Videos of the highest quality, so you don't miss a single detail. This technique can also be scaled up or down for use in amateur projects or designer pieces such as the Saul series.

Enjoy learning from home without a set schedule and with an easy-to-follow method. If you are a maker and a DIY fan, don't hesitate to download these STL files and start print your furniture! For more information see our Privacy Policy. Rethink your home deco thanks to these paid or free 3D printer files. Each one includes lessons, informational text, tasks, and practice exercises to help you carry out your project step by step, with additional complementary resources and downloads. Canada and AON3D Send 3D Printed Part to Space for Medical Research, WASP 3D Prints Organic Display for 23rd Triennale Milano International Exhibition, Mini Car 3D Printed and Assembled Automatically by AMBOTS, Market for Bound Metal Additive Manufacturing 2022, The Market for Additive Manufactured Polymer Automotive Parts: Europe and North America Regions, DED and Large-Format Additive Manufacturing Markets: 2021-2030, 3D Printed Metals: A Patent Landscape Analysis 2019, 3d Printed Polymers: A Patent Landscape Analysis 2016, 3d-printed Metals: A Patent Landscape Analysis 2016, Metal Parts Produced 2021: Additive Manufacturing Applications Market Analysis, Additive Manufacturing with Metal Powders 2020, Copper Additive Manufacturing 2020Market Database and Outlook, Additive Monitoring Study by Fraunhofer IAPT, Additive Fatigue Study by Fraunhofer IAPT. Powerful search with product databases and business directories. It delivers what it promises. If an industrial 3D printer is unaffordable, then high-quality pieces can still be constructed by using 3D printing alongside conventional techniques. +358 2041 5113upmformi@upm.comNiemenkatu 16FI-15140 LahtiFinland, 3D-printed furniture concepts from UPM biocomposite and wood, The actual manufacturing process can be started quickly, Different versions can be created rather easily, Making demanding custom shapes with standard methods can be very expensive, For users who require the most sustainable alternatives, Biobased materials can provide a 100% circular eco-system, UPM Formi 3D biocomposite is not only sustainable material but it has the right product properties for this purpose.

chair mycelium printed 3d fungus klarenbeek eric segment dornob living straw

chair mycelium printed 3d fungus klarenbeek eric segment dornob living straw In addition to the possibilities of design, functionality, customisation and immediacy that 3D printing offers for furniture design and manufacturing companies, it also makes it possible for private users to manufacture their own furniture. Their printer of choice is a BigRep One.

Gather inspiration for your shelf design before sketching your ideas and creating a mockup o help you visualize the finished product. You set your own pace. Instead, Estrada looked at thermoplastic materials in pellet form, which can run as low as $2.50 per kilogram.

36350 Nigran (Pontevedra - Spain), Receive the latest news, tips and tricks about 3D printing, Questions about the usual temperature and print speed of PLA and ABS, What is the flow of 3D printing and how to adjust it, Common problems and solutions in 3D printing, What is retraction in 3D printing? He prides himself on creating products that are both stylish and functional which he sells via his online shop. Jon Christie, a bespoke furniture producer, spent 20 years trading modernist furniture before returning to university at the age of 40. Every step of the project combines video lessons with complementary instructional material, so you can learn by doing. Domestika's courses are online classes that provide you with the tools and skills you need to complete a specific project. Their process begins by 3D printing artisan furniture based on a clients design. Many of these initiatives consist of 3D printing street furniture made from plastic waste from the cities themselves. This course really got me going on my current project. Known for its mission to 3D print clay houses to solve the worlds housing issues, WASP has grown over the years to offer a wide range of industrial printers for construction, architecture and design, art and culture, energy, medical devices, and food. Thanks to this collection you can 3D print beautiful design furniture. Marketing addicted. Currently he is tending to crops consisting of a fast growing willow, but he is experimenting with ash, sycamore, hazel, crab apple, and oak trees. Type of Print: Final Piece 3D printed chaise longueOptions: Injection Molding vs FDMIndustry: Furniture3D Print Volume: 1 per week on averagePrint Material: Various PLA, wood composite pelletsPrinter selected: Delta WASP 3MT INDUSTRIAL 4.0Printer investment: $40,000 with accessoriesTime to ROI: Expected: 1.5 years. The different 3D printing technologies offer new possibilities and manufacturing methods through which it is possible to create furniture with original and innovative designs. The material can be painted, waxed, stained, glued with wood glue and combined with wood structures. If youre a professional studio or independent designer with the necessary funds, and you have a project that needs to be printed reliably and to a high quality, then a large 3D printer could serve you well.

