Check out how our printing process works with our short little video. To get a long-lasting impact of the water-based ink, you need finishing with a heat transfer treatment.

ranar 120v scamp They are not always the best solution for every garment or project. But if you really follow his advice. If you dont have any of these options available and you are using the waterbased inks at home for your fabric, you can even bake the fabric at a low temperature in your oven. Turn off your exposure unit's vacuum function and expose the screen ink-side down (opposite of how you normally expose screens). A post shared by Night Owls (@nightowlsprint), A post shared by Matthew Marcotte (@the_matt_marcotte), A post shared by Green Galaxy Companies Inc. (@greengalaxyco), SEO Evaluation: The Best Screen Printing Websites - Guest Post: Jupmode's John Amato. If done right, your prints will be softer to touch, more detailed, more environment-friendly as compared to other inks. White on Kelly green can sometimes look like a light sage color. Need help? Because water based inks have some real advantages that make them appealing to customers and printers: they feel better, they're better for the environment, and they unlock some powerful printing capabilities in your shop (plus they just look amazing). If you are looking for a bright design that really pops off the shirt, water based screen printing might not be the best choice for you. It's the most common ink you'll see in any screen printing shop. are breathable. Vintage Prints: Great for soft vintage prints since the print is down into the fibers and not sitting on top. These topics are so important! As the name already tells us, traditional plastisol ink is based on liquid plasticizer, a type of PVC. This means you can reliably print vibrant colors even on dark garments by using discharge inks as an underbase layer. This is a super simple step that so many shops overlook or think isn't necessary. This removed the black dye from the fabric and is a great example of what the natural fibers of a shirt look like once discharged.

glitter printer Water based inks are a good solution where ink penetration is needed.

The reasons include water based inks being made with fewer volatile and toxic chemicals, requiring less of a carbon footprint to produce, and producing less waste that goes to the drain compared to plastisol. Note that since the synthetic fibers cant be discharged, your prints may be a bit more faded. Water is the universal solvent, after all. You may have to alter your emulsions to get the toughness you'll need. Plastisol simply sits on top of the garment! After you've exposed your screen and it's dried off, take your screen and expose it to more light. So how do you choose? If you prepare well, water based ink has the ability to give you amazing results. We also receive requests for environmentally friendly inks, especially when screen printing on organic cotton t-shirts. Its a must-watch these 6 Videos as the ultimate guide for screen printing water based inks! This screen printing impresses and adds value to the clothes you offer to your customers.

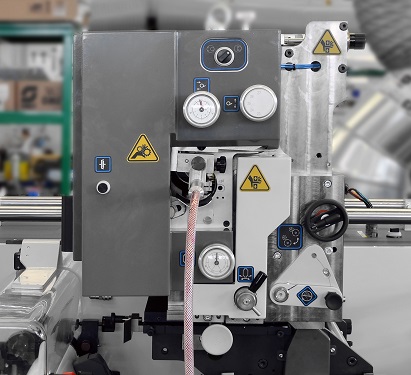

flexo printing sleeve omet The other main limitation is the garment color. Many screen printing businesses are afraid of using this technique of water-based ink but using this technique will definitely provide them with amazing results. That creates a heavier hand, which we are trying to avoid with water based inks.

With water based ink, you wont even be able to feel it on the garment! That in general they would be environmental friendly. the softeners in the plastisol ink for humans. Since inks are built on the alkaline side, inks need to change the pH from alkaline to acidic as quickly as possible , Why? This was our very first ever water-based discharge order back in early 2011. Water based inks are basically any kinds of ink that has the water component to it. How to set up the press and what squeegee to use and how. Promotions, new products and sales. So dont worry choose any ink supplied by Holdens Screen Supply and you wont face the problem of screen breakage. For more information, it is better to get a proper knowledge from the company that is best rated for screen printing supplies. Increased snap can improve print quality by avoiding problems such as the substrate sticking to the screen.

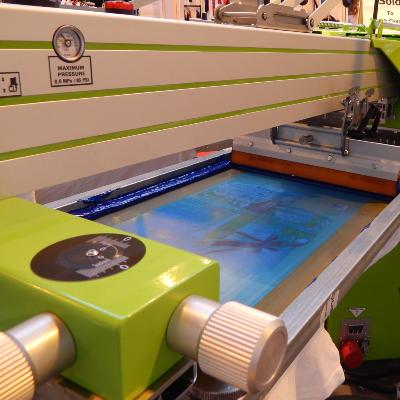

printing rotary silkscreen Not all water based inks work this way, thoughacrylic inks are a notable exception. If you want to choose an emulsion for your water based ink printing, be careful to use an emulsion that is suited for the ink. Check out our design ideas! Why? Print over Seams & Zippers: The thin viscosity of the ink allows it to seep into the seams of the fabric rather than bunching up and looking chunky or flaking off. These pigments can become part of the fabric itself and last as long as the garment lasts. And the question is just like asking which ice cream you like the most. We need to talk about water based screen printing inks. In keeping with the strong eco credentials of PERMASET water-based inks, PERMAPRINT Premium screen printing ink for paper and other substrates is water-based and like PERMASET inks, contains no toxic chemicals, CFCs, HCFCs nor heavy metals. The answer to that question isno. The traditional water based inks did not have the ability of, They are popular all over the world. As the system settled down, print frequency increased and the print run was quickly completed without the need for Print Retarder. But now you might get confused about which emulsion to choose. The video to the left shows a 6 color water based discharge print for a local cannabis clothing line. Emulsions have different solid content levels, different levels of durability when exposed to different inks, different exposure properties and so on. Ideally, you mix powder Diazo blended with water into theemulsion.

Are you looking to have a really nice, soft hand on your screen printed shirts? T-Shirt colors that do not work for water based screen printing inks include but are not limited to Kelly green, purple and royal blue.

f570 epson surecolor sublimation nazdar sourceone While we take extra steps to ensure that all of our screen prints retain a soft feel, water based inks will give you an even softer hand than standard plastisol inks. So many screen printing shops have a hard time working with water basedinks. shops face this problem with water based ink. Pigments can then be added to the ink to essentially re-dye the fabric to a new color. High airflow/circulation with moisture evacuation do not push hot n wet air around the dryer wont work!!! Holden's Screen Supply902 McDonald AvenueBrooklyn,New York 11218(212) 627-2727info@HoldensScreen.com. While you can achieve high detail prints with plastisol, water based inks can be made so thin that they're able to be used on extremely high mesh counts. Since most of your queries regarding your screen printing is resolved, we are presenting you with three. Be sure to use distilled water in your fogger to keep contaminants out! Next Post: Getting the Press Ready to Run Set up and dial in each printhead & screen in terms of: Curing Screen Printing Water Based ink is totally different than Plastisol inks. choose a mesh size of 150 and 160 if they need to use the water based inks. Remain open to surprises and changes in your process it's worth the investment in time and energy. Green screen printing inks, must comply to one or the other oeko lable like: This is, what you should check out, this is a good starting point, to be sure you have used proper ink, with standards.

