Mills come in varying designs. Using this item with half hard or hard wire is not recommended.

plants grinding pert If you own an economy mill, you will probably have to adjust the rollers from time to time.

sundwig andritz sfc It saves time and you dont have to keep checking or screwing up your tension. Presented below are a variety mills for your consideration ranging from el cheapo to wow, thats a lot of money! If the rollers are not parallel with each other, pull out the thickness adjusting wheel and turn either or both dials until the top roller fits flush with the bottom one. Five-roller mills are six-roller mills in which one of the rollers performs double duty. Already the best equipped laboratory in the specialty mixer business, our Test and Development Center was recently expanded. While it isn't the most accurate for sizing down as you go as a rolling mill would be, nor is it super strong, it can absolutely (temporarily) get the job done. I used liquid nails to glue it back together and still used it (carefully) for a while for rolling wire. **Remember: quality mills should last a lifetime (or more) so, to justify the expense (to yourself and/or your significant other, just say: Wow darling or Wow self, the cost of this (insert tool name here) works out to only 50.00 a year and arent I worth that? or something similarly convincing and heartfelt.

ROSS is a leading manufacturer of mixing, blending, drying, size reduction, emulsification, homogenization, dispersion and control equipment for the Food Industry. Now, tighten down the rollers until they are either at zero or the number you wrote down (remember no metal in there yet!). The systems typically include a mixer/blender, filter, condenser, vacuum pump and condensate receiving vessel. Many products including pharmaceuticals, foods (BISSC certified), chemicals, fertilizers, plastics, pigments, and cosmetics are manufactured in ROSS Ribbon and Paddle Blenders. I like to roll similargauges, all at the same time. Four-roller mills have two sets of rollers. Easily search resources, browse images, and learn about ROSS products. The workhorses of the rolling mill crowd!

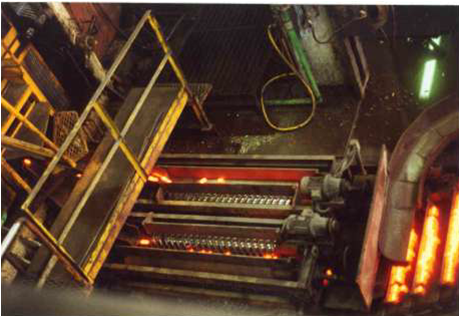

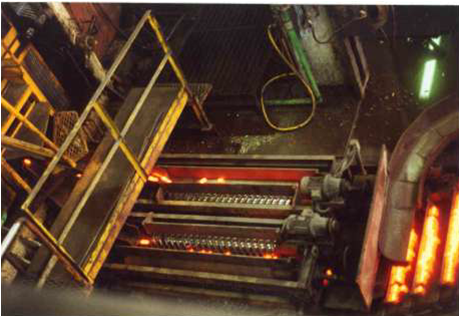

rolling cold mills reversing cmi A brand new manual mill typically can cost from us$150 to us$1600, depending on the qualityand features of the mill. Mixing parameters are easily replicated using electronic variable speed controls while the mixer operation itself is not nearly as labor intensive as in a three roll milling process.

Why? Finally, even if you use a rolling mill, the final shaping of wire is generally done in a draw plate, which is expensive, but about $100 instead of a rolling mill, which is around $800 - $1000 for a Durston (which, if youre going to invest in a tool, buy the best one you can get which will last a lifetime). The premier place for all your jewelry making needs. My new favorite rolling mills are from Pepetools. Although, neither line has been sufficient to convince my husband that these expenditures are truly a benefit to him. The company has a world class reputation for innovative engineering, superb construction and fast delivery. All of the company's employees now share in the ownership. An alternative to the mill, is of course, to buy ready rolled metal to your specifications, but that takes some of the fun of making the jewelry, so why not learn how to use a mill? You may want to tighten the rollers down a bit so its a tightish fit. . The Ross X-Series, QuadSlot and MegaShear inline ultra-high shear mixers consist of special rotor/stator generators operating at tip speeds over 11,000 ft/min. Tighten down the rollers but, not too tight.

