The concrete or gypsum parts can be painted and decorated afterwards, so that you get gates, bridge pillars or house facades in this way. This is the only way to ensure that the silicone does not flow out into possible cracks or underneath edges during pouring. While the first version used a silicone putty to make an impression mold, the second using a pourable/brush-able liquid silicone to make a mold. The smoothOn duplicating silicone is our favorite, as the material is extremely elastic and with Shore A 20 hardness is perfectly suited to reproduce even the most demanding shapes. For example, if you want to make Petri Dishes, you can colour round silicone molds. Why are Silicone Molds the best Choice for Resin Casting? The liquid pourable/brushable silicone rubber is for blanket, glove, or block molds. Make sure that the mass is evenly distributed everywhere. Anything is possible and can be filled with epoxy resin to create beautiful works of art or gifts. Note: The instructions for the EasyMold Silicone Putty do say that molds used repeatedly may accumulate a buildup of material from castings. In addition, as already mentioned, many molds are available. To test out my mold, I used a two-part epoxy resin colored with a light pink mica dye powder. This product is also water-resistant, almost odorless, and produces no VOCs. Your self-made frame has to be absolutely tight.

l7 epoxy Anything is possible and can be filled with epoxy resin to create beautiful works of art or gifts. The range of molds already available on the market is wide, because theoretically baking molds can also be used for resin art. I wanted to choose something a bit more difficult to make a mold of because Im a glutton for punishment. thin or thick silicone. The finished resin objects can be easily removed from the mold after curing due to the flexibility of the silicone. The softer the material, the easier it is to release the workpiece from the mold. I also used a heat gun to pop the bubbles and ensure it cured without any imperfections. Another advantage is that silicone is considered non-toxic.

So I mixxed up my two-part silicone first. This is due to its low exothermic rate, which means that it produces less heat as it cures. With Epoxy Resin, you can create your personalized tumbler. With a simple 1:1 mixing ratio, this low-viscosity liquid can be mixed and poured with the utmost ease. It really is easy to use, too. You should mix the components together thoroughly for 5 minutes, after which you will have another 5 minutes with which to mold and shape the silicone. In this case it is advisable to make a two piece or even multi piece mold.

Then I took a knife and cut out around the snowflake just to make the mold look a bit more professional. You should flatten the putty based on the depth of the impression youll need. If you are asking the, Read More How Long Does Polyurethane Take to Dry? Want more resin projects?

Quickly mix the two parts of silicone together. Common silicone molds are easily available on the market. In this way you can also easily remove the finished work piece later.

a dull surface, are quickly visible. Depending on the project, you can choose between thick or thin silicone rubber. If you use a self-made casting mold made of silicone, you are completely free in your design possibilities.

You can then add various elements such as glitter, stones, shells, flowers, etc. But what if you lack the molds for your project and they are not available on the market? Use vinyl or nitrile gloves. For beginners especially these molds are well suited to try out. Because they practically do not deform at all. This post may contain affiliate links. If your child is fascinated by your favourite piece of jewellery, you can create a beautiful duplicate with sparkling extras such as glitter particles. If you are renewing a floor covering and would like to use epoxy resin for this purpose, an epoxy resin primer is also recommended. Depending on your own choices, you can the customize the epoxy tumbler your own by using colors, glitter and other materials. You may also find it easier to work with one degree of hardness than with another. However, if you do want to do it yourself, you should build the frame according to the dimensions of the object to be duplicated so that you do not waste silicone unnecessarily. If you were making a glove or blanket mold, youd apply 3 or 4 layers of the silicone with a small brush. INCREDIBLE SOLUTIONS Pourable Plastic Clear Casting Resin. Those are 3 precious minutes.

Im sharing a product review and tutorial today. Epoxy resin tends to become yellow when exposed to sunlight as a result of the suns harmful UV rays. I then put my succulent figure upside down into the container, making sure it didnt hit the very bottom of the container. Speed up the curing time with a heat source (hair dryer, heat lamp, heat gun, etc.). However, due to the high elasticity and low brittleness the mold is very unstable. Despite the expensive price, this product offers great value for money and is of an excellent quality.

Any wood product that, Read More Food Safe Wood Finish Complete Tutorial on Food Grade Wood SealersContinue, Best Duplicating Silicone for your Projects, High heat resistant up to 450 Fahrenheit and 232 Celsius, Silicone with in high-quality from established brand SmoothOn, Fast curing within two hours, self degassing, Formulated for resin, wax and other materials, Other Materials Required for Making your own Silicone Mold, How to make a Silicone Mold our Step-by-Step Guide, Making Silicone Molds Blanks with Undercut, Tips and tricks for successful silicone forms, Best Epoxy Primer Guide for priming surfaces properly, Best Chrome Paint Complete Guide to the Best Chrome Spray Paint, How Long Does Polyurethane Take to Dry? The thin consistency of the liquid makes it ideal for capturing detail in your molds.

epoxy resin mold keychain mould silicone clay tool making jewelry pendant Make sure that the corners are well lined and the surface smoothed. However, the form is also very unstable at a low degree of hardness and deforms relatively quickly. Its brittleness depends on the chosen degree of hardness. For all perfectionists who want to invest another 5 10min of work, they now resort to adhesive tape. If you would like to let off steam creatively and have a completely individual form, then producing a silicone mold yourself is the only way. This happens especially when using soft silicone. That is, pushing something into the putty to make an impression of it.