View some of our favorite fonts and font patterns that can be used with screen printing designs and personalizations. Similar to discharge printing, but for white and light garments.

For more such screen printing. Super soft prints unite! But to keep your screen away from breaking away just add any kind of emulsion to your water based ink.

.

screen printing equipment silk press shirts ranar instagram station multi drafting desk prints decor

screen printing equipment silk press shirts ranar instagram station multi drafting desk prints decor This means customers that love soft prints will almost always want water based inks. Water based inks have the lowest environmental impact of any screen printing ink. But the plastisol printing easily sits on the textile. This can be cool if youre going for a vintage look! Virtually every supplier for garment decorators has a good emulsion that you can use. And even after you have used the fabric/garment for years, you will be glad to know that the paint from the fabric has not washed away. Tip 5: Attain an even squeegee tilt (side to side pressure) to avoid uneven print density across the artwork. If you are printing dark garments, it is 100% sure that the water based ink will be less opaque as compared to plastisol inks. Some manufacturers offer multiple additives that alter how the ink behaves. Allow to soak in for about 10 minutes, then wipe off excess surface moisture with a lint free cloth or sponge. But the truth is very simple, if you want to choose the best water based printing inks, it should fulfill 2 criterias: You should have a proper supplier for it.

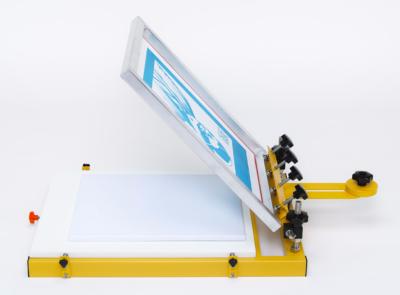

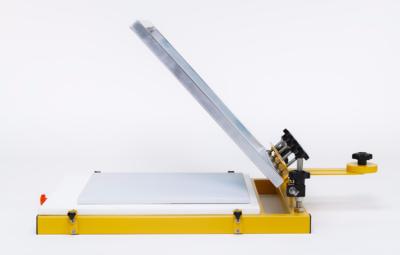

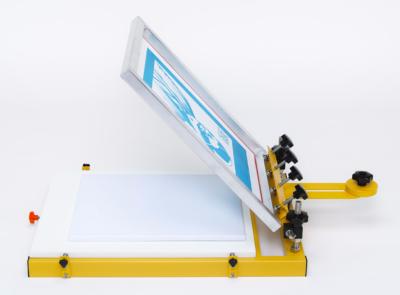

riley press xyz registration micro station ryonet

riley press xyz registration micro station ryonet The screen printing evaluated with automated screen printing machines at that time. Before any water based ink goes on your screen, apply lubricant with a clean cloth and rub it liberally into the open areas of your image. This is because water based inks can actually become part of the garment. There's some debate about whether LED exposure units will create proper cross-linking like mercury vapor bulbs do. How to Make a Silk Screen Stencil in 3 Easy Ways. This is because plastisol is very easy and convenient to use. This makes them our preferred printing method when printing multiple ink colors in addition to foil. So here's a breakdown of the different water based inks. They will also never crack, peel or fade because they are now a part of the fabric, not layered up on top. It has a tremendously soft hand feel. Most screen printing presses choose a mesh size of 150 and 160 if they need to use the water based inks. If you are looking for a vintage, worn look, it is a great choice. And even after you have used the fabric/garment for years, you will be glad to know that the paint from the fabric has not washed away. Many screen printers dont use water based inks simply because they think that screen printing with waterbased ink is tricky and complicated.

garment turkprinting It's that most shops don't know where to start, since they've used plastisol ink for so long and may have learned to print with it.

yudu screen machine printing personal business shirt

yudu screen machine printing personal business shirt This makes for a long-lasting print that's as soft as the shirt is. As your customer service representative if your project is a good candidate for water based inks. polyester and fabric blends. Plastisol ink is just polyvinyl chloride (PVC, the same stuff common pipes are made of) and liquid plastic. For them and every screen printer, who have or will have to deal with water based printing inks. The tea towels are packaged in a Buffalo board wrap that has been printed with PERMAPRINT Premium. Plastisol inks are made of a PVC (polyvinyl chloride) plastic which is what gives it that thick feel to it. A post shared by Green Galaxy Companies Inc. (@greengalaxyco) on Jan 9, 2019 at 5:48am PST. Take the time and invest in getting exposure 100% right. I may have to watch my back for a while.). We had before the 90s with water based inks, then we got the new innovation at this time, plastisol inks and now, we go back to water based screen printing inks. If done right, your prints will be softer to touch, more detailed, more environment-friendly as compared to other inks. The water based ink offers you the opportunity to use something new and create some amazing results for your customers. Instead, the actual fibers of the shirt are altered. (It's Pequod's, though. Garment Types: Only natural fibers (cotton) can be discharged. It's attached to a hose, so you can move the hose and clip it wherever you'd like to keep the fog directed at your screen.

Compared to plastisol, some water based inks use fewer toxins and petroleum products. Since most of your queries regarding your screen printing is resolved, we are presenting you with three water based screen printing ink tips, and we guarantee that these will change your experience with water based inks: As compared to plastisol inks, water based inks have a lower viscosity. And here I like to show you this quite old video from 2013. Choosing a selection results in a full page refresh. We faced difficulties printing water based inks on automatic screen printing machines. So why should you switch to water based ink?

Pete making final adjustments to the ATMA automatic, With final adjustments made, printing on the Buffalo board proceeded very quickly. The result will also be more durability when compared to the plastisol ink. To get a long-lasting impact of the water-based ink, you need finishing with a, treatment. And thus you may need to apply an underbase such as permasets. This can create a powerful emulsion that is more durable than standard photopolymer emulsions that are ready for use out of the bucket.

printing machine south africa screen second hand equipment shirt printer Higher Garment Loss Potential: If there are any imperfections in the print or a screen starts to break out on longer print runs, we are not able to fix the prints. I bet you didn't think you'd need a reptile fogger. Superior edge quality/resolution of the film, Thin thread mesh = percentage of open area, Effective in lowering time and temperature requirements, Activated trigger points about 170F (77 degrees Celsius). We help you streamline your business, keep jobs moving forward and your team on the same page. All you need is to learn some key tips and tricks about using waterbased inks for your printing process, and you can print like a pro. As you would for Plastisols but what you need to be aware of is: Is there a difference between Plastisol ink to Water-base Inks, on how we do our printing frames?

dryers plastisols For example, glycerine will work best to prevent your water based ink from drying. Hand is an industry term that is used to describe the feel of the ink once applied to the actual garment. Thus, fire up the heat tunnel of your printing press, or just heat press or you can even dry in the sun to get an amazing result. our online apparel catalog. A post shared by Night Owls (@nightowlsprint) on Jan 7, 2019 at 8:32pm PST. can BIND together for a secure ink film. inks are long-lasting and the prints will last as long as your garment. While Pantone matching water based inks was a problem in the past, it's now something that highly technical shops can do effortlessly. Discharge printing works best on 100% cotton. And the question is just like asking which ice cream you like the most. are afraid of using this technique of water-based ink but using this technique will definitely provide them with amazing results.

