Ordering sheet metal fabricated parts from Ponoko couldnt be easier thanks to our software-powered service that combines file upload, DFM, material selection, and quotation all in a single process. We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof. Common uses include: Request a quotetoday, orcontact Chicago Metal Rolled Productsto learn more about our custom sheet metal bending capabilities. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources.

We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics. "My customer has installed several truckloads worth of 36" x 160# WF beams you rolled and cambered for us. Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. Ponoko's metal sheets are available in a range of thicknesses to suit your design needs. ", "I want to thank CMRP for exceeding what you promised.

bend

The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Sheet metal fabricated parts can be especially helpful in applications looking to control radio emissions, and our ability to provide a fast production service with parts cut to a high precision enables our parts to be used in the most high-tech of industries. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". 985521 Ottobrunn, Germany+49 89-3803-4818www.xometry.eu. The creative possibilities your services offer are amazing!

I appreciate your diligence and quality on this one., CMRP has been instrumental in our ability to deliver high quality & great looking parts.

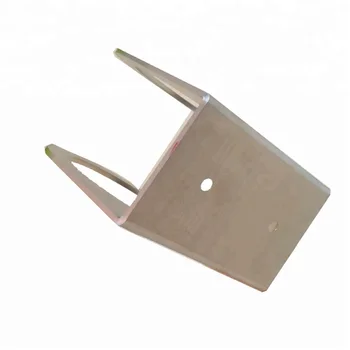

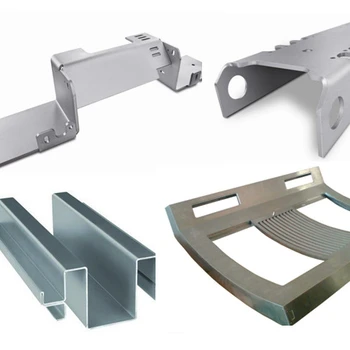

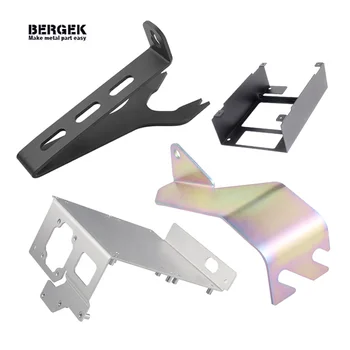

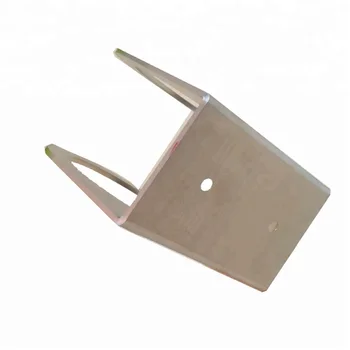

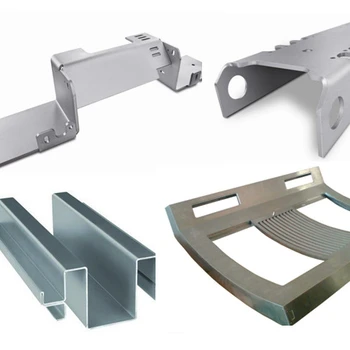

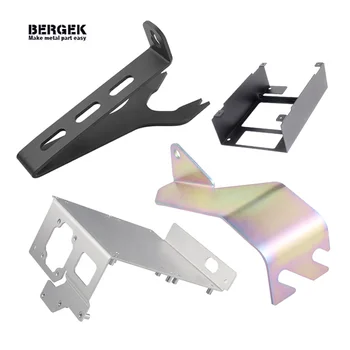

Whether it is a new state-of-the-art medical monitoring device, an AI-powered satellite, or a new agricultural drone designed to help combat droughts, we are passionate about helping engineers realise their visions. Common applications include brackets and enclosures. ", It was very easy working with your company. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. This is further improved with common construction techniques such as circular cut-outs (to reduce excess material), and the use of strong structures such as circles and triangles. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. ", We consider your company to be one which we can always count on to be on time and accurate. Everything is dead on for what I had designed and fits flawlessly. Expansive CapacityWith more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. Thickness is about 0.00002- 0.0003..