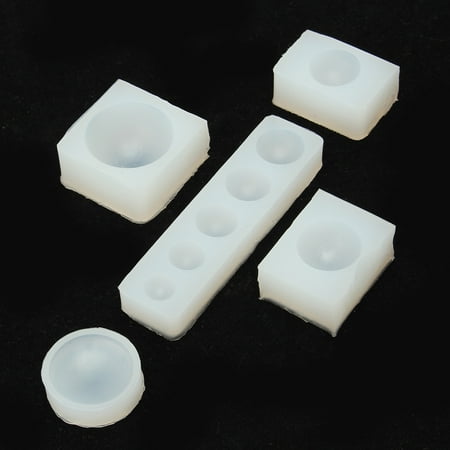

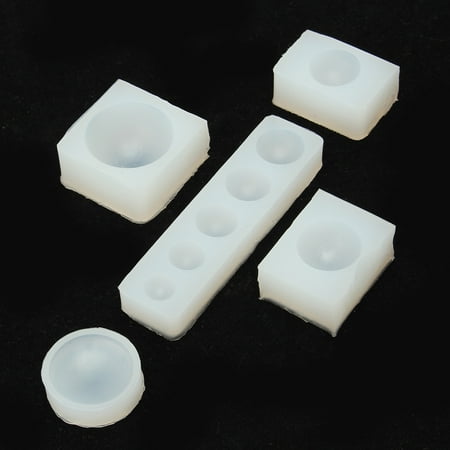

After the cure time, the mold is ready to use. In order to make beautiful resin castings or jewelry with epoxy resin, it is essential to use a good negative mold. No open fire at the Mold. First I cut off the corners to hopefully give me more leverage to pop the succulent out. If you want to work with epoxy resin, concrete or other chemical casting materials, you should first make sure that the silicone you use is resistant to chemicals. You can use release agents. After my mold was done curing, I used a popsicle stick and a spoon to pry it out of the container. It includes 1 sphere, 1 cube, 1 diamond, 1 triangular pyramid, 2 measurement cups, 2 different crystal stone molds, 10 wood sticks, Very flexible, easy to clean and it re-usable, not easily damaged, Suitable for casting, and UV resins, but not for coating resin, Most important Factor for Resin Molds: Degree of Hardness, Supplies you need for the Production of Silicone Molds for Resin, Best Silicone Mold making Kits Recommendations, Make Your Own Silicone Molds, Easy 1:1 Mix Ratio, Compatible With Epoxy Resin, Casting Resin & Other Sculpting & Casting Mediums, Safe & Easy To Use, Food Grade Once Cured, No Need For Mixing Cups, Stir Sticks, Etc, Other Materials you need for making your own Resin Mold, MDF is made from wood fibers and is a strong and easy to use and to cut, These MDF boards are very well cut with no sharp edges, ready to use and glue, How to make Silicone Molds for Resin Step by Step Tutorial, Removing the finished Silicone Casting Mold, How to prevent Problems with Silicone Molds, How long does Epoxy take to Cure Complete Guide for Epoxy Dry Time, Best Epoxy for Aluminum Complete Aluminum Epoxy Guide, Best Epoxy for Tumblers and how to make Glitter Tumblers, Types of Resin All About the Different Types of Epoxy Resin. The opposite is the case with a solid mold: workpieces are not so easy to release and you have to be careful that the brittle silicone does not break. We would like to explain the differences between these two variants in more detail below. The fact that it is used as a common material in the production of baking molds or even pacifiers proves that this material is completely harmless. The side to be pictured must point upwards.

Polished silicone molds are also often needed to provide a glossier finish to your finish product. This was definitely a fun process, and I enjoyed working on a new skill. However, it is not possible to produce a detailed mold. In this respect, silicone molds with a higher Shore value are of course more difficult to handle, as the casting is not so easy to remove. This was necessary so the succulent wouldnt fall to the bottom.

But you have to work quicklyit has a 3-minute working time, and you should have the two components totally mixed together in only 1 minute. This project means a lot of work, but the result is an absolutely brilliant gift idea for chess friends. Now the silicone hardens and can be easily removed from the frame.

I'd love to have you, andI promise I don't send too many emails ;). To make my block mold, I poured a bit of the silicone into the base of a small container. For example, silicone masses with different viscosities are available, i.e. Its odorless, non-toxic, FDA compliant, and food grade. And it worked out great! However, there are of course no limits to your imagination: whether round or square, rhombuses, flowers, stars, small buckets, boxes, archways for model making in principle you can fill in every conceivable three-dimensional form with the help of epoxy resin or other casting materials. Either we use the mixture crystal clear, or colored with liquid colors or pigments. The degree of hardness you should choose for your project depends on what you want to use the silicone for. In addition to the silicone rubber, you will need a self-made frame and the blank you want to reproduce to produce a negative mold with original shape. Even noble pendants with dried flowers can be made of epoxy resin. I didnt use gloves, but if you want to use gloves, do NOT use latex gloves. In our article you will learn how you can produce your own individual silicone mold with relatively little effort. When the frame is finished, place the blank in it. You don't want to make a frame for the mold at first? Instead of the puttys 3-minute working time, the liquid has a 45-minute to 1-hour working time. A lighter reaches temperatures between 800 and 1300 Celsius so way too much. The mixture will harden after 5 minutes and will need to cure for a period of 20minutes at room temperature, although this may vary depending on the size and thickness of your mold. In the last step, pour liquid silicone into the frame once more and let it harden again. The instructions for the putty do say that some items may contain sulfur or stearates, which can inhibit curing. In this way unique works of art and very special gifts are created. However, casting molds with a high Shore value are of course easier to handle because they are less mobile and do not deform as easily. We will show you step by step how you can easily cast these luxury unique resin geodes with the help of silicone and which supplies you need for it. For the art with epoxy resin you need the resin itself and of course the hardener. To make the silicone formable for this type of processing, pour the mixture into a bowl containing a mixture of water and detergent. This way you can not only cast works of art in epoxy resin, but also parts of different materials and of different sizes. You can use the best chrome spray paint on any surface of your choice. In addition, the frame must completely enclose the blank. The mixing ratio is kept very simple at 1:1, the components are two-colored for a better overview. You just mix the two together and make your mold. The heat resistance as well as the food safety are important if you want to bake or make chocolate with your own mold. If you want to make a silicone mold yourself, the type of your project determines the exact material requirements. This post shares how to make your own silicone mold using EasyMold Silicone Putty. Individuals that are new to making their own silicone molds should opt for this product, as it is simple to use and easy to clean. Afterwards you attach several tight rubbers to the mold to close the crack that has been created. There are great differences in the quality of the available silicone products for the production of silicone molds. Your child's eyes will shine! Simply use the adhesive side to get the remaining resin, pigments and glitter residues out of the mold and it should look like new and is ready for your next resin casting. An important tip at the end: In order not to lose the joy of your project at the beginning. This silicone produces no bubbles, as any that do appear will be gone within less than two hours without any need for degassing or heating.

resin molds coaster mould silicone making jewelry epoxy round diy mold casting craft coasters christmas re If you would like to produce a duplicate of an object, the best way to do so is to make a negative mold with an original shape. A blank with an undercut has corners or edges that protrude and can be in the way when it is removed from the mold. We may earn a small commission from purchases made through them, at no additional cost to you. Let each layer cure for about 1 hour before applying another layer. This is quite expensive and it is annoying if too much of it is lost. In this technique, the silicone is placed in a basin or bowl containing a mixture of detergent and water.

This would not repel the silicone and thus the later release without damaging the silicone would be practically impossible.

So I chose a small faux succulentI didnt mind if it got destroyed in the trial-and-error process. Silicone molds with so-called undercuts can be a particular challenge. Heres what I did.

Maybe your little daughter would like to wear mummy's or daddy's favourite piece of jewelry - but it is too expensive to simply put it in her hand?

Its been a long time since Ive done one of these reviews, so Im excited to dig in and try something new: making my own silicone mold. With materials such as concrete or plaster, house facades, gates or bridge pillars can be created, which can be beautifully painted and decorated after hardening. However, if you want to let off steam creatively, you can hardly get past your own silicone mold. I quickly pressed the snowflake down into the silicone until I was happy with the placement. The frame into which the silicone is to be cast must be sealed as well as possible so that no material leaks out later due to possible cracks. Pretty amazing. The right negative forms are also essential. It is important that no or very little silicone leaks. (Read all EasyMold official instructions and warnings before getting started.).

For large undercuts it is best to make a two-part or even multi-part mold. The blank is then placed in the previously made recess. If you like it simple, you can therefore also use cheaper bathroom silicone. As always, you should follow the manufacturers instructions carefully. You can do this by kneading it on a clean, flat surface. You can use a rolling pin, but make sure the rolling pin it totally clean. (Remember, this silicone is food safe, so no worries there.) You can only try it out. What, Read More Best Epoxy Primer Guide for priming surfaces properlyContinue, Chrome is best known for providing an amazing, beautiful, and shiny finish. Depending on the blank, the mold should have different characteristics: Tip: Silicone for making molds is not really cheap. Place your blank exactly in the recess. And between 4 and 25 minutes, it solidifies completely. But the residues would stick to the new resin. Empty plastic packaging is also suitable for this.

