10961 Berlin

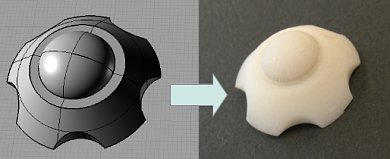

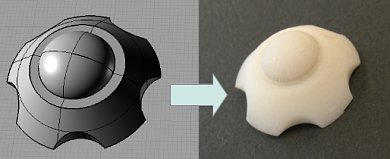

Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. Rapid prototyping means that you can quickly get a physical product in your hand, which is far better and easier to analyze than a CAD design on a computer screen. Rapid prototyping and 3D printing work together hand-in-hand for better and faster engineering. 50-E Concord Street See how 3D printed rapid prototypes are changing the way the world does business. Rapid prototyping with affordable in-house desktop 3D printersempowers you to create prototypes within a day and carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster. Use the Form 3 at various points of the product development process for a faster ROI. PolyJet is used across the automotive and aerospace industries, as well as in consumer goods and electronics, with niche applications in the medical industry creating very accurate, multi-material or color parts.

For functional testing, 3D printing cannot compete with solid CNC machined parts.

Complex geometries are possible, and SLS parts are far more resistant to wear-and-tear than SLA prototypes and therefore better suited to functional prototype testing. See our printers in action and learn about our technology. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design. With the ability to evaluate and improve prototypes repeatedly until youre completely satisfied, rapid prototyping lowers the chance of errors in the part before starting an expensive production run. ATNOM is one of the leading research and development centers for renewable solutions in Romania, such as high-performance lithium batteries for industrial and automotive applications, has recently acquired the industrial 3D printer BigRep PRO.

Large-scale 3D printing can bring these large-scale designs to life, allowing for a full iteration to be made and tested in less than the time it would take for a traditional tool to be made. Copyright 2022 3D Systems, Inc. All rights reserved. With an arsenal of additive manufacturing preparation. If not, tweaks can be made based on the findings to create the next iteration, and the next prototype can be quickly 3D printed. MJF prototyping is used to create durable jigs / fixtures, brackets, vessels within the oil and gas industry, fan housings and vents, electric component housings, mechanical assemblies, and enclosures. Cookie required to allow a user to stay logged in to a web site without needing to submit their username and password for each page visited. Refine. Make changes to the CAD file based on the feedback and tweak everything in preparation for 3D printing the next iteration overnight again. The definition of rapid prototyping is using CAD programs and a machine like a 3D printer or CNC mill to quickly produce prototypes, test them for shape or function, and tweak or iterate based on the feedback, so you can then print the next prototype and test it. Some FDM printers are dual extruder 3D printers, meaning they can print two different materials or colors of filament simultaneously, opening up a range of new design and prototyping options. Grow your business through volume production with consistent end-use functional parts. For example, if you needed a part featuring both flexible and rigid materials in separate areas, PolyJet would be the best rapid prototyping method for you. From showcasing the industrial value of 3D printing to highlighting successful use cases, BigReps webinars explore the most interesting aspects of 3D printing opportunities and possibilities. significantly decrease cost of ownership of your 3D printers by reducing the need for costly software seats by third party vendors. This increased frequency of iterations means that the designers have time and opportunity to improve the designs while still delivering within or before deadline. Test.

This fast turn-around enables companies to significantly improve product time-to-market as well as deliver a superior product within that shortened time. BigRep GmbH (HQ Europe)

