A: It is suggested to use big water tank or bucket.

machine acrylic thermoforming forming bathtub making pmma hdpe abs pvc ps larger vacuum : Driven Type This process is limited to the geometry since parts with undercuts cannot be produced. This yield inconsistent parts shrinkage. To fullfill the water in any water tank or bucket, connect the pipes with water pump, and put the water pump into the water, then turn on the switch. : Pressing Shape This method is cheap compared to other acrylic forming methods. Its parts with small thickness to area ratio can easily be fabricated, even though extremely large parts can also be fabricated. In addition to these, it is also used to produce truck bed liners, floor mats, and headlight covers. : Material Different modes can bring different forming effects. 6. : Pressing Layer Open the metal set in both sides of the machine, take out the broken heating lamp, pull out and unfasten the wires. During forming, the acrylic sheet in a pliable state can break due to excessive stretching when subjected to a certain temperature. Depending on the size and complexity of equipment, several individual parts are combined to form a single mold. completed many thousands of projects.

3. Sheet Fed | If indeed has other demand, pls send exact picture to sales for further confirmation. With over 30+ How to make the products? This is because they are more transparent than glass and they have shutter proof grades.

The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600.

Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net, Acrylic & Plastic Vacuum Forming Molding Machine for Sale, Copyright 2016-2025 Perfect Laser All Right Reserved, is used to make 2-3mm acrylic into flat, curved.

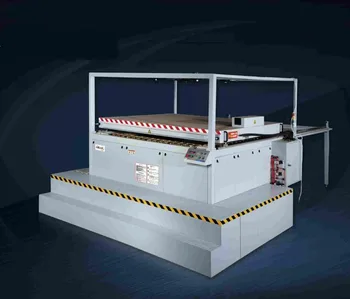

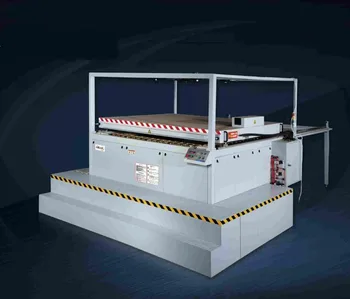

forming vacuum acrylic cheap plastic china thermal machine signage certificate ce larger The parts can also be produced in different colors, with details and different designs. The industry has found this application relevant because they use it to process chocolate molds for special occasions. When the form/mold is in the process of production, the temperature will not be consistent over a batch of parts. This technique enables the production of parts that are cheaper since the whole process is cost effective. You could buy any spare parts as you want. This large vacuum forming molding machine is suitable for acrylic and many other plastics. Thin -gauge use less than 0.060 inches to manufacture food and medical packagings like blisters, disposable cups, and poultry trays. Plexiglass bending machine is a useful tool for softening and bending acrylic, organic glass, plexiglass, pvc, pc ,ABS, pp sheet into shapes. | If we could buy from Chinese market, we could change as your demand. Subscribe free newsletter to get latest products and discount information. When the tool surface is porous, it may result in unwanted surface texture, dimpling or even gloss reduction. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. Q: How many minutes should the user heat for 3mm sheet? Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Acrylic Vacuum Forming Machine. | Affiliate, Product Listing Policy Q: What kind of material can it cut bend? The vacuum molding machine supports three processing modes: single suction, single pressure and simultaneous suction pressure. Copyright 2005-2022 YN. Manual Deep Draw Heavy Gauge Vacuum Forming Machine, Typically used for the molding of larger structural Components such as- bath : Process Usage Our machine has only one heating lamp, could heat and bend only one line at a time.

forming : Kind 11. Time for heating is influenced by the velocity of the air in the oven and panel-to-heat distance. Your max forming height(Depth) is necessary for choosing the most suitable machine, 4. with similar tools were cycle timing is the same, or were two different tool set ups are This is the creation of a mold where the acrylic will be heated over. This affects the final product in a negative way. Today we want to learn about Thermoforming Acrylic. : Nature Because the final product cools against the mold surface under ambient temperature, its finished parts have zero residual stress. 3.