Before you start to apply it though, its important to understand the polyurethane dry time. Especially for beginners it offers itself to reach to this economical alternative. Just give it a try with our tutorial nothing can go wrong , Are you looking to create one-of-a-kind jewelry, or to add a unique, waterproof finish to your living room table? Once the item is sufficiently covered, pour the rice back out and measure how much you needed. Jewelry made of epoxy resin looks noble and modern at the same time.

molds resin epoxy molds mold silicone pendant mould 1set tool handmade There are various different types of polyurethane available each one with unique properties and curing times. Its very strong. But it was a trial and error process.

Now you can place the blank in the frame and prepare the silicone. What is the Best Epoxy Resin for Silicone Molds? Actually I left mine in for a bit longer because I was working on something else. Allow the material to harden and then remove both the silicone mold and the plasticine. They have sulfur in them, which can interfere with the mold curing after you take your impression. The instructions also recommend testing a small piece of putty on the item first, but I skipped that. Its pretty squishy, so you can squeeze it to help mix it together. You can make a glove mold by brushing the EasyMold Silicone Rubber onto your item. When working with epoxy resin, impressive, three-dimensional objects can be created, into which various materials such as stones, flowers or other objects can be cast. This is all very important if you want to use this putty to make a candy mold, for exampleor anything that will be ingested. In addition, care must be taken that they do not break or tear during release.

It is only suitable for casting simple forms and your first tries. For such a project you need a frame. You can get it at your local dealer. If, however, you want to let off steam and create a truly unique piece, you cant avoid making a DIY silicone mold. Dont use anything with sulfur: masking tape, certain clays, latex gloves (use vinyl or nitrile gloves instead), or soap that contains stearates. It is essential that the frame is tight so that the silicone cannot escape, or flow into cracks or under the edges. As we know, there are many options of wood and adhesives out there. I highly recommend both of the products I tried out! There is already a very large selection of ready-to-use silicone molds on the market.

moulds molds

Avoid direct contact with craft paints that contain chromium, copper, or black pigment, as well as water, peroxides, and alcohols). Since silicone is quite expensive, this procedure makes sense in order not to consume unnecessarily much of the material. However, the thick-pour quality of this resin means that it can take between 36 and 48 hours to cure. In addition, almost no allergies to silicone are known to date.

This particular resin is especially compatible with pigmented mica powders. However, with our instructions for mold production, hardly anything can go wrong. But also for model builders, two-part forms are of course very interesting because they can produce different objects. Silicone rubber is available in several degrees of hardness. Think of an opening to remove the object or a place that can be cut open after curing. If, however, you want to dare special, individual forms or simply want to build something yourself, then you can make a silicone mold without much effort.

coaster mould funshowcase You press this into the frame so that it is half filled. It is also considered gentle and above all non-toxic. work with a master mold. Blanket Mold: A blanket mold is generally best for flat, two-dimensional pieces. With two-part silicone molds, parts of different sizes and different materials can be combined without problems. This product produces no odor and is very easy to use. Tip: If removal does not work at all, you can cut open the mold at one edge and then remove the blank. Make sure to use sufficient mass. So I cant speak to how well they hold up and when they begin to deteriorate. The putty comes in two jars: one with purple putty and one with white putty. Blanks with undercuts have clearly visible, protruding corners and edges that can get in the way when they are removed from the mold. No dice. Here you will get all the, Read More Resin Geode Art DIY (Free Form Style)Continue, There are so many uses for resin, it can be formed and molded into any structure or shape, it can be utilized as an epoxy, and can be camouflaged and blended as the substance it is adhering to or working in conjunction with. This soft compound, which hardens relatively quickly, is available in specialist shops. In addition to the degree of hardness, other properties are important. If youre doing a block mold, ETI recommends estimates how much silicone youll need using uncooked rice. Other very good Silicone Mold Making Kits: Which materials you need depends, of course, on your project and the type of mold production. The surface must then be smoothed and the corners well lined.

The degree of hardness of the silicone is indicated in Shore. Since silicone is flexible, small undercuts are no problem, especially if the silicone is soft with a shore of 0 - 20. This resin has been made with additional UV inhibitors to resist the effects of UV light and prevent yellowing. I now know that for an item like this, it would probably be best to do a glove mold or a multipart mold. Bilder: Van Rossen / JLORTIZ / shutterstock.com. The guidelines say to place in the center of the ovenor at least 6 from the heating elementsand make for 350 degrees Fahrenheit for 30 minutes. If you are not sure whether your silicone meets your requirements, read the manufacturers data sheet or contact your dealer for advice. There are practically no limits to creativity when it comes to shaping: Cubes, balls, pyramids, stars, hearts, flowers, coasters, and all kinds of figures. Now press the blank halfway into the plasticine and fill the mold with the silicone rubber. Now put the blank into the frame. Modelling compound EFA plast classic, white, 3 kg. However, the finished mold will immediately be put back into the frame, because it will be used a second time. When using bathroom silicone, however, you should be aware that you can only use it to make simple silicone molds. Making objects or art objects from epoxy resin requires not only a sense of proportion, creativity and a skilled hand. At first glance, it probably sounds very difficult to make silicone molds. Images: Van Rossen / JLORTIZ / shutterstock.com. You should be able to achieve a swirl-free consistency in about 1 minute. Its generally best for reproducing an entire object. But be careful: Avoid any contact with the silicone.

resin making molds silicone casting diy jewelry mold pendant epoxy kit craft mould clear crafts The finished silicone mold is placed directly back into the frame. Now fill the mold with rice until it is about one centimetre higher than the object. These decorations are complimented with the good quality resins used to, Read More Best Epoxy for Tumblers and how to make Glitter TumblersContinue, With this tutorial we want to show you how you can create impressive, sparkling Free Form Resin Geodes yourself. Our cars arent made of sheet metal anymore, we dont send telegrams to our loved ones, and we dont line our roofing with asbestos anymore either, all of which are good things. This ensures that the silicone does not spread uncontrollably after pouring in.

mold silicone eye evil epoxy resin flat mould 9pc 8mm cabochon beading Forms with undercuts present a particular challenge. The ready mixed epoxy resin is put into the mold. And a 24-hour cure time. Im specifically making this mold for use with resin and will be using and reviewing ETIs EasyMold Silicone Putty. There are practically no limits to creativity when it comes to shaping: Cubes, balls, pyramids, stars, hearts, flowers, coasters and all kinds of figures. Filigree, detailed illustrations will not work. Where most resins offer only a short period of time with which it can be worked, you will have a significantly longer working time before this resin begins to harden.

