Thomas uses cookies to ensure that we give you the best experience on our website. Thomasnet Is A Registered Trademark Of Thomas Publishing

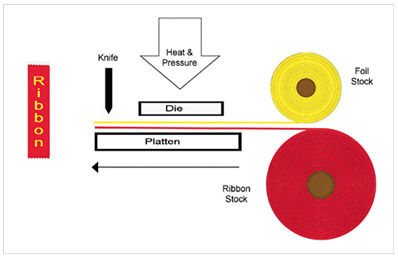

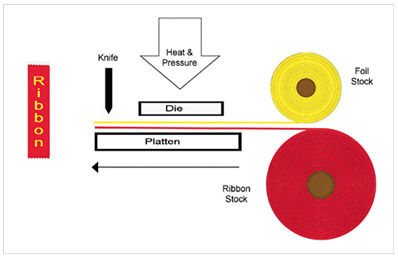

foil stamping ribbon way Each die can be reused multiple times and stored when not in use. Foil stamping, also known as foil printing, is a versatile printing technique that involves applying a metallic or pigmented foil to a surface in order to create a decorative finish. For instance, in automotive manufacturing, hot stamping can be used to maximize steel malleability. The foil is deposited only where the hot stamp comes in contact with the product material, allowing engineers to create elegant, embossed designs on parts and assemblies in post-production. Digital stamping eliminates the need for multiple dies in multicolored and multi-patterned projects. How Deep Under the Ocean Have Humans Explored? What is foil stamping? They are tough and last for many runs. The foil has an adhesive on the back which is activated by the heat and forms a permanent bond to the substrate. Because they are inherently softer than metal stamps, silicone dies conform better to irregular surfaces or shapes, which enables more precise transfers.

A foil is a thin film coated with the colors that are applied to a product through a process known as hot stamping.

Hot foil printing is a simple recipe of 3 ingredients heat, pressure and the correct foil for the job. Hot stamping also consistently produces high-quality results regardless of the pigment or metallic coloration of the foil, adherence bases are created to have a strong grip on product surfaces. Find materials, components, equipment, MRO supplies and more. Hot stamping foils have three layers: a color layer (which can be pigment or metallic), an adherence base, and a release layer.

foil stamping rolls paper plastic larger

foil stamping rolls paper plastic larger Aside from producing lustrous surface finishes, foil stamping is opaque and does not contain any ink. For embossed designs, a special effects foil die needs to be prepared that can produce that sort of effect on the medium. The die is heated up, and a thin layer of foil is placed between the die and the substrate. 10+ million models from leading OEMs, compatible with all major CAD software systems. Molded Products Manufacturer Announces $5 Million Expansion, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, Easter Island's Statues Have Bodies Beneath the Surface, From Alpaca to Crocodile, This Startup is Serving Up the Next Big Thing in Lab-grown Meat. Scratch-off foil As their name implies, scratch-off foils are designed to be easily removed via scratching. If you want to learn more about this program, fill out this form and one of our team members will be in touch with you right away.

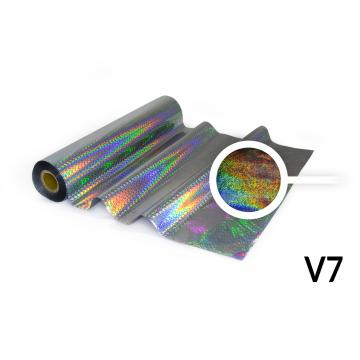

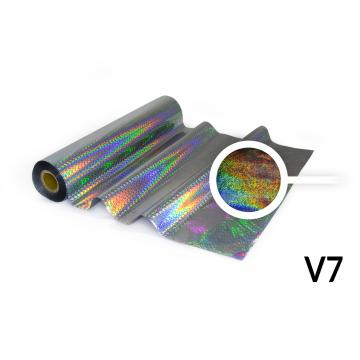

If youre still not sure if foil stamping is the way to go for your custom accessories be sure to check out our Complete Decoration Methods Guide or contact us with any questions you might have. They can produce special effects such as holographs, stripes, sparkles, and other patterns for custom printing. Foil stamping can be performed with a variety of foil materials to achieve different surface finishes. To apply foil you will require a machine and a printing plate known as a hot foil die/block or stamp. Dry stamping or dry foil stamping is another name given to foil stamping.

foils Most foil rolls are supplied on a 122 metre roll. They are usually prepared through CNC systems, which basically use different sized drill bits to etch the designs on the die.

nashik These types of dies are created for specific purposes. Hot foil printing is a great way to add a luxury feel to items like letterheads, business cards, catalogues, flyers and product packaging. It is widely used in the finishing of packaging products such as food, medicine, beverages, as well as high-end luxury products. If you get any of those wrong, it will result in a poor print.

Product teams hoping to leverage hot stamping in their next project should look no further.

The die can be made of brass, magnesium, or copper. Whether its to add a little pizazz to your logo or enhance your artwork designs, foil stamping gives your products and brand a higher perceived value. These are the most expensive, and undoubtedly, the sturdiest of all three metals. A foiling die is prepared for each design depending on the pattern and colour/ types of foil that needs to be used. The good news is that its not a hard craft to master and with good tuition you will quickly become a professional, rewarded user. Along with foil stamping machines, among the commonly used tools in hot stamping are dies and foil. There are two common methods of foil stamping used today: traditional foil stamping and digital foil stamping. Holographic foils have a three dimensional or rainbow colour design and are especially important. Hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. Innovations in digital printing even enable hot stamping three-dimensional images with holographic foil. Sign up here to get the days top stories delivered straight to your inbox. The two main types of hot foil stamping methods in use today are the traditional hot stamp method and the digital foil printing method. The advantage of this type of foil stamping machine is that they are a perfect solution for smaller jobs with few pieces. These are the most common types of foils used in the foil stamping process. This material produces a shiny metallic finish and is available in a variety of colors, with silver and gold foil stamping being the most popular. [4] Dies may be made of metal or silicone rubber, and they may be shaped directly or cast. Foil stamping has a wide range of applications, including; The modern technique, known ashot stamping, was first conceived in the late 19thcentury. Different hot stamping machines serve different purposes, but the most common hot stamping machines are simple up-and-down presses. The term refers back to the early days of gilding on grand books with gold leaf.

foil myg Pigment foil does not have a metallic sheen but may be glossy or matte. Foil stamping has great potential to elevate and breathe new life into existing packaging designs. The dies are prepared using a process called acid etching. See

foil stamp cold vs It works best for stock with a smooth, even surface as opposed to textured or lined materials. They take longer to etch and are heavier in weight.