Applications include the simple blending of dry powders to the sophisticated dispersion of solids into high viscosity fluids. Cover the mill with the oiled towel.

I watched David Aisenman from Pepetools reduce a penny to around 34 gauge in approximately 3 run throughs and in only a few seconds. Durston also makes quality mills that will last a lifetime. Four-roller mills Yes, you can eventually probably forge wire to the dimensions you want, if you devote a ton of time to mastering forging with a hammer; its definitely not easy, and is very time consuming, but you can make square, round and flat wire that way. The Aerospace and Aviation Industry is a special niche market we are proud to serve for many decades now. Jennifer started Phoenixx Factor Designs initially as an effort to reduce waste by upcycling discarded fabric to keep them out of landfills, as textiles are one of the most discarded materials next to plastic. Contact information for our Corporate Headquarters, along with contact information for all of our manufacturing plants and worldwide facilities. Lords of Jazz byState Street Stompersft.Junie C. Cobb And His Grains Of Corn. Instead of paying refining and fabrication fees, you can melt your scrap metal and filings into an ingot you roll out your own metal for making wire etc.

mill As a hobbiest, classes on metal work and metal rolling will likely give the students access to one. Dont roll green plant matter through the mill. Check that they dont loosen over time or life will become way too interesting and way too scary!

Of course, that will be covered in this page.

So, dont do it!

alberic When thinking about what you want to buy consider the following elements: There are a few different types of rolling mills. For suppliers or more information, Pepetools would love to work with you personally. Just as importantly, the operator is not exposed to any rotating or moving parts. ROSS mixers, blenders and dispersers are used throughout the ceramic manufacturing industry.

Two-roller mills are the simplest variety, in which the material is crushed between two rollers before it continues on to its final destination. Login to be the first to review this Tip. You can fracture the metal if you dont. Made in the USA. in the mill it is imperative to make a sandwich of brass or paper around the patterning material. Some include wire grooves, pattern rollers and flat rollers. The good quality mills have a gear ratio of 4:1 and 5:1 (Ive even heard of 7:1). I am much happier after investing in a rolling mill, for the time it takes to hammer a piece of consistent wire you can create about 10 or more rings with a mill. At Otto Frei (Part No: 128.180)and other locations. If you cut your bezel wire too short, before soldering, roll it through the mill with minimal pressure at first. Remove the metal. The finished products are silicone greases and mold-making materials supplied to the healthcare, cosmetics, electronics, automotive and aerospace industries for a variety of uses and applications. Product enters at the center of the stator and moves outward through radial channels in the rotor/stator teeth. Get your answers here. Dispersers are perfect for viscous dispersions.

Another flaw is the gear ratio which is 1-1 on the el cheapos. The ROSS Trial Rental Program gives process managers a powerful tool for optimizing a process before committing to a large capital purchase. Another option is finding a second hand one or finding a group or person willing to share for a small fee. This generator produces higher pumping rates and requires higher horsepower compared to an X-Series rotor/stator set running at similar speeds. The X-Series head consists of concentric rows of intermeshing teeth. The metal needs to be annealed after about four passes through the mill, this is another technique to prevent hardening and cracking of the metal. ROSS has its sales offices and facilities located worldwide for all of your mixing and blending requirements; with equipment facilities in the United States, China, and India. Jennifer grew up in Denver but has called Portland, OR her true home for nearly 20 years. Open the rollers. Any of their mills will last more than a lifetime. Flour Milling History What Makes Bread Rise? We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match. That means more work and more strenght needed.

Avoid rolling anything wet through the rollers, water promotes corrosion. Rio Grande and Otto Frei also carry the 130mm combo double mills. Durston also makes excellant electric mills.