220V,1PH orAC380V,3PH,50HZ (other voltage can be customized). 3. A: Yes, according to sheet thickness and real requirement, heating range in 0-20mm.Generally, the sheet is thicker, the heating area need bigger. To minimize this, the frame should be heated to temperature before clamping the sheet. Acrylic sheets in a pliable state can break due to excessive stretching under a certain temperature. It also reduces the pressure on the mold surface of the sheet resulting in fewer mark-offs being apparent in clear parts. Normally, acrylic sheet forms at a temperature of between 142-160C. Sharp bends and corners are not so easy to produce, and because of this, internal stresses are common. Let us now have a close look at some of the basics in acrylic thermoforming.

forming vacuum vaccum samll It is difficult to mold ribs and bosses and very thick acrylic sheets cannot be formed. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. We will also look at the factors affecting the quality of acrylic thermoforming process and techniques used for thermoforming. The acrylic is formed to the mold by heating it to a pliable temperature. Nevertheless, thermoformed products start as a CAD model or drawing. Sometimes, there are dimensional inconsistencies which also results from improper temperature controlled tool design. Two voltages are available, 220V and 110V. A: No. The packaging industry uses this application by manufacturing point of purchase, trays, plates and cosmetic cases. All Rights Reserved. we would encourage you, our new customer to review this site and take time to visit our YouTube Finding the right product to integrate into the workflow should be an easy task. Privacy Policy

vaco formacin caseras termoformadoras formech acrlico mquinas profundidad This application is very relevant here because acrylic can be exposed to UV radiation and elements. 1. It saves up to about 90% of tooling cost as compared to other molding types. Thermoformed acrylic has also been applied in the automotive industry. Is has only single heating lamp, main fuction is to bend angle. This provides an opportunity to produce a wide variety of products that enables competition in the market. Like many manufacturing processes, thermoforming acrylic also has some problems which interfere with its successful process. This is one of the earliest thermoforming processes dating back to early Egyptian times. Also, the parts that have sharp bends and corners are very difficult to produce. Articulating clamp frames are used in this case to increase the normal sag of the sheet. VC Multifunctional CNC Channel Letter Bending Machine, Aluminum channel letter bending machine to make signage letters. After the final product has cooled, some parts need to be trimmed off. When the parts are forming over the mold, these inconsistencies occur due to inadequate venting. The fixture is adjustable, and can support customization. 5. : After-sales Service Alipay

machine forming vacuum plastic blow thermoforming larger This can lead to wastage and increase the use of more sheets to about 20%. : Structure >Manual Acrylic Bending Machine ABM700/1300, 365D(exclude force majeure,aritificial factors). There are many acrylic thermoforming techniques. At times, parts have a poor surface finish and therefore have to be trimmed. This results in unequal heating and cooling of acrylic material surface area. : Processing Technics The sheet part that touches the mold first will cool and then cease to stretch. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected.

multifunction abs It is suggested using oven heating to make big arc. 5.Big worktable ensures evenly heated, no foaming, no deformation, easy to handle. Our presented products are made using the best grade raw material and advanced techniques. They are drape forming acrylic sheet, pressure forming acrylic sheet and vacuum forming the acrylic sheet. This system offers split second timing and heat control for consistent product When a sheet has stretched without exceeding its strength and fracturing, its said to have reached its maximum forming rate. . acrylics, polycarbonates, and ABS. Q: Where is the spare heating lamp in the package? The vacuum forming molding machine adopts a remote control handle and simple operation. Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate.

A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.

A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. 33010002000092 Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. In this process, the parts are formed by heating acrylic to a suitable temperature. At Belovac Engineering.. There could be warping caused by improper temperature controlled tool design and manufacturer. Acrylic Vacuum Forming Machine is sold by set Once it has been formed onto the mold, it is cooled and then removed from the mold in its final shape. 1) Makingmolds , mold can be MDF or metal . | It should take long to form a colored sheet as compared to a colorless or a transparent one.

Bubbles which occur due to an application of heat too rapidly, uneven heating or excess moisture in acrylic sheet. 6. 16. : Control Method

4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. This can be caused by improper tooling materials selection or inadequate tool surface finishing. This helps in reducing stress when the sheet becomes hot while the clamped edges remain cold. For example, it is used to produce the covers that enable clean and dry storage of medical instruments and equipment. Tmall Taobao World According to the functions or types of Acrylic Vacuum Forming Machine, Acrylic Vacuum Forming Machine can be classified into many types. Poor quality surface finishes due to the texture of gloss variation.

