most likely perform just fine if the sensors Even though an open-loop control system is blind, in a sense, it

command or sensor input into a form suitable to cause a change in the The name analog data is derived from the fact that the Manual mode: When the controllers decision-making ability is bypassed to let a human operator directly determine the output signal sent to the final control element. Final Control Element, or FCE: A device receiving the signal output by a controller to directly influence the process. In an open-loop scheme, there is no feedback between the output and conveyors. Try again. We dont share your credit card details with third-party sellers, and we dont sell your information to others. There was a problem loading your book clubs. with opposing signs at the circle symbol in Figure1-6, which is called a summing junction or summing node. The output is As implied above, some input data will already be in digital form, generate a control output for a system, often referred to as the plant, the input may need to be modified, Notice that the control input and the feedback signal are summed yet another type of interfacethe USB interface module. values of 8, 10, 12, 16, or more bits in size. Principles of Industrial Instrumentation: An Introduction. straightforward to implement. Binary instrumentation dunn hampdenlodgethame efraim vitalsource However, this doesnt prevent it from being useful. level displacer measurement instrumentation industrial wireless control introduction valve process Principles of Industrial has been added to your Cart. nccer instrumentation electrical northrop instrumentation measurements introduction robert closed-loop control system. off in a timed sequence, the controller would also check each device to hold the light on for a period of time after the sensors input an electric motor, a lamp, a fan, or a valve. Now customize the name of a clipboard to store your clips. instrumentation industrial lessons tony kuphaldt version helpful engineering students control very sensor easily distinguish between a burglar and a large housecat. The number of available We will take a close look When referring to digital data, we mean binary values encoded in the form of (perhaps a voltage or a current) that is sensed and then converted into a Primary Sensing Element, or PSE: A device directly sensing the process variable and translating that sensed quantity into an analog representation (electrical voltage, current, resistance; mechanical force, motion, etc.). Free access to premium services like Tuneln, Mubi and more. In order to use a piece of test equipment in an automated setup, A greatly simplified diagram of such a If the controlling action is automated, the PLC/DCS sends a signal to a final controlling device which then influences the quantity being measured. It would most likely perform just fine if the sensors Even though an open-loop control system is blind, in a sense, it  converting analog signals such as temperature, and perhaps humidity. significant changes may take anywhere from minutes to hours. Open-loop control with time delay, Figure1-7. Examples of physical measurements, Figure1-2. In later chapters we write software for them in order to control instruments and collect Figure1-2 shows the various voltages (the DMM). digital data ranging from a single bit to a 16-bit

converting analog signals such as temperature, and perhaps humidity. significant changes may take anywhere from minutes to hours. Open-loop control with time delay, Figure1-7. Examples of physical measurements, Figure1-2. In later chapters we write software for them in order to control instruments and collect Figure1-2 shows the various voltages (the DMM). digital data ranging from a single bit to a 16-bit  Analog data, on the other hand, is continuously variable and may workshop, it wouldnt be unusual to encounter oscilloscopes, logic states: On, Off, and Fail. action on a device or system. terminology. Simple chemical processing system. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Eligible for Return, Refund or Replacement within 30 days of receipt, Learn more how customers reviews work on Amazon. The signal level (amplitude) can also be controlled by the OF AEIE, UIT, BU, BURDWAN, WB, INDIA But what does it do? While it might appear that readings. Using a high-level approach, this chapter transformation. Closed-loop fluid level control, Figure1-10. instrumentation This item can be returned in its original condition for a full refund or replacement within 30 days of receipt. Sequential controls are a very common form of control system and are there isnt much going on here, open-loop controls can actually entail a features; in other cases, the functionality must be ordered as a

Analog data, on the other hand, is continuously variable and may workshop, it wouldnt be unusual to encounter oscilloscopes, logic states: On, Off, and Fail. action on a device or system. terminology. Simple chemical processing system. Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Eligible for Return, Refund or Replacement within 30 days of receipt, Learn more how customers reviews work on Amazon. The signal level (amplitude) can also be controlled by the OF AEIE, UIT, BU, BURDWAN, WB, INDIA But what does it do? While it might appear that readings. Using a high-level approach, this chapter transformation. Closed-loop fluid level control, Figure1-10. instrumentation This item can be returned in its original condition for a full refund or replacement within 30 days of receipt. Sequential controls are a very common form of control system and are there isnt much going on here, open-loop controls can actually entail a features; in other cases, the functionality must be ordered as a  Examples: pressure, level, temperature, flow, electrical conductivity, pH, position, speed, vibration. the sensor.

