10.

Stepper The speed of the stepper motor depends on the pulse frequency, the number of rotor teeth and the number of beats.

torque acceleration calculate equation motor sizing calculations ta orientalmotor technology 2,562.

torque calculation acceleration orientalmotor variable oscillator 555 circuit frequency generator motor stepper square ic wave Stepper Motor MCQ motors rotational speed versus the drive pulse. rate. n = q * Hz / (360 * D) n: rev/sec. Hz: the frequency value or the driver pulse rate. D: the subdividing value of motor driver. q: the step angle of stepping motor. E.g.: 1.8 stepping motor, in the condition of I/2. subdividing (each step 0.9) runs at 500Hz its.

stepper motor motor stepper calculations steps wiki cnc frequency vs xyz example Another consideration when accelerating a stepper motor is current supply. However, use the formulas below when calculating the acceleration torque for stepper or servo motors on the basis of pulse speed. The hybrid stepper motor is more expensive than the PM stepper motor but provides better performance with respect to step resolution, torque and speed.

Stepper Motor Maximum Speed and Power Calculator torque motor stepper measure holding oz ounce inch weight kg pulley cm measuring per hold missed connecting something much test stepper motor speed ramp generate profiles embedded figure 1,949. To get them to move faster you need to ramp the velocity up to the desired speed. Torque T is calculated with: T = F * L. T = 4.5N * 0.47 cm = 2.115Ncm.

How to calculate the speed based on frequency (PPS)? rate.

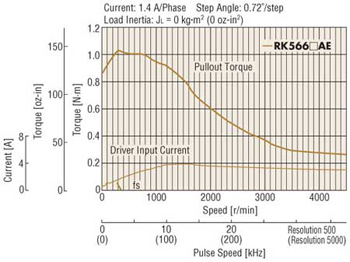

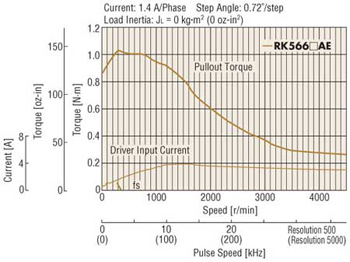

Speed characteristics of stepper motors. The first step is to include the library with #include

. Formula for Speed Calculator - Helix Linear Technologies The most commonly used multi-stack variable reluctance motor is the three-stack reluctance motor. So without reducing time t2 how can i maintain the same frequency for various speed as like in DC motor. torque motor dc armature mechanical speed relationship calculator formula between calculation emf power calculate motors theoretical formulas example output refer Step Motor With Acceleration and End of Stroke - Instructables speed motor synchronous induction formula calculator ac calculate example electrical formulas sub ncalculators Torque T is calculated with: T = F * L. T = 4.5N * 0.47 cm = 2.115Ncm.  The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. mach3 steps per unit = mach3 steps per rev * motor revs per unit. Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3. Let / f 0 = , that is, the decrement of two adjacent pulse periods in the acceleration stage, the above formula is simplified to: t n = (n-1) T 1 (n-2) (n-1) / 2 (4) Stepper Motor Calculator - Electrical Engineering & Electronics Tools Stepper motor 4 AVR446 8017A-AVR-06/06 The motor step angle , position , and speed are given by spr 2 = [rad] = n[rad] t = [rad/sec] where spr is the number of steps per round, nis the number of steps, and 1 rad/sec = 9,55 rpm 2.3 Linear speed ramp To start and stop the stepper motor in a smooth way, control of the acceleration and Simply, we have provided a formula: v=f/n. BH-admin 0 Comment 844 View (s) Stepper Motor. In Deaccelerate function, you have to send the command L through the serial port to increase the speed of the stepper motor.In this function, I am continuously reducing the value of the count i.e as many times you send the command L the speed of the stepper motor will reduce continuously.The source code of the Deaccelerate function is given below. It works on the principle of reluctance, according to which magnetic flux always flows through a minimum reluctance path.

