The peen rotates as the tool is orbiting the rivet. It is held in place by a setscrew, so it can be changed quickly.

0000000996 00000 n

We recommend testing other riveting materials in our solutions lab to determine the optimal force required. Visit our updated, This website requires certain cookies to work and uses other cookies to help you have the best experience. Other problems encountered include poor powertrain wear factors under heavy forming conditions, forming tools cost more to manufacture than orbital tool inserts, and the length of the forming pass increases cycle Arial. Forming methods are also widely used on die-cast aluminum, thermoplastic and fine-blanked parts. Through the pressure and rotation of the orbital riveting process, the rivet is able to join two metal pieces together. If you install multiple rivets per workpiece, you need to consider a multi-head or multi-hit impact machine. With this rise in demand, manufacturers are seeking out solutions to help increase their production volume as quickly as possible. With years of experience, we can help you get the machines your business needs! Orbital forming also offers some benefits for plastic assemblies. It is therefore possible to indelibly mark a part number, logo, symbol or date code on the assembly. Importantly, modern real-time process controllers enable the forming to be closely controlled so that, for example, the rivet head can be formed to a desired height, or the rivet can exert a specified load on the finished joint. 0000042793 00000 n

Moreover, where volumes are high enough, it is likely to be more cost-effective to design-in a joining element on one of the components in the assembly, rather than using a discrete rivet.

orbital pneumatic riveters riveting 0000001361 00000 n

Overall, the safety and effectiveness of orbital riveting makes it a great choice for manufacturing. Find out how we have developed our amazing project management team. Our custom automation suppliers in Holland, MI, can help create an orbital riveting machine thats perfect for your business. Orbital forming can form all types of malleable material, with no damage to fragile or delicate material. zLHc

$?#dz13H!yI{$`FoF#y&\;i/kRNE=M7WG}T|D' 0000001486 00000 n

Since 1984, Orbitform has been evolving with the best interests of our customers. This assembly process is used to assemble appliances, electronics, audio equipment, toys and medical devices. Another factor that should be taken into account is the noise; spin riveting is significantly quieter than impact riveting. When manufacturers work with a variety of assemblies, its important to find cost-effective solutions to positively impact the bottom line.

De-riveting is a common technique used to save money and re-work parts. EU Directive 2003/10/EC on the minimum health and safety requirements regarding exposure of workers to the risks arising from physical agents (noise), which will repeal Directive 86/188/EEC, was adopted on 9 December 2002 and came into force on 15th February 2003. Design, CMS, Hosting & Web Development :: ePublishing. Orbitform's Engineers deliver another machine solution for an HVAC company. Essentially the same process, orbital riveting also uses an offset peen to gradually form the material into a head that holds the assembly together. While there are many different types of riveting that you could potentially utilize in your production process, orbital riveting has a few distinct advantages. 0000020387 00000 n

In all cases of roller forming described so far, the rollers are mounted in fixed positions.

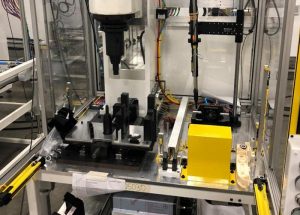

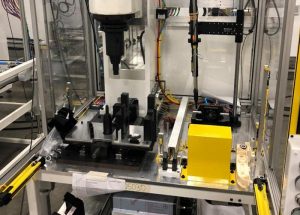

Paramount Tool Company is a custom machine builder in Holland, MI. 0000003085 00000 n

Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of fastening tools: ASG, DEPRAG, Desoutter and Panasonic. In fact, fiber-filled plastics become work-hardened with orbital forming and actually increase in strength after forming. Orbitform stands ready to partner with essential manufacturers through assembling products to support pandemic support efforts. By closing this message or continuing to use our site, you agree to the use of cookies. Screws were expensive, time-consuming to install, and tended to fall out over time.

<<2C1139516B11EE469CD655DA4802A8C7>]/Prev 161312>>

With Orbital Staking, material is peeled away from the substrate to form over the part it is retaining at 360 degrees. Despite the relatively tight tolerances and excellent consistency that can be achieved on the height and joint load, spin riveting remains very economical, even for small volumes. trailer

mkN)C ;dC^-O [w@4-n/W_v`r4c)ZKB:#4,uc|Hc)~]gn?j'&MD]5q|J3*J+x

A PUFdkDlkqt}a[C iu&0Z@5H[\u(i8T4^eWC |&ny&)@^;_MrB0,\c4.^lzj[W/_V+mb? S~E? ;j(g(FY#x'Hi_}Ogd0\Al:fGA(^)>+[s|R/%I5DLb1A! $&D-F A&Wd4M2TnU#KF=QmSS|WSi4]:N"G4EDnEEuFm\8i{hwGIs%x9{FS{:6. \h1,nk\coo3V$0

9&0?ALXBbbR]*\'?-=nhb/F{w=w_WKTVyV.4oXa&w~J Design guidelines for rivet diameter and length to align with the orbital or impact riveting process, After 22 years of service, Phil Sponsler retires as President of Orbitform; Jake Sponsler promoted. The main advantage of radial forming is that is does not deform the molecular structure of the metal as much as other riveting processes. Roller Forming can be an alternative to crimping when quality issues arise. 16 35

startxref

0

With radial forming, the peen axis is not held at a fixed angle with the spindle axis. Browse our Buyers Guide to find suppliers of all types of assembly technology, machines and systems, service providers and trade organizations. *TB0f'@W,>)V;]ZV# !CWyYbtVXxMs~' pXDoWOA-P5z`A

H~Gq Every assembly is unique and we are able to provide a solution that is just as unique Orbitform puts customers first as we strive to set new standards for excellence in Fastening, Forming, and Assembly. Become an informed consumer! Indeed, orbital riveting and orbital forming heads can be made remarkably compact, which enables these processes to be used where other joining methods would be difficult to execute. What preventative maintenance you should do for your Orbitform machines. In some applications it is desirable to avoid using a separate rivet perhaps in order to keep the parts count down, or to avoid the risk of intermetallic corrosion.

Orbital riveting is great for making permanent joints. hb``d``b`e`Tfa@ +n

@D[Xy_=/PDP#(f`Pf`bld`re}3Md\&(81;K,J&R\fai4X630@ =

Spring-loaded parts or loose assemblies are no problem for orbital forming. Other experts believe that there is no practical difference between the two processes. Compared to a single-hit machine, these impact riveters will reduce your cycle time and work area footprint while increasing production throughput. Our team includes mechanical designers, electrical designers, machinists, assemblers and programmers, all dedicated to Paramount's mission of designing and building the best. Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots. Were happy to work with you to design an orbital riveting machine that works with your business and your budget. They noticed that their powerhead would drift down when operators walked away. %g2OtyMA=6O^vVQ/ZTM~ != When seeking a solution for de-riveting assemblies, many manufacturers turn to Orbitform. However, both sides of the assembly must be accessible. Spin riveting is commonly used in applications as diverse as low-volume aerospace assemblies and high-volume automotive components. On the downside, it is claimed that the grain structure of orbital formed heads is not of the quality obtained with twin-spin rolls and radial forming. Leveraging our powerhead as a press, Orbitform completed the bushing flare and flatten in two locations with a multi-tool head. If youre assembling items that should never come apart, we can help you combine orbital riveting with custom assembly stations to create sturdy, high-quality joints that look uniform and neat. Orbital forming is a cold forming process using a peen tool held at a fixed angle to create a sweeping line of pressure around a rivet or tenon., This chart can help assist in determining what powerhead is required to form your mild steel rivet.

riveting orbital We're innovative problem solvers who envision the big picture without losing sight of the details. When changes in production happen, retooling existing equipment is a great option that can make a massive difference in Return-on-Investment. 0000037459 00000 n

In some cases orbital forming can be used to create a coined form and eliminate the need for snap rings or other retaining fasteners. [|z!sKw)5'O~};Bc9u`

>r`

E(klA,HBr<9;7GF8-)+k_BbBE%R5C[F

Form rivets close to other part features when normal assembly processes might have clearance issues. ".