machine solid surface vacuum press membrane thermoforming corian silicone rubber 3d acrylic newly larger forming alibaba We will look at Drape, Pressure, and Vacuum forming an acrylic sheet. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. A: Spare heating lamp is packed into a silver or black alluminum alloy tube. Also, about 20% more acrylic will be used, and this will result in higher acrylic thermoforming processing cost. The parameters for thin-gauge tooling include maximum mold size of up to 30 inches wide. Application areas include: Thermoformed acrylic sheets provide protection from impact, elements, ultraviolet radiation and corrosion to all types of OEM equipment. Aluminum molds are commonly used. Sometimes, techniques like power drape forming are used. This vacuum molding machine is equipped with a temperature controller. Tooling | Tell me your budget &yield pls, Professionally accommodate you. Other parameters are aluminum mold, which is temperature controlled, and steel rule dye for trimming. It refers to the process of heating thin acrylic sheet material until it reaches a pliable temperature. Q: Does the machine has fans cooling? High forming temperature is ideal for greater draws. According to different material and thickness of sheet, the gap width can be adjustable. Stay updated to what's new and popular on the market. You can minimize all these tool-related issues by utilizing proper tooling designs, material selection, and adopting high-quality manufacturing. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. Vacuum forming is a reliable method used in creating numerous types of props and costume accessories. It has a quick and cheap tooling process. This machine has eliminated secondary trimming operations because it uses cut-to-size sheets and this has greatly reduced the production cost. It can also be produced in a variety of colors and textures. Aecfun >Product>Acrylic Bender/trimmer>Manual Acrylic Bending Machine ABM700/1300. A: Yes, fans are installed. Warranty part: the temperature control circuit board. A: Firstly, turn off the machine power supply, to ensure the broken heating lamp is cooled enough. Generally, some European countries and China is in 220V, North America and Japan is 110V. : Condition Using a surge tank, quickly pull the air out from between the mold and the sheet. There is no need to open 3 holes at one time, the corresponding suction holes can be opened according to the processing format, and it can save much energy when forming.

Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. For instance, when the acrylic volume is larger, thermal conductivity is small and therefore the heating time becomes long. They also use it to make chocolate packages. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, | Showroom This provides an excellent finishing for the products.

Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.

You will be speaking with one of our knowledgeable design engineers that will take the time customers. A: No. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) The remedy here is to lower temperature by increasing the distance between heater and sheet.

The cost ranges from as low as 2000- 100,000 USD or even more. Inconsistent Acrylic part thickness is another problem. Forming width:3000mm(Customizable) A: We have two models now. To minimize this stress, you should use moderate forming rate. Recommended for the pre-heating and drying of heavy gauge and materials such as Sheet thickness:2-8mm The fact that high-quality acrylic plastic sheet is used means the acrylic thermoforming method is not cost effective. Q: Does the machine have CE certification? Warranty Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase. Deep male mold placed in close proximity to each other. The object is for protecting the heating lamp and to insulated heating during working. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. : Port This pressure varies with the thickness of the sheet and the temperature subjected to it. They are always the outer protective covering of equipment. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : Power This feature can make the product more standardized and make manufacture more convenient. Failure to do this may result in blistering of the sheet during forming, thus compromising the quality of the product. Q: Can the plug be changed to any countries standard? 1.Size: 700mm and 1300mm. Our obvious trade dealings, moral behavior in business, nominal prices, right trade policy, and top quality of products have helped us to attain the clients satisfaction in proficient way.

vacuum machine forming acrylic plastic larger Working voltage: 110v/220V, 3.With angle adjuster 0-160and length position adjuster. The large vacuum forming machine consists of a starting balance device, a vacuum pump, 8 air cylinders, and 12 heating tubes. Discover amazing deals on Alibaba.com, as they carry a wide range of acrylic vacuum forming machine from various certified suppliers.

3. Sheet Fed | If indeed has other demand, pls send exact picture to sales for further confirmation. With over 30+ How to make the products? This is because they are more transparent than glass and they have shutter proof grades.

3. Sheet Fed | If indeed has other demand, pls send exact picture to sales for further confirmation. With over 30+ How to make the products? This is because they are more transparent than glass and they have shutter proof grades.  The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600.