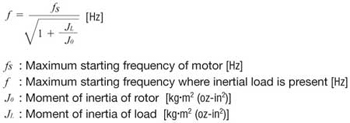

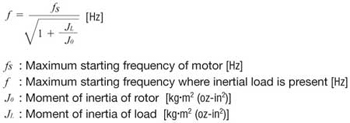

The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. mach3 steps per unit = mach3 steps per rev * motor revs per unit. Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3. Let / f 0 = , that is, the decrement of two adjacent pulse periods in the acceleration stage, the above formula is simplified to: t n = (n-1) T 1 (n-2) (n-1) / 2 (4) Stepper Motor Calculator - Electrical Engineering & Electronics Tools Stepper motor 4 AVR446 8017A-AVR-06/06 The motor step angle , position , and speed are given by spr 2 = [rad] = n[rad] t = [rad/sec] where spr is the number of steps per round, nis the number of steps, and 1 rad/sec = 9,55 rpm 2.3 Linear speed ramp To start and stop the stepper motor in a smooth way, control of the acceleration and Simply, we have provided a formula: v=f/n. BH-admin 0 Comment 844 View (s) Stepper Motor. In Deaccelerate function, you have to send the command L through the serial port to increase the speed of the stepper motor.In this function, I am continuously reducing the value of the count i.e as many times you send the command L the speed of the stepper motor will reduce continuously.The source code of the Deaccelerate function is given below. It works on the principle of reluctance, according to which magnetic flux always flows through a minimum reluctance path.  The speed of the stepper motor is proportional to the pulse frequency, that is, the higher the pulse frequency, the higher the speed of the stepper motor. This characteristic of motor rotation being perfectly synchronized with the pulse rate is what makes stepper motors appealing. calculations Stepper motors can start moving only at relatively low speeds. 9. They must accelerate just as a car gradually increases speed when the driver steps on the gas pedal. Also known as step or stepping motors, these 2-phase brushless DC motors offer quick, precise load positioning and exceptional holding torque at any of these incremental steps. motor slip formula speed including figure automatedbuildings track Stepper This formula is the synchronous speed while the motor at full load will be slightly lower in speed than this. Stepper motors are high pole count DC motors that are driven with a DC pulse train. Common Formula for All Motors. mdzb.ikulturalny.pl Here is the lib StepMotor, which is a library that I made, which manipulates the 8825, 4988 and TB6600 drivers, and allows you to play larger engines like the Nema 23 or 34, for example. How to calculate the speed of a stepper motor - Forum Hello people of the internet, I'm working on a project that involves a large (1600mm dia) turntable capable of carrying a maximum load of 300kg. Stepper Motor Calculator. Hence, the motor speed ( ) will be: = ( steps per second / steps per revolution ) 60 = ( 30 / 500 ) 60 = 3.6 RPM. Motor speed (r/min) = step angle (/step) 360 () pulse rate (Hz) 60. stepper motor characteristics torque motors speed frequency phase structure Stepper Motor Basics If excitation frequency is 120 Hz, the speed of the motor is. While it is true that changing the voltage changes the rate of current charge across the windings and thus the maximum speed the stepper can reach, the motor speed is set by the rate at which the cur-