Increase ROI when offering customizable products with adjustable assembly equipment.

This website requires certain cookies to work and uses other cookies to help you have the best experience. daF>t#z!'uvwv&'%KV}C}}CCo@>D3 xVr When manufacturers are ready to reshore, Orbitform is a trusted advisor.

riveting rivets pierce improved Furthermore, because the axial load applied is often as much as 80percent lower than for impact riveting, the equipment is comparatively lightweight, which reduces its footprint, and the fixturing can be relatively simple (Fig.2). > q(5y12+32Co|z LFG|\CQGT^-OAc_~cnv82-UT4~oLS6jt)qu=Y-?MIO*ymMm_|~+RZZ M Take Advantage of Orbitform's Permanent Assembly Processes, Permanent Assembly for Large Cylindrical Parts, Increase Throughput and Produce Parts Faster, How To Determine the Right Sized Powerhead. Whatever the challenge, we take it on with enthusiasm. HTMo0 Because it extends below the peen, it contacts the workpiece first, holding it in place. However, for tight assemblies, pure nylon and other unstable polymers are not suitable. Become an informed consumer!

ILb}YVP8c|]mnEUWz~xvg2~05R2s2M+"/w"'1%f1Q%bI$csPYtI7#kb(

FRS{Tb( .Wp.

riveting une into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots.

riveting

The tools can be adapted to work in close quarter. Orbital riveting is a cold-forming process, which means that it occurs at about room temperature and relies on high-speed rotation and downward pressure in order to shape the metal.

orbitform You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

machine riveting orbital double heads head caster ladder Orbital forming combines pressure and orbital motion to form a head to fasten parts. %%EOF

50 0 obj

<>stream

Unless a large mass of material is being formed, the workpiece is normally cool to the touch. The angle between the peen axis and spindle axis varies continuously between 0 to 6 degrees.

riveting orbital orbitform As manufacturing continues to grow and evolve, so too does the need to automate the assembly process. A solid rivet will have a smooth finish, whether it has a crowned, conical or flat head. This makes the machines safer to operate and work around, while also increasing the strength and hardness of the materials themselves (as heat can weaken the integrity of certain material types). Consequently such processes are popular for safety-critical assemblies and those where vibration or thermal cycling might otherwise cause problems (Fig.1). By closing this message or continuing to use our site, you agree to the use of cookies. If the rivet passes through, say, a polymer or soft metallic component, a load-spreading washer can be used beneath the head of the rivet which might also be shouldered. Spin riveting is, in comparison with impact riveting, a closely controlled process whereby two or more components are joined using one or more separate hollow or solid rivets. Other industries have discovered the benefits of orbital and radial forming, too.

Roller forming is available from a company called Orbitform and the forming heads usually have three identical rollers mounted in a circular pattern within a housing (Fig. However, the major difference lies with the process, itself. One difference is that the control of a joint can be held within limits that are slightly better than orbital forming. Copyright 2022. They can be held in place with spring-loaded devices. The tool then rotates around the vertical axis, while also applying an axial load. ;sQVbf(l}veUev

nY>1Gois3/8=\1C[JmKFi k }`9Yf+s/8fU(n-]7aHPQ:4QstWkPW8wv(6g/ P@DV`D@@D HDruGw6AI$j 1UqwwO!M\>PHNf,+|j'W'YTUM?#gB}*&EFAef!]zwJ4]=[Wk#n>7H>}U|TO lBT(Z,6n{a Orbital and radial forming has been used extensively in the automotive industry for years. xAi[Ane

CB.hr#biqVu@|S2%F# The peen is generally made of M2 drill-rod steel and heat-treated to a Rockwell C hardness of 60 to 64. Instead of the single axial stroke that is used in impact riveting, the forming tool (also referred to as a peen) contacts the rivet head at an angle of three to six degrees from the vertical. However, these are primarily limited to the cost of the equipment and the cycle time (typically 2 to 15 seconds). When emergencies happen, a proactive inventory strategy can save valuable time. The equipment also tends to be lighter and run more quietly than impact riveting machines, making for an efficient process.

@,PR6E9EB'Hgh UHWP}>-S54"KK7Up;fRtm7|S1?H3c){uFnIlB[}2C@\hh9

*aGm s[}?L)7\j3@ah5]VnWc|8=kB}}qussyshc-er-a5y3P*N#L*4&P[ziy K7c'RiNOKFQMGYC-0M? %PDF-1.3

%

2Od,bd"/l+!pM,g0gbs#%Ib DtFekVC^umMp)#}duM>{eWrFb?K]$131?_ Y2]lUF_B{QXPYs>)1hZDZ:wF|,O2\Si . Orbital flaring requires a sharpened peen tool for the orbital process. The technology is well within the reach of even small and midsized manufacturers.

Conical, flat, eyelet and crown are some common head shapes. 0000022286 00000 n

30 Years of Assembly Experience Working For You! 0000017064 00000 n

Radial forming was developed in Europe in the 1960s and is often confused with orbital forming.

In fact, orbital forming can handle metals with a hardness of up to Rockwell C hardness of 35.

orbital forming process riveting figure However, if the rollers are mounted such that they can be moved inwards, it is possible to crimp a component almost anywhere along its axis.

orbital riveting machines radial processing demo Orbital forming produces heads on rivets, pins and posts. Some plated surfaces will also remain intact, depending on the amount and quality of the plating material. An automotive parts supplier needed to permanently retain a sound-deadening baffle plate inside an engine cover. This new Jaw Lowering Safety Device solves the clearance challenges posed by typical impact riveting safety devices by using the already present jaws to check for clearance. Polycarbonate, ABS, Noryl and glass-filled nylon can be formed orbitally. Most thermoplastics lend themselves well to the process. If youre looking to incorporate orbital riveting into your manufacturing process, we can help! A semi-tubular or tubular rivet tenon is flared out to retain material together. Orbitform and a group of investors acquired C & B Machinery, provider of world-class disc grinding and metal removal equipment solutions. Precision machines operate at 1,700 rpm. Partnering with Orbitform can simplify this process.

riveting baltec orbital technology forming roller rivet Get real-time insight from Orbitform experts delivered to your inbox.

orbital riveting radial machines pneumatic bench type machine orbital riveters pneumatic tooling actuated spin cam same multi head power tested simple At Orbitform, we developed a unique riveting process called Hot Upset. In such applications, the term orbital riveting is often used instead of spin riveting. If youre in the manufacturing business, you know that orbital riveting can often be the best way to join two pieces of metal in a neat, uniform fashion.Orbital riveting is a safe and effective process that produces tight rivets, making it suitable for a wide variety of industries. However, there are some related processes, namely spin riveting, orbital riveting and orbital forming, that are experiencing a resurgence in interest, partly as a result of recent developments in real-time process control technology. 0000001906 00000 n