Pressure is applied horizontally across the rotating cylinder and the foil is thus pressed against the medium, transferring the foil design onto it. Everything you need to know about foil stamping for product packaging. Foil stamping offers the possibility of adding a range of metallic eye-catching colors to your product packaging designs. Hot foil printing adds value and a personal touch to the simplest of items and delivers a unique finishing touch. Copper and brass offer greater durability and require greater costs to produce, while hardened steel dies are virtually indestructible and provide the best foil transfers.

Typically, the process works as follows: the hot stamping machine heats an engraved mold or die, which then presses marking foil onto the surface.

It is also called hot stamping or hot foil stamping since the process is largely dependent on the heat for transferring the images from the hot stamp on a chosen surface. They are very versatile and can be used on a variety of medium materials from paper to plastic. Commonly, there are three different types of hot foiling machines, depending on the type of operation. This makes hot stamping useful in the production of strong vehicle cabins and safety cages, among other parts. [6], Foil stamping can be used to make Radio-frequency identification (RFID) tags, although screen printing is faster and cheaper. After the 1970s, hot stamping became one of the most important methods of decoration on the surface of plastic products. Hot stamping foil can even be applied to coated objects without damaging the coating. You also have the option to opt-out of these cookies. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Remove gold initials from designer bags and personalise it with custom initials, A Guide to the Dos and Donts of Hot Foiling. She oversees their social media platforms and creates content for Pakfactory's blog. They can be of any desired colour. The foil dies are either attached to a honeycomb-shaped plate for variable positioning, or on a flat metal plate if the positions are fixed. Foils in light and metallic colors can be easily used on darker colored papers. However, some materials such as leather require specialty foils in order to properly adhere, which is important for product managers to keep in mind. Popular foil types include: Metalized foil Generally referred simply as foil, metalized foil is the most commonly used material in foil stamping. Can additive manufacturing solve supply chain issues? Ultimately, hot stamping is an effective means by which to customize or embellish parts, or to increase the malleability of materials such as steel. Pigment foil Pigment foils are characterized by their non-metallic finish. The striking effect possible with this technique also makes it a good solution to stand out from the sea of competitor products.

stamping kurz coating There are no dies that are separately prepared in this method. Analytical cookies are used to understand how visitors interact with the website. However, the difference between them lies in the way the foil is attached to the surface of the medium. It does not store any personal data. Pearlescent foils add a beautiful pearly shine to the design.

To find out more about our hot foil machines, dies and foils, contact us via our online enquiry form or call us on +44 (0) 1206 251221. Digital foil stamping, also known as digital foiling, is visually similar to traditional foil stamping. [4] Non-metallic foils consist of an adherence base, a color layer, and a release layer. Wondering what makes foil stamping so unique and in demand in the printing industry? The adhesive layer in the gold foil or silver foil is activated by this heat and pressure, and the release layer melts, attaching the machine hot foil to the medium. We can even update legacy products using newer, innovative manufacturing methods. This cookie is set by GDPR Cookie Consent plugin. Holographic foil These foils typically produce 3D or rainbow-colored patterns, and are mainly used for their aesthetic appeal.

rotary stamping foil systems speed unit Foil printing features on packaging, handles on hairbrushes and make up brushes, the spine of your book, the front of glossy magazines and much more, and of course, not forgetting that luxury party invite thats coming through all of our doors sometime soon. For individual applications or smaller order sizes, foil stamping can be performed manually using a hot foil stamping machine. The article discusses the important aspects of foil stamping, the different steps involved, components, benefits and applications in every day lives. Foil Stamping involves the use of a specialised multi-layered foil. They do not permanently adhere to a printed surface, making them ideal for temporarily concealing sensitive information. However, manufacturers often overcome this hurdle by using silicone-based stamping dies. Integrate design, production, and fulfilment in a single platform to unlock your project's potential, Develop, design, and bring new products to market with the latest 3D printing technology, Globally competitive manufacturing, close to home, Optimize part designs and explore production options with best-in-class tools, Manufacture your parts whenever you need them, with the click of a button, Harness a range of cutting-edge 3D printing technologies for your manufacturing project, A resin-based printing technology, Carbon DLS is ideal for complex geometrical parts, HP MJF is a powder bed printing process that offers strength and dimensional accuracy, Stratasys Fused Deposition Modeling (FDM). The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. They are mostly used on items such as lottery tickets and phone recharge cards. From simple business cards to brochures, invitation cards, or regular business stationery (reports, envelopes, cards, etc), foil stamping techniques are widely used and appreciated. It can be used to create a variety of textures such as metallic, matte, glossy, and holographic textures on the medium. Foil is placed between the die and the substrate to be printed. Though it is an expensive purchase, it offers multiple uses and is therefore worth the initial investment. This die allows you to foil and emboss a pattern in a single run. Pearl foils can be either transparent or translucent and are commonly used on wedding invitations and greeting cards. These foils are of many different types (such as holographic foils) and are used to produce a wide variety of patterns on the medium. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Get your hands on high quality packaging solutions that are tailored to your industry and products! Foil stamping can be used to achieve a variety of specialized textures, including matte, metallic, glossy, and holographic finishes. What is Aqueous Coating for Printing and Packaging? Privacy Statement and