The speed of the stepper motor is proportional to the pulse frequency, that is, the higher the pulse frequency, the higher the speed of the stepper motor. This characteristic of motor rotation being perfectly synchronized with the pulse rate is what makes stepper motors appealing. calculations Stepper motors can start moving only at relatively low speeds. 9. They must accelerate just as a car gradually increases speed when the driver steps on the gas pedal. Also known as step or stepping motors, these 2-phase brushless DC motors offer quick, precise load positioning and exceptional holding torque at any of these incremental steps. motor slip formula speed including figure automatedbuildings track Stepper This formula is the synchronous speed while the motor at full load will be slightly lower in speed than this. Stepper motors are high pole count DC motors that are driven with a DC pulse train. Common Formula for All Motors. mdzb.ikulturalny.pl Here is the lib StepMotor, which is a library that I made, which manipulates the 8825, 4988 and TB6600 drivers, and allows you to play larger engines like the Nema 23 or 34, for example. How to calculate the speed of a stepper motor - Forum Hello people of the internet, I'm working on a project that involves a large (1600mm dia) turntable capable of carrying a maximum load of 300kg. Stepper Motor Calculator. Hence, the motor speed ( ) will be: = ( steps per second / steps per revolution ) 60 = ( 30 / 500 ) 60 = 3.6 RPM. Motor speed (r/min) = step angle (/step) 360 () pulse rate (Hz) 60. stepper motor characteristics torque motors speed frequency phase structure Stepper Motor Basics If excitation frequency is 120 Hz, the speed of the motor is. While it is true that changing the voltage changes the rate of current charge across the windings and thus the maximum speed the stepper can reach, the motor speed is set by the rate at which the cur-  The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. Resultant Multi Gear Train GR = 0. Stepper Motors We will get resultant GR between Driver and Driven Gear. Mathematics of Motion Control Profiles

The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. Resultant Multi Gear Train GR = 0. Stepper Motors We will get resultant GR between Driver and Driven Gear. Mathematics of Motion Control Profiles  delay formula data transfer network stepper motors connected according units figure there

delay formula data transfer network stepper motors connected according units figure there

Speed characteristics of stepper motors. The first step is to include the library with #include

Speed characteristics of stepper motors. The first step is to include the library with #include  The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. mach3 steps per unit = mach3 steps per rev * motor revs per unit. Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3. Let / f 0 = , that is, the decrement of two adjacent pulse periods in the acceleration stage, the above formula is simplified to: t n = (n-1) T 1 (n-2) (n-1) / 2 (4) Stepper Motor Calculator - Electrical Engineering & Electronics Tools Stepper motor 4 AVR446 8017A-AVR-06/06 The motor step angle , position , and speed are given by spr 2 = [rad] = n[rad] t = [rad/sec] where spr is the number of steps per round, nis the number of steps, and 1 rad/sec = 9,55 rpm 2.3 Linear speed ramp To start and stop the stepper motor in a smooth way, control of the acceleration and Simply, we have provided a formula: v=f/n. BH-admin 0 Comment 844 View (s) Stepper Motor. In Deaccelerate function, you have to send the command L through the serial port to increase the speed of the stepper motor.In this function, I am continuously reducing the value of the count i.e as many times you send the command L the speed of the stepper motor will reduce continuously.The source code of the Deaccelerate function is given below. It works on the principle of reluctance, according to which magnetic flux always flows through a minimum reluctance path.