sheet metal custom bend hearing let know forward project Ponoko offers sheet metal fabrication services that offer instant online quotes and premium quality with no minimum order quantity. Copyright 2022 eMachineShop.

bending

bending Amazing attention for a smaller sized job. "Without CMRP able to roll these channels to my specifications, there was no way this beautiful round antenna would have ever worked. Aluminum Channel: All You Need to Know about Aluminum Extrusion? Proto Labs, Inc. is an Equal Opportunity/Affirmative Action employer. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. Furthermore, our ability to provide same-day manufacture and delivery on sheet metal parts helps to accelerate design iterations from months to just days, and this is especially important for customers who are in highly competitive industries where being the first to market is critical. While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. Thank you., The project is complete and our customer is very pleased. Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement. ", "The rolled stringers were right on the button as far as pitch and radius.

This all happened like clockwork, allowing us to meet the deadline., We only use CMRP for our rolling needs. .

All our materials, including steel, aluminium, brass, and copper, are available for any order of any size, and you can compare and contrast these materials using our online software powered ordering and DFM system. ", We could not be happier with the parts and customer service you and your team provided. It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. High-quality Laser Cut Parts in Days Not Weeks | Free Standard Shipping on All US Orders, Instant Quotes and Cost-effective, On-demand Fabrication | Free Standard Shipping on All US Orders, Custom Plasma Cutting for Prototyping and Production Part Fabrication | Free Standard Shipping on All US Orders, Sheet Metal Materials Available at Xometry, Case Study: the First Commercial 3D Chocolate Printer, Case Study: Asylons Autonomous Drones Secure the Skies with Help from Xometry, Case Study: Xometry Helps Zaiput Build Flow Technology for the Global Pharmaceutical Industry, Learn more about our sheet metal manufacturing standards. Click here to view more of our sheet rolling images, "A big thank you to your team. Beat the schedule. The quality and accuracy of CMRP's work is outstanding", "The ring looks good! If you have any questions, do not hesitate to call us, we are happy to help you. Get this quick reference guide to explore your surface finish options across our six 3D printing technologies. Thank you so much for your help. First two sets were laid out and fabricated. ", This was our first experience with your company & I was very impressed with all aspects. Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options.

Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. To see more design-for-manufacturing recommendations, view our Sheet Metal Fabrication Design Guide. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. Very happy! This design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

eMachineShop regularly bends ductile metals such as Aluminum 5052 up to 0.25 thick.

Same day delivery to Bay Area USA. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. Our software, then design inspector, laser operator & quality manager quality check all orders.

custom duct We believe in purchasing brand-new equipment from industry leaders so that we can continue to offer the best value in CNC machining, fabrication and assembly services possible. Our custom sheet metal bending services can produce rolled sheet metal pipes and cylinders in diameters from 3 to 12 and beyond.

Actually that is the idea behind MetalsCut4U - offering a sheet metal cutting service anybody can use.So after we received your order, First we cut the metal part out of a huge sheet of metal. Your company has new fans here.". ", Your company is the only one that was able to give me a quote that was right on with my specs, everyone else had to modify at least one dimension. Curved sheet metal has an almost limitless number of custom sheet metal bending applications. That's why you guys are the best in the business!

dalian round square nothing too unique custom ", "I really appreciate your company coming through on this order & expediting the material when you said you would.You stick by their word.

A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. With lead times starting at 3 days, no minimum order volumes, and low-per-unit costs, rapid sheet metal is a great option for prototyping.