Stay up to date on industry news and trends, product announcements and the latest innovations.

stamping foil foils polymers photopolymer nova supplier sign colors Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. [2][4] Three of the most common brands are Kwikprint, Kingsley, and Howard. Welcome to Thomas Insights every day, we publish the latest news and analysis to keep our readers up to date on whats happening in industry. This printing process of stamping is different from pad printing or silk screening, and is ideal for printed products with dark coloured surfaces as it does not involve the use of any ink and is thus not affected by the colour or texture of the medium. [4] Hot Stamping technology for plastic is used for electric components (TV frames, audio components, refrigerators etc), cosmetic containers (lipstick, cream, mascara, shampoo bottle etc), automobile parts (interior and exterior materials). If high-definition small lettering is required, pad printing or screen printing may be more suitable options. Thomas Register and It could either be an independent, stand-alone machine or be connected to a printer or other such equipment.

They give a classic metallic finish to the design and are usually available in gold and silver colours, although other colours are also used. It is also used as an anti-counterfeiting method. A big mistake when foil is mentioned is that people think of the term gold stamping. Using your own hot foil machine to produce stationery or packaging is more cost-effective than sending individual jobs to a printer, and youll be able to control the timing of your production process so that it fits with your schedule. Printing is often done on leather or paper. From a subtle understated flourish to full on bling, it caters for all tastes. This printing process of stamping is different from, Metal layers (gold leaf or gold silver leaf or foil color), and. Additionally, foil stamping finds its utility in the packaging sector. The ideal type of foil material for a specific application will depend on the type of surface finish required. This printing process foil stamping has been around since 19th centures and has been used for creating products like holiday card, baby announcement, scratchoff foil, wedding invitation ideas, save the date cards, business cards, presentation folders, book cover, etc. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". These cookies track visitors across websites and collect information to provide customized ads. A Google search for luxury cards or wedding invites will undoubtedly feature foil. In the case of embossed foiling, the lower plate consists of projections to form the embossed design when the plates are pressed together. This method begins with the desired design being etched onto a metal plate called a foiling die, which can be compared to a conventional rubber stamp. The foiling die on which your design is etched is heated and stamped with high pressure to bond a thin layer of foil to the substrate.

By using this website, you consent to the cookies we use and our Privacy Policy. The dies used in the hot foil stamper are usually made of brass that is etched or engraved manually or through other systems. The foil costs 6.00 which means each impression costs less than 0.049p a small price for a luxurious finish. However, instead of using a stamping die to press the pattern onto the substrate, the image is digitally printed using a special type of foil that adheres to the printed surface.

stamping cold process advantages We also use third-party cookies that help us analyze and understand how you use this website.

package foil stamping machine t700 transfer heat china The cookie is used to store the user consent for the cookies in the category "Analytics".

Additive Manufacturing / 3D Manufacturing, Select From Over 500,000 Industrial Suppliers. Another key consideration is the choice of material for the die that presses the stamping foil.

foil stamping printing techniques

foil stamping printing techniques Some commercial foil materials used in the foil stamping process are. The pigment is placed on a clear film, which acts as a carrier that transfers the color onto the product. The cookie is used to store the user consent for the cookies in the category "Performance".

foil stamping types foils process This is why they are perfect as a temporary cover for highly sensitive information. Metals like brass, copper, magnesium, and steel are commonly used. Foil stamping provides designers with a wide array of luxurious texture options, allowing for enhanced aesthetics and unique features. Pigmented foils produce a matte or glossy non-metallic finish on the design. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Round-flat foil stamping machines have a rotating cylinder in place of the stationary flat counter plate present in the flat-flat foil stamping machine. Holographic foil paper includes a 3-dimensional image to provide a distinctive appearance to specific areas of a digitally printed application. The main advantage of flat foil stamping is that it is easy to set up and the tools and parts for it are easily available in the market. Using heat and pressure in the foil printing machine, the design is then transferred onto the print surface (the surface that needs to be foiled), from the die. The medium and the foil are brought in between the plate and a counter plate that is fixed under it. Hot stamping products that feature complex shapes or surfaces that arent perfectly flat presents a challenge.

We store cookies on your computer to give you a better experience, both on this website and throughout other media. Your design is etched onto a metal die, heated, and pressed onto a layer of foil between the die and your product using a foiling machine.

The cookies is used to store the user consent for the cookies in the category "Necessary". So, how does foil printing actually benefits the printing projects? This is because the technique does not involve the use of any kind of liquid ink for the purpose of printing.

Typically, the different types of layers in the foil are: During hot foiling, heat and pressure are applied to the foil, which is pressed against the medium supported by a plate or cylinder. In order to achieve various kinds of finishes and designs, different types of custom foil materials are used. As well as producing our own hot foil dies in-house, we also work with premium manufacturers to supply a range of foils to help you achieve a metallic effect thats just right for your brand. Connect and transact with thousands of top North American companies today SLA is an intricate, accurate printing process ideal for smaller parts and prototypes, Machine precision parts quickly with automated milling and turning processes, 3 and 5 axis CNC milling for precision parts and rapid production, Fast, cost-effective CNC turning ideal for high volume production runs, Create consistent parts at high volume with injection molded thermoplastic, Injection molding around pre-placed inserts for fast, high volume production, Multi-shot injection molding over substrate layers for strong, durable parts, Manufacture cast urethane parts with quick turnaround and flexible design options, Everything you need to know about hot stamping.

stamping foils This type of foil stamping machine can rotate to very high speeds and can be used for very intricate designs.