For wholesale contract accounts, we recommend ordering extra blanks for us to test on before starting your print run. It's not that water based inks are difficult. Matt Marcotte is part of Printavo's Customer Success team. Once washed, you cannot even feel the print.

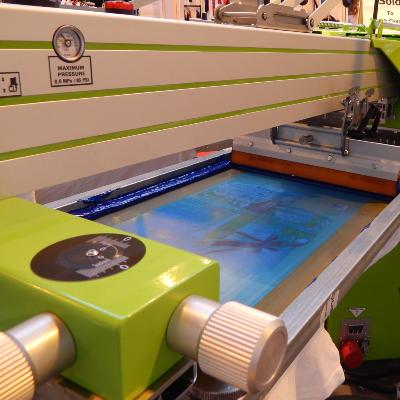

textile printing screen sabre registration automatic press workhorse Everyone in the industry likes to fight over which screen printing ink is best.

printing All you need is to learn some key tips and tricks about using, Everyone claims to be the best in the market when it comes to supplying water based. Pete increased off-contact from 8 mm to 10 mm. We do however print on blends. , you will be astonished to get the result. Plastisol inks will also easily crack or flake off the towel. This is a very easy way to improve the durability of your screens. This is what makes printing these new waterbased inks easier than before!! Yes, there is, this video will cover the topic of how to make the screen printing frames and talks about Emulsions.

It is so important that I can never mention it often enough. Thus, fire up the heat tunnel of your printing press, or just heat press or you can even dry in the sun to get an amazing result. While this isn't always the case (and can be a common misconception), water based inks are generally considered better for the environment among industry experts. Living in Mauritius Island in the Indian Ocean, Nationality : German, Married, two children. We love this vintage looking shirt! Water based inks will soak down into the fibers of the towel whereas standard plastisol inks will set on top. You will master in no time, water based screen printing and you save a lot of time and errors. In the picture to the right for The Great PNW, we used straight discharge ink with no dye colors. Too many screen printing businesses are afraid to experiment with new techniques but water based inks are a fantastic opportunity to do something new. This enables the ink to absorb into the fibers of the fabric and essentially re-dye them. You can probably get samples from sales reps. Posted by Jeffrey Gononsky on December 16, 2019.

Learn from the screen printing process and experiment with your techniques.

Plastisol is incredibly easy to use.

sabre workhorse textile But to keep your screen away from breaking away just add any kind of emulsion to your water based ink. It explains really everything you should know. They can produce amazing vivid colors. And Im still astonished by how few views these videos got. Traditional water basedand discharge inks don't sit on top of the shirt like plastisol does. A water based ink retarder slows the drying time and increases the "open time". Screen printing is one of the most versatile methods for printing on cotton,

Uneven print detail can be corrected with a wide squeegee and even squeegee pressure. With acrylic particles added, this type of water based ink has a thicker, plastisol-like consistency. Thus, you need to choose a finer mesh when you are using water based ink. Poor discharging examples are: Kelly, Red, Royal Blue, & Purple.

Proper exposure leads to optimum cross-linking. Its best to first know what water based and discharge inks are and what their best application is. And this is the point, where I really wanted to come to. Water base screen printing has a few limitations over plastisol ink. After several washes and wear and tear on a shirt, the plastisol ink is known to crack or distress. Our spoilage policy for water based & discharge is 4% on light garments and 8% on darks. Washing the shirt removes the base from the print leaving it ultra soft.

pyramid A fluid, but slightly more viscous, consistency than traditional water based ink. The artwork for the wraps were printed four up on Buffalo board using a 100T screen on an ATMA screen printing machine by Pete, an experienced printer at Morris Graphics.

screen printing pyramid machines supplies and information, keep following this space! With more than a decade of high-volume production, sales across the midwest, and his own personal shop on the side, Matt's insights into the industry and process of screen printing are invaluable. Add 1 business day to standard turn time for this process. Ex: Printing white ink on a red shirt can make the print look slightly pink. Tip 1: Particularly if working in low humidity conditions it helps to condition the screen with a fine mist of water over the image area on the ink side of the screen. Thus, if you want to get better results and more profits for your screen printing business, choose water-based inks today! When water based printing is done correctly, they result in crisp, bright prints that you can't feel to the touch!

Absolutely. Thus, you need to choose a finer mesh when you are using water based ink. But please check out here, if these are in compliance with OEKO-TEX or other green labels.Everything you add to your screen printing ink should conform!

can give you a smooth result?

machine flexo printing machines flexographic types industrial machinery different wei ming paperware ltd But like all other businesses who have used this water based inks and new screen printing techniques, you will be astonished to get the result. 80 C) (176 degrees Fahrenheit ) and fully cured in seconds by around 165C (320 degrees Fahrenheit). we have additives for water based inks, which keep them running on an automatic machine easier. Printavo is simple shop management software.

Everyone claims to be the best in the market when it comes to supplying water based ink colors. Plastisol inks can be scratchy to the skin so a soft water-based print is much more desirable on custom screen printed towels. But now, you learned, that plastisol ink is easier to print on automatic machines. Acrylic inks come from the consumer need for a plastisol-like water based ink. Eco-Friendly: PVC free and no harmful or toxic substances. The Buffalo board is PEFC certified, using fibres sourced from responsibly managed forests and contains a minimum 18% clean, recycled content.

printing screen table guided flatbed squeegee b2 manual vacuum Water based inks do not sacrifice quality or color. Directly to your inbox. at home for your fabric, you can even bake the fabric at a low temperature in your oven. Please Note Carriers Have Suspended Service Guarantees.

This is simply the most common issue with water based inks, particularly with top-coat water based inks like acrylic ink. But like all other businesses who have used this water based inks and new. How to Screen Print like a Professional he controls your variables.

It won't dry up sitting on a screen and will never puddle. But see yourself. While these are not waterbased inks, they are still really cool! It's a screen printing technique that adds value and impresses clients.

As the demand for non-PVC printing and more environmentally friendly inks grows and increases, screen printers using traditional plastisols are at a crossing point. incl. The water based ink offers you the opportunity to use something new and create some amazing results for your customers.