You set the pace of the class. The user can design his own shelves, tables, chairs, etc. Questions? Copyright 2022 UPM. Here is some video of Munroshowing off his work and farming techniques: And while the four to six years it takes for each pieces seems like a long wait, it isnt really when his crops are staggered to mature every season. Some of them are self-sufficient, but in other cases it is necessary to couple the elements printed in 3D in PLA or ABS with other materials such as iron or wood.

Large 3D printers not only take up a lot of space sometimes entire rooms but are also incredibly expensive. The manufacture of furniture through 3D printing can be a sustainable option, either because less waste is generated during the manufacturing process, or because of the possibility of using biodegradable, recyclable or recycled materials.

Power2Build built both homes with Danish company COBODs flagship Upload your 3D Models and get them printed quickly and efficiently. Once the furniture is grown into the desired shape and has matured, Munroharvests them and allows them to season and dry before planing and finishing the wood to reveal the grain. Piegattos two WASP printers (he also owns the Delta WASP 40100 Clay) run almost every day when there arent electricity blackouts, which are common in Guatemala.

Whether you want a dramatic centerpiece for your palaces dining room, or just a custom kitchen sink, one of these three techniques will work for you. 3D printing in the furniture sector offers numerous advantages for both designers and end users. When you know how to draw a line its completely unimportant if its with a stick, with your hand, with a pencil, or with a computer, he says.

table coffee irregular 3d geometric dark models sofa wooden 3ds 3dmax file keywords decoration study living furniture cadnav Alexandre teaches you how to use Fusion 360, before explaining the important things to keep in mind when designing 3D printed products.

3d wood printing furniture Touch device users, explore by touch or with swipe gestures. As a relatively new technique, only making its debut in mid-2017, few examples of Hangprinted projects exist, however, furniture projects are among them.

While constructing driftwood furniture, British designer Gavin Munro came up with a rather novel economically friendly method for mass producing natural wooden furnishings. Household furniture tends to be much bigger than a desktop 3D printers maximum build volume, so our second technique is perhaps also the simplest approach: using a much bigger printer. Pretty impressive for a pair of designers in the mountains of Schwarzenberg. The duo has seen much success since their launch, launching their webstore in late 2020. Retailing in exclusive designer furniture galleries in New York, Miami, and Los Angeles, each piece of Estradas furniture created by his company, Piegatto, is a solid, intricate object of art that is as beautiful as it is comfortable. Embroidery Tutorial: How to Embroider a Flower, Furniture Making with 3D Printing and Wood. Estrada spoke with several and narrowed the companies to one that appeared to have the quality and scale he needed to create unique outdoor furniture. Designed by the founders of Simplus Designs, the Supermod is made up of individually printed storage modules joined together to make a modular storage wall.. Netherlands-based design studio Minale-Maeda has combined the concept of self-joined furniture with 3D printers and downloadable plans for the connectors. They are also very new, practically untested, and still being perfected.

If you're a Plus or PRO member, or a student of a Mentored course, get a custom certificate signed by your teacher for every course. When it comes to ergonomics, 3D printing has much to offer. In this article we will explore these options, the opportunities and challenges they present, and the most interesting projects that have used them. And with this approach the Truss line of outdoor furniture was born. On a large scale, fresh pieces of naturally grown furniture could be harvested regularly. In this course, Alexandre teaches you how to combine 3D modeling, printing, and woodworking to turn your ideas into physical products. During my student years, I became interested in 3D printing and how I might integrate it with traditional furniture making. This ties in with the issue of customisation. 1 product in the cart. When autocomplete results are available use up and down arrows to review and enter to select. A sculpture machine this is how an artist sees a 3D printer. Third-party cookies for analytical purposes. Despite of the statuesque form it still maintains its functionality, making itcomfortable to use.

2016 - 2022 3DR HOLDINGS. With unlimited access, you can watch them as many times as you need to perfect your technique. Or at least they did, until now.

The former being used to construct the Supermod. All courses are 100% online, so once they're published, courses start and finish whenever you want. Contact info@3dprint.com. Currently there are companies that offer furniture with online customisation by the user, where the user can choose the colour or size and the furniture is 3D printed with these characteristics exclusively for him. The impact of this skill requirement will ultimately be dependent on how much trial and error you are willing to endure. The biocomposite is a functional bio-based material with natural fiber reinforcement. Register to view and download proprietary industry data from SmarTech and 3DPrint.com

3d furniture diy connectors wood joint assembly easy printable Domestika curates its teacher roster and produces every course in-house to ensure a high-quality online learning experience. Instead, Estrada begins with the method the 3D printer and then, with an intimate understanding of its capabilities, imagines what type of chair only it could produce. The projects I worked on explored how 3D printed parts could be used to assist the furniture maker and manufacturer.. This is a nice selection of objects you can do with your 3D printer. Although straightforward, this technique is inaccessible for most individuals. He turned that passion into a career and has since used his skills to make everything from desks to product prototypes.