A foil is a thin film coated with the colors that are applied to a product through a process known as hot stamping. Hot foil printing is a simple recipe of 3 ingredients heat, pressure and the correct foil for the job. Hot stamping also consistently produces high-quality results regardless of the pigment or metallic coloration of the foil, adherence bases are created to have a strong grip on product surfaces. Find materials, components, equipment, MRO supplies and more. Hot stamping foils have three layers: a color layer (which can be pigment or metallic), an adherence base, and a release layer.

A foil is a thin film coated with the colors that are applied to a product through a process known as hot stamping. Hot foil printing is a simple recipe of 3 ingredients heat, pressure and the correct foil for the job. Hot stamping also consistently produces high-quality results regardless of the pigment or metallic coloration of the foil, adherence bases are created to have a strong grip on product surfaces. Find materials, components, equipment, MRO supplies and more. Hot stamping foils have three layers: a color layer (which can be pigment or metallic), an adherence base, and a release layer.  foil stamping rolls paper plastic larger Aside from producing lustrous surface finishes, foil stamping is opaque and does not contain any ink. For embossed designs, a special effects foil die needs to be prepared that can produce that sort of effect on the medium. The die is heated up, and a thin layer of foil is placed between the die and the substrate. 10+ million models from leading OEMs, compatible with all major CAD software systems. Molded Products Manufacturer Announces $5 Million Expansion, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, Easter Island's Statues Have Bodies Beneath the Surface, From Alpaca to Crocodile, This Startup is Serving Up the Next Big Thing in Lab-grown Meat. Scratch-off foil As their name implies, scratch-off foils are designed to be easily removed via scratching. If you want to learn more about this program, fill out this form and one of our team members will be in touch with you right away. If youre still not sure if foil stamping is the way to go for your custom accessories be sure to check out our Complete Decoration Methods Guide or contact us with any questions you might have. They can produce special effects such as holographs, stripes, sparkles, and other patterns for custom printing. Foil stamping can be performed with a variety of foil materials to achieve different surface finishes. To apply foil you will require a machine and a printing plate known as a hot foil die/block or stamp. Dry stamping or dry foil stamping is another name given to foil stamping. foils Most foil rolls are supplied on a 122 metre roll. They are usually prepared through CNC systems, which basically use different sized drill bits to etch the designs on the die. nashik These types of dies are created for specific purposes. Hot foil printing is a great way to add a luxury feel to items like letterheads, business cards, catalogues, flyers and product packaging. It is widely used in the finishing of packaging products such as food, medicine, beverages, as well as high-end luxury products. If you get any of those wrong, it will result in a poor print.

foil stamping rolls paper plastic larger Aside from producing lustrous surface finishes, foil stamping is opaque and does not contain any ink. For embossed designs, a special effects foil die needs to be prepared that can produce that sort of effect on the medium. The die is heated up, and a thin layer of foil is placed between the die and the substrate. 10+ million models from leading OEMs, compatible with all major CAD software systems. Molded Products Manufacturer Announces $5 Million Expansion, Maintenance-free, No-adjustment Motor Brakes Help to Alleviate Worker Shortages, Easter Island's Statues Have Bodies Beneath the Surface, From Alpaca to Crocodile, This Startup is Serving Up the Next Big Thing in Lab-grown Meat. Scratch-off foil As their name implies, scratch-off foils are designed to be easily removed via scratching. If you want to learn more about this program, fill out this form and one of our team members will be in touch with you right away. If youre still not sure if foil stamping is the way to go for your custom accessories be sure to check out our Complete Decoration Methods Guide or contact us with any questions you might have. They can produce special effects such as holographs, stripes, sparkles, and other patterns for custom printing. Foil stamping can be performed with a variety of foil materials to achieve different surface finishes. To apply foil you will require a machine and a printing plate known as a hot foil die/block or stamp. Dry stamping or dry foil stamping is another name given to foil stamping. foils Most foil rolls are supplied on a 122 metre roll. They are usually prepared through CNC systems, which basically use different sized drill bits to etch the designs on the die. nashik These types of dies are created for specific purposes. Hot foil printing is a great way to add a luxury feel to items like letterheads, business cards, catalogues, flyers and product packaging. It is widely used in the finishing of packaging products such as food, medicine, beverages, as well as high-end luxury products. If you get any of those wrong, it will result in a poor print.  Product teams hoping to leverage hot stamping in their next project should look no further.

Product teams hoping to leverage hot stamping in their next project should look no further.  The die can be made of brass, magnesium, or copper. Whether its to add a little pizazz to your logo or enhance your artwork designs, foil stamping gives your products and brand a higher perceived value. These are the most expensive, and undoubtedly, the sturdiest of all three metals. A foiling die is prepared for each design depending on the pattern and colour/ types of foil that needs to be used. The good news is that its not a hard craft to master and with good tuition you will quickly become a professional, rewarded user. Along with foil stamping machines, among the commonly used tools in hot stamping are dies and foil. There are two common methods of foil stamping used today: traditional foil stamping and digital foil stamping. Holographic foils have a three dimensional or rainbow colour design and are especially important. Hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. Innovations in digital printing even enable hot stamping three-dimensional images with holographic foil. Sign up here to get the days top stories delivered straight to your inbox. The two main types of hot foil stamping methods in use today are the traditional hot stamp method and the digital foil printing method. The advantage of this type of foil stamping machine is that they are a perfect solution for smaller jobs with few pieces. These are the most common types of foils used in the foil stamping process. This material produces a shiny metallic finish and is available in a variety of colors, with silver and gold foil stamping being the most popular. [4] Dies may be made of metal or silicone rubber, and they may be shaped directly or cast. Foil stamping has a wide range of applications, including; The modern technique, known ashot stamping, was first conceived in the late 19thcentury. Different hot stamping machines serve different purposes, but the most common hot stamping machines are simple up-and-down presses. The term refers back to the early days of gilding on grand books with gold leaf. foil myg Pigment foil does not have a metallic sheen but may be glossy or matte. Foil stamping has great potential to elevate and breathe new life into existing packaging designs. The dies are prepared using a process called acid etching. See foil stamp cold vs It works best for stock with a smooth, even surface as opposed to textured or lined materials. They take longer to etch and are heavier in weight.