As the spindle rotates, the peen orbits the spindle axis. Can plastic fasteners be cold formed using the orbital process? Visit our updated. A single-point machine can be retrofitted with multipoint head. Find how Orbitform helped a customer develop a robust forming solution for their landing gear rotors and stators. All Rights Reserved BNP Media. EU Member States have until 6 April 2006 to transpose the Directive into local Regulations, after which employers will be obliged to meet the tighter requirements. 0000010769 00000 n

Companies such as DMG Engineering, of Pershore, UK, can assist with component and assembly design. Gear up for the latest and greatest on forming, fastening, automation, and overall assembly innovation. This movement progressively collapses the rivet or tenon shank down onto the upper material with each rotation, permanently forming a rivet head in the process.

riveting machine delivers ton force orbital adjustment precise forming pneumatic provides visual process status 0000033414 00000 n

The process is quiet, consumes little energy, and produces high-quality joints and heads, at high cycle speeds. Where should manufacturers start to investigate when experiencing rivet feeding challenges? The Benefits of Orbitally Forming a Flare, How We Can Support Your Manufacturing Needs, Combining Processes and Cutting The Costs, Articulating Roller Forming Solves Crisis, Why You Should Invest in Spare Parts and Tooling, Keeping Sprinkler Head Assembly Consistent, Students Work Together to Solve Real-World Problems, Continuous Improvement to the Milford Product Line, Attending AMC's 1st Annual Graduation Dinner, High Efficiency Process Created Through Orbital Forming, All Your Riveting Equipment Made In House, A Huge Thank You to All Who Serve Our Country, President of Orbitform Honored With Award, Find The Best Fit Machine With the Solutions Lab, The Breakthrough That Changed Manufacturing, Orbitform Hosts Jackson High School Students, Gaining Insight About Assembly Applications, Everyday Household Items Assembled With Riveting Machines, Manufacturing Products With the Best Assembly Process, Rollerforming Assembly For Large Diameter Parts, Providing High Quality Solutions for Food Processing Industry, Orbitform Engineers Take on New Challenges, Advantages of Orbital Riveting and Forming, Students Apply Engineering Knowledge To Competition, Developing Locking Mechanism for Spinal Support Plate, Orbitform Engineers Develop New Goose Neck Design, 9th Place Finish at the Michigan State Championship, Giving Vacuum Power Grips A Smooth Assembly Process, Working Together to Develop an Effective Assembly, Using Articulating Rollerforming in Conjunction With Servo Powerhead, Riveting Machine Rebuild Company Purchased By Orbitform, Working With A Furniture Mechanism Supplier, Permanently Assembling Metals Without The Hassle, Developing An Assembly Process For Coffee Mills, 4 Tips To Keep Your Orbital Assembly Running Smoothly, Impact Riveting Machines Creating Higher Efficiency. In most assemblies that are joined with threaded fasteners, the cost of the fasteners is not as important as the cost of installing them. 0000029032 00000 n

Submit a Request for Proposal (RFP) to suppliers of your choice with details on what you need with a click of a button. Quick response of Orbitform's Service Team has customer up and running quickly after machine crash. Plastic can form strong, consistent heads.

_^ 8IYd&rS7vl3qL0IkqUGXn"RIMt*bN{s;)RzSNsaLoe.*$k(czVD x1GulDOmJcJKAw9&9{vM)J/

How do engineers ensure a new product design aligns with a new assembly process? Even after machine shipment and installation. *! Unlike welding, it is straightforward to join dissimilar materials, plus there is no heat affected zone, no weld spatter and the finished surface is smooth, with no sharp edges. 0000001259 00000 n

This includes virtually all grades of mild steel, most alloys and nonferrous metals, such as aluminum, brass and copper. Here?s how to join piece parts mechanically with or without loose rivets.

riveting You may be missing significant advantages if you are using a temporary method in place of a permanent assembly when your parts do not require disassembly. reached out to Orbitform with a challenge in forming an endoscopic surgical tool. Instead, it is formed at room temperature. ;@-RtH#@iKlQofT'\ukpF!4x5^-POS6/8u7By;sM}M/9$9y~\O/svM9du.Wm-rT'rRx2f,?<2yK\N]a9eQFX>$]lSQ,5v$_vg4K1

q8 !d3Qm/q1AKCw|8$N

s|buk_ixx?

riveting contract riveter purchase process assembly single why The rollers have a profile that rolls the material to gradually create the desired form as the head advances along the axis of the assembly. The rivet or pin being worked orbitally cannot be headed without deformation of the shank under the formed head. It can also form nonround applications, such as a shaft with a single or double D shape, which is often required for high-torque applications. In many cases, orbital forming can replace compression rivets. 0000016626 00000 n

A multipoint head can be used if all of the points to be formed are on the same plane and if the center lines are between 0.3125 and 6.25 inches apart.

riveting orbital The peen presses on the rivet shank along a radial line that begins from the shank center. 0000003897 00000 n

0000000996 00000 n

We recommend testing other riveting materials in our solutions lab to determine the optimal force required. Visit our updated, This website requires certain cookies to work and uses other cookies to help you have the best experience. Other problems encountered include poor powertrain wear factors under heavy forming conditions, forming tools cost more to manufacture than orbital tool inserts, and the length of the forming pass increases cycle Arial. Forming methods are also widely used on die-cast aluminum, thermoplastic and fine-blanked parts. Through the pressure and rotation of the orbital riveting process, the rivet is able to join two metal pieces together. If you install multiple rivets per workpiece, you need to consider a multi-head or multi-hit impact machine. With this rise in demand, manufacturers are seeking out solutions to help increase their production volume as quickly as possible. With years of experience, we can help you get the machines your business needs! Orbital forming also offers some benefits for plastic assemblies. It is therefore possible to indelibly mark a part number, logo, symbol or date code on the assembly. Importantly, modern real-time process controllers enable the forming to be closely controlled so that, for example, the rivet head can be formed to a desired height, or the rivet can exert a specified load on the finished joint. 0000042793 00000 n

Moreover, where volumes are high enough, it is likely to be more cost-effective to design-in a joining element on one of the components in the assembly, rather than using a discrete rivet. orbital pneumatic riveters riveting 0000001361 00000 n

Overall, the safety and effectiveness of orbital riveting makes it a great choice for manufacturing. Find out how we have developed our amazing project management team. Our custom automation suppliers in Holland, MI, can help create an orbital riveting machine thats perfect for your business. Orbital forming can form all types of malleable material, with no damage to fragile or delicate material. zLHc

$?#dz13H!yI{$`FoF#y&\;i/kRNE=M7WG}T|D' 0000001486 00000 n

Since 1984, Orbitform has been evolving with the best interests of our customers. This assembly process is used to assemble appliances, electronics, audio equipment, toys and medical devices. Another factor that should be taken into account is the noise; spin riveting is significantly quieter than impact riveting. When manufacturers work with a variety of assemblies, its important to find cost-effective solutions to positively impact the bottom line.