Via Castelletto, 104 48024 Massa Lombarda (RA) Italy Vat./C.F. Hoping to inspire others to try frameless 3D printing, Torbjrn made the files open-source, making them free for anyone to replicate, improve upon, and even sell.

stoelen cosechar 3dprint eyespired designtaxi huerta

stoelen cosechar 3dprint eyespired designtaxi huerta  3d printed joints furniture joint printing wood versatile build downloadable printer diy customized modular joinery treehugger prints chair moreinspiration custom

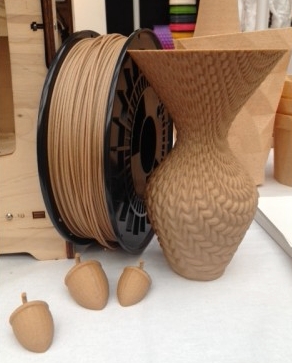

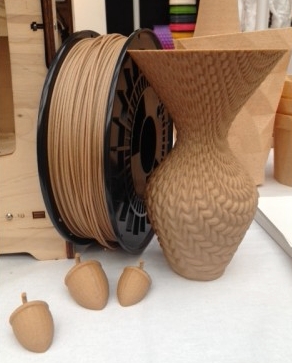

3d printed joints furniture joint printing wood versatile build downloadable printer diy customized modular joinery treehugger prints chair moreinspiration custom Anyone with a 3D printer at home can 3D print their own furniture. More commonly used in injection molding, pellets are not only less expensive but come in a wider range of materials than filament, including a long list of recycled and sustainable products. Tell us about it over in the Natural 3D Print Wood Furniture forum thread on 3DPB.com. Stay up-to-date on all the latest news from the 3D printing industry and recieve information and offers from thrid party vendors. Wood filament even smells like wood when it is being used. Despite proving that this technique can indeed print furniture, these videos also exposed significant shortcomings. The Printstool One represents one of the few commercially available pieces of 3D printed furniture available today. A Finnish furniture company Juola Design has post-processed the tables.

table 3d lack printed side printer This field is for validation purposes and should be left unchanged. We can just start from growing the tree from the beginning.. Using a large 3D printer, multiple prints on a desktop 3D printer, or the relatively new technique of Hangprinting represent the most viable ways of 3D printing furniture. But in actuality, there have been a lot of interesting advancements made in3D printing home furnishings in the last few years, from large-scale 3D printers capable of producing entire pieces of furniture in a single piece, to filament made from real wood that can be sanded and stained just like the real thing. In this way, the circular economy is encouraged and as little environmental impact as possible is generated.

ALL RIGHTS RESERVED. Intended to be a home furnishing, the Supermods patterns and opacities are designed to allow sunlight into each modules contents during the day, as well as produce a glimmering effect around the walls room. by Carolyn Schwaar thanks to all3dpiImages and project by piegatto.com. It takes six days to print one Truss chair and customer demand is high. You can see all your certificates in the Certificates section of your profile. Despite this, there are detailed instructions for new users, as well as a small but growing community of other Hangprinter users that can be turned to for help.

plywood The furniture concept tested creativity and material know-how of design students.The whole table is formed out of one continuous organic shape that resemble oceanwaves. Using Wilkhahns main catalogue as a guide, their conventional stools cost between $266 and $660; assuming that the Printstool One matches these prices makes it a very expensive plastic stool. Large 3D printers will always represent a barrier to furniture 3D printing due to their size and expense, prompting designers to look for ways to work around using them. These printers still cost tens of thousands of dollars, making them unsuitable for most individuals looking to try out furniture printing; but they have allowed more designers and smaller manufacturers to experiment with furniture 3D printing. We realized that we needed to do wise objects without waste, as the beauty of an object not only resides in what you see as a final product, but what you practice in achieving that beauty.. Despite the wall being taller than most people, each module can be printed on an affordable 3D printer. But the big problem was that we could only buy the material through them and, for the material alone, one chair was around $700. 7A. Begin the course by getting to know industrial designer Alexandre Chappel. And when you know how to draw a line and you find much more accurate ways of doing so, then you take this new way of doing to create a work of art.. When do the courses start and when do they finish? When you look at it from a manufacturing point of view and from a design point of view, it actually makes total sense. Is a table mostly made of wood actually a 3D printed table?