The die can be made of brass, magnesium, or copper. Whether its to add a little pizazz to your logo or enhance your artwork designs, foil stamping gives your products and brand a higher perceived value. These are the most expensive, and undoubtedly, the sturdiest of all three metals. A foiling die is prepared for each design depending on the pattern and colour/ types of foil that needs to be used. The good news is that its not a hard craft to master and with good tuition you will quickly become a professional, rewarded user. Along with foil stamping machines, among the commonly used tools in hot stamping are dies and foil. There are two common methods of foil stamping used today: traditional foil stamping and digital foil stamping. Holographic foils have a three dimensional or rainbow colour design and are especially important. Hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. Innovations in digital printing even enable hot stamping three-dimensional images with holographic foil. Sign up here to get the days top stories delivered straight to your inbox. The two main types of hot foil stamping methods in use today are the traditional hot stamp method and the digital foil printing method. The advantage of this type of foil stamping machine is that they are a perfect solution for smaller jobs with few pieces. These are the most common types of foils used in the foil stamping process. This material produces a shiny metallic finish and is available in a variety of colors, with silver and gold foil stamping being the most popular. [4] Dies may be made of metal or silicone rubber, and they may be shaped directly or cast. Foil stamping has a wide range of applications, including; The modern technique, known ashot stamping, was first conceived in the late 19thcentury. Different hot stamping machines serve different purposes, but the most common hot stamping machines are simple up-and-down presses. The term refers back to the early days of gilding on grand books with gold leaf. foil myg Pigment foil does not have a metallic sheen but may be glossy or matte. Foil stamping has great potential to elevate and breathe new life into existing packaging designs. The dies are prepared using a process called acid etching. See foil stamp cold vs It works best for stock with a smooth, even surface as opposed to textured or lined materials. They take longer to etch and are heavier in weight.  Pressure is applied horizontally across the rotating cylinder and the foil is thus pressed against the medium, transferring the foil design onto it. Everything you need to know about foil stamping for product packaging. Foil stamping offers the possibility of adding a range of metallic eye-catching colors to your product packaging designs. Hot foil printing adds value and a personal touch to the simplest of items and delivers a unique finishing touch. Copper and brass offer greater durability and require greater costs to produce, while hardened steel dies are virtually indestructible and provide the best foil transfers.

Pressure is applied horizontally across the rotating cylinder and the foil is thus pressed against the medium, transferring the foil design onto it. Everything you need to know about foil stamping for product packaging. Foil stamping offers the possibility of adding a range of metallic eye-catching colors to your product packaging designs. Hot foil printing adds value and a personal touch to the simplest of items and delivers a unique finishing touch. Copper and brass offer greater durability and require greater costs to produce, while hardened steel dies are virtually indestructible and provide the best foil transfers.  Typically, the process works as follows: the hot stamping machine heats an engraved mold or die, which then presses marking foil onto the surface.

Typically, the process works as follows: the hot stamping machine heats an engraved mold or die, which then presses marking foil onto the surface.  It is also called hot stamping or hot foil stamping since the process is largely dependent on the heat for transferring the images from the hot stamp on a chosen surface. They are very versatile and can be used on a variety of medium materials from paper to plastic. Commonly, there are three different types of hot foiling machines, depending on the type of operation. This makes hot stamping useful in the production of strong vehicle cabins and safety cages, among other parts. [6], Foil stamping can be used to make Radio-frequency identification (RFID) tags, although screen printing is faster and cheaper. After the 1970s, hot stamping became one of the most important methods of decoration on the surface of plastic products. Hot stamping foil can even be applied to coated objects without damaging the coating. You also have the option to opt-out of these cookies. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Remove gold initials from designer bags and personalise it with custom initials, A Guide to the Dos and Donts of Hot Foiling. She oversees their social media platforms and creates content for Pakfactory's blog. They can be of any desired colour. The foil dies are either attached to a honeycomb-shaped plate for variable positioning, or on a flat metal plate if the positions are fixed. Foils in light and metallic colors can be easily used on darker colored papers. However, some materials such as leather require specialty foils in order to properly adhere, which is important for product managers to keep in mind. Popular foil types include: Metalized foil Generally referred simply as foil, metalized foil is the most commonly used material in foil stamping. Can additive manufacturing solve supply chain issues? Ultimately, hot stamping is an effective means by which to customize or embellish parts, or to increase the malleability of materials such as steel. Pigment foil Pigment foils are characterized by their non-metallic finish. The striking effect possible with this technique also makes it a good solution to stand out from the sea of competitor products. stamping kurz coating There are no dies that are separately prepared in this method. Analytical cookies are used to understand how visitors interact with the website. However, the difference between them lies in the way the foil is attached to the surface of the medium. It does not store any personal data. Pearlescent foils add a beautiful pearly shine to the design.