This shortens wait times, as feedback can translate immediately to an updated design file that can in turn be 3D printed as quickly as just a few hours. The prototype is tested for shape, color and aesthetics if a cosmetic model, or testing function such as the prototypes heat or impact resistance. Competitive positioning requires that development and introduction be quick, especially in the consumer market. The time it takes an idea to move from concept to deliverable should be as short as possible. This cookie is strictly necessary for Cloudflare's security features and cannot be turned off. Designed to protect industrial workflows by preventing material degradation that leads to lost time and damages, the BigRep SHIELD secures filament in ideal conditions for both short and long-term storage. This uses up additional materials and requires more cleaning up afterwards. On the other hand, CNC milling is subtractive, removing excess material until you reach a final design. Produce tough, durable parts from a range of production-grade nylon materials that have been optimized, validated and tested to ensure quality, with isotropic 3D mechanical properties. Those are session cookies. When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Wilmington, MA 01887 How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. Rapid prototyping with 3D printing is the quick, easy, cost effective way to turn great ideas into successful products. Attention must be paid to detail, to how the final part will be manufactured (especially if this will be done in a different process than the prototype; for example, 3D printing a prototype for a part that will ultimately be injection molded) as well as how the final part will be post-processed/finished. There is no single best 3D printer, this all depends on the materials, size of prototype and a variety of other factors. Furniture maker Steelcase experienced this benefit first-hand as they use their large-format BigRep 3D printer to create new furniture designs: A functional prototype does just that: it functions. BigRep Private Ltd. Starting with conceptual mockups and building toward a functional prototype, each successive prototype is a step toward a fully engineered final design. Rapid prototyping can ease your entire engineering process in a big way with large-format 3D printing. Before you can 3D print your final prototype, you need a design. Whereas evolution takes tens of thousands of years, the same principles could be augmented using cutting edge technologies and new iterations can be produced every hour now with 3D printing. Multiple materials and over 360k available colors come together to create the most realistic models and prototypes possible. With a high precision 3D printing process, the parts produced will reflect the CAD data provided, resulting in high-quality prototypes for thorough fit and function testing. Unilever had both efficiency problems and quality issues. No supports are required for SLS 3D printing prototyping as the part lies on the remaining unsintered powder, reducing the need for post-processing and leaving good surface finishes on parts. Choose fromindustrial-grade nylon11 or nylon 12, flame retardant nylon 12, fiber-reinforced, glass-filled, and aluminum-filled materials. The BigRep GmbH gets supported by funds from the Pro FIT program. Subscribe to our newsletter for useful tips, news and resources around industrial 3D printing. Discover more, LARGE-SCALE Microsoft's Clarity is a tool which provides website usage statistics, sessions recording and heatmaps. Many products bound for the mass market are bound for mass production, and this may mean in a different manufacturing process. Some high quality, industrial-standard filaments we recommend for FDM rapid prototyping: Once the part has been printed, you can decide if the prototype is fit for purpose and whether it is good enough to go ahead and start manufacturing. They can also print supports in a soluble filament material like HIPS or PVA, so when dissolved away afterwards, youre left with just your model and none of the imperfections that can occur during support removal.

For perfomance reasons we use Cloudflare as a CDN network. 3D printed architectural models, courtesy LGM, Prototype electronic slider case 3D printed on Figure 4 3d printer, Fast, Affordable 3D Printing with Figure 4 at Rapid Application Group, Birdstone Proves Packaging Design with Clear 3D Printed Prototypes, 3D Printing Helps Drive R&D at Renault Sport Formula One Team, More than 15 times faster prototyping than alternative methods, Delivering Tools for Agile Product Development. Sometimes 3D scanning is also used to create a model of the part to be iterated on, such as a 3D printed car part. Tweak your design and repeat the process. Explore the broad range of FDM and PolyJet materials for all of your rapid prototyping scenarios. Delivering 3D print speeds of up to 100 mm per hour, Figure 4 Standalone offers unparalleled ease-of-use, repeatability and part quality never before seen in the industry.

Learn how industry-leading companies are putting 3D printing to use as we explore four applications that are helping increase productivity, reduce leads times and improve time to market. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. Curious to see how much you can save? While the upfront cost of a printer setup can feel intimidating, it can pay for itself in just a couple of weeks or monthswhen you compare it with how much youd spend on outsourcing or an alternative production method. We recommend reading the following guides for choosing a rapid prototyping 3D software tool: We've covered the 3D printing industry since 2017, tested over a dozen of the world's most popular 3D printers, and we're dedicated to being the most informative 3D printing site in the world to help democratize the technology. The uses and purposes of appearance models can vary greatly throughout product development and can add value at any stage. BigRep develops the worlds largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.