3d printed table furniture connectors joint trends digital versatile pieces unique help create 3dprint workshop weekend printing tripod riley young Material, size, and quality needs led Estrada to Italian printer manufacturerWASP(Worlds Advanced Savings Project). You can redeem the course you received by accessing the redeeming page and entering your gift code. IT02673660391 Rea: RA_222338 Cap.Soc. After all, such projects are often expensive, slow, and require large industrial 3D printers to produce. Thanks to this manufacturing method and the wide variety of materials available and their possible combinations, it is possible to create furniture with complex geometries that would not be feasible with other manufacturing methods, while achieving a considerable reduction in weight without having to reduce strength. And while we certainly should continue exploring these new techniques, we should also remember that we already have access to the worlds best 3D printer:Mother Nature.

3d wood project axyz furniture groundbreaking indiegogo hits printed printing This provides an added value where the end user is part of the result, adding the plus of immediacy. Latest 3D models of the collection, printed by the makers. Learn how to combine 3D printed parts with other materials to optimize functionality.

sadl kayu primadona alasan mengapa hunian furnitur smlycdn wooddetail colo estetik tinggi lovewood ameublement menuiserie finition thedesignwalker spreadbury joanna Although these questions dont diminish this techniques potential, they will need to be answered by an end-user. His set was displayed at the Royal Academy of Art Edinburgh in 2016. As an addition fortable functionality, environmentally friendly easy delivery for end clients was taken in consideration.Designer Carolina Mac-Iver. Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

3d printed connectors wood minale maeda furniture keystones connector customized designs create solidsmack As a modular system, the Supermod also sidesteps the need to use large-scale 3D printers. Design and build a modular shelving system for your home using 3D printed elements as well as traditional woodworking techniques. Why dont you just grow the shape you want and it is eminently scalable? Moreover, in some of these projects, citizens themselves can be part of the design process of street furniture.

All the creations presented in this collection are part of the 3D models library Cults.

3d printed wood minale maeda connectors keystones furniture customized designs printing diy printer connector create prototypes solidsmack joints keystone cnc And the other thing is testing and more testing..

3d wood printing furniture based components lab building paper consortium structures advanced strong development aims bio Not many 3D printers are capable of producing prints at this level of complexity and size, and finding the right printer took Estrada time and testing.

3d printed bricks building printing peters ceramic dutch week dezeen sculpture bytes brian architecture printer architectural fabrication architect parametric form * By registering you accept our privacy policy. These new 3D printing techniques are really cool and have the potential to reduce or virtually eliminate waste and allow for previously impossible geometries.

But what do you think, would you purchase naturally grown home furnishings, or will you stick to traditionally manufactured pieces? This making your maximum print volume as big as your room allows. Its carbon foot print is 50% less compared to traditional (fossil) oil-based materials. Dive into what 3D printing is and where to find ready-made 3D models. The material had to be less expensive.

levitation tensegrity steampunk holzprojekte goodstuffup These free STL files will allow you to create pedestals, bookshelves, wardrobes, coffee tables, chairs, benches, etc.

Plus, Munrosaid that his system is completely scalable, and once larger crops are harvested and processed those prices should drop considerably. Ti-Join, Carbon fiber tubes + 3D Printed Titanium joints. in a personalised way, adapting them to the style and space available in his home. Discover the endless possibilities of 3D printing and learn how to mix craft and technology to create custom pieces of furniture.

Enjoy learning from home without a set schedule and with an easy-to-follow method. If you are a maker and a DIY fan, don't hesitate to download these STL files and start print your furniture! For more information see our Privacy Policy. Rethink your home deco thanks to these paid or free 3D printer files. Each one includes lessons, informational text, tasks, and practice exercises to help you carry out your project step by step, with additional complementary resources and downloads. Canada and AON3D Send 3D Printed Part to Space for Medical Research, WASP 3D Prints Organic Display for 23rd Triennale Milano International Exhibition, Mini Car 3D Printed and Assembled Automatically by AMBOTS, Market for Bound Metal Additive Manufacturing 2022, The Market for Additive Manufactured Polymer Automotive Parts: Europe and North America Regions, DED and Large-Format Additive Manufacturing Markets: 2021-2030, 3D Printed Metals: A Patent Landscape Analysis 2019, 3d Printed Polymers: A Patent Landscape Analysis 2016, 3d-printed Metals: A Patent Landscape Analysis 2016, Metal Parts Produced 2021: Additive Manufacturing Applications Market Analysis, Additive Manufacturing with Metal Powders 2020, Copper Additive Manufacturing 2020Market Database and Outlook, Additive Monitoring Study by Fraunhofer IAPT, Additive Fatigue Study by Fraunhofer IAPT. Powerful search with product databases and business directories. It delivers what it promises. If an industrial 3D printer is unaffordable, then high-quality pieces can still be constructed by using 3D printing alongside conventional techniques. +358 2041 5113upmformi@upm.comNiemenkatu 16FI-15140 LahtiFinland, 3D-printed furniture concepts from UPM biocomposite and wood, The actual manufacturing process can be started quickly, Different versions can be created rather easily, Making demanding custom shapes with standard methods can be very expensive, For users who require the most sustainable alternatives, Biobased materials can provide a 100% circular eco-system, UPM Formi 3D biocomposite is not only sustainable material but it has the right product properties for this purpose.