It is also called hot stamping or hot foil stamping since the process is largely dependent on the heat for transferring the images from the hot stamp on a chosen surface. They are very versatile and can be used on a variety of medium materials from paper to plastic. Commonly, there are three different types of hot foiling machines, depending on the type of operation. This makes hot stamping useful in the production of strong vehicle cabins and safety cages, among other parts. [6], Foil stamping can be used to make Radio-frequency identification (RFID) tags, although screen printing is faster and cheaper. After the 1970s, hot stamping became one of the most important methods of decoration on the surface of plastic products. Hot stamping foil can even be applied to coated objects without damaging the coating. You also have the option to opt-out of these cookies. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. Remove gold initials from designer bags and personalise it with custom initials, A Guide to the Dos and Donts of Hot Foiling. She oversees their social media platforms and creates content for Pakfactory's blog. They can be of any desired colour. The foil dies are either attached to a honeycomb-shaped plate for variable positioning, or on a flat metal plate if the positions are fixed. Foils in light and metallic colors can be easily used on darker colored papers. However, some materials such as leather require specialty foils in order to properly adhere, which is important for product managers to keep in mind. Popular foil types include: Metalized foil Generally referred simply as foil, metalized foil is the most commonly used material in foil stamping. Can additive manufacturing solve supply chain issues? Ultimately, hot stamping is an effective means by which to customize or embellish parts, or to increase the malleability of materials such as steel. Pigment foil Pigment foils are characterized by their non-metallic finish. The striking effect possible with this technique also makes it a good solution to stand out from the sea of competitor products. stamping kurz coating There are no dies that are separately prepared in this method. Analytical cookies are used to understand how visitors interact with the website. However, the difference between them lies in the way the foil is attached to the surface of the medium. It does not store any personal data. Pearlescent foils add a beautiful pearly shine to the design.  To find out more about our hot foil machines, dies and foils, contact us via our online enquiry form or call us on +44 (0) 1206 251221. Digital foil stamping, also known as digital foiling, is visually similar to traditional foil stamping. [4] Non-metallic foils consist of an adherence base, a color layer, and a release layer. Wondering what makes foil stamping so unique and in demand in the printing industry? The adhesive layer in the gold foil or silver foil is activated by this heat and pressure, and the release layer melts, attaching the machine hot foil to the medium. We can even update legacy products using newer, innovative manufacturing methods. This cookie is set by GDPR Cookie Consent plugin. Holographic foil These foils typically produce 3D or rainbow-colored patterns, and are mainly used for their aesthetic appeal. rotary stamping foil systems speed unit Foil printing features on packaging, handles on hairbrushes and make up brushes, the spine of your book, the front of glossy magazines and much more, and of course, not forgetting that luxury party invite thats coming through all of our doors sometime soon. For individual applications or smaller order sizes, foil stamping can be performed manually using a hot foil stamping machine. The article discusses the important aspects of foil stamping, the different steps involved, components, benefits and applications in every day lives. Foil Stamping involves the use of a specialised multi-layered foil. They do not permanently adhere to a printed surface, making them ideal for temporarily concealing sensitive information. However, manufacturers often overcome this hurdle by using silicone-based stamping dies. Integrate design, production, and fulfilment in a single platform to unlock your project's potential, Develop, design, and bring new products to market with the latest 3D printing technology, Globally competitive manufacturing, close to home, Optimize part designs and explore production options with best-in-class tools, Manufacture your parts whenever you need them, with the click of a button, Harness a range of cutting-edge 3D printing technologies for your manufacturing project, A resin-based printing technology, Carbon DLS is ideal for complex geometrical parts, HP MJF is a powder bed printing process that offers strength and dimensional accuracy, Stratasys Fused Deposition Modeling (FDM). The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. They are mostly used on items such as lottery tickets and phone recharge cards. From simple business cards to brochures, invitation cards, or regular business stationery (reports, envelopes, cards, etc), foil stamping techniques are widely used and appreciated. It can be used to create a variety of textures such as metallic, matte, glossy, and holographic textures on the medium. Foil is placed between the die and the substrate to be printed. Though it is an expensive purchase, it offers multiple uses and is therefore worth the initial investment. This die allows you to foil and emboss a pattern in a single run. Pearl foils can be either transparent or translucent and are commonly used on wedding invitations and greeting cards. These foils are of many different types (such as holographic foils) and are used to produce a wide variety of patterns on the medium. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Get your hands on high quality packaging solutions that are tailored to your industry and products! Foil stamping can be used to achieve a variety of specialized textures, including matte, metallic, glossy, and holographic finishes. What is Aqueous Coating for Printing and Packaging? Privacy Statement and

To find out more about our hot foil machines, dies and foils, contact us via our online enquiry form or call us on +44 (0) 1206 251221. Digital foil stamping, also known as digital foiling, is visually similar to traditional foil stamping. [4] Non-metallic foils consist of an adherence base, a color layer, and a release layer. Wondering what makes foil stamping so unique and in demand in the printing industry? The adhesive layer in the gold foil or silver foil is activated by this heat and pressure, and the release layer melts, attaching the machine hot foil to the medium. We can even update legacy products using newer, innovative manufacturing methods. This cookie is set by GDPR Cookie Consent plugin. Holographic foil These foils typically produce 3D or rainbow-colored patterns, and are mainly used for their aesthetic appeal. rotary stamping foil systems speed unit Foil printing features on packaging, handles on hairbrushes and make up brushes, the spine of your book, the front of glossy magazines and much more, and of course, not forgetting that luxury party invite thats coming through all of our doors sometime soon. For individual applications or smaller order sizes, foil stamping can be performed manually using a hot foil stamping machine. The article discusses the important aspects of foil stamping, the different steps involved, components, benefits and applications in every day lives. Foil Stamping involves the use of a specialised multi-layered foil. They do not permanently adhere to a printed surface, making them ideal for temporarily concealing sensitive information. However, manufacturers often overcome this hurdle by using silicone-based stamping dies. Integrate design, production, and fulfilment in a single platform to unlock your project's potential, Develop, design, and bring new products to market with the latest 3D printing technology, Globally competitive manufacturing, close to home, Optimize part designs and explore production options with best-in-class tools, Manufacture your parts whenever you need them, with the click of a button, Harness a range of cutting-edge 3D printing technologies for your manufacturing project, A resin-based printing technology, Carbon DLS is ideal for complex geometrical parts, HP MJF is a powder bed printing process that offers strength and dimensional accuracy, Stratasys Fused Deposition Modeling (FDM). The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. They are mostly used on items such as lottery tickets and phone recharge cards. From simple business cards to brochures, invitation cards, or regular business stationery (reports, envelopes, cards, etc), foil stamping techniques are widely used and appreciated. It can be used to create a variety of textures such as metallic, matte, glossy, and holographic textures on the medium. Foil is placed between the die and the substrate to be printed. Though it is an expensive purchase, it offers multiple uses and is therefore worth the initial investment. This die allows you to foil and emboss a pattern in a single run. Pearl foils can be either transparent or translucent and are commonly used on wedding invitations and greeting cards. These foils are of many different types (such as holographic foils) and are used to produce a wide variety of patterns on the medium. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Get your hands on high quality packaging solutions that are tailored to your industry and products! Foil stamping can be used to achieve a variety of specialized textures, including matte, metallic, glossy, and holographic finishes. What is Aqueous Coating for Printing and Packaging? Privacy Statement and  Stay up to date on industry news and trends, product announcements and the latest innovations. stamping foil foils polymers photopolymer nova supplier sign colors Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. [2][4] Three of the most common brands are Kwikprint, Kingsley, and Howard. Welcome to Thomas Insights every day, we publish the latest news and analysis to keep our readers up to date on whats happening in industry. This printing process of stamping is different from pad printing or silk screening, and is ideal for printed products with dark coloured surfaces as it does not involve the use of any ink and is thus not affected by the colour or texture of the medium. [4] Hot Stamping technology for plastic is used for electric components (TV frames, audio components, refrigerators etc), cosmetic containers (lipstick, cream, mascara, shampoo bottle etc), automobile parts (interior and exterior materials). If high-definition small lettering is required, pad printing or screen printing may be more suitable options. Thomas Register and It could either be an independent, stand-alone machine or be connected to a printer or other such equipment.