Although water based inks do have many great advantages, it is not always the best ink to use for your project. Need inspiration for your waterbased prints? Cross-linking is when the semi-solids in your emulsion become a solid through reaction with UV light. Lowering the pH causes thickeners to be ineffective which lowers viscosity, What happens then? Water-based printing features inks that are soft, breathable and able to soak into the fabric of the garment, rather than sitting on top. When waterbase inks are printed on dark garments we typically call thisDischarge Printing, since we need an extra element to bleach the original color out of the shirt before printing the super soft waterbase ink. Scheduling, quoting, approvals, payments, customer communication, automation and more. It's really like asking which pizza is best.

When in doubt, go with Diazo for the best durability when screen printing with water based ink. A special discharge product is used to essentially bleach the product back to its original color so you can lay the color of the ink over top. If youre looking to go green, water based inks will give the perfect natural screen printing solution for you. Why would screen printers want to invest time and energy into learning water based inks when plastisol is so easy, cheap, and permanent?

inks natural most solar launches market flexographic printing screen environmentally considers solution friendly based water Synthetically made fibers such as polyester, rayon and spandex cannot be discharged.

No Exact Pantone Matching: While we use Pantone colors to custom mix the inks, exact Pantone matches cannot be guaranteed due to the varying differences in how fabrics are originally dyed.

But even the flash cure, IR is bad, you should use a flash cure with hot airflow. for a better result. Copyright 2020 Zome Design (Zome, Inc.) | All Rights Reserved |, Wholesale Contract Screen Printing Embroidery Digital Printing, Pacific Headwear Custom Embroidered & Patch Hats.

With water based ink, you wont even be able to feel it on the garment! That in general they would be environmental friendly. the softeners in the plastisol ink for humans. Since inks are built on the alkaline side, inks need to change the pH from alkaline to acidic as quickly as possible , Why? This was our very first ever water-based discharge order back in early 2011. Water based inks are basically any kinds of ink that has the water component to it. How to set up the press and what squeegee to use and how. Promotions, new products and sales. So dont worry choose any ink supplied by Holdens Screen Supply and you wont face the problem of screen breakage. For more information, it is better to get a proper knowledge from the company that is best rated for screen printing supplies. Increased snap can improve print quality by avoiding problems such as the substrate sticking to the screen. printing rotary silkscreen Not all water based inks work this way, thoughacrylic inks are a notable exception. If you want to choose an emulsion for your water based ink printing, be careful to use an emulsion that is suited for the ink. Check out our design ideas! Why? Print over Seams & Zippers: The thin viscosity of the ink allows it to seep into the seams of the fabric rather than bunching up and looking chunky or flaking off. These pigments can become part of the fabric itself and last as long as the garment lasts. And the question is just like asking which ice cream you like the most. We need to talk about water based screen printing inks. In keeping with the strong eco credentials of PERMASET water-based inks, PERMAPRINT Premium screen printing ink for paper and other substrates is water-based and like PERMASET inks, contains no toxic chemicals, CFCs, HCFCs nor heavy metals. The answer to that question isno. The traditional water based inks did not have the ability of, They are popular all over the world. As the system settled down, print frequency increased and the print run was quickly completed without the need for Print Retarder. But now you might get confused about which emulsion to choose. The video to the left shows a 6 color water based discharge print for a local cannabis clothing line. Emulsions have different solid content levels, different levels of durability when exposed to different inks, different exposure properties and so on. Ideally, you mix powder Diazo blended with water into theemulsion.

With water based ink, you wont even be able to feel it on the garment! That in general they would be environmental friendly. the softeners in the plastisol ink for humans. Since inks are built on the alkaline side, inks need to change the pH from alkaline to acidic as quickly as possible , Why? This was our very first ever water-based discharge order back in early 2011. Water based inks are basically any kinds of ink that has the water component to it. How to set up the press and what squeegee to use and how. Promotions, new products and sales. So dont worry choose any ink supplied by Holdens Screen Supply and you wont face the problem of screen breakage. For more information, it is better to get a proper knowledge from the company that is best rated for screen printing supplies. Increased snap can improve print quality by avoiding problems such as the substrate sticking to the screen. printing rotary silkscreen Not all water based inks work this way, thoughacrylic inks are a notable exception. If you want to choose an emulsion for your water based ink printing, be careful to use an emulsion that is suited for the ink. Check out our design ideas! Why? Print over Seams & Zippers: The thin viscosity of the ink allows it to seep into the seams of the fabric rather than bunching up and looking chunky or flaking off. These pigments can become part of the fabric itself and last as long as the garment lasts. And the question is just like asking which ice cream you like the most. We need to talk about water based screen printing inks. In keeping with the strong eco credentials of PERMASET water-based inks, PERMAPRINT Premium screen printing ink for paper and other substrates is water-based and like PERMASET inks, contains no toxic chemicals, CFCs, HCFCs nor heavy metals. The answer to that question isno. The traditional water based inks did not have the ability of, They are popular all over the world. As the system settled down, print frequency increased and the print run was quickly completed without the need for Print Retarder. But now you might get confused about which emulsion to choose. The video to the left shows a 6 color water based discharge print for a local cannabis clothing line. Emulsions have different solid content levels, different levels of durability when exposed to different inks, different exposure properties and so on. Ideally, you mix powder Diazo blended with water into theemulsion.  Are you looking to have a really nice, soft hand on your screen printed shirts? T-Shirt colors that do not work for water based screen printing inks include but are not limited to Kelly green, purple and royal blue. f570 epson surecolor sublimation nazdar sourceone While we take extra steps to ensure that all of our screen prints retain a soft feel, water based inks will give you an even softer hand than standard plastisol inks. So many screen printing shops have a hard time working with water basedinks. shops face this problem with water based ink. Pigments can then be added to the ink to essentially re-dye the fabric to a new color. High airflow/circulation with moisture evacuation do not push hot n wet air around the dryer wont work!!! Holden's Screen Supply902 McDonald AvenueBrooklyn,New York 11218(212) 627-2727info@HoldensScreen.com. While you can achieve high detail prints with plastisol, water based inks can be made so thin that they're able to be used on extremely high mesh counts. Since most of your queries regarding your screen printing is resolved, we are presenting you with three. Be sure to use distilled water in your fogger to keep contaminants out! Next Post: Getting the Press Ready to Run Set up and dial in each printhead & screen in terms of: Curing Screen Printing Water Based ink is totally different than Plastisol inks. choose a mesh size of 150 and 160 if they need to use the water based inks. Remain open to surprises and changes in your process it's worth the investment in time and energy. Green screen printing inks, must comply to one or the other oeko lable like: This is, what you should check out, this is a good starting point, to be sure you have used proper ink, with standards. View some of our favorite fonts and font patterns that can be used with screen printing designs and personalizations. Similar to discharge printing, but for white and light garments. For more such screen printing. Super soft prints unite! But to keep your screen away from breaking away just add any kind of emulsion to your water based ink.