MultiJet Printing solutions for bigger prototypes. 3D printing wasnt commercially available in the 1970s when this occurred, but if it were to happen in the present day, 3D printing and rapid prototyping could create the ideal nozzle in record time.

Latin-America (Espaol) (Espaol (Mxico)), South-Korea () (()).

Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. Rapid prototyping means that you can quickly get a physical product in your hand, which is far better and easier to analyze than a CAD design on a computer screen. Rapid prototyping and 3D printing work together hand-in-hand for better and faster engineering. 50-E Concord Street See how 3D printed rapid prototypes are changing the way the world does business. Rapid prototyping with affordable in-house desktop 3D printersempowers you to create prototypes within a day and carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster. Use the Form 3 at various points of the product development process for a faster ROI. PolyJet is used across the automotive and aerospace industries, as well as in consumer goods and electronics, with niche applications in the medical industry creating very accurate, multi-material or color parts.

Using an ink jet style of 3D printing, MJP also delivers easy support removal with the melt-away wax supports. Rapid prototyping means that you can quickly get a physical product in your hand, which is far better and easier to analyze than a CAD design on a computer screen. Rapid prototyping and 3D printing work together hand-in-hand for better and faster engineering. 50-E Concord Street See how 3D printed rapid prototypes are changing the way the world does business. Rapid prototyping with affordable in-house desktop 3D printersempowers you to create prototypes within a day and carry out multiple iterations of design, size, shape, or assembly based on results of real-life testing and analysis, helping you to bring better products to market faster. Use the Form 3 at various points of the product development process for a faster ROI. PolyJet is used across the automotive and aerospace industries, as well as in consumer goods and electronics, with niche applications in the medical industry creating very accurate, multi-material or color parts.  For functional testing, 3D printing cannot compete with solid CNC machined parts.

For functional testing, 3D printing cannot compete with solid CNC machined parts.  Complex geometries are possible, and SLS parts are far more resistant to wear-and-tear than SLA prototypes and therefore better suited to functional prototype testing. See our printers in action and learn about our technology. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design. With the ability to evaluate and improve prototypes repeatedly until youre completely satisfied, rapid prototyping lowers the chance of errors in the part before starting an expensive production run. ATNOM is one of the leading research and development centers for renewable solutions in Romania, such as high-performance lithium batteries for industrial and automotive applications, has recently acquired the industrial 3D printer BigRep PRO.

Complex geometries are possible, and SLS parts are far more resistant to wear-and-tear than SLA prototypes and therefore better suited to functional prototype testing. See our printers in action and learn about our technology. These prototypes also enable engineers to consider how exactly to best manufacture the eventual final design. With the ability to evaluate and improve prototypes repeatedly until youre completely satisfied, rapid prototyping lowers the chance of errors in the part before starting an expensive production run. ATNOM is one of the leading research and development centers for renewable solutions in Romania, such as high-performance lithium batteries for industrial and automotive applications, has recently acquired the industrial 3D printer BigRep PRO.  Large-scale 3D printing can bring these large-scale designs to life, allowing for a full iteration to be made and tested in less than the time it would take for a traditional tool to be made. Copyright 2022 3D Systems, Inc. All rights reserved. With an arsenal of additive manufacturing preparation. If not, tweaks can be made based on the findings to create the next iteration, and the next prototype can be quickly 3D printed. MJF prototyping is used to create durable jigs / fixtures, brackets, vessels within the oil and gas industry, fan housings and vents, electric component housings, mechanical assemblies, and enclosures. Cookie required to allow a user to stay logged in to a web site without needing to submit their username and password for each page visited. Refine. Make changes to the CAD file based on the feedback and tweak everything in preparation for 3D printing the next iteration overnight again. The definition of rapid prototyping is using CAD programs and a machine like a 3D printer or CNC mill to quickly produce prototypes, test them for shape or function, and tweak or iterate based on the feedback, so you can then print the next prototype and test it. Some FDM printers are dual extruder 3D printers, meaning they can print two different materials or colors of filament simultaneously, opening up a range of new design and prototyping options. Grow your business through volume production with consistent end-use functional parts. For example, if you needed a part featuring both flexible and rigid materials in separate areas, PolyJet would be the best rapid prototyping method for you. From showcasing the industrial value of 3D printing to highlighting successful use cases, BigReps webinars explore the most interesting aspects of 3D printing opportunities and possibilities. significantly decrease cost of ownership of your 3D printers by reducing the need for costly software seats by third party vendors. This increased frequency of iterations means that the designers have time and opportunity to improve the designs while still delivering within or before deadline. Test.