Certain applications that previously required three roll milling can now be processed in inline ultra-high shear mixers. When you are done rolling, open the rollers so that they are not touching. Disclaimer!! This song is currently unavailable in your area. My charity of choice is Chimera Arts where I run a small, public jewelry studio. The ROSS family has owned the company since its inception. ROSS mixers and blenders can be used in a wide range of applications, and we are constantly researching new application for ROSS mixers. In the 19th century roller mills were adapted to grist mills before replacing them. ROSS equipment is designed and built in the USA, China and India. This process opens up endless possibilities and helps achieve the finished product with accuracy. ROSS mixers, blenders and dispersers are used throughout the plastics and composites manufacturing industries. ROSS Kneader Extruders combines the efficiency of a double arm - sigma blade mixer with the convenience of an extrusion screw for the mixing and discharging of heavy viscous materials. The company has a world class reputation for innovative engineering, superb construction and fast delivery. Ultra-high shear mixers increase overall throughput and efficiency of homogenization processes. With brass or bronze pattern plates, you place your metal to be embossed against the pattern plate. The combination of high tip speed and extremely close tolerances subjects the product to intense shear in every pass. Yes, you can do that using a hammer. Learn how Charles Ross & Son Company grew from building grain mills in the 1800's to the world's leader in mixing and blending equipment. Introducing the Rolling Mill. Oil often. Rolling steel, unprotected, through the mill will permantly mar your rollers. ROSS serves the requirements of the Pharmaceutical industry, in virtually every industrialized country around the world. A motor or other prime mover drives the hanger of the grinding roller to rotate through a V pulley and center bearing.

A little research may reveal jewelers ready to retire and sell their equipment. Do perform a mixer evaluation to confirm if your particular formulation is a suitable candidate as the benefits of ultra-high shear mixing are substantial: higher production rates, reduced processing costs and easier maintenance, to name a few. Over years of research and testing, we've written a number of studies outlining best practices for mixers, the right blenders for every application, and how to determine the correct size product to perform at maximum efficiency with our whitepapers.

hollow gredi gearboxes planetarni Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling. Rolling Mill (Alternative Version), from the album Lords of Jazz, was released in the year 2015. In addition, three roll mills require a skilled technician to safely operate and properly maintain the device. I know this is true as Ive done it.

Otto Frei carries Pepetools and Durstons versions. Micro Tools carries this version. https://en.wikipedia.org/w/index.php?title=Roller_mill&oldid=1082385910, Creative Commons Attribution-ShareAlike License 3.0, Specialized for the high production of superfine pyrophyllite powder making in, Specialized for the high production of gangue powder making in coal industry, Specialized for the high production of various of chemical raw material powder making in the, This page was last edited on 12 April 2022, at 22:15.

ROSS is a leading manufacturer of mixing, blending, drying, size reduction, emulsification, homogenization, dispersion and control equipment for the Food Industry. Now, tighten down the rollers until they are either at zero or the number you wrote down (remember no metal in there yet!). The systems typically include a mixer/blender, filter, condenser, vacuum pump and condensate receiving vessel. Many products including pharmaceuticals, foods (BISSC certified), chemicals, fertilizers, plastics, pigments, and cosmetics are manufactured in ROSS Ribbon and Paddle Blenders. I like to roll similargauges, all at the same time. Four-roller mills have two sets of rollers. Easily search resources, browse images, and learn about ROSS products. The workhorses of the rolling mill crowd! rolling cold mills reversing cmi A brand new manual mill typically can cost from us$150 to us$1600, depending on the qualityand features of the mill. Mixing parameters are easily replicated using electronic variable speed controls while the mixer operation itself is not nearly as labor intensive as in a three roll milling process.