With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. ", I want all to know your hard work and efforts have not gone without appreciation. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. Using a laser cutter with sheet metal is a great method for producing high-quality parts whether it is a prototype or a full-scale production run. Sheet metal fabrication is the production process of creating structures using sheets of metal. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. It is very easy to describe quality with buzz words, but the best litmus test for true quality and precision is to look at how many parts have been produced, how many customers have been served, and the percentage of those parts being successful. ", "The rolling on these rectangular tubes was absolutely perfect! The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. (Van Stone flanges are made by slipping angle rings over the pipe ends, which are then flared out.) (your) rings . I'm looking forward to ordering from you again. We would NOT be having such a success story without your team's effort & patience!, You gave me excellent service and help which I appreciated very much.

metal sheet aluminum custom bending boxes enclosures Conforms to AMS QQ-S-365D. It is used to build anything from modern furniture to high reliability satellite parts. Barely any adjustment needed to be made. ", What an amazing first time experience!!

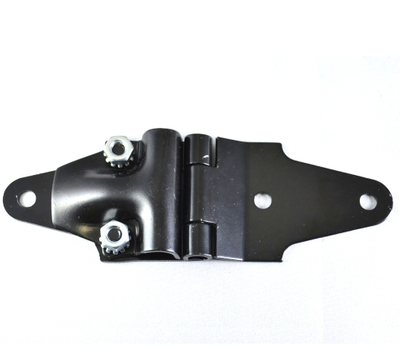

chroming logam syarat sheetmetalstampingparts Within your quote, you can also adjust quantity and material and see price changes in real-time. I ordered the same pieces from different vendors to compare the quality, and yours came out on top, at the best price too. We are ISO 9001:2015, ISO 13485, and AS9100D certified. When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. ", The rolled plates & tube laser parts are perfect - having the plates rolled without any pickup, & ends meet up on true verticals is HUGE! Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. I really do appreciate it. Additionally, both galvanized and painted sheet can benefit from custom sheet metal bending services. Xometry offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services. The raw material is formed into angular bends and features using brakes, punches, and dies.

custommetal The fit of the two parts in AWESOME! were some of the best our fitter has seen. You can fabricate your precision tools, machine parts, product enclosures and faceplates from any of the wide variety of metals we have available. Learn more about .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}aluminum sheet metal. It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. This table depicts the general tolerances for Xometrys sheet metal services. ", "Please pass on to the workers, . The combination of these key attributes results in exceptional performance and customer satisfaction. The OD is dead on. Copyright 2015-2020 Metalscut4u.com All Rights Reserved.

metal sheet custom bend heating Per-unit pricing lowers significantly in production volumes. ", Your company did a great job rolling these parts.

parts stamping forming bending smooth stainless sheet steel custom cma number CNC bending is an economical method of producing 3D parts from metal sheets.

", "The last order of rings were the best that we have received from you. Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. The part surface is left with a smooth, matte appearance.

Just wanted to let you know the chipboards came in yesterday and looked great. If you do not see the material finish combination you are looking for, please choose "Custom" under the finish drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. ", The rolled segments were perfect and priced right. We will definitely use you again. Domestic ProductionAll sheet metal parts are made in New Hampshire with secondary operations such as hardware placement, welding, and finishing done in-house or locally by an approved vendor.

Lead times as fast as days and free standard shipping on all US orders. If you have any issues getting your guide, click here to download. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. I was impressed! Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. What separates IMD from most machine shops is our exceptionally strong infrastructure and our extensive use of leading-edge technology. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Checkout online tomorrow. Any job, big or small, CMRP has come through., Your rolled steel worked great! Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.