Large-scale 3D printing can bring these large-scale designs to life, allowing for a full iteration to be made and tested in less than the time it would take for a traditional tool to be made. Copyright 2022 3D Systems, Inc. All rights reserved. With an arsenal of additive manufacturing preparation. If not, tweaks can be made based on the findings to create the next iteration, and the next prototype can be quickly 3D printed. MJF prototyping is used to create durable jigs / fixtures, brackets, vessels within the oil and gas industry, fan housings and vents, electric component housings, mechanical assemblies, and enclosures. Cookie required to allow a user to stay logged in to a web site without needing to submit their username and password for each page visited. Refine. Make changes to the CAD file based on the feedback and tweak everything in preparation for 3D printing the next iteration overnight again. The definition of rapid prototyping is using CAD programs and a machine like a 3D printer or CNC mill to quickly produce prototypes, test them for shape or function, and tweak or iterate based on the feedback, so you can then print the next prototype and test it. Some FDM printers are dual extruder 3D printers, meaning they can print two different materials or colors of filament simultaneously, opening up a range of new design and prototyping options. Grow your business through volume production with consistent end-use functional parts. For example, if you needed a part featuring both flexible and rigid materials in separate areas, PolyJet would be the best rapid prototyping method for you. From showcasing the industrial value of 3D printing to highlighting successful use cases, BigReps webinars explore the most interesting aspects of 3D printing opportunities and possibilities. significantly decrease cost of ownership of your 3D printers by reducing the need for costly software seats by third party vendors. This increased frequency of iterations means that the designers have time and opportunity to improve the designs while still delivering within or before deadline. Test.  This fast turn-around enables companies to significantly improve product time-to-market as well as deliver a superior product within that shortened time. BigRep GmbH (HQ Europe)

This fast turn-around enables companies to significantly improve product time-to-market as well as deliver a superior product within that shortened time. BigRep GmbH (HQ Europe)  This shortens wait times, as feedback can translate immediately to an updated design file that can in turn be 3D printed as quickly as just a few hours. The prototype is tested for shape, color and aesthetics if a cosmetic model, or testing function such as the prototypes heat or impact resistance. Competitive positioning requires that development and introduction be quick, especially in the consumer market. The time it takes an idea to move from concept to deliverable should be as short as possible. This cookie is strictly necessary for Cloudflare's security features and cannot be turned off. Designed to protect industrial workflows by preventing material degradation that leads to lost time and damages, the BigRep SHIELD secures filament in ideal conditions for both short and long-term storage. This uses up additional materials and requires more cleaning up afterwards. On the other hand, CNC milling is subtractive, removing excess material until you reach a final design. Produce tough, durable parts from a range of production-grade nylon materials that have been optimized, validated and tested to ensure quality, with isotropic 3D mechanical properties. Those are session cookies. When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Wilmington, MA 01887 How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. Rapid prototyping with 3D printing is the quick, easy, cost effective way to turn great ideas into successful products. Attention must be paid to detail, to how the final part will be manufactured (especially if this will be done in a different process than the prototype; for example, 3D printing a prototype for a part that will ultimately be injection molded) as well as how the final part will be post-processed/finished. There is no single best 3D printer, this all depends on the materials, size of prototype and a variety of other factors. Furniture maker Steelcase experienced this benefit first-hand as they use their large-format BigRep 3D printer to create new furniture designs: A functional prototype does just that: it functions. BigRep Private Ltd. Starting with conceptual mockups and building toward a functional prototype, each successive prototype is a step toward a fully engineered final design. Rapid prototyping can ease your entire engineering process in a big way with large-format 3D printing. Before you can 3D print your final prototype, you need a design. Whereas evolution takes tens of thousands of years, the same principles could be augmented using cutting edge technologies and new iterations can be produced every hour now with 3D printing. Multiple materials and over 360k available colors come together to create the most realistic models and prototypes possible. With a high precision 3D printing process, the parts produced will reflect the CAD data provided, resulting in high-quality prototypes for thorough fit and function testing. Unilever had both efficiency problems and quality issues. No supports are required for SLS 3D printing prototyping as the part lies on the remaining unsintered powder, reducing the need for post-processing and leaving good surface finishes on parts. Choose fromindustrial-grade nylon11 or nylon 12, flame retardant nylon 12, fiber-reinforced, glass-filled, and aluminum-filled materials. The BigRep GmbH gets supported by funds from the Pro FIT program. Subscribe to our newsletter for useful tips, news and resources around industrial 3D printing. Discover more, LARGE-SCALE Microsoft's Clarity is a tool which provides website usage statistics, sessions recording and heatmaps. Many products bound for the mass market are bound for mass production, and this may mean in a different manufacturing process. Some high quality, industrial-standard filaments we recommend for FDM rapid prototyping: Once the part has been printed, you can decide if the prototype is fit for purpose and whether it is good enough to go ahead and start manufacturing. They can also print supports in a soluble filament material like HIPS or PVA, so when dissolved away afterwards, youre left with just your model and none of the imperfections that can occur during support removal.