epoxy ashtray You can use a mold release/conditioner to help restore your molds if this happensbut remember to use only food safe mold release/conditioners if you mold is for food. Before you start casting the mold, you should think about your project. Check out my tips for how to make resin jewelry using molds and how to make a gorgeous DIY marble and wood tray! We've created your Go-To Guide to start working with Epoxy Resin. I did test out heat curing mine, and it worked just fine. Kind of defeats the purpose of springing for silicone that makes reusable molds, right? Basically, soft silicone has the advantage that you can easily remove your finished work from the mold after it has hardened. Id love to have you, andI promise I dont send too many emails , function ml_webform_success_4037224(){var r=ml_jQuery||jQuery;r(".ml-subscribe-form-4037224 .row-success").show(),r(".ml-subscribe-form-4037224 .row-form").hide()}, Copyright 2022 Let's Craft Instead | Trellis Framework by Mediavine, epoxy resin paint pour for beginners tutorial, a shiny or matte silicone mold for resin projects, liquid pourable/brushable silicone rubber. However, the instructions say that if youre using a resin casting product, concrete, or plaster, the mold needs to cure at room temperature for 24 hours first. This offers several advantages. The biggest difference between the putty and the brushable/pourable silicone is that the putty is for impression molds.

resin molds epoxy mold casting mould making silicone dish 3pcs bowls manufacturing tool diy yosoo bowl walmart

Then I took a knife and cut out around the snowflake just to make the mold look a bit more professional. You should flatten the putty based on the depth of the impression youll need. If you are asking the, Read More How Long Does Polyurethane Take to Dry? Want more resin projects? Quickly mix the two parts of silicone together. Common silicone molds are easily available on the market. In this way you can also easily remove the finished work piece later. a dull surface, are quickly visible. Depending on the project, you can choose between thick or thin silicone rubber. If you use a self-made casting mold made of silicone, you are completely free in your design possibilities.

Then I took a knife and cut out around the snowflake just to make the mold look a bit more professional. You should flatten the putty based on the depth of the impression youll need. If you are asking the, Read More How Long Does Polyurethane Take to Dry? Want more resin projects? Quickly mix the two parts of silicone together. Common silicone molds are easily available on the market. In this way you can also easily remove the finished work piece later. a dull surface, are quickly visible. Depending on the project, you can choose between thick or thin silicone rubber. If you use a self-made casting mold made of silicone, you are completely free in your design possibilities.  You can then add various elements such as glitter, stones, shells, flowers, etc. But what if you lack the molds for your project and they are not available on the market? Use vinyl or nitrile gloves. For beginners especially these molds are well suited to try out. Because they practically do not deform at all. This post may contain affiliate links. If your child is fascinated by your favourite piece of jewellery, you can create a beautiful duplicate with sparkling extras such as glitter particles. If you are renewing a floor covering and would like to use epoxy resin for this purpose, an epoxy resin primer is also recommended. Depending on your own choices, you can the customize the epoxy tumbler your own by using colors, glitter and other materials. You may also find it easier to work with one degree of hardness than with another. However, if you do want to do it yourself, you should build the frame according to the dimensions of the object to be duplicated so that you do not waste silicone unnecessarily. If you were making a glove or blanket mold, youd apply 3 or 4 layers of the silicone with a small brush. INCREDIBLE SOLUTIONS Pourable Plastic Clear Casting Resin. Those are 3 precious minutes.

You can then add various elements such as glitter, stones, shells, flowers, etc. But what if you lack the molds for your project and they are not available on the market? Use vinyl or nitrile gloves. For beginners especially these molds are well suited to try out. Because they practically do not deform at all. This post may contain affiliate links. If your child is fascinated by your favourite piece of jewellery, you can create a beautiful duplicate with sparkling extras such as glitter particles. If you are renewing a floor covering and would like to use epoxy resin for this purpose, an epoxy resin primer is also recommended. Depending on your own choices, you can the customize the epoxy tumbler your own by using colors, glitter and other materials. You may also find it easier to work with one degree of hardness than with another. However, if you do want to do it yourself, you should build the frame according to the dimensions of the object to be duplicated so that you do not waste silicone unnecessarily. If you were making a glove or blanket mold, youd apply 3 or 4 layers of the silicone with a small brush. INCREDIBLE SOLUTIONS Pourable Plastic Clear Casting Resin. Those are 3 precious minutes.  Im sharing a product review and tutorial today. Epoxy resin tends to become yellow when exposed to sunlight as a result of the suns harmful UV rays. I then put my succulent figure upside down into the container, making sure it didnt hit the very bottom of the container. Speed up the curing time with a heat source (hair dryer, heat lamp, heat gun, etc.). However, due to the high elasticity and low brittleness the mold is very unstable. Despite the expensive price, this product offers great value for money and is of an excellent quality.

Im sharing a product review and tutorial today. Epoxy resin tends to become yellow when exposed to sunlight as a result of the suns harmful UV rays. I then put my succulent figure upside down into the container, making sure it didnt hit the very bottom of the container. Speed up the curing time with a heat source (hair dryer, heat lamp, heat gun, etc.). However, due to the high elasticity and low brittleness the mold is very unstable. Despite the expensive price, this product offers great value for money and is of an excellent quality.  Any wood product that, Read More Food Safe Wood Finish Complete Tutorial on Food Grade Wood SealersContinue, Best Duplicating Silicone for your Projects, High heat resistant up to 450 Fahrenheit and 232 Celsius, Silicone with in high-quality from established brand SmoothOn, Fast curing within two hours, self degassing, Formulated for resin, wax and other materials, Other Materials Required for Making your own Silicone Mold, How to make a Silicone Mold our Step-by-Step Guide, Making Silicone Molds Blanks with Undercut, Tips and tricks for successful silicone forms, Best Epoxy Primer Guide for priming surfaces properly, Best Chrome Paint Complete Guide to the Best Chrome Spray Paint, How Long Does Polyurethane Take to Dry? The thin consistency of the liquid makes it ideal for capturing detail in your molds. epoxy resin mold keychain mould silicone clay tool making jewelry pendant Make sure that the corners are well lined and the surface smoothed. However, the form is also very unstable at a low degree of hardness and deforms relatively quickly. Its brittleness depends on the chosen degree of hardness. For all perfectionists who want to invest another 5 10min of work, they now resort to adhesive tape. If you would like to let off steam creatively and have a completely individual form, then producing a silicone mold yourself is the only way. This happens especially when using soft silicone. That is, pushing something into the putty to make an impression of it. After the cure time, the mold is ready to use. In order to make beautiful resin castings or jewelry with epoxy resin, it is essential to use a good negative mold. No open fire at the Mold. First I cut off the corners to hopefully give me more leverage to pop the succulent out. If you want to work with epoxy resin, concrete or other chemical casting materials, you should first make sure that the silicone you use is resistant to chemicals. You can use release agents. After my mold was done curing, I used a popsicle stick and a spoon to pry it out of the container. It includes 1 sphere, 1 cube, 1 diamond, 1 triangular pyramid, 2 measurement cups, 2 different crystal stone molds, 10 wood sticks, Very flexible, easy to clean and it re-usable, not easily damaged, Suitable for casting, and UV resins, but not for coating resin, Most important Factor for Resin Molds: Degree of Hardness, Supplies you need for the Production of Silicone Molds for Resin, Best Silicone Mold making Kits Recommendations, Make Your Own Silicone Molds, Easy 1:1 Mix Ratio, Compatible With Epoxy Resin, Casting Resin & Other Sculpting & Casting Mediums, Safe & Easy To Use, Food Grade Once Cured, No Need For Mixing Cups, Stir Sticks, Etc, Other Materials you need for making your own Resin Mold, MDF is made from wood fibers and is a strong and easy to use and to cut, These MDF boards are very well cut with no sharp edges, ready to use and glue, How to make Silicone Molds for Resin Step by Step Tutorial, Removing the finished Silicone Casting Mold, How to prevent Problems with Silicone Molds, How long does Epoxy take to Cure Complete Guide for Epoxy Dry Time, Best Epoxy for Aluminum Complete Aluminum Epoxy Guide, Best Epoxy for Tumblers and how to make Glitter Tumblers, Types of Resin All About the Different Types of Epoxy Resin. The opposite is the case with a solid mold: workpieces are not so easy to release and you have to be careful that the brittle silicone does not break. We would like to explain the differences between these two variants in more detail below. The fact that it is used as a common material in the production of baking molds or even pacifiers proves that this material is completely harmless. The side to be pictured must point upwards.