0000000996 00000 n

We recommend testing other riveting materials in our solutions lab to determine the optimal force required. Visit our updated, This website requires certain cookies to work and uses other cookies to help you have the best experience. Other problems encountered include poor powertrain wear factors under heavy forming conditions, forming tools cost more to manufacture than orbital tool inserts, and the length of the forming pass increases cycle Arial. Forming methods are also widely used on die-cast aluminum, thermoplastic and fine-blanked parts. Through the pressure and rotation of the orbital riveting process, the rivet is able to join two metal pieces together. If you install multiple rivets per workpiece, you need to consider a multi-head or multi-hit impact machine. With this rise in demand, manufacturers are seeking out solutions to help increase their production volume as quickly as possible. With years of experience, we can help you get the machines your business needs! Orbital forming also offers some benefits for plastic assemblies. It is therefore possible to indelibly mark a part number, logo, symbol or date code on the assembly. Importantly, modern real-time process controllers enable the forming to be closely controlled so that, for example, the rivet head can be formed to a desired height, or the rivet can exert a specified load on the finished joint. 0000042793 00000 n

Moreover, where volumes are high enough, it is likely to be more cost-effective to design-in a joining element on one of the components in the assembly, rather than using a discrete rivet. orbital pneumatic riveters riveting 0000001361 00000 n

Overall, the safety and effectiveness of orbital riveting makes it a great choice for manufacturing. Find out how we have developed our amazing project management team. Our custom automation suppliers in Holland, MI, can help create an orbital riveting machine thats perfect for your business. Orbital forming can form all types of malleable material, with no damage to fragile or delicate material. zLHc

$?#dz13H!yI{$`FoF#y&\;i/kRNE=M7WG}T|D' 0000001486 00000 n

Since 1984, Orbitform has been evolving with the best interests of our customers. This assembly process is used to assemble appliances, electronics, audio equipment, toys and medical devices. Another factor that should be taken into account is the noise; spin riveting is significantly quieter than impact riveting. When manufacturers work with a variety of assemblies, its important to find cost-effective solutions to positively impact the bottom line.  De-riveting is a common technique used to save money and re-work parts. EU Directive 2003/10/EC on the minimum health and safety requirements regarding exposure of workers to the risks arising from physical agents (noise), which will repeal Directive 86/188/EEC, was adopted on 9 December 2002 and came into force on 15th February 2003. Design, CMS, Hosting & Web Development :: ePublishing. Orbitform's Engineers deliver another machine solution for an HVAC company. Essentially the same process, orbital riveting also uses an offset peen to gradually form the material into a head that holds the assembly together. While there are many different types of riveting that you could potentially utilize in your production process, orbital riveting has a few distinct advantages. 0000020387 00000 n

In all cases of roller forming described so far, the rollers are mounted in fixed positions.

De-riveting is a common technique used to save money and re-work parts. EU Directive 2003/10/EC on the minimum health and safety requirements regarding exposure of workers to the risks arising from physical agents (noise), which will repeal Directive 86/188/EEC, was adopted on 9 December 2002 and came into force on 15th February 2003. Design, CMS, Hosting & Web Development :: ePublishing. Orbitform's Engineers deliver another machine solution for an HVAC company. Essentially the same process, orbital riveting also uses an offset peen to gradually form the material into a head that holds the assembly together. While there are many different types of riveting that you could potentially utilize in your production process, orbital riveting has a few distinct advantages. 0000020387 00000 n

In all cases of roller forming described so far, the rollers are mounted in fixed positions.  Paramount Tool Company is a custom machine builder in Holland, MI. 0000003085 00000 n

Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of fastening tools: ASG, DEPRAG, Desoutter and Panasonic. In fact, fiber-filled plastics become work-hardened with orbital forming and actually increase in strength after forming. Orbitform stands ready to partner with essential manufacturers through assembling products to support pandemic support efforts. By closing this message or continuing to use our site, you agree to the use of cookies. Screws were expensive, time-consuming to install, and tended to fall out over time. <<2C1139516B11EE469CD655DA4802A8C7>]/Prev 161312>>

With Orbital Staking, material is peeled away from the substrate to form over the part it is retaining at 360 degrees. Despite the relatively tight tolerances and excellent consistency that can be achieved on the height and joint load, spin riveting remains very economical, even for small volumes. trailer

mkN)C ;dC^-O [w@4-n/W_v`r4c)ZKB:#4,uc|Hc)~]gn?j'&MD]5q|J3*J+x

A PUFdkDlkqt}a[C iu&0Z@5H[\u(i8T4^eWC |&ny&)@^;_MrB0,\c4.^lzj[W/_V+mb? S~E? ;j(g(FY#x'Hi_}Ogd0\Al:fGA(^)>+[s|R/%I5DLb1A! $&D-F A&Wd4M2TnU#KF=QmSS|WSi4]:N"G4EDnEEuFm\8i{hwGIs%x9{FS{:6. \h1,nk\coo3V$0

9&0?ALXBbbR]*\'?-=nhb/F{w=w_WKTVyV.4oXa&w~J Design guidelines for rivet diameter and length to align with the orbital or impact riveting process, After 22 years of service, Phil Sponsler retires as President of Orbitform; Jake Sponsler promoted. The main advantage of radial forming is that is does not deform the molecular structure of the metal as much as other riveting processes. Roller Forming can be an alternative to crimping when quality issues arise. 16 35

startxref

0

With radial forming, the peen axis is not held at a fixed angle with the spindle axis. Browse our Buyers Guide to find suppliers of all types of assembly technology, machines and systems, service providers and trade organizations. *TB0f'@W,>)V;]ZV# !CWyYbtVXxMs~' pXDoWOA-P5z`A

H~Gq Every assembly is unique and we are able to provide a solution that is just as unique Orbitform puts customers first as we strive to set new standards for excellence in Fastening, Forming, and Assembly. Become an informed consumer! Indeed, orbital riveting and orbital forming heads can be made remarkably compact, which enables these processes to be used where other joining methods would be difficult to execute. What preventative maintenance you should do for your Orbitform machines. In some applications it is desirable to avoid using a separate rivet perhaps in order to keep the parts count down, or to avoid the risk of intermetallic corrosion.

Paramount Tool Company is a custom machine builder in Holland, MI. 0000003085 00000 n

Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of fastening tools: ASG, DEPRAG, Desoutter and Panasonic. In fact, fiber-filled plastics become work-hardened with orbital forming and actually increase in strength after forming. Orbitform stands ready to partner with essential manufacturers through assembling products to support pandemic support efforts. By closing this message or continuing to use our site, you agree to the use of cookies. Screws were expensive, time-consuming to install, and tended to fall out over time. <<2C1139516B11EE469CD655DA4802A8C7>]/Prev 161312>>

With Orbital Staking, material is peeled away from the substrate to form over the part it is retaining at 360 degrees. Despite the relatively tight tolerances and excellent consistency that can be achieved on the height and joint load, spin riveting remains very economical, even for small volumes. trailer

mkN)C ;dC^-O [w@4-n/W_v`r4c)ZKB:#4,uc|Hc)~]gn?j'&MD]5q|J3*J+x

A PUFdkDlkqt}a[C iu&0Z@5H[\u(i8T4^eWC |&ny&)@^;_MrB0,\c4.^lzj[W/_V+mb? S~E? ;j(g(FY#x'Hi_}Ogd0\Al:fGA(^)>+[s|R/%I5DLb1A! $&D-F A&Wd4M2TnU#KF=QmSS|WSi4]:N"G4EDnEEuFm\8i{hwGIs%x9{FS{:6. \h1,nk\coo3V$0