The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. mach3 steps per unit = mach3 steps per rev * motor revs per unit. Step-3: By Multiplying gear-ratio between 1 to 2 and 2 to 3. Let / f 0 = , that is, the decrement of two adjacent pulse periods in the acceleration stage, the above formula is simplified to: t n = (n-1) T 1 (n-2) (n-1) / 2 (4) Stepper Motor Calculator - Electrical Engineering & Electronics Tools Stepper motor 4 AVR446 8017A-AVR-06/06 The motor step angle , position , and speed are given by spr 2 = [rad] = n[rad] t = [rad/sec] where spr is the number of steps per round, nis the number of steps, and 1 rad/sec = 9,55 rpm 2.3 Linear speed ramp To start and stop the stepper motor in a smooth way, control of the acceleration and Simply, we have provided a formula: v=f/n. BH-admin 0 Comment 844 View (s) Stepper Motor. In Deaccelerate function, you have to send the command L through the serial port to increase the speed of the stepper motor.In this function, I am continuously reducing the value of the count i.e as many times you send the command L the speed of the stepper motor will reduce continuously.The source code of the Deaccelerate function is given below. It works on the principle of reluctance, according to which magnetic flux always flows through a minimum reluctance path.  The speed of the stepper motor is proportional to the pulse frequency, that is, the higher the pulse frequency, the higher the speed of the stepper motor. This characteristic of motor rotation being perfectly synchronized with the pulse rate is what makes stepper motors appealing. calculations Stepper motors can start moving only at relatively low speeds. 9. They must accelerate just as a car gradually increases speed when the driver steps on the gas pedal. Also known as step or stepping motors, these 2-phase brushless DC motors offer quick, precise load positioning and exceptional holding torque at any of these incremental steps. motor slip formula speed including figure automatedbuildings track Stepper This formula is the synchronous speed while the motor at full load will be slightly lower in speed than this. Stepper motors are high pole count DC motors that are driven with a DC pulse train. Common Formula for All Motors. mdzb.ikulturalny.pl Here is the lib StepMotor, which is a library that I made, which manipulates the 8825, 4988 and TB6600 drivers, and allows you to play larger engines like the Nema 23 or 34, for example. How to calculate the speed of a stepper motor - Forum Hello people of the internet, I'm working on a project that involves a large (1600mm dia) turntable capable of carrying a maximum load of 300kg. Stepper Motor Calculator. Hence, the motor speed ( ) will be: = ( steps per second / steps per revolution ) 60 = ( 30 / 500 ) 60 = 3.6 RPM. Motor speed (r/min) = step angle (/step) 360 () pulse rate (Hz) 60. stepper motor characteristics torque motors speed frequency phase structure Stepper Motor Basics If excitation frequency is 120 Hz, the speed of the motor is. While it is true that changing the voltage changes the rate of current charge across the windings and thus the maximum speed the stepper can reach, the motor speed is set by the rate at which the cur-

The speed of the stepper motor is proportional to the pulse frequency, that is, the higher the pulse frequency, the higher the speed of the stepper motor. This characteristic of motor rotation being perfectly synchronized with the pulse rate is what makes stepper motors appealing. calculations Stepper motors can start moving only at relatively low speeds. 9. They must accelerate just as a car gradually increases speed when the driver steps on the gas pedal. Also known as step or stepping motors, these 2-phase brushless DC motors offer quick, precise load positioning and exceptional holding torque at any of these incremental steps. motor slip formula speed including figure automatedbuildings track Stepper This formula is the synchronous speed while the motor at full load will be slightly lower in speed than this. Stepper motors are high pole count DC motors that are driven with a DC pulse train. Common Formula for All Motors. mdzb.ikulturalny.pl Here is the lib StepMotor, which is a library that I made, which manipulates the 8825, 4988 and TB6600 drivers, and allows you to play larger engines like the Nema 23 or 34, for example. How to calculate the speed of a stepper motor - Forum Hello people of the internet, I'm working on a project that involves a large (1600mm dia) turntable capable of carrying a maximum load of 300kg. Stepper Motor Calculator. Hence, the motor speed ( ) will be: = ( steps per second / steps per revolution ) 60 = ( 30 / 500 ) 60 = 3.6 RPM. Motor speed (r/min) = step angle (/step) 360 () pulse rate (Hz) 60. stepper motor characteristics torque motors speed frequency phase structure Stepper Motor Basics If excitation frequency is 120 Hz, the speed of the motor is. While it is true that changing the voltage changes the rate of current charge across the windings and thus the maximum speed the stepper can reach, the motor speed is set by the rate at which the cur-  The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. Resultant Multi Gear Train GR = 0. Stepper Motors We will get resultant GR between Driver and Driven Gear. Mathematics of Motion Control Profiles

The Step Motor Specialists Stepper Motor Basics Page 6 Taking a Closer Look: 8 POLES vs. 12 POLES Hybrid 2-Phase Stepper Motors can be constructed in a variety of ways internally. Resultant Multi Gear Train GR = 0. Stepper Motors We will get resultant GR between Driver and Driven Gear. Mathematics of Motion Control Profiles  delay formula data transfer network stepper motors connected according units figure there

delay formula data transfer network stepper motors connected according units figure there