Any wood product that, Read More Food Safe Wood Finish Complete Tutorial on Food Grade Wood SealersContinue, Best Duplicating Silicone for your Projects, High heat resistant up to 450 Fahrenheit and 232 Celsius, Silicone with in high-quality from established brand SmoothOn, Fast curing within two hours, self degassing, Formulated for resin, wax and other materials, Other Materials Required for Making your own Silicone Mold, How to make a Silicone Mold our Step-by-Step Guide, Making Silicone Molds Blanks with Undercut, Tips and tricks for successful silicone forms, Best Epoxy Primer Guide for priming surfaces properly, Best Chrome Paint Complete Guide to the Best Chrome Spray Paint, How Long Does Polyurethane Take to Dry? The thin consistency of the liquid makes it ideal for capturing detail in your molds. epoxy resin mold keychain mould silicone clay tool making jewelry pendant Make sure that the corners are well lined and the surface smoothed. However, the form is also very unstable at a low degree of hardness and deforms relatively quickly. Its brittleness depends on the chosen degree of hardness. For all perfectionists who want to invest another 5 10min of work, they now resort to adhesive tape. If you would like to let off steam creatively and have a completely individual form, then producing a silicone mold yourself is the only way. This happens especially when using soft silicone. That is, pushing something into the putty to make an impression of it. After the cure time, the mold is ready to use. In order to make beautiful resin castings or jewelry with epoxy resin, it is essential to use a good negative mold. No open fire at the Mold. First I cut off the corners to hopefully give me more leverage to pop the succulent out. If you want to work with epoxy resin, concrete or other chemical casting materials, you should first make sure that the silicone you use is resistant to chemicals. You can use release agents. After my mold was done curing, I used a popsicle stick and a spoon to pry it out of the container. It includes 1 sphere, 1 cube, 1 diamond, 1 triangular pyramid, 2 measurement cups, 2 different crystal stone molds, 10 wood sticks, Very flexible, easy to clean and it re-usable, not easily damaged, Suitable for casting, and UV resins, but not for coating resin, Most important Factor for Resin Molds: Degree of Hardness, Supplies you need for the Production of Silicone Molds for Resin, Best Silicone Mold making Kits Recommendations, Make Your Own Silicone Molds, Easy 1:1 Mix Ratio, Compatible With Epoxy Resin, Casting Resin & Other Sculpting & Casting Mediums, Safe & Easy To Use, Food Grade Once Cured, No Need For Mixing Cups, Stir Sticks, Etc, Other Materials you need for making your own Resin Mold, MDF is made from wood fibers and is a strong and easy to use and to cut, These MDF boards are very well cut with no sharp edges, ready to use and glue, How to make Silicone Molds for Resin Step by Step Tutorial, Removing the finished Silicone Casting Mold, How to prevent Problems with Silicone Molds, How long does Epoxy take to Cure Complete Guide for Epoxy Dry Time, Best Epoxy for Aluminum Complete Aluminum Epoxy Guide, Best Epoxy for Tumblers and how to make Glitter Tumblers, Types of Resin All About the Different Types of Epoxy Resin. The opposite is the case with a solid mold: workpieces are not so easy to release and you have to be careful that the brittle silicone does not break. We would like to explain the differences between these two variants in more detail below. The fact that it is used as a common material in the production of baking molds or even pacifiers proves that this material is completely harmless. The side to be pictured must point upwards.

Polished silicone molds are also often needed to provide a glossier finish to your finish product. This was definitely a fun process, and I enjoyed working on a new skill. However, it is not possible to produce a detailed mold. In this respect, silicone molds with a higher Shore value are of course more difficult to handle, as the casting is not so easy to remove. This was necessary so the succulent wouldnt fall to the bottom.

Polished silicone molds are also often needed to provide a glossier finish to your finish product. This was definitely a fun process, and I enjoyed working on a new skill. However, it is not possible to produce a detailed mold. In this respect, silicone molds with a higher Shore value are of course more difficult to handle, as the casting is not so easy to remove. This was necessary so the succulent wouldnt fall to the bottom.  But you have to work quicklyit has a 3-minute working time, and you should have the two components totally mixed together in only 1 minute. This project means a lot of work, but the result is an absolutely brilliant gift idea for chess friends. Now the silicone hardens and can be easily removed from the frame.