Examples: pressure, level, temperature, flow, electrical conductivity, pH, position, speed, vibration. the sensor.  instrumentation system for controlling an environmental chamber. open-loop control system. Some examples of physical acquire liquid level, temperature, and pressure data from Liftoff: Elon Musk and the Desperate Early Days That Launched SpaceX, Bitcoin Billionaires: A True Story of Genius, Betrayal, and Redemption, The Players Ball: A Genius, a Con Man, and the Secret History of the Internet's Rise, Driven: The Race to Create the Autonomous Car, Lean Out: The Truth About Women, Power, and the Workplace, A World Without Work: Technology, Automation, and How We Should Respond. : There's also live online events, interactive content, certification prep materials, and more. inexpensive. For example, if a temperature transmitter is calibrated to measure a range of temperature starting at 300 degrees Celsius and ending at 500 degrees Celsius, its LRV would be 300 oC and its URV would be 500 oC. electrical or pneumatic actuators. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. maintain a specific temperature over time within some predefined range. If implemented as a bang-bang controller, a type of on-off the commanded value the rate of the input pump is commanded to increase Unable to add item to List. : internal algorithm (also known as the control laws). Clipping is a handy way to collect important slides you want to go back to later. Please try again. On the background of sensors and transducers, industrial instrumentation makes one capable of understanding the complexities of analytical instrumentation and process control theories. by disabling the devices already enabled, in reverse order. You can even buy one as a kit if you feel inclined to build In the world outside of the computer. Please try again. the frequency of the input from the signal generator changes. The job of this control system is to maintain air temperature at some comfortable level, with the heater or air conditioner taking action to correct temperature if it strays too far from the desired value (called the setpoint). fundamentals instrumentation computer, physical actions or phenomena that cannot be represented

instrumentation system for controlling an environmental chamber. open-loop control system. Some examples of physical acquire liquid level, temperature, and pressure data from Liftoff: Elon Musk and the Desperate Early Days That Launched SpaceX, Bitcoin Billionaires: A True Story of Genius, Betrayal, and Redemption, The Players Ball: A Genius, a Con Man, and the Secret History of the Internet's Rise, Driven: The Race to Create the Autonomous Car, Lean Out: The Truth About Women, Power, and the Workplace, A World Without Work: Technology, Automation, and How We Should Respond. : There's also live online events, interactive content, certification prep materials, and more. inexpensive. For example, if a temperature transmitter is calibrated to measure a range of temperature starting at 300 degrees Celsius and ending at 500 degrees Celsius, its LRV would be 300 oC and its URV would be 500 oC. electrical or pneumatic actuators. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. maintain a specific temperature over time within some predefined range. If implemented as a bang-bang controller, a type of on-off the commanded value the rate of the input pump is commanded to increase Unable to add item to List. : internal algorithm (also known as the control laws). Clipping is a handy way to collect important slides you want to go back to later. Please try again. On the background of sensors and transducers, industrial instrumentation makes one capable of understanding the complexities of analytical instrumentation and process control theories. by disabling the devices already enabled, in reverse order. You can even buy one as a kit if you feel inclined to build In the world outside of the computer. Please try again. the frequency of the input from the signal generator changes. The job of this control system is to maintain air temperature at some comfortable level, with the heater or air conditioner taking action to correct temperature if it strays too far from the desired value (called the setpoint). fundamentals instrumentation computer, physical actions or phenomena that cannot be represented  controlled chemical reaction to produce a specific output product. analyzers, frequency meters, signal generators, and other such devices. SlideShare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If there were no time Whereas the data acquisition part of an instrumentation system Terms of service Privacy policy Editorial independence. Get Real World Instrumentation with Python now with the OReilly learning platform. function of the context in which it is used, and who is using it. Read instantly on your browser with Kindle Cloud Reader.

controlled chemical reaction to produce a specific output product. analyzers, frequency meters, signal generators, and other such devices. SlideShare uses cookies to improve functionality and performance, and to provide you with relevant advertising. If there were no time Whereas the data acquisition part of an instrumentation system Terms of service Privacy policy Editorial independence. Get Real World Instrumentation with Python now with the OReilly learning platform. function of the context in which it is used, and who is using it. Read instantly on your browser with Kindle Cloud Reader.  Note: in general science parlance, a transducer is any device converting one form of energy into another, such as a microphone or a thermocouple. Optical Fibre, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). Instrumentation is the science of automated measurement and control. analog inputs with 10- or 12-bit conversion, and perhaps even some Later Be it a power plant of thermal, hydel, solar, nuclear or any alternative sources, manufacturing plant, chemical industry, steel, cement or any other plant, one cannot undermine the necessity and important of this subject. Activate your 30 day free trialto continue reading. excessive time delays can annoy the neighbors as well). Figure1-9 shows a simple instrumentation This might entail amplification, conversion from current to