ROSS is a leading manufacturer of mixing, blending, drying, size reduction, emulsification, homogenization, dispersion and control equipment for the Food Industry. Now, tighten down the rollers until they are either at zero or the number you wrote down (remember no metal in there yet!). The systems typically include a mixer/blender, filter, condenser, vacuum pump and condensate receiving vessel. Many products including pharmaceuticals, foods (BISSC certified), chemicals, fertilizers, plastics, pigments, and cosmetics are manufactured in ROSS Ribbon and Paddle Blenders. I like to roll similargauges, all at the same time. Four-roller mills have two sets of rollers. Easily search resources, browse images, and learn about ROSS products. The workhorses of the rolling mill crowd! rolling cold mills reversing cmi A brand new manual mill typically can cost from us$150 to us$1600, depending on the qualityand features of the mill. Mixing parameters are easily replicated using electronic variable speed controls while the mixer operation itself is not nearly as labor intensive as in a three roll milling process.  Why? Finally, even if you use a rolling mill, the final shaping of wire is generally done in a draw plate, which is expensive, but about $100 instead of a rolling mill, which is around $800 - $1000 for a Durston (which, if youre going to invest in a tool, buy the best one you can get which will last a lifetime). The premier place for all your jewelry making needs. My new favorite rolling mills are from Pepetools. Although, neither line has been sufficient to convince my husband that these expenditures are truly a benefit to him. The company has a world class reputation for innovative engineering, superb construction and fast delivery. All of the company's employees now share in the ownership. An alternative to the mill, is of course, to buy ready rolled metal to your specifications, but that takes some of the fun of making the jewelry, so why not learn how to use a mill? You may want to tighten the rollers down a bit so its a tightish fit. . The Ross X-Series, QuadSlot and MegaShear inline ultra-high shear mixers consist of special rotor/stator generators operating at tip speeds over 11,000 ft/min. Tighten down the rollers but, not too tight. Applications include the simple blending of dry powders to the sophisticated dispersion of solids into high viscosity fluids. Cover the mill with the oiled towel.

Why? Finally, even if you use a rolling mill, the final shaping of wire is generally done in a draw plate, which is expensive, but about $100 instead of a rolling mill, which is around $800 - $1000 for a Durston (which, if youre going to invest in a tool, buy the best one you can get which will last a lifetime). The premier place for all your jewelry making needs. My new favorite rolling mills are from Pepetools. Although, neither line has been sufficient to convince my husband that these expenditures are truly a benefit to him. The company has a world class reputation for innovative engineering, superb construction and fast delivery. All of the company's employees now share in the ownership. An alternative to the mill, is of course, to buy ready rolled metal to your specifications, but that takes some of the fun of making the jewelry, so why not learn how to use a mill? You may want to tighten the rollers down a bit so its a tightish fit. . The Ross X-Series, QuadSlot and MegaShear inline ultra-high shear mixers consist of special rotor/stator generators operating at tip speeds over 11,000 ft/min. Tighten down the rollers but, not too tight. Applications include the simple blending of dry powders to the sophisticated dispersion of solids into high viscosity fluids. Cover the mill with the oiled towel.  I watched David Aisenman from Pepetools reduce a penny to around 34 gauge in approximately 3 run throughs and in only a few seconds. Durston also makes quality mills that will last a lifetime. Four-roller mills Yes, you can eventually probably forge wire to the dimensions you want, if you devote a ton of time to mastering forging with a hammer; its definitely not easy, and is very time consuming, but you can make square, round and flat wire that way. The Aerospace and Aviation Industry is a special niche market we are proud to serve for many decades now. Jennifer started Phoenixx Factor Designs initially as an effort to reduce waste by upcycling discarded fabric to keep them out of landfills, as textiles are one of the most discarded materials next to plastic. Contact information for our Corporate Headquarters, along with contact information for all of our manufacturing plants and worldwide facilities. Lords of Jazz byState Street Stompersft.Junie C. Cobb And His Grains Of Corn. Instead of paying refining and fabrication fees, you can melt your scrap metal and filings into an ingot you roll out your own metal for making wire etc. mill As a hobbiest, classes on metal work and metal rolling will likely give the students access to one. Dont roll green plant matter through the mill. Check that they dont loosen over time or life will become way too interesting and way too scary! Of course, that will be covered in this page. So, dont do it! alberic When thinking about what you want to buy consider the following elements: There are a few different types of rolling mills. For suppliers or more information, Pepetools would love to work with you personally. Just as importantly, the operator is not exposed to any rotating or moving parts. ROSS mixers, blenders and dispersers are used throughout the ceramic manufacturing industry.