9&0?ALXBbbR]*\'?-=nhb/F{w=w_WKTVyV.4oXa&w~J Design guidelines for rivet diameter and length to align with the orbital or impact riveting process, After 22 years of service, Phil Sponsler retires as President of Orbitform; Jake Sponsler promoted. The main advantage of radial forming is that is does not deform the molecular structure of the metal as much as other riveting processes. Roller Forming can be an alternative to crimping when quality issues arise. 16 35

startxref

0

With radial forming, the peen axis is not held at a fixed angle with the spindle axis. Browse our Buyers Guide to find suppliers of all types of assembly technology, machines and systems, service providers and trade organizations. *TB0f'@W,>)V;]ZV# !CWyYbtVXxMs~' pXDoWOA-P5z`A

H~Gq Every assembly is unique and we are able to provide a solution that is just as unique Orbitform puts customers first as we strive to set new standards for excellence in Fastening, Forming, and Assembly. Become an informed consumer! Indeed, orbital riveting and orbital forming heads can be made remarkably compact, which enables these processes to be used where other joining methods would be difficult to execute. What preventative maintenance you should do for your Orbitform machines. In some applications it is desirable to avoid using a separate rivet perhaps in order to keep the parts count down, or to avoid the risk of intermetallic corrosion.  Orbital riveting is great for making permanent joints. hb``d``b`e`Tfa@ +n

@D[Xy_=/PDP#(f`Pf`bld`re}3Md\&(81;K,J&R\fai4X630@ =

Spring-loaded parts or loose assemblies are no problem for orbital forming. Other experts believe that there is no practical difference between the two processes. Compared to a single-hit machine, these impact riveters will reduce your cycle time and work area footprint while increasing production throughput. Our team includes mechanical designers, electrical designers, machinists, assemblers and programmers, all dedicated to Paramount's mission of designing and building the best. Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots. Were happy to work with you to design an orbital riveting machine that works with your business and your budget. They noticed that their powerhead would drift down when operators walked away. %g2OtyMA=6O^vVQ/ZTM~ != When seeking a solution for de-riveting assemblies, many manufacturers turn to Orbitform. However, both sides of the assembly must be accessible. Spin riveting is commonly used in applications as diverse as low-volume aerospace assemblies and high-volume automotive components. On the downside, it is claimed that the grain structure of orbital formed heads is not of the quality obtained with twin-spin rolls and radial forming. Leveraging our powerhead as a press, Orbitform completed the bushing flare and flatten in two locations with a multi-tool head. If youre assembling items that should never come apart, we can help you combine orbital riveting with custom assembly stations to create sturdy, high-quality joints that look uniform and neat. Orbital forming is a cold forming process using a peen tool held at a fixed angle to create a sweeping line of pressure around a rivet or tenon., This chart can help assist in determining what powerhead is required to form your mild steel rivet. riveting orbital We're innovative problem solvers who envision the big picture without losing sight of the details. When changes in production happen, retooling existing equipment is a great option that can make a massive difference in Return-on-Investment. 0000037459 00000 n

In some cases orbital forming can be used to create a coined form and eliminate the need for snap rings or other retaining fasteners. [|z!sKw)5'O~};Bc9u`

>r`

E(klA,HBr<9;7GF8-)+k_BbBE%R5C[F

Orbital riveting is great for making permanent joints. hb``d``b`e`Tfa@ +n

@D[Xy_=/PDP#(f`Pf`bld`re}3Md\&(81;K,J&R\fai4X630@ =

Spring-loaded parts or loose assemblies are no problem for orbital forming. Other experts believe that there is no practical difference between the two processes. Compared to a single-hit machine, these impact riveters will reduce your cycle time and work area footprint while increasing production throughput. Our team includes mechanical designers, electrical designers, machinists, assemblers and programmers, all dedicated to Paramount's mission of designing and building the best. Tune into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots. Were happy to work with you to design an orbital riveting machine that works with your business and your budget. They noticed that their powerhead would drift down when operators walked away. %g2OtyMA=6O^vVQ/ZTM~ != When seeking a solution for de-riveting assemblies, many manufacturers turn to Orbitform. However, both sides of the assembly must be accessible. Spin riveting is commonly used in applications as diverse as low-volume aerospace assemblies and high-volume automotive components. On the downside, it is claimed that the grain structure of orbital formed heads is not of the quality obtained with twin-spin rolls and radial forming. Leveraging our powerhead as a press, Orbitform completed the bushing flare and flatten in two locations with a multi-tool head. If youre assembling items that should never come apart, we can help you combine orbital riveting with custom assembly stations to create sturdy, high-quality joints that look uniform and neat. Orbital forming is a cold forming process using a peen tool held at a fixed angle to create a sweeping line of pressure around a rivet or tenon., This chart can help assist in determining what powerhead is required to form your mild steel rivet. riveting orbital We're innovative problem solvers who envision the big picture without losing sight of the details. When changes in production happen, retooling existing equipment is a great option that can make a massive difference in Return-on-Investment. 0000037459 00000 n

In some cases orbital forming can be used to create a coined form and eliminate the need for snap rings or other retaining fasteners. [|z!sKw)5'O~};Bc9u`

>r`

E(klA,HBr<9;7GF8-)+k_BbBE%R5C[F  Form rivets close to other part features when normal assembly processes might have clearance issues. ".

Form rivets close to other part features when normal assembly processes might have clearance issues. ".  Increase ROI when offering customizable products with adjustable assembly equipment.

Increase ROI when offering customizable products with adjustable assembly equipment.  This website requires certain cookies to work and uses other cookies to help you have the best experience. daF>t#z!'uvwv&'%KV}C}}CCo@>D3 xVr When manufacturers are ready to reshore, Orbitform is a trusted advisor. riveting rivets pierce improved Furthermore, because the axial load applied is often as much as 80percent lower than for impact riveting, the equipment is comparatively lightweight, which reduces its footprint, and the fixturing can be relatively simple (Fig.2). > q(5y12+32Co|z LFG|\CQGT^-OAc_~cnv82-UT4~oLS6jt)qu=Y-?MIO*ymMm_|~+RZZ M Take Advantage of Orbitform's Permanent Assembly Processes, Permanent Assembly for Large Cylindrical Parts, Increase Throughput and Produce Parts Faster, How To Determine the Right Sized Powerhead. Whatever the challenge, we take it on with enthusiasm. HTMo0 Because it extends below the peen, it contacts the workpiece first, holding it in place. However, for tight assemblies, pure nylon and other unstable polymers are not suitable. Become an informed consumer!