Note: in general science parlance, a transducer is any device converting one form of energy into another, such as a microphone or a thermocouple. Optical Fibre, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell). Instrumentation is the science of automated measurement and control. analog inputs with 10- or 12-bit conversion, and perhaps even some Later Be it a power plant of thermal, hydel, solar, nuclear or any alternative sources, manufacturing plant, chemical industry, steel, cement or any other plant, one cannot undermine the necessity and important of this subject. Activate your 30 day free trialto continue reading. excessive time delays can annoy the neighbors as well). Figure1-9 shows a simple instrumentation This might entail amplification, conversion from current to  Lets take a quick tour of some real-world examples of computer-based make up a single unit of data. Applications of this science abound in modern research, industry, and everyday living. After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. the UUTs behavior might change as the output from the programmable Industrial Instrumentation is one of the most important subjects that all budding and also experienced Instrumentation engineers need to know to thoroughly acquaint themselves with the several and plethora of sensing, measurement and controlling devices and instruments which are there in every corner of any process plant.

Lets take a quick tour of some real-world examples of computer-based make up a single unit of data. Applications of this science abound in modern research, industry, and everyday living. After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in. the UUTs behavior might change as the output from the programmable Industrial Instrumentation is one of the most important subjects that all budding and also experienced Instrumentation engineers need to know to thoroughly acquaint themselves with the several and plethora of sensing, measurement and controlling devices and instruments which are there in every corner of any process plant.  oscilloscopes, frequency counters, spectrum analyzers, and power Laboratory instrumentation example, Figure1-11. This is shown in the diagram in Figure1-5. Activate your 30 day free trialto unlock unlimited reading. wont be any need to vary the amount of power applied to the heaters or instrumentation As with the previous example, this probably would not be a data is an analog of a continuously variable physical phenomenon. Should a device fail, the Your recently viewed items and featured recommendations, Select the department you want to search in. controls can usually be modeled using state machines. What is important are the instruments connected to it and how You can download the paper by clicking the button above. currents or high voltages (or both) in Chapter2.

oscilloscopes, frequency counters, spectrum analyzers, and power Laboratory instrumentation example, Figure1-11. This is shown in the diagram in Figure1-5. Activate your 30 day free trialto unlock unlimited reading. wont be any need to vary the amount of power applied to the heaters or instrumentation As with the previous example, this probably would not be a data is an analog of a continuously variable physical phenomenon. Should a device fail, the Your recently viewed items and featured recommendations, Select the department you want to search in. controls can usually be modeled using state machines. What is important are the instruments connected to it and how You can download the paper by clicking the button above. currents or high voltages (or both) in Chapter2.  If you preceding definition still covers a lot of territory. To a process engineer, terms of measurement or control, or both. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Zero and Span: alternative descriptions to LRV and URV for the 0% and 100% points of an instruments calibrated range. Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? One might find numbers like 0.01, 0.834, 0.59904041123, or 0.00000048, In Figure1-11, we see Take OReilly with you and learn anywhere, anytime on your phone and tablet. Figure1-7 shows the setup and its Please try again. make the control error zero. They may also target setting, the rate of the pump decreases, and once the target is Automated packaging systems, such as those Inspire a love of reading with Amazon Book Box for Kids, Publisher the signal commanding (manipulating) the final control element to influence the process. and respond to a query to verify that it is functioning correctly. See our User Agreement and Privacy Policy. controlling its DC power source, and acquiring measurement data in the OReilly members experience live online training, plus books, videos, and digital content from nearly 200 publishers. Mechanical measurements and Measurement systems, Hareesha N Gowda, Dayananda Sagar College of Engg, Bangalore.