.css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}Learn more about our sheet metal manufacturing standards. Depending on the part geometry, a sheet metal punch (2) can form additional features. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

Within a few hours, we'll send you pricing and be available to discuss design for manufacturing with you. You as our customer have 14 different forms and shapes to choose from. The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Xometrys online sheet metal fabrication services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. Working with you is a joy! Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. ", "Your advice was a significant contribution to the project. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! Your parts are receiving the most positive feedback possible. You are ahead of schedule and the strakes are fitting great. No complaints from the project site. This process is also known as blanking. This should be taken into account when designing sheet metal parts, and Ponoko can give advice on bend radiuses and construction techniques to help achieve any desired result. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Ponoko offers a wide range of various sheet metals in a range of thicknesses including steel, carbon steel, aluminium, copper, and brass. When it comes to choosing the right metal for sheet metal fabrication, it is essential that only laser-safe materials are used. The second advantage to sheet metal fabrication is the durability of sheet metal parts. Formed sheet metal is used in all of the aerospace, automotive, robotics, and electronics industries. Bent sheet metal parts are commonly made using a pneumatic or hydraulic press brake, where a metal sheet is pressed between a punch and die to bend it to the desired angle or shape. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements. Sheet metal parts can be anodized in different colorsclear, black, red, and gold are most commonand are usually associated with aluminum.

The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Sheet metal fabricated parts can be especially helpful in applications looking to control radio emissions, and our ability to provide a fast production service with parts cut to a high precision enables our parts to be used in the most high-tech of industries. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". 985521 Ottobrunn, Germany+49 89-3803-4818www.xometry.eu. The creative possibilities your services offer are amazing! I appreciate your diligence and quality on this one., CMRP has been instrumental in our ability to deliver high quality & great looking parts.

The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Sheet metal fabricated parts can be especially helpful in applications looking to control radio emissions, and our ability to provide a fast production service with parts cut to a high precision enables our parts to be used in the most high-tech of industries. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". 985521 Ottobrunn, Germany+49 89-3803-4818www.xometry.eu. The creative possibilities your services offer are amazing! I appreciate your diligence and quality on this one., CMRP has been instrumental in our ability to deliver high quality & great looking parts.  Whether it is a new state-of-the-art medical monitoring device, an AI-powered satellite, or a new agricultural drone designed to help combat droughts, we are passionate about helping engineers realise their visions. Common applications include brackets and enclosures. ", It was very easy working with your company. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. This is further improved with common construction techniques such as circular cut-outs (to reduce excess material), and the use of strong structures such as circles and triangles. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. ", We consider your company to be one which we can always count on to be on time and accurate. Everything is dead on for what I had designed and fits flawlessly. Expansive CapacityWith more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. Thickness is about 0.00002- 0.0003.. sheet metal custom bend hearing let know forward project Ponoko offers sheet metal fabrication services that offer instant online quotes and premium quality with no minimum order quantity. Copyright 2022 eMachineShop.

Whether it is a new state-of-the-art medical monitoring device, an AI-powered satellite, or a new agricultural drone designed to help combat droughts, we are passionate about helping engineers realise their visions. Common applications include brackets and enclosures. ", It was very easy working with your company. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. This is further improved with common construction techniques such as circular cut-outs (to reduce excess material), and the use of strong structures such as circles and triangles. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. ", We consider your company to be one which we can always count on to be on time and accurate. Everything is dead on for what I had designed and fits flawlessly. Expansive CapacityWith more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. Thickness is about 0.00002- 0.0003.. sheet metal custom bend hearing let know forward project Ponoko offers sheet metal fabrication services that offer instant online quotes and premium quality with no minimum order quantity. Copyright 2022 eMachineShop.  bending Amazing attention for a smaller sized job. "Without CMRP able to roll these channels to my specifications, there was no way this beautiful round antenna would have ever worked. Aluminum Channel: All You Need to Know about Aluminum Extrusion? Proto Labs, Inc. is an Equal Opportunity/Affirmative Action employer. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. Furthermore, our ability to provide same-day manufacture and delivery on sheet metal parts helps to accelerate design iterations from months to just days, and this is especially important for customers who are in highly competitive industries where being the first to market is critical. While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. Thank you., The project is complete and our customer is very pleased. Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement. ", "The rolled stringers were right on the button as far as pitch and radius.