This website requires certain cookies to work and uses other cookies to help you have the best experience. daF>t#z!'uvwv&'%KV}C}}CCo@>D3 xVr When manufacturers are ready to reshore, Orbitform is a trusted advisor. riveting rivets pierce improved Furthermore, because the axial load applied is often as much as 80percent lower than for impact riveting, the equipment is comparatively lightweight, which reduces its footprint, and the fixturing can be relatively simple (Fig.2). > q(5y12+32Co|z LFG|\CQGT^-OAc_~cnv82-UT4~oLS6jt)qu=Y-?MIO*ymMm_|~+RZZ M Take Advantage of Orbitform's Permanent Assembly Processes, Permanent Assembly for Large Cylindrical Parts, Increase Throughput and Produce Parts Faster, How To Determine the Right Sized Powerhead. Whatever the challenge, we take it on with enthusiasm. HTMo0 Because it extends below the peen, it contacts the workpiece first, holding it in place. However, for tight assemblies, pure nylon and other unstable polymers are not suitable. Become an informed consumer!  ILb}YVP8c|]mnEUWz~xvg2~05R2s2M+"/w"'1%f1Q%bI$csPYtI7#kb(

FRS{Tb( .Wp. riveting une into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots. riveting

ILb}YVP8c|]mnEUWz~xvg2~05R2s2M+"/w"'1%f1Q%bI$csPYtI7#kb(

FRS{Tb( .Wp. riveting une into this exclusive panel discussion featuring executives from four of the nations top suppliers of robotic technology: ATI Industrial Automation, Epson Robots, FANUC America and Universal Robots. riveting  The tools can be adapted to work in close quarter. Orbital riveting is a cold-forming process, which means that it occurs at about room temperature and relies on high-speed rotation and downward pressure in order to shape the metal. orbitform You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days. machine riveting orbital double heads head caster ladder Orbital forming combines pressure and orbital motion to form a head to fasten parts. %%EOF

50 0 obj

<>stream

The tools can be adapted to work in close quarter. Orbital riveting is a cold-forming process, which means that it occurs at about room temperature and relies on high-speed rotation and downward pressure in order to shape the metal. orbitform You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days. machine riveting orbital double heads head caster ladder Orbital forming combines pressure and orbital motion to form a head to fasten parts. %%EOF

50 0 obj

<>stream

Unless a large mass of material is being formed, the workpiece is normally cool to the touch. The angle between the peen axis and spindle axis varies continuously between 0 to 6 degrees. riveting orbital orbitform As manufacturing continues to grow and evolve, so too does the need to automate the assembly process. A solid rivet will have a smooth finish, whether it has a crowned, conical or flat head. This makes the machines safer to operate and work around, while also increasing the strength and hardness of the materials themselves (as heat can weaken the integrity of certain material types). Consequently such processes are popular for safety-critical assemblies and those where vibration or thermal cycling might otherwise cause problems (Fig.1). By closing this message or continuing to use our site, you agree to the use of cookies. If the rivet passes through, say, a polymer or soft metallic component, a load-spreading washer can be used beneath the head of the rivet which might also be shouldered. Spin riveting is, in comparison with impact riveting, a closely controlled process whereby two or more components are joined using one or more separate hollow or solid rivets. Other industries have discovered the benefits of orbital and radial forming, too.

Unless a large mass of material is being formed, the workpiece is normally cool to the touch. The angle between the peen axis and spindle axis varies continuously between 0 to 6 degrees. riveting orbital orbitform As manufacturing continues to grow and evolve, so too does the need to automate the assembly process. A solid rivet will have a smooth finish, whether it has a crowned, conical or flat head. This makes the machines safer to operate and work around, while also increasing the strength and hardness of the materials themselves (as heat can weaken the integrity of certain material types). Consequently such processes are popular for safety-critical assemblies and those where vibration or thermal cycling might otherwise cause problems (Fig.1). By closing this message or continuing to use our site, you agree to the use of cookies. If the rivet passes through, say, a polymer or soft metallic component, a load-spreading washer can be used beneath the head of the rivet which might also be shouldered. Spin riveting is, in comparison with impact riveting, a closely controlled process whereby two or more components are joined using one or more separate hollow or solid rivets. Other industries have discovered the benefits of orbital and radial forming, too.  Roller forming is available from a company called Orbitform and the forming heads usually have three identical rollers mounted in a circular pattern within a housing (Fig. However, the major difference lies with the process, itself. One difference is that the control of a joint can be held within limits that are slightly better than orbital forming. Copyright 2022. They can be held in place with spring-loaded devices. The tool then rotates around the vertical axis, while also applying an axial load. ;sQVbf(l}veUev

nY>1Gois3/8=\1C[JmKFi k }`9Yf+s/8fU(n-]7aHPQ:4QstWkPW8wv(6g/ P@DV`D@@D HDruGw6AI$j 1UqwwO!M\>PHNf,+|j'W'YTUM?#gB}*&EFAef!]zwJ4]=[Wk#n>7H>}U|TO lBT(Z,6n{a Orbital and radial forming has been used extensively in the automotive industry for years. xAi[Ane

CB.hr#biqVu@|S2%F# The peen is generally made of M2 drill-rod steel and heat-treated to a Rockwell C hardness of 60 to 64. Instead of the single axial stroke that is used in impact riveting, the forming tool (also referred to as a peen) contacts the rivet head at an angle of three to six degrees from the vertical. However, these are primarily limited to the cost of the equipment and the cycle time (typically 2 to 15 seconds). When emergencies happen, a proactive inventory strategy can save valuable time. The equipment also tends to be lighter and run more quietly than impact riveting machines, making for an efficient process.

Roller forming is available from a company called Orbitform and the forming heads usually have three identical rollers mounted in a circular pattern within a housing (Fig. However, the major difference lies with the process, itself. One difference is that the control of a joint can be held within limits that are slightly better than orbital forming. Copyright 2022. They can be held in place with spring-loaded devices. The tool then rotates around the vertical axis, while also applying an axial load. ;sQVbf(l}veUev

nY>1Gois3/8=\1C[JmKFi k }`9Yf+s/8fU(n-]7aHPQ:4QstWkPW8wv(6g/ P@DV`D@@D HDruGw6AI$j 1UqwwO!M\>PHNf,+|j'W'YTUM?#gB}*&EFAef!]zwJ4]=[Wk#n>7H>}U|TO lBT(Z,6n{a Orbital and radial forming has been used extensively in the automotive industry for years. xAi[Ane

CB.hr#biqVu@|S2%F# The peen is generally made of M2 drill-rod steel and heat-treated to a Rockwell C hardness of 60 to 64. Instead of the single axial stroke that is used in impact riveting, the forming tool (also referred to as a peen) contacts the rivet head at an angle of three to six degrees from the vertical. However, these are primarily limited to the cost of the equipment and the cycle time (typically 2 to 15 seconds). When emergencies happen, a proactive inventory strategy can save valuable time. The equipment also tends to be lighter and run more quietly than impact riveting machines, making for an efficient process.  @,PR6E9EB'Hgh UHWP}>-S54"KK7Up;fRtm7|S1?H3c){uFnIlB[}2C@\hh9

*aGm s[}?L)7\j3@ah5]VnWc|8=kB}}qussyshc-er-a5y3P*N#L*4&P[ziy K7c'RiNOKFQMGYC-0M? %PDF-1.3

%

2Od,bd"/l+!pM,g0gbs#%Ib DtFekVC^umMp)#}duM>{eWrFb?K]$131?_ Y2]lUF_B{QXPYs>)1hZDZ:wF|,O2\Si . Orbital flaring requires a sharpened peen tool for the orbital process. The technology is well within the reach of even small and midsized manufacturers.