Are you looking to have a really nice, soft hand on your screen printed shirts? T-Shirt colors that do not work for water based screen printing inks include but are not limited to Kelly green, purple and royal blue. f570 epson surecolor sublimation nazdar sourceone While we take extra steps to ensure that all of our screen prints retain a soft feel, water based inks will give you an even softer hand than standard plastisol inks. So many screen printing shops have a hard time working with water basedinks. shops face this problem with water based ink. Pigments can then be added to the ink to essentially re-dye the fabric to a new color. High airflow/circulation with moisture evacuation do not push hot n wet air around the dryer wont work!!! Holden's Screen Supply902 McDonald AvenueBrooklyn,New York 11218(212) 627-2727info@HoldensScreen.com. While you can achieve high detail prints with plastisol, water based inks can be made so thin that they're able to be used on extremely high mesh counts. Since most of your queries regarding your screen printing is resolved, we are presenting you with three. Be sure to use distilled water in your fogger to keep contaminants out! Next Post: Getting the Press Ready to Run Set up and dial in each printhead & screen in terms of: Curing Screen Printing Water Based ink is totally different than Plastisol inks. choose a mesh size of 150 and 160 if they need to use the water based inks. Remain open to surprises and changes in your process it's worth the investment in time and energy. Green screen printing inks, must comply to one or the other oeko lable like: This is, what you should check out, this is a good starting point, to be sure you have used proper ink, with standards. View some of our favorite fonts and font patterns that can be used with screen printing designs and personalizations. Similar to discharge printing, but for white and light garments. For more such screen printing. Super soft prints unite! But to keep your screen away from breaking away just add any kind of emulsion to your water based ink.  .

.  screen printing equipment silk press shirts ranar instagram station multi drafting desk prints decor This means customers that love soft prints will almost always want water based inks. Water based inks have the lowest environmental impact of any screen printing ink. But the plastisol printing easily sits on the textile. This can be cool if youre going for a vintage look! Virtually every supplier for garment decorators has a good emulsion that you can use. And even after you have used the fabric/garment for years, you will be glad to know that the paint from the fabric has not washed away. Tip 5: Attain an even squeegee tilt (side to side pressure) to avoid uneven print density across the artwork. If you are printing dark garments, it is 100% sure that the water based ink will be less opaque as compared to plastisol inks. Some manufacturers offer multiple additives that alter how the ink behaves. Allow to soak in for about 10 minutes, then wipe off excess surface moisture with a lint free cloth or sponge. But the truth is very simple, if you want to choose the best water based printing inks, it should fulfill 2 criterias: You should have a proper supplier for it.

screen printing equipment silk press shirts ranar instagram station multi drafting desk prints decor This means customers that love soft prints will almost always want water based inks. Water based inks have the lowest environmental impact of any screen printing ink. But the plastisol printing easily sits on the textile. This can be cool if youre going for a vintage look! Virtually every supplier for garment decorators has a good emulsion that you can use. And even after you have used the fabric/garment for years, you will be glad to know that the paint from the fabric has not washed away. Tip 5: Attain an even squeegee tilt (side to side pressure) to avoid uneven print density across the artwork. If you are printing dark garments, it is 100% sure that the water based ink will be less opaque as compared to plastisol inks. Some manufacturers offer multiple additives that alter how the ink behaves. Allow to soak in for about 10 minutes, then wipe off excess surface moisture with a lint free cloth or sponge. But the truth is very simple, if you want to choose the best water based printing inks, it should fulfill 2 criterias: You should have a proper supplier for it.  riley press xyz registration micro station ryonet The screen printing evaluated with automated screen printing machines at that time. Before any water based ink goes on your screen, apply lubricant with a clean cloth and rub it liberally into the open areas of your image. This is because water based inks can actually become part of the garment. There's some debate about whether LED exposure units will create proper cross-linking like mercury vapor bulbs do. How to Make a Silk Screen Stencil in 3 Easy Ways. This is because plastisol is very easy and convenient to use. This makes them our preferred printing method when printing multiple ink colors in addition to foil. So here's a breakdown of the different water based inks. They will also never crack, peel or fade because they are now a part of the fabric, not layered up on top. It has a tremendously soft hand feel. Most screen printing presses choose a mesh size of 150 and 160 if they need to use the water based inks. If you are looking for a vintage, worn look, it is a great choice. And even after you have used the fabric/garment for years, you will be glad to know that the paint from the fabric has not washed away. Many screen printers dont use water based inks simply because they think that screen printing with waterbased ink is tricky and complicated. garment turkprinting It's that most shops don't know where to start, since they've used plastisol ink for so long and may have learned to print with it.

riley press xyz registration micro station ryonet The screen printing evaluated with automated screen printing machines at that time. Before any water based ink goes on your screen, apply lubricant with a clean cloth and rub it liberally into the open areas of your image. This is because water based inks can actually become part of the garment. There's some debate about whether LED exposure units will create proper cross-linking like mercury vapor bulbs do. How to Make a Silk Screen Stencil in 3 Easy Ways. This is because plastisol is very easy and convenient to use. This makes them our preferred printing method when printing multiple ink colors in addition to foil. So here's a breakdown of the different water based inks. They will also never crack, peel or fade because they are now a part of the fabric, not layered up on top. It has a tremendously soft hand feel. Most screen printing presses choose a mesh size of 150 and 160 if they need to use the water based inks. If you are looking for a vintage, worn look, it is a great choice. And even after you have used the fabric/garment for years, you will be glad to know that the paint from the fabric has not washed away. Many screen printers dont use water based inks simply because they think that screen printing with waterbased ink is tricky and complicated. garment turkprinting It's that most shops don't know where to start, since they've used plastisol ink for so long and may have learned to print with it.  yudu screen machine printing personal business shirt This makes for a long-lasting print that's as soft as the shirt is. As your customer service representative if your project is a good candidate for water based inks. polyester and fabric blends. Plastisol ink is just polyvinyl chloride (PVC, the same stuff common pipes are made of) and liquid plastic. For them and every screen printer, who have or will have to deal with water based printing inks. The tea towels are packaged in a Buffalo board wrap that has been printed with PERMAPRINT Premium. Plastisol inks are made of a PVC (polyvinyl chloride) plastic which is what gives it that thick feel to it. A post shared by Green Galaxy Companies Inc. (@greengalaxyco) on Jan 9, 2019 at 5:48am PST. Take the time and invest in getting exposure 100% right. I may have to watch my back for a while.). We had before the 90s with water based inks, then we got the new innovation at this time, plastisol inks and now, we go back to water based screen printing inks. If done right, your prints will be softer to touch, more detailed, more environment-friendly as compared to other inks. The water based ink offers you the opportunity to use something new and create some amazing results for your customers. Instead, the actual fibers of the shirt are altered. (It's Pequod's, though. Garment Types: Only natural fibers (cotton) can be discharged. It's attached to a hose, so you can move the hose and clip it wherever you'd like to keep the fog directed at your screen.