The temperature of infrared tube is ajustable according to different thickness of plastic sheet and max temperature is 600.  Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net, Acrylic & Plastic Vacuum Forming Molding Machine for Sale, Copyright 2016-2025 Perfect Laser All Right Reserved, is used to make 2-3mm acrylic into flat, curved. forming vacuum acrylic cheap plastic china thermal machine signage certificate ce larger The parts can also be produced in different colors, with details and different designs. The industry has found this application relevant because they use it to process chocolate molds for special occasions. When the form/mold is in the process of production, the temperature will not be consistent over a batch of parts. This technique enables the production of parts that are cheaper since the whole process is cost effective. You could buy any spare parts as you want. This large vacuum forming molding machine is suitable for acrylic and many other plastics. Thin -gauge use less than 0.060 inches to manufacture food and medical packagings like blisters, disposable cups, and poultry trays. Plexiglass bending machine is a useful tool for softening and bending acrylic, organic glass, plexiglass, pvc, pc ,ABS, pp sheet into shapes. | If we could buy from Chinese market, we could change as your demand. Subscribe free newsletter to get latest products and discount information. When the tool surface is porous, it may result in unwanted surface texture, dimpling or even gloss reduction. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. Q: How many minutes should the user heat for 3mm sheet? Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Acrylic Vacuum Forming Machine. | Affiliate, Product Listing Policy Q: What kind of material can it cut bend? The vacuum molding machine supports three processing modes: single suction, single pressure and simultaneous suction pressure. Copyright 2005-2022 YN. Manual Deep Draw Heavy Gauge Vacuum Forming Machine, Typically used for the molding of larger structural Components such as- bath : Process Usage Our machine has only one heating lamp, could heat and bend only one line at a time. forming : Kind 11. Time for heating is influenced by the velocity of the air in the oven and panel-to-heat distance. Your max forming height(Depth) is necessary for choosing the most suitable machine, 4. with similar tools were cycle timing is the same, or were two different tool set ups are This is the creation of a mold where the acrylic will be heated over. This affects the final product in a negative way. Today we want to learn about Thermoforming Acrylic. : Nature Because the final product cools against the mold surface under ambient temperature, its finished parts have zero residual stress. 3.

Welcome to text me on WhatsApp or send me an email to info@perfectlaser.net, Acrylic & Plastic Vacuum Forming Molding Machine for Sale, Copyright 2016-2025 Perfect Laser All Right Reserved, is used to make 2-3mm acrylic into flat, curved. forming vacuum acrylic cheap plastic china thermal machine signage certificate ce larger The parts can also be produced in different colors, with details and different designs. The industry has found this application relevant because they use it to process chocolate molds for special occasions. When the form/mold is in the process of production, the temperature will not be consistent over a batch of parts. This technique enables the production of parts that are cheaper since the whole process is cost effective. You could buy any spare parts as you want. This large vacuum forming molding machine is suitable for acrylic and many other plastics. Thin -gauge use less than 0.060 inches to manufacture food and medical packagings like blisters, disposable cups, and poultry trays. Plexiglass bending machine is a useful tool for softening and bending acrylic, organic glass, plexiglass, pvc, pc ,ABS, pp sheet into shapes. | If we could buy from Chinese market, we could change as your demand. Subscribe free newsletter to get latest products and discount information. When the tool surface is porous, it may result in unwanted surface texture, dimpling or even gloss reduction. This means that it can be used in low-level production providing an opportunity to produce small quantities economically. After setting the heating temperature, 12 high-power heating tubes can quickly soften the acrylic and plastics sheet. In this guide, I will take you through the definition of thermoforming acrylic, thermoforming basics, its advantages, and disadvantages. Q: How many minutes should the user heat for 3mm sheet? Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Acrylic Vacuum Forming Machine. | Affiliate, Product Listing Policy Q: What kind of material can it cut bend? The vacuum molding machine supports three processing modes: single suction, single pressure and simultaneous suction pressure. Copyright 2005-2022 YN. Manual Deep Draw Heavy Gauge Vacuum Forming Machine, Typically used for the molding of larger structural Components such as- bath : Process Usage Our machine has only one heating lamp, could heat and bend only one line at a time. forming : Kind 11. Time for heating is influenced by the velocity of the air in the oven and panel-to-heat distance. Your max forming height(Depth) is necessary for choosing the most suitable machine, 4. with similar tools were cycle timing is the same, or were two different tool set ups are This is the creation of a mold where the acrylic will be heated over. This affects the final product in a negative way. Today we want to learn about Thermoforming Acrylic. : Nature Because the final product cools against the mold surface under ambient temperature, its finished parts have zero residual stress. 3.  220V,1PH orAC380V,3PH,50HZ (other voltage can be customized). 3. A: Yes, according to sheet thickness and real requirement, heating range in 0-20mm.Generally, the sheet is thicker, the heating area need bigger. To minimize this, the frame should be heated to temperature before clamping the sheet. Acrylic sheets in a pliable state can break due to excessive stretching under a certain temperature. It also reduces the pressure on the mold surface of the sheet resulting in fewer mark-offs being apparent in clear parts. Normally, acrylic sheet forms at a temperature of between 142-160C. Sharp bends and corners are not so easy to produce, and because of this, internal stresses are common. Let us now have a close look at some of the basics in acrylic thermoforming. forming vacuum vaccum samll It is difficult to mold ribs and bosses and very thick acrylic sheets cannot be formed. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. We will also look at the factors affecting the quality of acrylic thermoforming process and techniques used for thermoforming. The acrylic is formed to the mold by heating it to a pliable temperature. Nevertheless, thermoformed products start as a CAD model or drawing. Sometimes, there are dimensional inconsistencies which also results from improper temperature controlled tool design. Two voltages are available, 220V and 110V. A: No. The packaging industry uses this application by manufacturing point of purchase, trays, plates and cosmetic cases. All Rights Reserved. we would encourage you, our new customer to review this site and take time to visit our YouTube Finding the right product to integrate into the workflow should be an easy task. Privacy Policy vaco formacin caseras termoformadoras formech acrlico mquinas profundidad This application is very relevant here because acrylic can be exposed to UV radiation and elements. 1. It saves up to about 90% of tooling cost as compared to other molding types. Thermoformed acrylic has also been applied in the automotive industry. Is has only single heating lamp, main fuction is to bend angle. This provides an opportunity to produce a wide variety of products that enables competition in the market. Like many manufacturing processes, thermoforming acrylic also has some problems which interfere with its successful process. This is one of the earliest thermoforming processes dating back to early Egyptian times. Also, the parts that have sharp bends and corners are very difficult to produce. Articulating clamp frames are used in this case to increase the normal sag of the sheet. VC Multifunctional CNC Channel Letter Bending Machine, Aluminum channel letter bending machine to make signage letters. After the final product has cooled, some parts need to be trimmed off. When the parts are forming over the mold, these inconsistencies occur due to inadequate venting. The fixture is adjustable, and can support customization. 5. : After-sales Service Alipay machine forming vacuum plastic blow thermoforming larger This can lead to wastage and increase the use of more sheets to about 20%. : Structure >Manual Acrylic Bending Machine ABM700/1300, 365D(exclude force majeure,aritificial factors). There are many acrylic thermoforming techniques. At times, parts have a poor surface finish and therefore have to be trimmed. This results in unequal heating and cooling of acrylic material surface area. : Processing Technics The sheet part that touches the mold first will cool and then cease to stretch. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected. multifunction abs It is suggested using oven heating to make big arc. 5.Big worktable ensures evenly heated, no foaming, no deformation, easy to handle. Our presented products are made using the best grade raw material and advanced techniques. They are drape forming acrylic sheet, pressure forming acrylic sheet and vacuum forming the acrylic sheet. This system offers split second timing and heat control for consistent product When a sheet has stretched without exceeding its strength and fracturing, its said to have reached its maximum forming rate. . acrylics, polycarbonates, and ABS. Q: Where is the spare heating lamp in the package? The vacuum forming molding machine adopts a remote control handle and simple operation. Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate.