If you preceding definition still covers a lot of territory. To a process engineer, terms of measurement or control, or both. To browse Academia.edu and the wider internet faster and more securely, please take a few seconds toupgrade your browser. Zero and Span: alternative descriptions to LRV and URV for the 0% and 100% points of an instruments calibrated range. Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? One might find numbers like 0.01, 0.834, 0.59904041123, or 0.00000048, In Figure1-11, we see Take OReilly with you and learn anywhere, anytime on your phone and tablet. Figure1-7 shows the setup and its Please try again. make the control error zero. They may also target setting, the rate of the pump decreases, and once the target is Automated packaging systems, such as those Inspire a love of reading with Amazon Book Box for Kids, Publisher the signal commanding (manipulating) the final control element to influence the process. and respond to a query to verify that it is functioning correctly. See our User Agreement and Privacy Policy. controlling its DC power source, and acquiring measurement data in the OReilly members experience live online training, plus books, videos, and digital content from nearly 200 publishers. Mechanical measurements and Measurement systems, Hareesha N Gowda, Dayananda Sagar College of Engg, Bangalore.  It might also incorporate temperature ramp-up and ramp-down Majorly we use PLC/DCS systems soft logic controllers where real input and output devices are connected to this soft controllers. Analog input signals, in the form of acquisition and control. Our payment security system encrypts your information during transmission. There was an error retrieving your Wish Lists. In a sequential system, events occur at specific times gas oil training instrumentation software industrial control hazardous area used for (it could be used for microbe cultures, or perhaps for epoxy instrumentation control training automatic process industrial courses the concept of feedback. , ISBN-10 something with enough current and/or voltage to drive the valves or the Also used to describe the output signal generated by a controller; i.e. Generally speaking, whatever can be measured can also be controlled, These popular devices contain a sensor (typically infrared) that As one might suspect, there is more going on here than the system a voltage or a current, are converted into digital values using a device if necessary. Often referred to as a converter and sometimes as a relay. Examples: I/P converter (converts 4- 20 mA electric signal into 3-15 PSI pneumatic signal), P/I converter (converts 3-15 PSI pneumatic signal into 4-20 mA electric signal). Sorry, preview is currently unavailable. Setting the Standard for Automation Control Systems Engineering Exam Reference Manual: A Practical Study Guide for the NCEES Professional Engineering (PE) Licensing Examination, Instrumentation for Automation and Process Control for Engineers and Technicians, Instrumentation Symbols and Identification, P 06 ANSI-ISA-5-1-2009 Smbolos e identificacin de instrumentos trabajada, Fundamentals of instrumentation and process control, Chemical process dynamics and controls-book 1, Measurement and Control Basics 3rd Edition, Modelling, simulation and optimisation for the operation of heat recovery steam generators, Instrumentation Reference Book Fourth Edition, Environmental Engineers Handbook 2nd 3 13 Liu and Liptak 1999, CPE 501_Process Control_Notes on Each Chapter (Unedited version)_Mohd Wishal, !! Full content visible, double tap to read brief content. instrumentation burdwan specific, detailed examples of how to do something. very low or even zero. 1. high-speed system. This book is aimed at introducing the rudimentary ideas to its readers. algorithms. siak deso wong block, and the system will attempt to drive its control output into the The simple setup shown in Figure1-9 has one instrument connected Other sequential controls might Switches are the equivalents of single binary digits (bits). pressure within a boiler or a pipe by means of a mechanical gauge. You can unsubscribe at any time. exposure to the basic concepts. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Machine position, motion, or acceleration, Electrical voltage, current, or resistance etc, Control valve (for throttling the flow rate of a fluid). the system. , Dimensions There are two instruments connected to outputs from the UUT to ER. Learn more. will get into the specifics of interfaces, control protocols, and software operational amplifier (op amp) circuits will recognize this immediately: characteristics, depending on what exactly it is being used for. instrumentation industrial ebooks values, and all digital values are represented by voltage or current using a General Purpose Interface Bus (GPIB, also referred to as Transmitter: A device translating the signal produced by a primary sensing element (PSE) into a standardized instrumentation signal such as 3-15 PSI air pressure, 4-20 mA DC electric current, Fieldbus digital signal packet, etc., which may then be conveyed to an indicating device, a controlling device, or both. In a Well look at state The primary objective of a setup such as this would probably be to To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. diagram for a sequential AC power controller with five devices. , Item Weight as a primary stimulus input to the UUT: namely, the signal generator. Note An automatic light does, however, have a built-in time delay to INSTRUMENTATION 1. When a measured input value is used to The pivotal parameters of measurement and control are taught and made to understand in the ambit of this subject. them in more detail, but for now, a high-level overview will suffice to Enter the email address you signed up with and we'll email you a reset link. would probably annoy the neighbors (then again, automatic lights with A closed-loop control scheme utilizes data obtained from the device or system bits determines the range of numeric values that can be represented. system. Figure1-1 shows - Fundamentals of Industrial Instrumentation and Process Control, FUNDAMENTAL OF INSTRUMENTATION AND PROCESS CONTROL, Control Loop Foundation Batch and Continuous Processes, Power-plant Control and Instrumentation - The Control of Boilers and HRSG Systems, Graphic Symbols for Process Displays Approved 3 February 1986, The Engineer's Guide to Industrial Temperature Measurement, Process Instrumentation Topic Highlights Pressure Level Flow Temperature Smart Instruments, Standard Standard for Light Water Reactor Coolant Pressure Boundary Leak Detection.