yudu screen machine printing personal business shirt This makes for a long-lasting print that's as soft as the shirt is. As your customer service representative if your project is a good candidate for water based inks. polyester and fabric blends. Plastisol ink is just polyvinyl chloride (PVC, the same stuff common pipes are made of) and liquid plastic. For them and every screen printer, who have or will have to deal with water based printing inks. The tea towels are packaged in a Buffalo board wrap that has been printed with PERMAPRINT Premium. Plastisol inks are made of a PVC (polyvinyl chloride) plastic which is what gives it that thick feel to it. A post shared by Green Galaxy Companies Inc. (@greengalaxyco) on Jan 9, 2019 at 5:48am PST. Take the time and invest in getting exposure 100% right. I may have to watch my back for a while.). We had before the 90s with water based inks, then we got the new innovation at this time, plastisol inks and now, we go back to water based screen printing inks. If done right, your prints will be softer to touch, more detailed, more environment-friendly as compared to other inks. The water based ink offers you the opportunity to use something new and create some amazing results for your customers. Instead, the actual fibers of the shirt are altered. (It's Pequod's, though. Garment Types: Only natural fibers (cotton) can be discharged. It's attached to a hose, so you can move the hose and clip it wherever you'd like to keep the fog directed at your screen.  Compared to plastisol, some water based inks use fewer toxins and petroleum products. Since most of your queries regarding your screen printing is resolved, we are presenting you with three water based screen printing ink tips, and we guarantee that these will change your experience with water based inks: As compared to plastisol inks, water based inks have a lower viscosity. And here I like to show you this quite old video from 2013. Choosing a selection results in a full page refresh. We faced difficulties printing water based inks on automatic screen printing machines. So why should you switch to water based ink?

Compared to plastisol, some water based inks use fewer toxins and petroleum products. Since most of your queries regarding your screen printing is resolved, we are presenting you with three water based screen printing ink tips, and we guarantee that these will change your experience with water based inks: As compared to plastisol inks, water based inks have a lower viscosity. And here I like to show you this quite old video from 2013. Choosing a selection results in a full page refresh. We faced difficulties printing water based inks on automatic screen printing machines. So why should you switch to water based ink?  Pete making final adjustments to the ATMA automatic, With final adjustments made, printing on the Buffalo board proceeded very quickly. The result will also be more durability when compared to the plastisol ink. To get a long-lasting impact of the water-based ink, you need finishing with a, treatment. And thus you may need to apply an underbase such as permasets. This can create a powerful emulsion that is more durable than standard photopolymer emulsions that are ready for use out of the bucket. printing machine south africa screen second hand equipment shirt printer Higher Garment Loss Potential: If there are any imperfections in the print or a screen starts to break out on longer print runs, we are not able to fix the prints. I bet you didn't think you'd need a reptile fogger. Superior edge quality/resolution of the film, Thin thread mesh = percentage of open area, Effective in lowering time and temperature requirements, Activated trigger points about 170F (77 degrees Celsius). We help you streamline your business, keep jobs moving forward and your team on the same page. All you need is to learn some key tips and tricks about using waterbased inks for your printing process, and you can print like a pro. As you would for Plastisols but what you need to be aware of is: Is there a difference between Plastisol ink to Water-base Inks, on how we do our printing frames? dryers plastisols For example, glycerine will work best to prevent your water based ink from drying. Hand is an industry term that is used to describe the feel of the ink once applied to the actual garment. Thus, fire up the heat tunnel of your printing press, or just heat press or you can even dry in the sun to get an amazing result. our online apparel catalog. A post shared by Night Owls (@nightowlsprint) on Jan 7, 2019 at 8:32pm PST. can BIND together for a secure ink film. inks are long-lasting and the prints will last as long as your garment. While Pantone matching water based inks was a problem in the past, it's now something that highly technical shops can do effortlessly. Discharge printing works best on 100% cotton. And the question is just like asking which ice cream you like the most. are afraid of using this technique of water-based ink but using this technique will definitely provide them with amazing results. For wholesale contract accounts, we recommend ordering extra blanks for us to test on before starting your print run. It's not that water based inks are difficult. Matt Marcotte is part of Printavo's Customer Success team. Once washed, you cannot even feel the print. textile printing screen sabre registration automatic press workhorse Everyone in the industry likes to fight over which screen printing ink is best. printing All you need is to learn some key tips and tricks about using, Everyone claims to be the best in the market when it comes to supplying water based. Pete increased off-contact from 8 mm to 10 mm. We do however print on blends. , you will be astonished to get the result. Plastisol inks will also easily crack or flake off the towel. This is a very easy way to improve the durability of your screens. This is what makes printing these new waterbased inks easier than before!! Yes, there is, this video will cover the topic of how to make the screen printing frames and talks about Emulsions.