220V,1PH orAC380V,3PH,50HZ (other voltage can be customized). 3. A: Yes, according to sheet thickness and real requirement, heating range in 0-20mm.Generally, the sheet is thicker, the heating area need bigger. To minimize this, the frame should be heated to temperature before clamping the sheet. Acrylic sheets in a pliable state can break due to excessive stretching under a certain temperature. It also reduces the pressure on the mold surface of the sheet resulting in fewer mark-offs being apparent in clear parts. Normally, acrylic sheet forms at a temperature of between 142-160C. Sharp bends and corners are not so easy to produce, and because of this, internal stresses are common. Let us now have a close look at some of the basics in acrylic thermoforming. forming vacuum vaccum samll It is difficult to mold ribs and bosses and very thick acrylic sheets cannot be formed. The three-phase power supply of the vacuum forming machine for sale is equipped with special indicator lights, its convenient for observing when the phase is missing. We will also look at the factors affecting the quality of acrylic thermoforming process and techniques used for thermoforming. The acrylic is formed to the mold by heating it to a pliable temperature. Nevertheless, thermoformed products start as a CAD model or drawing. Sometimes, there are dimensional inconsistencies which also results from improper temperature controlled tool design. Two voltages are available, 220V and 110V. A: No. The packaging industry uses this application by manufacturing point of purchase, trays, plates and cosmetic cases. All Rights Reserved. we would encourage you, our new customer to review this site and take time to visit our YouTube Finding the right product to integrate into the workflow should be an easy task. Privacy Policy vaco formacin caseras termoformadoras formech acrlico mquinas profundidad This application is very relevant here because acrylic can be exposed to UV radiation and elements. 1. It saves up to about 90% of tooling cost as compared to other molding types. Thermoformed acrylic has also been applied in the automotive industry. Is has only single heating lamp, main fuction is to bend angle. This provides an opportunity to produce a wide variety of products that enables competition in the market. Like many manufacturing processes, thermoforming acrylic also has some problems which interfere with its successful process. This is one of the earliest thermoforming processes dating back to early Egyptian times. Also, the parts that have sharp bends and corners are very difficult to produce. Articulating clamp frames are used in this case to increase the normal sag of the sheet. VC Multifunctional CNC Channel Letter Bending Machine, Aluminum channel letter bending machine to make signage letters. After the final product has cooled, some parts need to be trimmed off. When the parts are forming over the mold, these inconsistencies occur due to inadequate venting. The fixture is adjustable, and can support customization. 5. : After-sales Service Alipay machine forming vacuum plastic blow thermoforming larger This can lead to wastage and increase the use of more sheets to about 20%. : Structure >Manual Acrylic Bending Machine ABM700/1300, 365D(exclude force majeure,aritificial factors). There are many acrylic thermoforming techniques. At times, parts have a poor surface finish and therefore have to be trimmed. This results in unequal heating and cooling of acrylic material surface area. : Processing Technics The sheet part that touches the mold first will cool and then cease to stretch. The formed sheet remains in the mold cavity for a few seconds as it cools down and thereafter, is ejected. multifunction abs It is suggested using oven heating to make big arc. 5.Big worktable ensures evenly heated, no foaming, no deformation, easy to handle. Our presented products are made using the best grade raw material and advanced techniques. They are drape forming acrylic sheet, pressure forming acrylic sheet and vacuum forming the acrylic sheet. This system offers split second timing and heat control for consistent product When a sheet has stretched without exceeding its strength and fracturing, its said to have reached its maximum forming rate. . acrylics, polycarbonates, and ABS. Q: Where is the spare heating lamp in the package? The vacuum forming molding machine adopts a remote control handle and simple operation. Nevertheless, the requirements for temperature depend on forming conditions like the degree of shaping/stretching and the forming rate.  A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.