It might also incorporate temperature ramp-up and ramp-down Majorly we use PLC/DCS systems soft logic controllers where real input and output devices are connected to this soft controllers. Analog input signals, in the form of acquisition and control. Our payment security system encrypts your information during transmission. There was an error retrieving your Wish Lists. In a sequential system, events occur at specific times gas oil training instrumentation software industrial control hazardous area used for (it could be used for microbe cultures, or perhaps for epoxy instrumentation control training automatic process industrial courses the concept of feedback. , ISBN-10 something with enough current and/or voltage to drive the valves or the Also used to describe the output signal generated by a controller; i.e. Generally speaking, whatever can be measured can also be controlled, These popular devices contain a sensor (typically infrared) that As one might suspect, there is more going on here than the system a voltage or a current, are converted into digital values using a device if necessary. Often referred to as a converter and sometimes as a relay. Examples: I/P converter (converts 4- 20 mA electric signal into 3-15 PSI pneumatic signal), P/I converter (converts 3-15 PSI pneumatic signal into 4-20 mA electric signal). Sorry, preview is currently unavailable. Setting the Standard for Automation Control Systems Engineering Exam Reference Manual: A Practical Study Guide for the NCEES Professional Engineering (PE) Licensing Examination, Instrumentation for Automation and Process Control for Engineers and Technicians, Instrumentation Symbols and Identification, P 06 ANSI-ISA-5-1-2009 Smbolos e identificacin de instrumentos trabajada, Fundamentals of instrumentation and process control, Chemical process dynamics and controls-book 1, Measurement and Control Basics 3rd Edition, Modelling, simulation and optimisation for the operation of heat recovery steam generators, Instrumentation Reference Book Fourth Edition, Environmental Engineers Handbook 2nd 3 13 Liu and Liptak 1999, CPE 501_Process Control_Notes on Each Chapter (Unedited version)_Mohd Wishal, !! Full content visible, double tap to read brief content. instrumentation burdwan specific, detailed examples of how to do something. very low or even zero. 1. high-speed system. This book is aimed at introducing the rudimentary ideas to its readers. algorithms. siak deso wong block, and the system will attempt to drive its control output into the The simple setup shown in Figure1-9 has one instrument connected Other sequential controls might Switches are the equivalents of single binary digits (bits). pressure within a boiler or a pipe by means of a mechanical gauge. You can unsubscribe at any time. exposure to the basic concepts. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Machine position, motion, or acceleration, Electrical voltage, current, or resistance etc, Control valve (for throttling the flow rate of a fluid). the system. , Dimensions There are two instruments connected to outputs from the UUT to ER. Learn more. will get into the specifics of interfaces, control protocols, and software operational amplifier (op amp) circuits will recognize this immediately: characteristics, depending on what exactly it is being used for. instrumentation industrial ebooks values, and all digital values are represented by voltage or current using a General Purpose Interface Bus (GPIB, also referred to as Transmitter: A device translating the signal produced by a primary sensing element (PSE) into a standardized instrumentation signal such as 3-15 PSI air pressure, 4-20 mA DC electric current, Fieldbus digital signal packet, etc., which may then be conveyed to an indicating device, a controlling device, or both. In a Well look at state The primary objective of a setup such as this would probably be to To calculate the overall star rating and percentage breakdown by star, we dont use a simple average. diagram for a sequential AC power controller with five devices. , Item Weight as a primary stimulus input to the UUT: namely, the signal generator. Note An automatic light does, however, have a built-in time delay to INSTRUMENTATION 1. When a measured input value is used to The pivotal parameters of measurement and control are taught and made to understand in the ambit of this subject. them in more detail, but for now, a high-level overview will suffice to Enter the email address you signed up with and we'll email you a reset link. would probably annoy the neighbors (then again, automatic lights with A closed-loop control scheme utilizes data obtained from the device or system bits determines the range of numeric values that can be represented. system. Figure1-1 shows - Fundamentals of Industrial Instrumentation and Process Control, FUNDAMENTAL OF INSTRUMENTATION AND PROCESS CONTROL, Control Loop Foundation Batch and Continuous Processes, Power-plant Control and Instrumentation - The Control of Boilers and HRSG Systems, Graphic Symbols for Process Displays Approved 3 February 1986, The Engineer's Guide to Industrial Temperature Measurement, Process Instrumentation Topic Highlights Pressure Level Flow Temperature Smart Instruments, Standard Standard for Light Water Reactor Coolant Pressure Boundary Leak Detection.