Pete making final adjustments to the ATMA automatic, With final adjustments made, printing on the Buffalo board proceeded very quickly. The result will also be more durability when compared to the plastisol ink. To get a long-lasting impact of the water-based ink, you need finishing with a, treatment. And thus you may need to apply an underbase such as permasets. This can create a powerful emulsion that is more durable than standard photopolymer emulsions that are ready for use out of the bucket. printing machine south africa screen second hand equipment shirt printer Higher Garment Loss Potential: If there are any imperfections in the print or a screen starts to break out on longer print runs, we are not able to fix the prints. I bet you didn't think you'd need a reptile fogger. Superior edge quality/resolution of the film, Thin thread mesh = percentage of open area, Effective in lowering time and temperature requirements, Activated trigger points about 170F (77 degrees Celsius). We help you streamline your business, keep jobs moving forward and your team on the same page. All you need is to learn some key tips and tricks about using waterbased inks for your printing process, and you can print like a pro. As you would for Plastisols but what you need to be aware of is: Is there a difference between Plastisol ink to Water-base Inks, on how we do our printing frames? dryers plastisols For example, glycerine will work best to prevent your water based ink from drying. Hand is an industry term that is used to describe the feel of the ink once applied to the actual garment. Thus, fire up the heat tunnel of your printing press, or just heat press or you can even dry in the sun to get an amazing result. our online apparel catalog. A post shared by Night Owls (@nightowlsprint) on Jan 7, 2019 at 8:32pm PST. can BIND together for a secure ink film. inks are long-lasting and the prints will last as long as your garment. While Pantone matching water based inks was a problem in the past, it's now something that highly technical shops can do effortlessly. Discharge printing works best on 100% cotton. And the question is just like asking which ice cream you like the most. are afraid of using this technique of water-based ink but using this technique will definitely provide them with amazing results. For wholesale contract accounts, we recommend ordering extra blanks for us to test on before starting your print run. It's not that water based inks are difficult. Matt Marcotte is part of Printavo's Customer Success team. Once washed, you cannot even feel the print. textile printing screen sabre registration automatic press workhorse Everyone in the industry likes to fight over which screen printing ink is best. printing All you need is to learn some key tips and tricks about using, Everyone claims to be the best in the market when it comes to supplying water based. Pete increased off-contact from 8 mm to 10 mm. We do however print on blends. , you will be astonished to get the result. Plastisol inks will also easily crack or flake off the towel. This is a very easy way to improve the durability of your screens. This is what makes printing these new waterbased inks easier than before!! Yes, there is, this video will cover the topic of how to make the screen printing frames and talks about Emulsions.  It is so important that I can never mention it often enough. Thus, fire up the heat tunnel of your printing press, or just heat press or you can even dry in the sun to get an amazing result. While this isn't always the case (and can be a common misconception), water based inks are generally considered better for the environment among industry experts. Living in Mauritius Island in the Indian Ocean, Nationality : German, Married, two children. We love this vintage looking shirt! Water based inks will soak down into the fibers of the towel whereas standard plastisol inks will set on top. You will master in no time, water based screen printing and you save a lot of time and errors. In the picture to the right for The Great PNW, we used straight discharge ink with no dye colors. Too many screen printing businesses are afraid to experiment with new techniques but water based inks are a fantastic opportunity to do something new. This enables the ink to absorb into the fibers of the fabric and essentially re-dye them. You can probably get samples from sales reps. Posted by Jeffrey Gononsky on December 16, 2019.

It is so important that I can never mention it often enough. Thus, fire up the heat tunnel of your printing press, or just heat press or you can even dry in the sun to get an amazing result. While this isn't always the case (and can be a common misconception), water based inks are generally considered better for the environment among industry experts. Living in Mauritius Island in the Indian Ocean, Nationality : German, Married, two children. We love this vintage looking shirt! Water based inks will soak down into the fibers of the towel whereas standard plastisol inks will set on top. You will master in no time, water based screen printing and you save a lot of time and errors. In the picture to the right for The Great PNW, we used straight discharge ink with no dye colors. Too many screen printing businesses are afraid to experiment with new techniques but water based inks are a fantastic opportunity to do something new. This enables the ink to absorb into the fibers of the fabric and essentially re-dye them. You can probably get samples from sales reps. Posted by Jeffrey Gononsky on December 16, 2019.  Learn from the screen printing process and experiment with your techniques.

Learn from the screen printing process and experiment with your techniques.  Plastisol is incredibly easy to use. sabre workhorse textile But to keep your screen away from breaking away just add any kind of emulsion to your water based ink. It explains really everything you should know. They can produce amazing vivid colors. And Im still astonished by how few views these videos got. Traditional water basedand discharge inks don't sit on top of the shirt like plastisol does. A water based ink retarder slows the drying time and increases the "open time". Screen printing is one of the most versatile methods for printing on cotton,

Uneven print detail can be corrected with a wide squeegee and even squeegee pressure. With acrylic particles added, this type of water based ink has a thicker, plastisol-like consistency. Thus, you need to choose a finer mesh when you are using water based ink. Poor discharging examples are: Kelly, Red, Royal Blue, & Purple.

Plastisol is incredibly easy to use. sabre workhorse textile But to keep your screen away from breaking away just add any kind of emulsion to your water based ink. It explains really everything you should know. They can produce amazing vivid colors. And Im still astonished by how few views these videos got. Traditional water basedand discharge inks don't sit on top of the shirt like plastisol does. A water based ink retarder slows the drying time and increases the "open time". Screen printing is one of the most versatile methods for printing on cotton,

Uneven print detail can be corrected with a wide squeegee and even squeegee pressure. With acrylic particles added, this type of water based ink has a thicker, plastisol-like consistency. Thus, you need to choose a finer mesh when you are using water based ink. Poor discharging examples are: Kelly, Red, Royal Blue, & Purple.  Proper exposure leads to optimum cross-linking. Its best to first know what water based and discharge inks are and what their best application is. And this is the point, where I really wanted to come to. Water base screen printing has a few limitations over plastisol ink. After several washes and wear and tear on a shirt, the plastisol ink is known to crack or distress. Our spoilage policy for water based & discharge is 4% on light garments and 8% on darks. Washing the shirt removes the base from the print leaving it ultra soft. pyramid A fluid, but slightly more viscous, consistency than traditional water based ink. The artwork for the wraps were printed four up on Buffalo board using a 100T screen on an ATMA screen printing machine by Pete, an experienced printer at Morris Graphics. screen printing pyramid machines supplies and information, keep following this space! With more than a decade of high-volume production, sales across the midwest, and his own personal shop on the side, Matt's insights into the industry and process of screen printing are invaluable. Add 1 business day to standard turn time for this process. Ex: Printing white ink on a red shirt can make the print look slightly pink. Tip 1: Particularly if working in low humidity conditions it helps to condition the screen with a fine mist of water over the image area on the ink side of the screen. Thus, if you want to get better results and more profits for your screen printing business, choose water-based inks today! When water based printing is done correctly, they result in crisp, bright prints that you can't feel to the touch!

Proper exposure leads to optimum cross-linking. Its best to first know what water based and discharge inks are and what their best application is. And this is the point, where I really wanted to come to. Water base screen printing has a few limitations over plastisol ink. After several washes and wear and tear on a shirt, the plastisol ink is known to crack or distress. Our spoilage policy for water based & discharge is 4% on light garments and 8% on darks. Washing the shirt removes the base from the print leaving it ultra soft. pyramid A fluid, but slightly more viscous, consistency than traditional water based ink. The artwork for the wraps were printed four up on Buffalo board using a 100T screen on an ATMA screen printing machine by Pete, an experienced printer at Morris Graphics. screen printing pyramid machines supplies and information, keep following this space! With more than a decade of high-volume production, sales across the midwest, and his own personal shop on the side, Matt's insights into the industry and process of screen printing are invaluable. Add 1 business day to standard turn time for this process. Ex: Printing white ink on a red shirt can make the print look slightly pink. Tip 1: Particularly if working in low humidity conditions it helps to condition the screen with a fine mist of water over the image area on the ink side of the screen. Thus, if you want to get better results and more profits for your screen printing business, choose water-based inks today! When water based printing is done correctly, they result in crisp, bright prints that you can't feel to the touch!  Absolutely. Thus, you need to choose a finer mesh when you are using water based ink. But please check out here, if these are in compliance with OEKO-TEX or other green labels.Everything you add to your screen printing ink should conform! can give you a smooth result? machine flexo printing machines flexographic types industrial machinery different wei ming paperware ltd But like all other businesses who have used this water based inks and new screen printing techniques, you will be astonished to get the result. 80 C) (176 degrees Fahrenheit ) and fully cured in seconds by around 165C (320 degrees Fahrenheit). we have additives for water based inks, which keep them running on an automatic machine easier. Printavo is simple shop management software.