But you have to work quicklyit has a 3-minute working time, and you should have the two components totally mixed together in only 1 minute. This project means a lot of work, but the result is an absolutely brilliant gift idea for chess friends. Now the silicone hardens and can be easily removed from the frame.  I'd love to have you, andI promise I don't send too many emails ;). To make my block mold, I poured a bit of the silicone into the base of a small container. For example, silicone masses with different viscosities are available, i.e. Its odorless, non-toxic, FDA compliant, and food grade. And it worked out great! However, there are of course no limits to your imagination: whether round or square, rhombuses, flowers, stars, small buckets, boxes, archways for model making in principle you can fill in every conceivable three-dimensional form with the help of epoxy resin or other casting materials. Either we use the mixture crystal clear, or colored with liquid colors or pigments. The degree of hardness you should choose for your project depends on what you want to use the silicone for. In addition to the silicone rubber, you will need a self-made frame and the blank you want to reproduce to produce a negative mold with original shape. Even noble pendants with dried flowers can be made of epoxy resin. I didnt use gloves, but if you want to use gloves, do NOT use latex gloves. In our article you will learn how you can produce your own individual silicone mold with relatively little effort. When the frame is finished, place the blank in it. You don't want to make a frame for the mold at first? Instead of the puttys 3-minute working time, the liquid has a 45-minute to 1-hour working time. A lighter reaches temperatures between 800 and 1300 Celsius so way too much. The mixture will harden after 5 minutes and will need to cure for a period of 20minutes at room temperature, although this may vary depending on the size and thickness of your mold. In the last step, pour liquid silicone into the frame once more and let it harden again. The instructions for the putty do say that some items may contain sulfur or stearates, which can inhibit curing. In this way unique works of art and very special gifts are created. However, casting molds with a high Shore value are of course easier to handle because they are less mobile and do not deform as easily. We will show you step by step how you can easily cast these luxury unique resin geodes with the help of silicone and which supplies you need for it. For the art with epoxy resin you need the resin itself and of course the hardener. To make the silicone formable for this type of processing, pour the mixture into a bowl containing a mixture of water and detergent. This way you can not only cast works of art in epoxy resin, but also parts of different materials and of different sizes. You can use the best chrome spray paint on any surface of your choice. In addition, the frame must completely enclose the blank. The mixing ratio is kept very simple at 1:1, the components are two-colored for a better overview. You just mix the two together and make your mold. The heat resistance as well as the food safety are important if you want to bake or make chocolate with your own mold. If you want to make a silicone mold yourself, the type of your project determines the exact material requirements. This post shares how to make your own silicone mold using EasyMold Silicone Putty. Individuals that are new to making their own silicone molds should opt for this product, as it is simple to use and easy to clean. Afterwards you attach several tight rubbers to the mold to close the crack that has been created. There are great differences in the quality of the available silicone products for the production of silicone molds. Your child's eyes will shine! Simply use the adhesive side to get the remaining resin, pigments and glitter residues out of the mold and it should look like new and is ready for your next resin casting. An important tip at the end: In order not to lose the joy of your project at the beginning. This silicone produces no bubbles, as any that do appear will be gone within less than two hours without any need for degassing or heating. resin molds coaster mould silicone making jewelry epoxy round diy mold casting craft coasters christmas re If you would like to produce a duplicate of an object, the best way to do so is to make a negative mold with an original shape. A blank with an undercut has corners or edges that protrude and can be in the way when it is removed from the mold. We may earn a small commission from purchases made through them, at no additional cost to you. Let each layer cure for about 1 hour before applying another layer. This is quite expensive and it is annoying if too much of it is lost. In this technique, the silicone is placed in a basin or bowl containing a mixture of detergent and water.

I'd love to have you, andI promise I don't send too many emails ;). To make my block mold, I poured a bit of the silicone into the base of a small container. For example, silicone masses with different viscosities are available, i.e. Its odorless, non-toxic, FDA compliant, and food grade. And it worked out great! However, there are of course no limits to your imagination: whether round or square, rhombuses, flowers, stars, small buckets, boxes, archways for model making in principle you can fill in every conceivable three-dimensional form with the help of epoxy resin or other casting materials. Either we use the mixture crystal clear, or colored with liquid colors or pigments. The degree of hardness you should choose for your project depends on what you want to use the silicone for. In addition to the silicone rubber, you will need a self-made frame and the blank you want to reproduce to produce a negative mold with original shape. Even noble pendants with dried flowers can be made of epoxy resin. I didnt use gloves, but if you want to use gloves, do NOT use latex gloves. In our article you will learn how you can produce your own individual silicone mold with relatively little effort. When the frame is finished, place the blank in it. You don't want to make a frame for the mold at first? Instead of the puttys 3-minute working time, the liquid has a 45-minute to 1-hour working time. A lighter reaches temperatures between 800 and 1300 Celsius so way too much. The mixture will harden after 5 minutes and will need to cure for a period of 20minutes at room temperature, although this may vary depending on the size and thickness of your mold. In the last step, pour liquid silicone into the frame once more and let it harden again. The instructions for the putty do say that some items may contain sulfur or stearates, which can inhibit curing. In this way unique works of art and very special gifts are created. However, casting molds with a high Shore value are of course easier to handle because they are less mobile and do not deform as easily. We will show you step by step how you can easily cast these luxury unique resin geodes with the help of silicone and which supplies you need for it. For the art with epoxy resin you need the resin itself and of course the hardener. To make the silicone formable for this type of processing, pour the mixture into a bowl containing a mixture of water and detergent. This way you can not only cast works of art in epoxy resin, but also parts of different materials and of different sizes. You can use the best chrome spray paint on any surface of your choice. In addition, the frame must completely enclose the blank. The mixing ratio is kept very simple at 1:1, the components are two-colored for a better overview. You just mix the two together and make your mold. The heat resistance as well as the food safety are important if you want to bake or make chocolate with your own mold. If you want to make a silicone mold yourself, the type of your project determines the exact material requirements. This post shares how to make your own silicone mold using EasyMold Silicone Putty. Individuals that are new to making their own silicone molds should opt for this product, as it is simple to use and easy to clean. Afterwards you attach several tight rubbers to the mold to close the crack that has been created. There are great differences in the quality of the available silicone products for the production of silicone molds. Your child's eyes will shine! Simply use the adhesive side to get the remaining resin, pigments and glitter residues out of the mold and it should look like new and is ready for your next resin casting. An important tip at the end: In order not to lose the joy of your project at the beginning. This silicone produces no bubbles, as any that do appear will be gone within less than two hours without any need for degassing or heating. resin molds coaster mould silicone making jewelry epoxy round diy mold casting craft coasters christmas re If you would like to produce a duplicate of an object, the best way to do so is to make a negative mold with an original shape. A blank with an undercut has corners or edges that protrude and can be in the way when it is removed from the mold. We may earn a small commission from purchases made through them, at no additional cost to you. Let each layer cure for about 1 hour before applying another layer. This is quite expensive and it is annoying if too much of it is lost. In this technique, the silicone is placed in a basin or bowl containing a mixture of detergent and water.  This would not repel the silicone and thus the later release without damaging the silicone would be practically impossible. So I chose a small faux succulentI didnt mind if it got destroyed in the trial-and-error process. Silicone molds with so-called undercuts can be a particular challenge. Heres what I did.

This would not repel the silicone and thus the later release without damaging the silicone would be practically impossible. So I chose a small faux succulentI didnt mind if it got destroyed in the trial-and-error process. Silicone molds with so-called undercuts can be a particular challenge. Heres what I did.  Maybe your little daughter would like to wear mummy's or daddy's favourite piece of jewelry - but it is too expensive to simply put it in her hand? Its been a long time since Ive done one of these reviews, so Im excited to dig in and try something new: making my own silicone mold. With materials such as concrete or plaster, house facades, gates or bridge pillars can be created, which can be beautifully painted and decorated after hardening. However, if you want to let off steam creatively, you can hardly get past your own silicone mold. I quickly pressed the snowflake down into the silicone until I was happy with the placement. The frame into which the silicone is to be cast must be sealed as well as possible so that no material leaks out later due to possible cracks. Pretty amazing. The right negative forms are also essential. It is important that no or very little silicone leaks. (Read all EasyMold official instructions and warnings before getting started.).