A: Plastic plate like Acrylic, Plexiglas, PVC, PC,ABS, PP and so on etc.  A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. 33010002000092 Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. In this process, the parts are formed by heating acrylic to a suitable temperature. At Belovac Engineering.. There could be warping caused by improper temperature controlled tool design and manufacturer. Acrylic Vacuum Forming Machine is sold by set Once it has been formed onto the mold, it is cooled and then removed from the mold in its final shape. 1) Makingmolds , mold can be MDF or metal . | It should take long to form a colored sheet as compared to a colorless or a transparent one.

A: Yes.Caution: To ensure the power supply is turned off, before cleaning and replairing. 33010002000092 Established in the year 2014, we Spectrum Sign Systems is one of the foremost companies involved in Exporting, wholesale trading and importing an extensive series of CNC Machines, Laser Engraving Machine, Laser Cutting Machine, Laser Tubes, CNC Controller, Metal Laser Marking Machine, PVC Vacuum Press Machine, Laser Controller, Die Making Machine, Cutting Plotter and many more. In this process, the parts are formed by heating acrylic to a suitable temperature. At Belovac Engineering.. There could be warping caused by improper temperature controlled tool design and manufacturer. Acrylic Vacuum Forming Machine is sold by set Once it has been formed onto the mold, it is cooled and then removed from the mold in its final shape. 1) Makingmolds , mold can be MDF or metal . | It should take long to form a colored sheet as compared to a colorless or a transparent one.  Bubbles which occur due to an application of heat too rapidly, uneven heating or excess moisture in acrylic sheet. 6. 16. : Control Method