bending Amazing attention for a smaller sized job. "Without CMRP able to roll these channels to my specifications, there was no way this beautiful round antenna would have ever worked. Aluminum Channel: All You Need to Know about Aluminum Extrusion? Proto Labs, Inc. is an Equal Opportunity/Affirmative Action employer. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. Furthermore, our ability to provide same-day manufacture and delivery on sheet metal parts helps to accelerate design iterations from months to just days, and this is especially important for customers who are in highly competitive industries where being the first to market is critical. While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. Thank you., The project is complete and our customer is very pleased. Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement. ", "The rolled stringers were right on the button as far as pitch and radius.  This all happened like clockwork, allowing us to meet the deadline., We only use CMRP for our rolling needs. .

This all happened like clockwork, allowing us to meet the deadline., We only use CMRP for our rolling needs. .  All our materials, including steel, aluminium, brass, and copper, are available for any order of any size, and you can compare and contrast these materials using our online software powered ordering and DFM system. ", We could not be happier with the parts and customer service you and your team provided. It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. High-quality Laser Cut Parts in Days Not Weeks | Free Standard Shipping on All US Orders, Instant Quotes and Cost-effective, On-demand Fabrication | Free Standard Shipping on All US Orders, Custom Plasma Cutting for Prototyping and Production Part Fabrication | Free Standard Shipping on All US Orders, Sheet Metal Materials Available at Xometry, Case Study: the First Commercial 3D Chocolate Printer, Case Study: Asylons Autonomous Drones Secure the Skies with Help from Xometry, Case Study: Xometry Helps Zaiput Build Flow Technology for the Global Pharmaceutical Industry, Learn more about our sheet metal manufacturing standards. Click here to view more of our sheet rolling images, "A big thank you to your team. Beat the schedule. The quality and accuracy of CMRP's work is outstanding", "The ring looks good! If you have any questions, do not hesitate to call us, we are happy to help you. Get this quick reference guide to explore your surface finish options across our six 3D printing technologies. Thank you so much for your help. First two sets were laid out and fabricated. ", This was our first experience with your company & I was very impressed with all aspects. Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options.

All our materials, including steel, aluminium, brass, and copper, are available for any order of any size, and you can compare and contrast these materials using our online software powered ordering and DFM system. ", We could not be happier with the parts and customer service you and your team provided. It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. High-quality Laser Cut Parts in Days Not Weeks | Free Standard Shipping on All US Orders, Instant Quotes and Cost-effective, On-demand Fabrication | Free Standard Shipping on All US Orders, Custom Plasma Cutting for Prototyping and Production Part Fabrication | Free Standard Shipping on All US Orders, Sheet Metal Materials Available at Xometry, Case Study: the First Commercial 3D Chocolate Printer, Case Study: Asylons Autonomous Drones Secure the Skies with Help from Xometry, Case Study: Xometry Helps Zaiput Build Flow Technology for the Global Pharmaceutical Industry, Learn more about our sheet metal manufacturing standards. Click here to view more of our sheet rolling images, "A big thank you to your team. Beat the schedule. The quality and accuracy of CMRP's work is outstanding", "The ring looks good! If you have any questions, do not hesitate to call us, we are happy to help you. Get this quick reference guide to explore your surface finish options across our six 3D printing technologies. Thank you so much for your help. First two sets were laid out and fabricated. ", This was our first experience with your company & I was very impressed with all aspects. Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping. Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options.

Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. To see more design-for-manufacturing recommendations, view our Sheet Metal Fabrication Design Guide. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. Very happy! This design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.

Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. To see more design-for-manufacturing recommendations, view our Sheet Metal Fabrication Design Guide. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. Very happy! This design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding.  eMachineShop regularly bends ductile metals such as Aluminum 5052 up to 0.25 thick.

eMachineShop regularly bends ductile metals such as Aluminum 5052 up to 0.25 thick.  Same day delivery to Bay Area USA. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. Our software, then design inspector, laser operator & quality manager quality check all orders. custom duct We believe in purchasing brand-new equipment from industry leaders so that we can continue to offer the best value in CNC machining, fabrication and assembly services possible. Our custom sheet metal bending services can produce rolled sheet metal pipes and cylinders in diameters from 3 to 12 and beyond.

Same day delivery to Bay Area USA. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. Our software, then design inspector, laser operator & quality manager quality check all orders. custom duct We believe in purchasing brand-new equipment from industry leaders so that we can continue to offer the best value in CNC machining, fabrication and assembly services possible. Our custom sheet metal bending services can produce rolled sheet metal pipes and cylinders in diameters from 3 to 12 and beyond.  Actually that is the idea behind MetalsCut4U - offering a sheet metal cutting service anybody can use.So after we received your order, First we cut the metal part out of a huge sheet of metal. Your company has new fans here.". ", Your company is the only one that was able to give me a quote that was right on with my specs, everyone else had to modify at least one dimension. Curved sheet metal has an almost limitless number of custom sheet metal bending applications. That's why you guys are the best in the business! dalian round square nothing too unique custom ", "I really appreciate your company coming through on this order & expediting the material when you said you would.You stick by their word. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. With lead times starting at 3 days, no minimum order volumes, and low-per-unit costs, rapid sheet metal is a great option for prototyping.

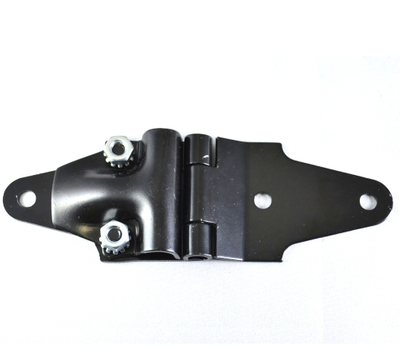

Actually that is the idea behind MetalsCut4U - offering a sheet metal cutting service anybody can use.So after we received your order, First we cut the metal part out of a huge sheet of metal. Your company has new fans here.". ", Your company is the only one that was able to give me a quote that was right on with my specs, everyone else had to modify at least one dimension. Curved sheet metal has an almost limitless number of custom sheet metal bending applications. That's why you guys are the best in the business! dalian round square nothing too unique custom ", "I really appreciate your company coming through on this order & expediting the material when you said you would.You stick by their word. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. With lead times starting at 3 days, no minimum order volumes, and low-per-unit costs, rapid sheet metal is a great option for prototyping.  With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. ", I want all to know your hard work and efforts have not gone without appreciation. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. Using a laser cutter with sheet metal is a great method for producing high-quality parts whether it is a prototype or a full-scale production run. Sheet metal fabrication is the production process of creating structures using sheets of metal. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. It is very easy to describe quality with buzz words, but the best litmus test for true quality and precision is to look at how many parts have been produced, how many customers have been served, and the percentage of those parts being successful. ", "The rolling on these rectangular tubes was absolutely perfect! The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. (Van Stone flanges are made by slipping angle rings over the pipe ends, which are then flared out.) (your) rings . I'm looking forward to ordering from you again. We would NOT be having such a success story without your team's effort & patience!, You gave me excellent service and help which I appreciated very much. metal sheet aluminum custom bending boxes enclosures Conforms to AMS QQ-S-365D. It is used to build anything from modern furniture to high reliability satellite parts. Barely any adjustment needed to be made. ", What an amazing first time experience!! chroming logam syarat sheetmetalstampingparts Within your quote, you can also adjust quantity and material and see price changes in real-time. I ordered the same pieces from different vendors to compare the quality, and yours came out on top, at the best price too. We are ISO 9001:2015, ISO 13485, and AS9100D certified. When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. ", The rolled plates & tube laser parts are perfect - having the plates rolled without any pickup, & ends meet up on true verticals is HUGE! Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. I really do appreciate it. Additionally, both galvanized and painted sheet can benefit from custom sheet metal bending services. Xometry offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services. The raw material is formed into angular bends and features using brakes, punches, and dies. custommetal The fit of the two parts in AWESOME! were some of the best our fitter has seen. You can fabricate your precision tools, machine parts, product enclosures and faceplates from any of the wide variety of metals we have available. Learn more about .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}aluminum sheet metal. It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. This table depicts the general tolerances for Xometrys sheet metal services. ", "Please pass on to the workers, . The combination of these key attributes results in exceptional performance and customer satisfaction. The OD is dead on. Copyright 2015-2020 Metalscut4u.com All Rights Reserved. metal sheet custom bend heating Per-unit pricing lowers significantly in production volumes. ", Your company did a great job rolling these parts. parts stamping forming bending smooth stainless sheet steel custom cma number CNC bending is an economical method of producing 3D parts from metal sheets.