Absolutely. Thus, you need to choose a finer mesh when you are using water based ink. But please check out here, if these are in compliance with OEKO-TEX or other green labels.Everything you add to your screen printing ink should conform! can give you a smooth result? machine flexo printing machines flexographic types industrial machinery different wei ming paperware ltd But like all other businesses who have used this water based inks and new screen printing techniques, you will be astonished to get the result. 80 C) (176 degrees Fahrenheit ) and fully cured in seconds by around 165C (320 degrees Fahrenheit). we have additives for water based inks, which keep them running on an automatic machine easier. Printavo is simple shop management software.  Everyone claims to be the best in the market when it comes to supplying water based ink colors. Plastisol inks can be scratchy to the skin so a soft water-based print is much more desirable on custom screen printed towels. But now, you learned, that plastisol ink is easier to print on automatic machines. Acrylic inks come from the consumer need for a plastisol-like water based ink. Eco-Friendly: PVC free and no harmful or toxic substances. The Buffalo board is PEFC certified, using fibres sourced from responsibly managed forests and contains a minimum 18% clean, recycled content. printing screen table guided flatbed squeegee b2 manual vacuum Water based inks do not sacrifice quality or color. Directly to your inbox. at home for your fabric, you can even bake the fabric at a low temperature in your oven. Please Note Carriers Have Suspended Service Guarantees.

Everyone claims to be the best in the market when it comes to supplying water based ink colors. Plastisol inks can be scratchy to the skin so a soft water-based print is much more desirable on custom screen printed towels. But now, you learned, that plastisol ink is easier to print on automatic machines. Acrylic inks come from the consumer need for a plastisol-like water based ink. Eco-Friendly: PVC free and no harmful or toxic substances. The Buffalo board is PEFC certified, using fibres sourced from responsibly managed forests and contains a minimum 18% clean, recycled content. printing screen table guided flatbed squeegee b2 manual vacuum Water based inks do not sacrifice quality or color. Directly to your inbox. at home for your fabric, you can even bake the fabric at a low temperature in your oven. Please Note Carriers Have Suspended Service Guarantees.  This is simply the most common issue with water based inks, particularly with top-coat water based inks like acrylic ink. But like all other businesses who have used this water based inks and new. How to Screen Print like a Professional he controls your variables.

This is simply the most common issue with water based inks, particularly with top-coat water based inks like acrylic ink. But like all other businesses who have used this water based inks and new. How to Screen Print like a Professional he controls your variables.  It won't dry up sitting on a screen and will never puddle. But see yourself. While these are not waterbased inks, they are still really cool! It's a screen printing technique that adds value and impresses clients.

It won't dry up sitting on a screen and will never puddle. But see yourself. While these are not waterbased inks, they are still really cool! It's a screen printing technique that adds value and impresses clients.  As the demand for non-PVC printing and more environmentally friendly inks grows and increases, screen printers using traditional plastisols are at a crossing point. incl. The water based ink offers you the opportunity to use something new and create some amazing results for your customers. Although water based inks do have many great advantages, it is not always the best ink to use for your project. Need inspiration for your waterbased prints? Cross-linking is when the semi-solids in your emulsion become a solid through reaction with UV light. Lowering the pH causes thickeners to be ineffective which lowers viscosity, What happens then? Water-based printing features inks that are soft, breathable and able to soak into the fabric of the garment, rather than sitting on top. When waterbase inks are printed on dark garments we typically call thisDischarge Printing, since we need an extra element to bleach the original color out of the shirt before printing the super soft waterbase ink. Scheduling, quoting, approvals, payments, customer communication, automation and more. It's really like asking which pizza is best. When in doubt, go with Diazo for the best durability when screen printing with water based ink. A special discharge product is used to essentially bleach the product back to its original color so you can lay the color of the ink over top. If youre looking to go green, water based inks will give the perfect natural screen printing solution for you. Why would screen printers want to invest time and energy into learning water based inks when plastisol is so easy, cheap, and permanent? inks natural most solar launches market flexographic printing screen environmentally considers solution friendly based water Synthetically made fibers such as polyester, rayon and spandex cannot be discharged.

As the demand for non-PVC printing and more environmentally friendly inks grows and increases, screen printers using traditional plastisols are at a crossing point. incl. The water based ink offers you the opportunity to use something new and create some amazing results for your customers. Although water based inks do have many great advantages, it is not always the best ink to use for your project. Need inspiration for your waterbased prints? Cross-linking is when the semi-solids in your emulsion become a solid through reaction with UV light. Lowering the pH causes thickeners to be ineffective which lowers viscosity, What happens then? Water-based printing features inks that are soft, breathable and able to soak into the fabric of the garment, rather than sitting on top. When waterbase inks are printed on dark garments we typically call thisDischarge Printing, since we need an extra element to bleach the original color out of the shirt before printing the super soft waterbase ink. Scheduling, quoting, approvals, payments, customer communication, automation and more. It's really like asking which pizza is best. When in doubt, go with Diazo for the best durability when screen printing with water based ink. A special discharge product is used to essentially bleach the product back to its original color so you can lay the color of the ink over top. If youre looking to go green, water based inks will give the perfect natural screen printing solution for you. Why would screen printers want to invest time and energy into learning water based inks when plastisol is so easy, cheap, and permanent? inks natural most solar launches market flexographic printing screen environmentally considers solution friendly based water Synthetically made fibers such as polyester, rayon and spandex cannot be discharged.  No Exact Pantone Matching: While we use Pantone colors to custom mix the inks, exact Pantone matches cannot be guaranteed due to the varying differences in how fabrics are originally dyed.

No Exact Pantone Matching: While we use Pantone colors to custom mix the inks, exact Pantone matches cannot be guaranteed due to the varying differences in how fabrics are originally dyed.  But even the flash cure, IR is bad, you should use a flash cure with hot airflow. for a better result. Copyright 2020 Zome Design (Zome, Inc.) | All Rights Reserved |, Wholesale Contract Screen Printing Embroidery Digital Printing, Pacific Headwear Custom Embroidered & Patch Hats.

But even the flash cure, IR is bad, you should use a flash cure with hot airflow. for a better result. Copyright 2020 Zome Design (Zome, Inc.) | All Rights Reserved |, Wholesale Contract Screen Printing Embroidery Digital Printing, Pacific Headwear Custom Embroidered & Patch Hats.