@,PR6E9EB'Hgh UHWP}>-S54"KK7Up;fRtm7|S1?H3c){uFnIlB[}2C@\hh9

*aGm s[}?L)7\j3@ah5]VnWc|8=kB}}qussyshc-er-a5y3P*N#L*4&P[ziy K7c'RiNOKFQMGYC-0M? %PDF-1.3

%

2Od,bd"/l+!pM,g0gbs#%Ib DtFekVC^umMp)#}duM>{eWrFb?K]$131?_ Y2]lUF_B{QXPYs>)1hZDZ:wF|,O2\Si . Orbital flaring requires a sharpened peen tool for the orbital process. The technology is well within the reach of even small and midsized manufacturers.  Conical, flat, eyelet and crown are some common head shapes. 0000022286 00000 n

30 Years of Assembly Experience Working For You! 0000017064 00000 n

Radial forming was developed in Europe in the 1960s and is often confused with orbital forming. In fact, orbital forming can handle metals with a hardness of up to Rockwell C hardness of 35. orbital forming process riveting figure However, if the rollers are mounted such that they can be moved inwards, it is possible to crimp a component almost anywhere along its axis. orbital riveting machines radial processing demo Orbital forming produces heads on rivets, pins and posts. Some plated surfaces will also remain intact, depending on the amount and quality of the plating material. An automotive parts supplier needed to permanently retain a sound-deadening baffle plate inside an engine cover. This new Jaw Lowering Safety Device solves the clearance challenges posed by typical impact riveting safety devices by using the already present jaws to check for clearance. Polycarbonate, ABS, Noryl and glass-filled nylon can be formed orbitally. Most thermoplastics lend themselves well to the process. If youre looking to incorporate orbital riveting into your manufacturing process, we can help! A semi-tubular or tubular rivet tenon is flared out to retain material together. Orbitform and a group of investors acquired C & B Machinery, provider of world-class disc grinding and metal removal equipment solutions. Precision machines operate at 1,700 rpm. Partnering with Orbitform can simplify this process. riveting baltec orbital technology forming roller rivet Get real-time insight from Orbitform experts delivered to your inbox. orbital riveting radial machines pneumatic bench type machine orbital riveters pneumatic tooling actuated spin cam same multi head power tested simple At Orbitform, we developed a unique riveting process called Hot Upset. In such applications, the term orbital riveting is often used instead of spin riveting. If youre in the manufacturing business, you know that orbital riveting can often be the best way to join two pieces of metal in a neat, uniform fashion.Orbital riveting is a safe and effective process that produces tight rivets, making it suitable for a wide variety of industries. However, there are some related processes, namely spin riveting, orbital riveting and orbital forming, that are experiencing a resurgence in interest, partly as a result of recent developments in real-time process control technology. 0000001906 00000 n

As the spindle rotates, the peen orbits the spindle axis. Can plastic fasteners be cold formed using the orbital process? Visit our updated. A single-point machine can be retrofitted with multipoint head. Find how Orbitform helped a customer develop a robust forming solution for their landing gear rotors and stators. All Rights Reserved BNP Media. EU Member States have until 6 April 2006 to transpose the Directive into local Regulations, after which employers will be obliged to meet the tighter requirements. 0000010769 00000 n

Companies such as DMG Engineering, of Pershore, UK, can assist with component and assembly design. Gear up for the latest and greatest on forming, fastening, automation, and overall assembly innovation. This movement progressively collapses the rivet or tenon shank down onto the upper material with each rotation, permanently forming a rivet head in the process. riveting machine delivers ton force orbital adjustment precise forming pneumatic provides visual process status 0000033414 00000 n

The process is quiet, consumes little energy, and produces high-quality joints and heads, at high cycle speeds. Where should manufacturers start to investigate when experiencing rivet feeding challenges? The Benefits of Orbitally Forming a Flare, How We Can Support Your Manufacturing Needs, Combining Processes and Cutting The Costs, Articulating Roller Forming Solves Crisis, Why You Should Invest in Spare Parts and Tooling, Keeping Sprinkler Head Assembly Consistent, Students Work Together to Solve Real-World Problems, Continuous Improvement to the Milford Product Line, Attending AMC's 1st Annual Graduation Dinner, High Efficiency Process Created Through Orbital Forming, All Your Riveting Equipment Made In House, A Huge Thank You to All Who Serve Our Country, President of Orbitform Honored With Award, Find The Best Fit Machine With the Solutions Lab, The Breakthrough That Changed Manufacturing, Orbitform Hosts Jackson High School Students, Gaining Insight About Assembly Applications, Everyday Household Items Assembled With Riveting Machines, Manufacturing Products With the Best Assembly Process, Rollerforming Assembly For Large Diameter Parts, Providing High Quality Solutions for Food Processing Industry, Orbitform Engineers Take on New Challenges, Advantages of Orbital Riveting and Forming, Students Apply Engineering Knowledge To Competition, Developing Locking Mechanism for Spinal Support Plate, Orbitform Engineers Develop New Goose Neck Design, 9th Place Finish at the Michigan State Championship, Giving Vacuum Power Grips A Smooth Assembly Process, Working Together to Develop an Effective Assembly, Using Articulating Rollerforming in Conjunction With Servo Powerhead, Riveting Machine Rebuild Company Purchased By Orbitform, Working With A Furniture Mechanism Supplier, Permanently Assembling Metals Without The Hassle, Developing An Assembly Process For Coffee Mills, 4 Tips To Keep Your Orbital Assembly Running Smoothly, Impact Riveting Machines Creating Higher Efficiency. In most assemblies that are joined with threaded fasteners, the cost of the fasteners is not as important as the cost of installing them. 0000029032 00000 n

Submit a Request for Proposal (RFP) to suppliers of your choice with details on what you need with a click of a button. Quick response of Orbitform's Service Team has customer up and running quickly after machine crash. Plastic can form strong, consistent heads.

Conical, flat, eyelet and crown are some common head shapes. 0000022286 00000 n

30 Years of Assembly Experience Working For You! 0000017064 00000 n

Radial forming was developed in Europe in the 1960s and is often confused with orbital forming. In fact, orbital forming can handle metals with a hardness of up to Rockwell C hardness of 35. orbital forming process riveting figure However, if the rollers are mounted such that they can be moved inwards, it is possible to crimp a component almost anywhere along its axis. orbital riveting machines radial processing demo Orbital forming produces heads on rivets, pins and posts. Some plated surfaces will also remain intact, depending on the amount and quality of the plating material. An automotive parts supplier needed to permanently retain a sound-deadening baffle plate inside an engine cover. This new Jaw Lowering Safety Device solves the clearance challenges posed by typical impact riveting safety devices by using the already present jaws to check for clearance. Polycarbonate, ABS, Noryl and glass-filled nylon can be formed orbitally. Most thermoplastics lend themselves well to the process. If youre looking to incorporate orbital riveting into your manufacturing process, we can help! A semi-tubular or tubular rivet tenon is flared out to retain material together. Orbitform and a group of investors acquired C & B Machinery, provider of world-class disc grinding and metal removal equipment solutions. Precision machines operate at 1,700 rpm. Partnering with Orbitform can simplify this process. riveting baltec orbital technology forming roller rivet Get real-time insight from Orbitform experts delivered to your inbox. orbital riveting radial machines pneumatic bench type machine orbital riveters pneumatic tooling actuated spin cam same multi head power tested simple At Orbitform, we developed a unique riveting process called Hot Upset. In such applications, the term orbital riveting is often used instead of spin riveting. If youre in the manufacturing business, you know that orbital riveting can often be the best way to join two pieces of metal in a neat, uniform fashion.Orbital riveting is a safe and effective process that produces tight rivets, making it suitable for a wide variety of industries. However, there are some related processes, namely spin riveting, orbital riveting and orbital forming, that are experiencing a resurgence in interest, partly as a result of recent developments in real-time process control technology. 0000001906 00000 n