This shortens wait times, as feedback can translate immediately to an updated design file that can in turn be 3D printed as quickly as just a few hours. The prototype is tested for shape, color and aesthetics if a cosmetic model, or testing function such as the prototypes heat or impact resistance. Competitive positioning requires that development and introduction be quick, especially in the consumer market. The time it takes an idea to move from concept to deliverable should be as short as possible. This cookie is strictly necessary for Cloudflare's security features and cannot be turned off. Designed to protect industrial workflows by preventing material degradation that leads to lost time and damages, the BigRep SHIELD secures filament in ideal conditions for both short and long-term storage. This uses up additional materials and requires more cleaning up afterwards. On the other hand, CNC milling is subtractive, removing excess material until you reach a final design. Produce tough, durable parts from a range of production-grade nylon materials that have been optimized, validated and tested to ensure quality, with isotropic 3D mechanical properties. Those are session cookies. When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Wilmington, MA 01887 How a specialized local engineering company supported a major airline during the pandemic with jet engine covers made with 3D printed molds. Rapid prototyping with 3D printing is the quick, easy, cost effective way to turn great ideas into successful products. Attention must be paid to detail, to how the final part will be manufactured (especially if this will be done in a different process than the prototype; for example, 3D printing a prototype for a part that will ultimately be injection molded) as well as how the final part will be post-processed/finished. There is no single best 3D printer, this all depends on the materials, size of prototype and a variety of other factors. Furniture maker Steelcase experienced this benefit first-hand as they use their large-format BigRep 3D printer to create new furniture designs: A functional prototype does just that: it functions. BigRep Private Ltd. Starting with conceptual mockups and building toward a functional prototype, each successive prototype is a step toward a fully engineered final design. Rapid prototyping can ease your entire engineering process in a big way with large-format 3D printing. Before you can 3D print your final prototype, you need a design. Whereas evolution takes tens of thousands of years, the same principles could be augmented using cutting edge technologies and new iterations can be produced every hour now with 3D printing. Multiple materials and over 360k available colors come together to create the most realistic models and prototypes possible. With a high precision 3D printing process, the parts produced will reflect the CAD data provided, resulting in high-quality prototypes for thorough fit and function testing. Unilever had both efficiency problems and quality issues. No supports are required for SLS 3D printing prototyping as the part lies on the remaining unsintered powder, reducing the need for post-processing and leaving good surface finishes on parts. Choose fromindustrial-grade nylon11 or nylon 12, flame retardant nylon 12, fiber-reinforced, glass-filled, and aluminum-filled materials. The BigRep GmbH gets supported by funds from the Pro FIT program. Subscribe to our newsletter for useful tips, news and resources around industrial 3D printing. Discover more, LARGE-SCALE Microsoft's Clarity is a tool which provides website usage statistics, sessions recording and heatmaps. Many products bound for the mass market are bound for mass production, and this may mean in a different manufacturing process. Some high quality, industrial-standard filaments we recommend for FDM rapid prototyping: Once the part has been printed, you can decide if the prototype is fit for purpose and whether it is good enough to go ahead and start manufacturing. They can also print supports in a soluble filament material like HIPS or PVA, so when dissolved away afterwards, youre left with just your model and none of the imperfections that can occur during support removal.  For perfomance reasons we use Cloudflare as a CDN network. 3D printed architectural models, courtesy LGM, Prototype electronic slider case 3D printed on Figure 4 3d printer, Fast, Affordable 3D Printing with Figure 4 at Rapid Application Group, Birdstone Proves Packaging Design with Clear 3D Printed Prototypes, 3D Printing Helps Drive R&D at Renault Sport Formula One Team, More than 15 times faster prototyping than alternative methods, Delivering Tools for Agile Product Development. Sometimes 3D scanning is also used to create a model of the part to be iterated on, such as a 3D printed car part. Tweak your design and repeat the process. Explore the broad range of FDM and PolyJet materials for all of your rapid prototyping scenarios. Delivering 3D print speeds of up to 100 mm per hour, Figure 4 Standalone offers unparalleled ease-of-use, repeatability and part quality never before seen in the industry.