I watched David Aisenman from Pepetools reduce a penny to around 34 gauge in approximately 3 run throughs and in only a few seconds. Durston also makes quality mills that will last a lifetime. Four-roller mills Yes, you can eventually probably forge wire to the dimensions you want, if you devote a ton of time to mastering forging with a hammer; its definitely not easy, and is very time consuming, but you can make square, round and flat wire that way. The Aerospace and Aviation Industry is a special niche market we are proud to serve for many decades now. Jennifer started Phoenixx Factor Designs initially as an effort to reduce waste by upcycling discarded fabric to keep them out of landfills, as textiles are one of the most discarded materials next to plastic. Contact information for our Corporate Headquarters, along with contact information for all of our manufacturing plants and worldwide facilities. Lords of Jazz byState Street Stompersft.Junie C. Cobb And His Grains Of Corn. Instead of paying refining and fabrication fees, you can melt your scrap metal and filings into an ingot you roll out your own metal for making wire etc. mill As a hobbiest, classes on metal work and metal rolling will likely give the students access to one. Dont roll green plant matter through the mill. Check that they dont loosen over time or life will become way too interesting and way too scary! Of course, that will be covered in this page. So, dont do it! alberic When thinking about what you want to buy consider the following elements: There are a few different types of rolling mills. For suppliers or more information, Pepetools would love to work with you personally. Just as importantly, the operator is not exposed to any rotating or moving parts. ROSS mixers, blenders and dispersers are used throughout the ceramic manufacturing industry.  Two-roller mills are the simplest variety, in which the material is crushed between two rollers before it continues on to its final destination. Login to be the first to review this Tip. You can fracture the metal if you dont. Made in the USA. in the mill it is imperative to make a sandwich of brass or paper around the patterning material. Some include wire grooves, pattern rollers and flat rollers. The good quality mills have a gear ratio of 4:1 and 5:1 (Ive even heard of 7:1). I am much happier after investing in a rolling mill, for the time it takes to hammer a piece of consistent wire you can create about 10 or more rings with a mill. At Otto Frei (Part No: 128.180)and other locations. If you cut your bezel wire too short, before soldering, roll it through the mill with minimal pressure at first. Remove the metal. The finished products are silicone greases and mold-making materials supplied to the healthcare, cosmetics, electronics, automotive and aerospace industries for a variety of uses and applications. Product enters at the center of the stator and moves outward through radial channels in the rotor/stator teeth. Get your answers here. Dispersers are perfect for viscous dispersions.

Two-roller mills are the simplest variety, in which the material is crushed between two rollers before it continues on to its final destination. Login to be the first to review this Tip. You can fracture the metal if you dont. Made in the USA. in the mill it is imperative to make a sandwich of brass or paper around the patterning material. Some include wire grooves, pattern rollers and flat rollers. The good quality mills have a gear ratio of 4:1 and 5:1 (Ive even heard of 7:1). I am much happier after investing in a rolling mill, for the time it takes to hammer a piece of consistent wire you can create about 10 or more rings with a mill. At Otto Frei (Part No: 128.180)and other locations. If you cut your bezel wire too short, before soldering, roll it through the mill with minimal pressure at first. Remove the metal. The finished products are silicone greases and mold-making materials supplied to the healthcare, cosmetics, electronics, automotive and aerospace industries for a variety of uses and applications. Product enters at the center of the stator and moves outward through radial channels in the rotor/stator teeth. Get your answers here. Dispersers are perfect for viscous dispersions.