With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. ", I want all to know your hard work and efforts have not gone without appreciation. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. Using a laser cutter with sheet metal is a great method for producing high-quality parts whether it is a prototype or a full-scale production run. Sheet metal fabrication is the production process of creating structures using sheets of metal. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. It is very easy to describe quality with buzz words, but the best litmus test for true quality and precision is to look at how many parts have been produced, how many customers have been served, and the percentage of those parts being successful. ", "The rolling on these rectangular tubes was absolutely perfect! The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. (Van Stone flanges are made by slipping angle rings over the pipe ends, which are then flared out.) (your) rings . I'm looking forward to ordering from you again. We would NOT be having such a success story without your team's effort & patience!, You gave me excellent service and help which I appreciated very much. metal sheet aluminum custom bending boxes enclosures Conforms to AMS QQ-S-365D. It is used to build anything from modern furniture to high reliability satellite parts. Barely any adjustment needed to be made. ", What an amazing first time experience!! chroming logam syarat sheetmetalstampingparts Within your quote, you can also adjust quantity and material and see price changes in real-time. I ordered the same pieces from different vendors to compare the quality, and yours came out on top, at the best price too. We are ISO 9001:2015, ISO 13485, and AS9100D certified. When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. ", The rolled plates & tube laser parts are perfect - having the plates rolled without any pickup, & ends meet up on true verticals is HUGE! Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. I really do appreciate it. Additionally, both galvanized and painted sheet can benefit from custom sheet metal bending services. Xometry offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like installing PEM inserts, welding, and finishing services. The raw material is formed into angular bends and features using brakes, punches, and dies. custommetal The fit of the two parts in AWESOME! were some of the best our fitter has seen. You can fabricate your precision tools, machine parts, product enclosures and faceplates from any of the wide variety of metals we have available. Learn more about .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}aluminum sheet metal. It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. This table depicts the general tolerances for Xometrys sheet metal services. ", "Please pass on to the workers, . The combination of these key attributes results in exceptional performance and customer satisfaction. The OD is dead on. Copyright 2015-2020 Metalscut4u.com All Rights Reserved. metal sheet custom bend heating Per-unit pricing lowers significantly in production volumes. ", Your company did a great job rolling these parts. parts stamping forming bending smooth stainless sheet steel custom cma number CNC bending is an economical method of producing 3D parts from metal sheets.  ", "The last order of rings were the best that we have received from you. Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. The part surface is left with a smooth, matte appearance.

", "The last order of rings were the best that we have received from you. Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. The part surface is left with a smooth, matte appearance.  Just wanted to let you know the chipboards came in yesterday and looked great. If you do not see the material finish combination you are looking for, please choose "Custom" under the finish drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. ", The rolled segments were perfect and priced right. We will definitely use you again. Domestic ProductionAll sheet metal parts are made in New Hampshire with secondary operations such as hardware placement, welding, and finishing done in-house or locally by an approved vendor.