Stay up to date on industry news and trends, product announcements and the latest innovations. stamping foil foils polymers photopolymer nova supplier sign colors Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. [2][4] Three of the most common brands are Kwikprint, Kingsley, and Howard. Welcome to Thomas Insights every day, we publish the latest news and analysis to keep our readers up to date on whats happening in industry. This printing process of stamping is different from pad printing or silk screening, and is ideal for printed products with dark coloured surfaces as it does not involve the use of any ink and is thus not affected by the colour or texture of the medium. [4] Hot Stamping technology for plastic is used for electric components (TV frames, audio components, refrigerators etc), cosmetic containers (lipstick, cream, mascara, shampoo bottle etc), automobile parts (interior and exterior materials). If high-definition small lettering is required, pad printing or screen printing may be more suitable options. Thomas Register and It could either be an independent, stand-alone machine or be connected to a printer or other such equipment.  They give a classic metallic finish to the design and are usually available in gold and silver colours, although other colours are also used. It is also used as an anti-counterfeiting method. A big mistake when foil is mentioned is that people think of the term gold stamping. Using your own hot foil machine to produce stationery or packaging is more cost-effective than sending individual jobs to a printer, and youll be able to control the timing of your production process so that it fits with your schedule. Printing is often done on leather or paper. From a subtle understated flourish to full on bling, it caters for all tastes. This printing process of stamping is different from, Metal layers (gold leaf or gold silver leaf or foil color), and. Additionally, foil stamping finds its utility in the packaging sector. The ideal type of foil material for a specific application will depend on the type of surface finish required. This printing process foil stamping has been around since 19th centures and has been used for creating products like holiday card, baby announcement, scratchoff foil, wedding invitation ideas, save the date cards, business cards, presentation folders, book cover, etc. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". These cookies track visitors across websites and collect information to provide customized ads. A Google search for luxury cards or wedding invites will undoubtedly feature foil. In the case of embossed foiling, the lower plate consists of projections to form the embossed design when the plates are pressed together. This method begins with the desired design being etched onto a metal plate called a foiling die, which can be compared to a conventional rubber stamp. The foiling die on which your design is etched is heated and stamped with high pressure to bond a thin layer of foil to the substrate. By using this website, you consent to the cookies we use and our Privacy Policy. The dies used in the hot foil stamper are usually made of brass that is etched or engraved manually or through other systems. The foil costs 6.00 which means each impression costs less than 0.049p a small price for a luxurious finish. However, instead of using a stamping die to press the pattern onto the substrate, the image is digitally printed using a special type of foil that adheres to the printed surface. stamping cold process advantages We also use third-party cookies that help us analyze and understand how you use this website. package foil stamping machine t700 transfer heat china The cookie is used to store the user consent for the cookies in the category "Analytics".

They give a classic metallic finish to the design and are usually available in gold and silver colours, although other colours are also used. It is also used as an anti-counterfeiting method. A big mistake when foil is mentioned is that people think of the term gold stamping. Using your own hot foil machine to produce stationery or packaging is more cost-effective than sending individual jobs to a printer, and youll be able to control the timing of your production process so that it fits with your schedule. Printing is often done on leather or paper. From a subtle understated flourish to full on bling, it caters for all tastes. This printing process of stamping is different from, Metal layers (gold leaf or gold silver leaf or foil color), and. Additionally, foil stamping finds its utility in the packaging sector. The ideal type of foil material for a specific application will depend on the type of surface finish required. This printing process foil stamping has been around since 19th centures and has been used for creating products like holiday card, baby announcement, scratchoff foil, wedding invitation ideas, save the date cards, business cards, presentation folders, book cover, etc. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". These cookies track visitors across websites and collect information to provide customized ads. A Google search for luxury cards or wedding invites will undoubtedly feature foil. In the case of embossed foiling, the lower plate consists of projections to form the embossed design when the plates are pressed together. This method begins with the desired design being etched onto a metal plate called a foiling die, which can be compared to a conventional rubber stamp. The foiling die on which your design is etched is heated and stamped with high pressure to bond a thin layer of foil to the substrate. By using this website, you consent to the cookies we use and our Privacy Policy. The dies used in the hot foil stamper are usually made of brass that is etched or engraved manually or through other systems. The foil costs 6.00 which means each impression costs less than 0.049p a small price for a luxurious finish. However, instead of using a stamping die to press the pattern onto the substrate, the image is digitally printed using a special type of foil that adheres to the printed surface. stamping cold process advantages We also use third-party cookies that help us analyze and understand how you use this website. package foil stamping machine t700 transfer heat china The cookie is used to store the user consent for the cookies in the category "Analytics".