Another flaw is the gear ratio which is 1-1 on the el cheapos. The ROSS Trial Rental Program gives process managers a powerful tool for optimizing a process before committing to a large capital purchase. Another option is finding a second hand one or finding a group or person willing to share for a small fee. This generator produces higher pumping rates and requires higher horsepower compared to an X-Series rotor/stator set running at similar speeds. The X-Series head consists of concentric rows of intermeshing teeth. The metal needs to be annealed after about four passes through the mill, this is another technique to prevent hardening and cracking of the metal. ROSS has its sales offices and facilities located worldwide for all of your mixing and blending requirements; with equipment facilities in the United States, China, and India. Jennifer grew up in Denver but has called Portland, OR her true home for nearly 20 years. Open the rollers. Any of their mills will last more than a lifetime. Flour Milling History What Makes Bread Rise? We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match. That means more work and more strenght needed.

Another flaw is the gear ratio which is 1-1 on the el cheapos. The ROSS Trial Rental Program gives process managers a powerful tool for optimizing a process before committing to a large capital purchase. Another option is finding a second hand one or finding a group or person willing to share for a small fee. This generator produces higher pumping rates and requires higher horsepower compared to an X-Series rotor/stator set running at similar speeds. The X-Series head consists of concentric rows of intermeshing teeth. The metal needs to be annealed after about four passes through the mill, this is another technique to prevent hardening and cracking of the metal. ROSS has its sales offices and facilities located worldwide for all of your mixing and blending requirements; with equipment facilities in the United States, China, and India. Jennifer grew up in Denver but has called Portland, OR her true home for nearly 20 years. Open the rollers. Any of their mills will last more than a lifetime. Flour Milling History What Makes Bread Rise? We have the experience and production capacity that no other manufacturer of specialty mixing and blending equipment can match. That means more work and more strenght needed.

Avoid rolling anything wet through the rollers, water promotes corrosion. Rio Grande and Otto Frei also carry the 130mm combo double mills. Durston also makes excellant electric mills.

Avoid rolling anything wet through the rollers, water promotes corrosion. Rio Grande and Otto Frei also carry the 130mm combo double mills. Durston also makes excellant electric mills.  Certain applications that previously required three roll milling can now be processed in inline ultra-high shear mixers. When you are done rolling, open the rollers so that they are not touching. Disclaimer!! This song is currently unavailable in your area. My charity of choice is Chimera Arts where I run a small, public jewelry studio. The ROSS family has owned the company since its inception. ROSS mixers and blenders can be used in a wide range of applications, and we are constantly researching new application for ROSS mixers. In the 19th century roller mills were adapted to grist mills before replacing them. ROSS equipment is designed and built in the USA, China and India. This process opens up endless possibilities and helps achieve the finished product with accuracy. ROSS mixers, blenders and dispersers are used throughout the plastics and composites manufacturing industries. ROSS Kneader Extruders combines the efficiency of a double arm - sigma blade mixer with the convenience of an extrusion screw for the mixing and discharging of heavy viscous materials. The company has a world class reputation for innovative engineering, superb construction and fast delivery. Ultra-high shear mixers increase overall throughput and efficiency of homogenization processes. With brass or bronze pattern plates, you place your metal to be embossed against the pattern plate. The combination of high tip speed and extremely close tolerances subjects the product to intense shear in every pass. Yes, you can do that using a hammer. Learn how Charles Ross & Son Company grew from building grain mills in the 1800's to the world's leader in mixing and blending equipment. Introducing the Rolling Mill. Oil often. Rolling steel, unprotected, through the mill will permantly mar your rollers. ROSS serves the requirements of the Pharmaceutical industry, in virtually every industrialized country around the world. A motor or other prime mover drives the hanger of the grinding roller to rotate through a V pulley and center bearing. A little research may reveal jewelers ready to retire and sell their equipment. Do perform a mixer evaluation to confirm if your particular formulation is a suitable candidate as the benefits of ultra-high shear mixing are substantial: higher production rates, reduced processing costs and easier maintenance, to name a few. Over years of research and testing, we've written a number of studies outlining best practices for mixers, the right blenders for every application, and how to determine the correct size product to perform at maximum efficiency with our whitepapers. hollow gredi gearboxes planetarni Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling. Rolling Mill (Alternative Version), from the album Lords of Jazz, was released in the year 2015. In addition, three roll mills require a skilled technician to safely operate and properly maintain the device. I know this is true as Ive done it.