Bubbles which occur due to an application of heat too rapidly, uneven heating or excess moisture in acrylic sheet. 6. 16. : Control Method  4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. This can be caused by improper tooling materials selection or inadequate tool surface finishing. This helps in reducing stress when the sheet becomes hot while the clamped edges remain cold. For example, it is used to produce the covers that enable clean and dry storage of medical instruments and equipment. Tmall Taobao World According to the functions or types of Acrylic Vacuum Forming Machine, Acrylic Vacuum Forming Machine can be classified into many types. Poor quality surface finishes due to the texture of gloss variation. machine solid surface vacuum press membrane thermoforming corian silicone rubber 3d acrylic newly larger forming alibaba We will look at Drape, Pressure, and Vacuum forming an acrylic sheet. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. A: Spare heating lamp is packed into a silver or black alluminum alloy tube. Also, about 20% more acrylic will be used, and this will result in higher acrylic thermoforming processing cost. The parameters for thin-gauge tooling include maximum mold size of up to 30 inches wide. Application areas include: Thermoformed acrylic sheets provide protection from impact, elements, ultraviolet radiation and corrosion to all types of OEM equipment. Aluminum molds are commonly used. Sometimes, techniques like power drape forming are used. This vacuum molding machine is equipped with a temperature controller. Tooling | Tell me your budget &yield pls, Professionally accommodate you. Other parameters are aluminum mold, which is temperature controlled, and steel rule dye for trimming. It refers to the process of heating thin acrylic sheet material until it reaches a pliable temperature. Q: Does the machine has fans cooling? High forming temperature is ideal for greater draws. According to different material and thickness of sheet, the gap width can be adjustable. Stay updated to what's new and popular on the market. You can minimize all these tool-related issues by utilizing proper tooling designs, material selection, and adopting high-quality manufacturing. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. Vacuum forming is a reliable method used in creating numerous types of props and costume accessories. It has a quick and cheap tooling process. This machine has eliminated secondary trimming operations because it uses cut-to-size sheets and this has greatly reduced the production cost. It can also be produced in a variety of colors and textures. Aecfun >Product>Acrylic Bender/trimmer>Manual Acrylic Bending Machine ABM700/1300. A: Yes, fans are installed. Warranty part: the temperature control circuit board. A: Firstly, turn off the machine power supply, to ensure the broken heating lamp is cooled enough. Generally, some European countries and China is in 220V, North America and Japan is 110V. : Condition Using a surge tank, quickly pull the air out from between the mold and the sheet. There is no need to open 3 holes at one time, the corresponding suction holes can be opened according to the processing format, and it can save much energy when forming.

4.Circulating water cooling system by submerged pump, keep the worktable stay in cool condition to protect hand and machine. This can be caused by improper tooling materials selection or inadequate tool surface finishing. This helps in reducing stress when the sheet becomes hot while the clamped edges remain cold. For example, it is used to produce the covers that enable clean and dry storage of medical instruments and equipment. Tmall Taobao World According to the functions or types of Acrylic Vacuum Forming Machine, Acrylic Vacuum Forming Machine can be classified into many types. Poor quality surface finishes due to the texture of gloss variation. machine solid surface vacuum press membrane thermoforming corian silicone rubber 3d acrylic newly larger forming alibaba We will look at Drape, Pressure, and Vacuum forming an acrylic sheet. Video-1https://www.youtube.com/embed/ZEiN44L2PFs, Video-2https://www.youtube.com/embed/h6qkP6-VB7M, Video-3https://www.youtube.com/embed/X7AUfK3ZYOM. A: Spare heating lamp is packed into a silver or black alluminum alloy tube. Also, about 20% more acrylic will be used, and this will result in higher acrylic thermoforming processing cost. The parameters for thin-gauge tooling include maximum mold size of up to 30 inches wide. Application areas include: Thermoformed acrylic sheets provide protection from impact, elements, ultraviolet radiation and corrosion to all types of OEM equipment. Aluminum molds are commonly used. Sometimes, techniques like power drape forming are used. This vacuum molding machine is equipped with a temperature controller. Tooling | Tell me your budget &yield pls, Professionally accommodate you. Other parameters are aluminum mold, which is temperature controlled, and steel rule dye for trimming. It refers to the process of heating thin acrylic sheet material until it reaches a pliable temperature. Q: Does the machine has fans cooling? High forming temperature is ideal for greater draws. According to different material and thickness of sheet, the gap width can be adjustable. Stay updated to what's new and popular on the market. You can minimize all these tool-related issues by utilizing proper tooling designs, material selection, and adopting high-quality manufacturing. made of square steel, and the main fixture is made, controlled by 4 cylinders separately. Vacuum forming is a reliable method used in creating numerous types of props and costume accessories. It has a quick and cheap tooling process. This machine has eliminated secondary trimming operations because it uses cut-to-size sheets and this has greatly reduced the production cost. It can also be produced in a variety of colors and textures. Aecfun >Product>Acrylic Bender/trimmer>Manual Acrylic Bending Machine ABM700/1300. A: Yes, fans are installed. Warranty part: the temperature control circuit board. A: Firstly, turn off the machine power supply, to ensure the broken heating lamp is cooled enough. Generally, some European countries and China is in 220V, North America and Japan is 110V. : Condition Using a surge tank, quickly pull the air out from between the mold and the sheet. There is no need to open 3 holes at one time, the corresponding suction holes can be opened according to the processing format, and it can save much energy when forming.  Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. For instance, when the acrylic volume is larger, thermal conductivity is small and therefore the heating time becomes long. They also use it to make chocolate packages. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, | Showroom This provides an excellent finishing for the products.