For perfomance reasons we use Cloudflare as a CDN network. 3D printed architectural models, courtesy LGM, Prototype electronic slider case 3D printed on Figure 4 3d printer, Fast, Affordable 3D Printing with Figure 4 at Rapid Application Group, Birdstone Proves Packaging Design with Clear 3D Printed Prototypes, 3D Printing Helps Drive R&D at Renault Sport Formula One Team, More than 15 times faster prototyping than alternative methods, Delivering Tools for Agile Product Development. Sometimes 3D scanning is also used to create a model of the part to be iterated on, such as a 3D printed car part. Tweak your design and repeat the process. Explore the broad range of FDM and PolyJet materials for all of your rapid prototyping scenarios. Delivering 3D print speeds of up to 100 mm per hour, Figure 4 Standalone offers unparalleled ease-of-use, repeatability and part quality never before seen in the industry.  Learn how industry-leading companies are putting 3D printing to use as we explore four applications that are helping increase productivity, reduce leads times and improve time to market. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. Curious to see how much you can save? While the upfront cost of a printer setup can feel intimidating, it can pay for itself in just a couple of weeks or monthswhen you compare it with how much youd spend on outsourcing or an alternative production method. We recommend reading the following guides for choosing a rapid prototyping 3D software tool: We've covered the 3D printing industry since 2017, tested over a dozen of the world's most popular 3D printers, and we're dedicated to being the most informative 3D printing site in the world to help democratize the technology. The uses and purposes of appearance models can vary greatly throughout product development and can add value at any stage. BigRep develops the worlds largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.

Learn how industry-leading companies are putting 3D printing to use as we explore four applications that are helping increase productivity, reduce leads times and improve time to market. Choose from 3 colours, a spool size range from 750g to 8 kg, to meet any industrial print requirement. Curious to see how much you can save? While the upfront cost of a printer setup can feel intimidating, it can pay for itself in just a couple of weeks or monthswhen you compare it with how much youd spend on outsourcing or an alternative production method. We recommend reading the following guides for choosing a rapid prototyping 3D software tool: We've covered the 3D printing industry since 2017, tested over a dozen of the world's most popular 3D printers, and we're dedicated to being the most informative 3D printing site in the world to help democratize the technology. The uses and purposes of appearance models can vary greatly throughout product development and can add value at any stage. BigRep develops the worlds largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. The goal of rapid prototyping is to reach this stage faster than ever before using conventional prototyping workflows.  Latin-America (Espaol) (Espaol (Mxico)), South-Korea () (()).

Latin-America (Espaol) (Espaol (Mxico)), South-Korea () (()).