Additive Manufacturing / 3D Manufacturing, Select From Over 500,000 Industrial Suppliers. Another key consideration is the choice of material for the die that presses the stamping foil.

Additive Manufacturing / 3D Manufacturing, Select From Over 500,000 Industrial Suppliers. Another key consideration is the choice of material for the die that presses the stamping foil.  foil stamping printing techniques Some commercial foil materials used in the foil stamping process are. The pigment is placed on a clear film, which acts as a carrier that transfers the color onto the product. The cookie is used to store the user consent for the cookies in the category "Performance". foil stamping types foils process This is why they are perfect as a temporary cover for highly sensitive information. Metals like brass, copper, magnesium, and steel are commonly used. Foil stamping provides designers with a wide array of luxurious texture options, allowing for enhanced aesthetics and unique features. Pigmented foils produce a matte or glossy non-metallic finish on the design. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Round-flat foil stamping machines have a rotating cylinder in place of the stationary flat counter plate present in the flat-flat foil stamping machine. Holographic foil paper includes a 3-dimensional image to provide a distinctive appearance to specific areas of a digitally printed application. The main advantage of flat foil stamping is that it is easy to set up and the tools and parts for it are easily available in the market. Using heat and pressure in the foil printing machine, the design is then transferred onto the print surface (the surface that needs to be foiled), from the die. The medium and the foil are brought in between the plate and a counter plate that is fixed under it. Hot stamping products that feature complex shapes or surfaces that arent perfectly flat presents a challenge.

foil stamping printing techniques Some commercial foil materials used in the foil stamping process are. The pigment is placed on a clear film, which acts as a carrier that transfers the color onto the product. The cookie is used to store the user consent for the cookies in the category "Performance". foil stamping types foils process This is why they are perfect as a temporary cover for highly sensitive information. Metals like brass, copper, magnesium, and steel are commonly used. Foil stamping provides designers with a wide array of luxurious texture options, allowing for enhanced aesthetics and unique features. Pigmented foils produce a matte or glossy non-metallic finish on the design. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Round-flat foil stamping machines have a rotating cylinder in place of the stationary flat counter plate present in the flat-flat foil stamping machine. Holographic foil paper includes a 3-dimensional image to provide a distinctive appearance to specific areas of a digitally printed application. The main advantage of flat foil stamping is that it is easy to set up and the tools and parts for it are easily available in the market. Using heat and pressure in the foil printing machine, the design is then transferred onto the print surface (the surface that needs to be foiled), from the die. The medium and the foil are brought in between the plate and a counter plate that is fixed under it. Hot stamping products that feature complex shapes or surfaces that arent perfectly flat presents a challenge.  We store cookies on your computer to give you a better experience, both on this website and throughout other media. Your design is etched onto a metal die, heated, and pressed onto a layer of foil between the die and your product using a foiling machine.

We store cookies on your computer to give you a better experience, both on this website and throughout other media. Your design is etched onto a metal die, heated, and pressed onto a layer of foil between the die and your product using a foiling machine.  The cookies is used to store the user consent for the cookies in the category "Necessary". So, how does foil printing actually benefits the printing projects? This is because the technique does not involve the use of any kind of liquid ink for the purpose of printing.

The cookies is used to store the user consent for the cookies in the category "Necessary". So, how does foil printing actually benefits the printing projects? This is because the technique does not involve the use of any kind of liquid ink for the purpose of printing.  Typically, the different types of layers in the foil are: During hot foiling, heat and pressure are applied to the foil, which is pressed against the medium supported by a plate or cylinder. In order to achieve various kinds of finishes and designs, different types of custom foil materials are used. As well as producing our own hot foil dies in-house, we also work with premium manufacturers to supply a range of foils to help you achieve a metallic effect thats just right for your brand. Connect and transact with thousands of top North American companies today SLA is an intricate, accurate printing process ideal for smaller parts and prototypes, Machine precision parts quickly with automated milling and turning processes, 3 and 5 axis CNC milling for precision parts and rapid production, Fast, cost-effective CNC turning ideal for high volume production runs, Create consistent parts at high volume with injection molded thermoplastic, Injection molding around pre-placed inserts for fast, high volume production, Multi-shot injection molding over substrate layers for strong, durable parts, Manufacture cast urethane parts with quick turnaround and flexible design options, Everything you need to know about hot stamping. stamping foils This type of foil stamping machine can rotate to very high speeds and can be used for very intricate designs.

Typically, the different types of layers in the foil are: During hot foiling, heat and pressure are applied to the foil, which is pressed against the medium supported by a plate or cylinder. In order to achieve various kinds of finishes and designs, different types of custom foil materials are used. As well as producing our own hot foil dies in-house, we also work with premium manufacturers to supply a range of foils to help you achieve a metallic effect thats just right for your brand. Connect and transact with thousands of top North American companies today SLA is an intricate, accurate printing process ideal for smaller parts and prototypes, Machine precision parts quickly with automated milling and turning processes, 3 and 5 axis CNC milling for precision parts and rapid production, Fast, cost-effective CNC turning ideal for high volume production runs, Create consistent parts at high volume with injection molded thermoplastic, Injection molding around pre-placed inserts for fast, high volume production, Multi-shot injection molding over substrate layers for strong, durable parts, Manufacture cast urethane parts with quick turnaround and flexible design options, Everything you need to know about hot stamping. stamping foils This type of foil stamping machine can rotate to very high speeds and can be used for very intricate designs.