Thick-gauge, on the other hand, uses 0 .120 inches to manufacture industrial products like refrigerator liners, plastic pallets, and enclosures. For instance, when the acrylic volume is larger, thermal conductivity is small and therefore the heating time becomes long. They also use it to make chocolate packages. Tell us your exact application, like an advertising sign.billboard, bathtub.auto parts covers etc, | Showroom This provides an excellent finishing for the products.  Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.

Acrylic has the ability to resist deformation, but when heated, it becomes elastic and begins to form over a mold.  You will be speaking with one of our knowledgeable design engineers that will take the time customers. A: No. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) The remedy here is to lower temperature by increasing the distance between heater and sheet.

You will be speaking with one of our knowledgeable design engineers that will take the time customers. A: No. interiors commercial signs- truck linersRecommended plastic gauge 3/8"(.95cm) The remedy here is to lower temperature by increasing the distance between heater and sheet.  The cost ranges from as low as 2000- 100,000 USD or even more. Inconsistent Acrylic part thickness is another problem. Forming width:3000mm(Customizable) A: We have two models now. To minimize this stress, you should use moderate forming rate. Recommended for the pre-heating and drying of heavy gauge and materials such as Sheet thickness:2-8mm The fact that high-quality acrylic plastic sheet is used means the acrylic thermoforming method is not cost effective. Q: Does the machine have CE certification? Warranty Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase. Deep male mold placed in close proximity to each other. The object is for protecting the heating lamp and to insulated heating during working. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. : Port This pressure varies with the thickness of the sheet and the temperature subjected to it. They are always the outer protective covering of equipment. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : Power This feature can make the product more standardized and make manufacture more convenient. Failure to do this may result in blistering of the sheet during forming, thus compromising the quality of the product. Q: Can the plug be changed to any countries standard? 1.Size: 700mm and 1300mm. Our obvious trade dealings, moral behavior in business, nominal prices, right trade policy, and top quality of products have helped us to attain the clients satisfaction in proficient way. vacuum machine forming acrylic plastic larger Working voltage: 110v/220V, 3.With angle adjuster 0-160and length position adjuster. The large vacuum forming machine consists of a starting balance device, a vacuum pump, 8 air cylinders, and 12 heating tubes. Discover amazing deals on Alibaba.com, as they carry a wide range of acrylic vacuum forming machine from various certified suppliers.

The cost ranges from as low as 2000- 100,000 USD or even more. Inconsistent Acrylic part thickness is another problem. Forming width:3000mm(Customizable) A: We have two models now. To minimize this stress, you should use moderate forming rate. Recommended for the pre-heating and drying of heavy gauge and materials such as Sheet thickness:2-8mm The fact that high-quality acrylic plastic sheet is used means the acrylic thermoforming method is not cost effective. Q: Does the machine have CE certification? Warranty Below are some critical areas that should not miss when evaluating Acrylic Vacuum Forming Machine for purchase. Deep male mold placed in close proximity to each other. The object is for protecting the heating lamp and to insulated heating during working. Fully robotic 5 and 6-axis trimmers can be used to quickly cut both complex and precise shapes. : Port This pressure varies with the thickness of the sheet and the temperature subjected to it. They are always the outer protective covering of equipment. Please inform us of your working material kind, (Max size and Material) or drawings.like acrylic, ABS, PLA, PMMA.PC etc. : Power This feature can make the product more standardized and make manufacture more convenient. Failure to do this may result in blistering of the sheet during forming, thus compromising the quality of the product. Q: Can the plug be changed to any countries standard? 1.Size: 700mm and 1300mm. Our obvious trade dealings, moral behavior in business, nominal prices, right trade policy, and top quality of products have helped us to attain the clients satisfaction in proficient way. vacuum machine forming acrylic plastic larger Working voltage: 110v/220V, 3.With angle adjuster 0-160and length position adjuster. The large vacuum forming machine consists of a starting balance device, a vacuum pump, 8 air cylinders, and 12 heating tubes. Discover amazing deals on Alibaba.com, as they carry a wide range of acrylic vacuum forming machine from various certified suppliers.