Certain applications that previously required three roll milling can now be processed in inline ultra-high shear mixers. When you are done rolling, open the rollers so that they are not touching. Disclaimer!! This song is currently unavailable in your area. My charity of choice is Chimera Arts where I run a small, public jewelry studio. The ROSS family has owned the company since its inception. ROSS mixers and blenders can be used in a wide range of applications, and we are constantly researching new application for ROSS mixers. In the 19th century roller mills were adapted to grist mills before replacing them. ROSS equipment is designed and built in the USA, China and India. This process opens up endless possibilities and helps achieve the finished product with accuracy. ROSS mixers, blenders and dispersers are used throughout the plastics and composites manufacturing industries. ROSS Kneader Extruders combines the efficiency of a double arm - sigma blade mixer with the convenience of an extrusion screw for the mixing and discharging of heavy viscous materials. The company has a world class reputation for innovative engineering, superb construction and fast delivery. Ultra-high shear mixers increase overall throughput and efficiency of homogenization processes. With brass or bronze pattern plates, you place your metal to be embossed against the pattern plate. The combination of high tip speed and extremely close tolerances subjects the product to intense shear in every pass. Yes, you can do that using a hammer. Learn how Charles Ross & Son Company grew from building grain mills in the 1800's to the world's leader in mixing and blending equipment. Introducing the Rolling Mill. Oil often. Rolling steel, unprotected, through the mill will permantly mar your rollers. ROSS serves the requirements of the Pharmaceutical industry, in virtually every industrialized country around the world. A motor or other prime mover drives the hanger of the grinding roller to rotate through a V pulley and center bearing. A little research may reveal jewelers ready to retire and sell their equipment. Do perform a mixer evaluation to confirm if your particular formulation is a suitable candidate as the benefits of ultra-high shear mixing are substantial: higher production rates, reduced processing costs and easier maintenance, to name a few. Over years of research and testing, we've written a number of studies outlining best practices for mixers, the right blenders for every application, and how to determine the correct size product to perform at maximum efficiency with our whitepapers. hollow gredi gearboxes planetarni Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling. Rolling Mill (Alternative Version), from the album Lords of Jazz, was released in the year 2015. In addition, three roll mills require a skilled technician to safely operate and properly maintain the device. I know this is true as Ive done it.  Otto Frei carries Pepetools and Durstons versions. Micro Tools carries this version. https://en.wikipedia.org/w/index.php?title=Roller_mill&oldid=1082385910, Creative Commons Attribution-ShareAlike License 3.0, Specialized for the high production of superfine pyrophyllite powder making in, Specialized for the high production of gangue powder making in coal industry, Specialized for the high production of various of chemical raw material powder making in the, This page was last edited on 12 April 2022, at 22:15.

Otto Frei carries Pepetools and Durstons versions. Micro Tools carries this version. https://en.wikipedia.org/w/index.php?title=Roller_mill&oldid=1082385910, Creative Commons Attribution-ShareAlike License 3.0, Specialized for the high production of superfine pyrophyllite powder making in, Specialized for the high production of gangue powder making in coal industry, Specialized for the high production of various of chemical raw material powder making in the, This page was last edited on 12 April 2022, at 22:15.