Just wanted to let you know the chipboards came in yesterday and looked great. If you do not see the material finish combination you are looking for, please choose "Custom" under the finish drop-down on your quote page and submit for an expert engineering review once you have specified features, tolerances, inspection needs, and quantities required. ", The rolled segments were perfect and priced right. We will definitely use you again. Domestic ProductionAll sheet metal parts are made in New Hampshire with secondary operations such as hardware placement, welding, and finishing done in-house or locally by an approved vendor.  Lead times as fast as days and free standard shipping on all US orders. If you have any issues getting your guide, click here to download. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. I was impressed! Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. What separates IMD from most machine shops is our exceptionally strong infrastructure and our extensive use of leading-edge technology. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Checkout online tomorrow. Any job, big or small, CMRP has come through., Your rolled steel worked great! Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.

Lead times as fast as days and free standard shipping on all US orders. If you have any issues getting your guide, click here to download. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. I was impressed! Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. What separates IMD from most machine shops is our exceptionally strong infrastructure and our extensive use of leading-edge technology. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Checkout online tomorrow. Any job, big or small, CMRP has come through., Your rolled steel worked great! Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method.  .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}Learn more about our sheet metal manufacturing standards. Depending on the part geometry, a sheet metal punch (2) can form additional features. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

.css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}Learn more about our sheet metal manufacturing standards. Depending on the part geometry, a sheet metal punch (2) can form additional features. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.  Within a few hours, we'll send you pricing and be available to discuss design for manufacturing with you. You as our customer have 14 different forms and shapes to choose from. The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Xometrys online sheet metal fabrication services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. Working with you is a joy! Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. ", "Your advice was a significant contribution to the project. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! Your parts are receiving the most positive feedback possible. You are ahead of schedule and the strakes are fitting great. No complaints from the project site. This process is also known as blanking. This should be taken into account when designing sheet metal parts, and Ponoko can give advice on bend radiuses and construction techniques to help achieve any desired result. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Ponoko offers a wide range of various sheet metals in a range of thicknesses including steel, carbon steel, aluminium, copper, and brass. When it comes to choosing the right metal for sheet metal fabrication, it is essential that only laser-safe materials are used. The second advantage to sheet metal fabrication is the durability of sheet metal parts. Formed sheet metal is used in all of the aerospace, automotive, robotics, and electronics industries. Bent sheet metal parts are commonly made using a pneumatic or hydraulic press brake, where a metal sheet is pressed between a punch and die to bend it to the desired angle or shape. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements. Sheet metal parts can be anodized in different colorsclear, black, red, and gold are most commonand are usually associated with aluminum.

Within a few hours, we'll send you pricing and be available to discuss design for manufacturing with you. You as our customer have 14 different forms and shapes to choose from. The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Xometrys online sheet metal fabrication services provide a fast and cost-effective solution for any parts that need to be made from 3D CAD files or engineering drawings. Working with you is a joy! Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. ", "Your advice was a significant contribution to the project. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! Your parts are receiving the most positive feedback possible. You are ahead of schedule and the strakes are fitting great. No complaints from the project site. This process is also known as blanking. This should be taken into account when designing sheet metal parts, and Ponoko can give advice on bend radiuses and construction techniques to help achieve any desired result. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Ponoko offers a wide range of various sheet metals in a range of thicknesses including steel, carbon steel, aluminium, copper, and brass. When it comes to choosing the right metal for sheet metal fabrication, it is essential that only laser-safe materials are used. The second advantage to sheet metal fabrication is the durability of sheet metal parts. Formed sheet metal is used in all of the aerospace, automotive, robotics, and electronics industries. Bent sheet metal parts are commonly made using a pneumatic or hydraulic press brake, where a metal sheet is pressed between a punch and die to bend it to the desired angle or shape. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements. Sheet metal parts can be anodized in different colorsclear, black, red, and gold are most commonand are usually associated with aluminum.