As the spindle rotates, the peen orbits the spindle axis. Can plastic fasteners be cold formed using the orbital process? Visit our updated. A single-point machine can be retrofitted with multipoint head. Find how Orbitform helped a customer develop a robust forming solution for their landing gear rotors and stators. All Rights Reserved BNP Media. EU Member States have until 6 April 2006 to transpose the Directive into local Regulations, after which employers will be obliged to meet the tighter requirements. 0000010769 00000 n

Companies such as DMG Engineering, of Pershore, UK, can assist with component and assembly design. Gear up for the latest and greatest on forming, fastening, automation, and overall assembly innovation. This movement progressively collapses the rivet or tenon shank down onto the upper material with each rotation, permanently forming a rivet head in the process. riveting machine delivers ton force orbital adjustment precise forming pneumatic provides visual process status 0000033414 00000 n

The process is quiet, consumes little energy, and produces high-quality joints and heads, at high cycle speeds. Where should manufacturers start to investigate when experiencing rivet feeding challenges? The Benefits of Orbitally Forming a Flare, How We Can Support Your Manufacturing Needs, Combining Processes and Cutting The Costs, Articulating Roller Forming Solves Crisis, Why You Should Invest in Spare Parts and Tooling, Keeping Sprinkler Head Assembly Consistent, Students Work Together to Solve Real-World Problems, Continuous Improvement to the Milford Product Line, Attending AMC's 1st Annual Graduation Dinner, High Efficiency Process Created Through Orbital Forming, All Your Riveting Equipment Made In House, A Huge Thank You to All Who Serve Our Country, President of Orbitform Honored With Award, Find The Best Fit Machine With the Solutions Lab, The Breakthrough That Changed Manufacturing, Orbitform Hosts Jackson High School Students, Gaining Insight About Assembly Applications, Everyday Household Items Assembled With Riveting Machines, Manufacturing Products With the Best Assembly Process, Rollerforming Assembly For Large Diameter Parts, Providing High Quality Solutions for Food Processing Industry, Orbitform Engineers Take on New Challenges, Advantages of Orbital Riveting and Forming, Students Apply Engineering Knowledge To Competition, Developing Locking Mechanism for Spinal Support Plate, Orbitform Engineers Develop New Goose Neck Design, 9th Place Finish at the Michigan State Championship, Giving Vacuum Power Grips A Smooth Assembly Process, Working Together to Develop an Effective Assembly, Using Articulating Rollerforming in Conjunction With Servo Powerhead, Riveting Machine Rebuild Company Purchased By Orbitform, Working With A Furniture Mechanism Supplier, Permanently Assembling Metals Without The Hassle, Developing An Assembly Process For Coffee Mills, 4 Tips To Keep Your Orbital Assembly Running Smoothly, Impact Riveting Machines Creating Higher Efficiency. In most assemblies that are joined with threaded fasteners, the cost of the fasteners is not as important as the cost of installing them. 0000029032 00000 n

Submit a Request for Proposal (RFP) to suppliers of your choice with details on what you need with a click of a button. Quick response of Orbitform's Service Team has customer up and running quickly after machine crash. Plastic can form strong, consistent heads.  _^ 8IYd&rS7vl3qL0IkqUGXn"RIMt*bN{s;)RzSNsaLoe.*$k(czVD x1GulDOmJcJKAw9&9{vM)J/

How do engineers ensure a new product design aligns with a new assembly process? Even after machine shipment and installation. *! Unlike welding, it is straightforward to join dissimilar materials, plus there is no heat affected zone, no weld spatter and the finished surface is smooth, with no sharp edges. 0000001259 00000 n

This includes virtually all grades of mild steel, most alloys and nonferrous metals, such as aluminum, brass and copper. Here?s how to join piece parts mechanically with or without loose rivets. riveting You may be missing significant advantages if you are using a temporary method in place of a permanent assembly when your parts do not require disassembly. reached out to Orbitform with a challenge in forming an endoscopic surgical tool. Instead, it is formed at room temperature. ;@-RtH#@iKlQofT'\ukpF!4x5^-POS6/8u7By;sM}M/9$9y~\O/svM9du.Wm-rT'rRx2f,?<2yK\N]a9eQFX>$]lSQ,5v$_vg4K1

q8 !d3Qm/q1AKCw|8$N

s|buk_ixx? riveting contract riveter purchase process assembly single why The rollers have a profile that rolls the material to gradually create the desired form as the head advances along the axis of the assembly. The rivet or pin being worked orbitally cannot be headed without deformation of the shank under the formed head. It can also form nonround applications, such as a shaft with a single or double D shape, which is often required for high-torque applications. In many cases, orbital forming can replace compression rivets. 0000016626 00000 n

A multipoint head can be used if all of the points to be formed are on the same plane and if the center lines are between 0.3125 and 6.25 inches apart. riveting orbital The peen presses on the rivet shank along a radial line that begins from the shank center. 0000003897 00000 n

_^ 8IYd&rS7vl3qL0IkqUGXn"RIMt*bN{s;)RzSNsaLoe.*$k(czVD x1GulDOmJcJKAw9&9{vM)J/

How do engineers ensure a new product design aligns with a new assembly process? Even after machine shipment and installation. *! Unlike welding, it is straightforward to join dissimilar materials, plus there is no heat affected zone, no weld spatter and the finished surface is smooth, with no sharp edges. 0000001259 00000 n

This includes virtually all grades of mild steel, most alloys and nonferrous metals, such as aluminum, brass and copper. Here?s how to join piece parts mechanically with or without loose rivets. riveting You may be missing significant advantages if you are using a temporary method in place of a permanent assembly when your parts do not require disassembly. reached out to Orbitform with a challenge in forming an endoscopic surgical tool. Instead, it is formed at room temperature. ;@-RtH#@iKlQofT'\ukpF!4x5^-POS6/8u7By;sM}M/9$9y~\O/svM9du.Wm-rT'rRx2f,?<2yK\N]a9eQFX>$]lSQ,5v$_vg4K1

q8 !d3Qm/q1AKCw|8$N

s|buk_ixx? riveting contract riveter purchase process assembly single why The rollers have a profile that rolls the material to gradually create the desired form as the head advances along the axis of the assembly. The rivet or pin being worked orbitally cannot be headed without deformation of the shank under the formed head. It can also form nonround applications, such as a shaft with a single or double D shape, which is often required for high-torque applications. In many cases, orbital forming can replace compression rivets. 0000016626 00000 n

A multipoint head can be used if all of the points to be formed are on the same plane and if the center lines are between 0.3125 and 6.25 inches apart. riveting orbital The peen presses on the rivet shank along a radial line that begins from the shank center. 0000003897 00000 n