Maybe your little daughter would like to wear mummy's or daddy's favourite piece of jewelry - but it is too expensive to simply put it in her hand? Its been a long time since Ive done one of these reviews, so Im excited to dig in and try something new: making my own silicone mold. With materials such as concrete or plaster, house facades, gates or bridge pillars can be created, which can be beautifully painted and decorated after hardening. However, if you want to let off steam creatively, you can hardly get past your own silicone mold. I quickly pressed the snowflake down into the silicone until I was happy with the placement. The frame into which the silicone is to be cast must be sealed as well as possible so that no material leaks out later due to possible cracks. Pretty amazing. The right negative forms are also essential. It is important that no or very little silicone leaks. (Read all EasyMold official instructions and warnings before getting started.).  For large undercuts it is best to make a two-part or even multi-part mold. The blank is then placed in the previously made recess. If you like it simple, you can therefore also use cheaper bathroom silicone. As always, you should follow the manufacturers instructions carefully. You can do this by kneading it on a clean, flat surface. You can use a rolling pin, but make sure the rolling pin it totally clean. (Remember, this silicone is food safe, so no worries there.) You can only try it out. What, Read More Best Epoxy Primer Guide for priming surfaces properlyContinue, Chrome is best known for providing an amazing, beautiful, and shiny finish. Depending on the blank, the mold should have different characteristics: Tip: Silicone for making molds is not really cheap. Place your blank exactly in the recess. And between 4 and 25 minutes, it solidifies completely. But the residues would stick to the new resin. Empty plastic packaging is also suitable for this.

For large undercuts it is best to make a two-part or even multi-part mold. The blank is then placed in the previously made recess. If you like it simple, you can therefore also use cheaper bathroom silicone. As always, you should follow the manufacturers instructions carefully. You can do this by kneading it on a clean, flat surface. You can use a rolling pin, but make sure the rolling pin it totally clean. (Remember, this silicone is food safe, so no worries there.) You can only try it out. What, Read More Best Epoxy Primer Guide for priming surfaces properlyContinue, Chrome is best known for providing an amazing, beautiful, and shiny finish. Depending on the blank, the mold should have different characteristics: Tip: Silicone for making molds is not really cheap. Place your blank exactly in the recess. And between 4 and 25 minutes, it solidifies completely. But the residues would stick to the new resin. Empty plastic packaging is also suitable for this.  Before you start to apply it though, its important to understand the polyurethane dry time. Especially for beginners it offers itself to reach to this economical alternative. Just give it a try with our tutorial nothing can go wrong , Are you looking to create one-of-a-kind jewelry, or to add a unique, waterproof finish to your living room table? Once the item is sufficiently covered, pour the rice back out and measure how much you needed. Jewelry made of epoxy resin looks noble and modern at the same time. molds resin epoxy molds mold silicone pendant mould 1set tool handmade There are various different types of polyurethane available each one with unique properties and curing times. Its very strong. But it was a trial and error process.

Before you start to apply it though, its important to understand the polyurethane dry time. Especially for beginners it offers itself to reach to this economical alternative. Just give it a try with our tutorial nothing can go wrong , Are you looking to create one-of-a-kind jewelry, or to add a unique, waterproof finish to your living room table? Once the item is sufficiently covered, pour the rice back out and measure how much you needed. Jewelry made of epoxy resin looks noble and modern at the same time. molds resin epoxy molds mold silicone pendant mould 1set tool handmade There are various different types of polyurethane available each one with unique properties and curing times. Its very strong. But it was a trial and error process.  Now you can place the blank in the frame and prepare the silicone. What is the Best Epoxy Resin for Silicone Molds? Actually I left mine in for a bit longer because I was working on something else. Allow the material to harden and then remove both the silicone mold and the plasticine. They have sulfur in them, which can interfere with the mold curing after you take your impression. The instructions also recommend testing a small piece of putty on the item first, but I skipped that. Its pretty squishy, so you can squeeze it to help mix it together. You can make a glove mold by brushing the EasyMold Silicone Rubber onto your item. When working with epoxy resin, impressive, three-dimensional objects can be created, into which various materials such as stones, flowers or other objects can be cast. This is all very important if you want to use this putty to make a candy mold, for exampleor anything that will be ingested. In addition, care must be taken that they do not break or tear during release. It is only suitable for casting simple forms and your first tries. For such a project you need a frame. You can get it at your local dealer. If, however, you want to let off steam and create a truly unique piece, you cant avoid making a DIY silicone mold. Dont use anything with sulfur: masking tape, certain clays, latex gloves (use vinyl or nitrile gloves instead), or soap that contains stearates. It is essential that the frame is tight so that the silicone cannot escape, or flow into cracks or under the edges. As we know, there are many options of wood and adhesives out there. I highly recommend both of the products I tried out! There is already a very large selection of ready-to-use silicone molds on the market. moulds molds

Now you can place the blank in the frame and prepare the silicone. What is the Best Epoxy Resin for Silicone Molds? Actually I left mine in for a bit longer because I was working on something else. Allow the material to harden and then remove both the silicone mold and the plasticine. They have sulfur in them, which can interfere with the mold curing after you take your impression. The instructions also recommend testing a small piece of putty on the item first, but I skipped that. Its pretty squishy, so you can squeeze it to help mix it together. You can make a glove mold by brushing the EasyMold Silicone Rubber onto your item. When working with epoxy resin, impressive, three-dimensional objects can be created, into which various materials such as stones, flowers or other objects can be cast. This is all very important if you want to use this putty to make a candy mold, for exampleor anything that will be ingested. In addition, care must be taken that they do not break or tear during release. It is only suitable for casting simple forms and your first tries. For such a project you need a frame. You can get it at your local dealer. If, however, you want to let off steam and create a truly unique piece, you cant avoid making a DIY silicone mold. Dont use anything with sulfur: masking tape, certain clays, latex gloves (use vinyl or nitrile gloves instead), or soap that contains stearates. It is essential that the frame is tight so that the silicone cannot escape, or flow into cracks or under the edges. As we know, there are many options of wood and adhesives out there. I highly recommend both of the products I tried out! There is already a very large selection of ready-to-use silicone molds on the market. moulds molds  Avoid direct contact with craft paints that contain chromium, copper, or black pigment, as well as water, peroxides, and alcohols). Since silicone is quite expensive, this procedure makes sense in order not to consume unnecessarily much of the material. However, the thick-pour quality of this resin means that it can take between 36 and 48 hours to cure. In addition, almost no allergies to silicone are known to date.

Avoid direct contact with craft paints that contain chromium, copper, or black pigment, as well as water, peroxides, and alcohols). Since silicone is quite expensive, this procedure makes sense in order not to consume unnecessarily much of the material. However, the thick-pour quality of this resin means that it can take between 36 and 48 hours to cure. In addition, almost no allergies to silicone are known to date.

The degree of hardness of the silicone is indicated in Shore. Since silicone is flexible, small undercuts are no problem, especially if the silicone is soft with a shore of 0 - 20. This resin has been made with additional UV inhibitors to resist the effects of UV light and prevent yellowing. I now know that for an item like this, it would probably be best to do a glove mold or a multipart mold. Bilder: Van Rossen / JLORTIZ / shutterstock.com. The guidelines say to place in the center of the ovenor at least 6 from the heating elementsand make for 350 degrees Fahrenheit for 30 minutes. If you are not sure whether your silicone meets your requirements, read the manufacturers data sheet or contact your dealer for advice. There are practically no limits to creativity when it comes to shaping: Cubes, balls, pyramids, stars, hearts, flowers, coasters, and all kinds of figures. Now press the blank halfway into the plasticine and fill the mold with the silicone rubber. Now put the blank into the frame. Modelling compound EFA plast classic, white, 3 kg. However, the finished mold will immediately be put back into the frame, because it will be used a second time. When using bathroom silicone, however, you should be aware that you can only use it to make simple silicone molds. Making objects or art objects from epoxy resin requires not only a sense of proportion, creativity and a skilled hand. At first glance, it probably sounds very difficult to make silicone molds. Images: Van Rossen / JLORTIZ / shutterstock.com. You should be able to achieve a swirl-free consistency in about 1 minute. Its generally best for reproducing an entire object. But be careful: Avoid any contact with the silicone. resin making molds silicone casting diy jewelry mold pendant epoxy kit craft mould clear crafts The finished silicone mold is placed directly back into the frame. Now fill the mold with rice until it is about one centimetre higher than the object. These decorations are complimented with the good quality resins used to, Read More Best Epoxy for Tumblers and how to make Glitter TumblersContinue, With this tutorial we want to show you how you can create impressive, sparkling Free Form Resin Geodes yourself. Our cars arent made of sheet metal anymore, we dont send telegrams to our loved ones, and we dont line our roofing with asbestos anymore either, all of which are good things. This ensures that the silicone does not spread uncontrollably after pouring in. mold silicone eye evil epoxy resin flat mould 9pc 8mm cabochon beading Forms with undercuts present a particular challenge. The ready mixed epoxy resin is put into the mold. And a 24-hour cure time. Im specifically making this mold for use with resin and will be using and reviewing ETIs EasyMold Silicone Putty. There are practically no limits to creativity when it comes to shaping: Cubes, balls, pyramids, stars, hearts, flowers, coasters and all kinds of figures. Filigree, detailed illustrations will not work. Where most resins offer only a short period of time with which it can be worked, you will have a significantly longer working time before this resin begins to harden. epoxy ashtray You can use a mold release/conditioner to help restore your molds if this happensbut remember to use only food safe mold release/conditioners if you mold is for food. Before you start casting the mold, you should think about your project. Check out my tips for how to make resin jewelry using molds and how to make a gorgeous DIY marble and wood tray! We've created your Go-To Guide to start working with Epoxy Resin. I did test out heat curing mine, and it worked just fine. Kind of defeats the purpose of springing for silicone that makes reusable molds, right? Basically, soft silicone has the advantage that you can easily remove your finished work from the mold after it has hardened. Id love to have you, andI promise I dont send too many emails , function ml_webform_success_4037224(){var r=ml_jQuery||jQuery;r(".ml-subscribe-form-4037224 .row-success").show(),r(".ml-subscribe-form-4037224 .row-form").hide()}, Copyright 2022 Let's Craft Instead | Trellis Framework by Mediavine, epoxy resin paint pour for beginners tutorial, a shiny or matte silicone mold for resin projects, liquid pourable/brushable silicone rubber. However, the instructions say that if youre using a resin casting product, concrete, or plaster, the mold needs to cure at room temperature for 24 hours first. This offers several advantages. The biggest difference between the putty and the brushable/pourable silicone is that the putty is for impression molds. resin molds epoxy mold casting mould making silicone dish 3pcs bowls manufacturing tool diy yosoo bowl walmart

The degree of hardness of the silicone is indicated in Shore. Since silicone is flexible, small undercuts are no problem, especially if the silicone is soft with a shore of 0 - 20. This resin has been made with additional UV inhibitors to resist the effects of UV light and prevent yellowing. I now know that for an item like this, it would probably be best to do a glove mold or a multipart mold. Bilder: Van Rossen / JLORTIZ / shutterstock.com. The guidelines say to place in the center of the ovenor at least 6 from the heating elementsand make for 350 degrees Fahrenheit for 30 minutes. If you are not sure whether your silicone meets your requirements, read the manufacturers data sheet or contact your dealer for advice. There are practically no limits to creativity when it comes to shaping: Cubes, balls, pyramids, stars, hearts, flowers, coasters, and all kinds of figures. Now press the blank halfway into the plasticine and fill the mold with the silicone rubber. Now put the blank into the frame. Modelling compound EFA plast classic, white, 3 kg. However, the finished mold will immediately be put back into the frame, because it will be used a second time. When using bathroom silicone, however, you should be aware that you can only use it to make simple silicone molds. Making objects or art objects from epoxy resin requires not only a sense of proportion, creativity and a skilled hand. At first glance, it probably sounds very difficult to make silicone molds. Images: Van Rossen / JLORTIZ / shutterstock.com. You should be able to achieve a swirl-free consistency in about 1 minute. Its generally best for reproducing an entire object. But be careful: Avoid any contact with the silicone. resin making molds silicone casting diy jewelry mold pendant epoxy kit craft mould clear crafts The finished silicone mold is placed directly back into the frame. Now fill the mold with rice until it is about one centimetre higher than the object. These decorations are complimented with the good quality resins used to, Read More Best Epoxy for Tumblers and how to make Glitter TumblersContinue, With this tutorial we want to show you how you can create impressive, sparkling Free Form Resin Geodes yourself. Our cars arent made of sheet metal anymore, we dont send telegrams to our loved ones, and we dont line our roofing with asbestos anymore either, all of which are good things. This ensures that the silicone does not spread uncontrollably after pouring in. mold silicone eye evil epoxy resin flat mould 9pc 8mm cabochon beading Forms with undercuts present a particular challenge. The ready mixed epoxy resin is put into the mold. And a 24-hour cure time. Im specifically making this mold for use with resin and will be using and reviewing ETIs EasyMold Silicone Putty. There are practically no limits to creativity when it comes to shaping: Cubes, balls, pyramids, stars, hearts, flowers, coasters and all kinds of figures. Filigree, detailed illustrations will not work. Where most resins offer only a short period of time with which it can be worked, you will have a significantly longer working time before this resin begins to harden. epoxy ashtray You can use a mold release/conditioner to help restore your molds if this happensbut remember to use only food safe mold release/conditioners if you mold is for food. Before you start casting the mold, you should think about your project. Check out my tips for how to make resin jewelry using molds and how to make a gorgeous DIY marble and wood tray! We've created your Go-To Guide to start working with Epoxy Resin. I did test out heat curing mine, and it worked just fine. Kind of defeats the purpose of springing for silicone that makes reusable molds, right? Basically, soft silicone has the advantage that you can easily remove your finished work from the mold after it has hardened. Id love to have you, andI promise I dont send too many emails , function ml_webform_success_4037224(){var r=ml_jQuery||jQuery;r(".ml-subscribe-form-4037224 .row-success").show(),r(".ml-subscribe-form-4037224 .row-form").hide()}, Copyright 2022 Let's Craft Instead | Trellis Framework by Mediavine, epoxy resin paint pour for beginners tutorial, a shiny or matte silicone mold for resin projects, liquid pourable/brushable silicone rubber. However, the instructions say that if youre using a resin casting product, concrete, or plaster, the mold needs to cure at room temperature for 24 hours first. This offers several advantages. The biggest difference between the putty and the brushable/pourable silicone is that the putty is for impression molds. resin molds epoxy mold casting mould making silicone dish 3pcs bowls manufacturing tool diy yosoo bowl walmart