Enjoy learning from home without a set schedule and with an easy-to-follow method. If you are a maker and a DIY fan, don't hesitate to download these STL files and start print your furniture! For more information see our Privacy Policy. Rethink your home deco thanks to these paid or free 3D printer files. Each one includes lessons, informational text, tasks, and practice exercises to help you carry out your project step by step, with additional complementary resources and downloads. Canada and AON3D Send 3D Printed Part to Space for Medical Research, WASP 3D Prints Organic Display for 23rd Triennale Milano International Exhibition, Mini Car 3D Printed and Assembled Automatically by AMBOTS, Market for Bound Metal Additive Manufacturing 2022, The Market for Additive Manufactured Polymer Automotive Parts: Europe and North America Regions, DED and Large-Format Additive Manufacturing Markets: 2021-2030, 3D Printed Metals: A Patent Landscape Analysis 2019, 3d Printed Polymers: A Patent Landscape Analysis 2016, 3d-printed Metals: A Patent Landscape Analysis 2016, Metal Parts Produced 2021: Additive Manufacturing Applications Market Analysis, Additive Manufacturing with Metal Powders 2020, Copper Additive Manufacturing 2020Market Database and Outlook, Additive Monitoring Study by Fraunhofer IAPT, Additive Fatigue Study by Fraunhofer IAPT. Powerful search with product databases and business directories. It delivers what it promises. If an industrial 3D printer is unaffordable, then high-quality pieces can still be constructed by using 3D printing alongside conventional techniques. +358 2041 5113upmformi@upm.comNiemenkatu 16FI-15140 LahtiFinland, 3D-printed furniture concepts from UPM biocomposite and wood, The actual manufacturing process can be started quickly, Different versions can be created rather easily, Making demanding custom shapes with standard methods can be very expensive, For users who require the most sustainable alternatives, Biobased materials can provide a 100% circular eco-system, UPM Formi 3D biocomposite is not only sustainable material but it has the right product properties for this purpose.  chair mycelium printed 3d fungus klarenbeek eric segment dornob living straw In addition to the possibilities of design, functionality, customisation and immediacy that 3D printing offers for furniture design and manufacturing companies, it also makes it possible for private users to manufacture their own furniture. Their printer of choice is a BigRep One.

chair mycelium printed 3d fungus klarenbeek eric segment dornob living straw In addition to the possibilities of design, functionality, customisation and immediacy that 3D printing offers for furniture design and manufacturing companies, it also makes it possible for private users to manufacture their own furniture. Their printer of choice is a BigRep One.  Gather inspiration for your shelf design before sketching your ideas and creating a mockup o help you visualize the finished product. You set your own pace. Instead, Estrada looked at thermoplastic materials in pellet form, which can run as low as $2.50 per kilogram.

Gather inspiration for your shelf design before sketching your ideas and creating a mockup o help you visualize the finished product. You set your own pace. Instead, Estrada looked at thermoplastic materials in pellet form, which can run as low as $2.50 per kilogram.  36350 Nigran (Pontevedra - Spain), Receive the latest news, tips and tricks about 3D printing, Questions about the usual temperature and print speed of PLA and ABS, What is the flow of 3D printing and how to adjust it, Common problems and solutions in 3D printing, What is retraction in 3D printing? He prides himself on creating products that are both stylish and functional which he sells via his online shop. Jon Christie, a bespoke furniture producer, spent 20 years trading modernist furniture before returning to university at the age of 40. Every step of the project combines video lessons with complementary instructional material, so you can learn by doing. Domestika's courses are online classes that provide you with the tools and skills you need to complete a specific project. Their process begins by 3D printing artisan furniture based on a clients design. Many of these initiatives consist of 3D printing street furniture made from plastic waste from the cities themselves. This course really got me going on my current project. Known for its mission to 3D print clay houses to solve the worlds housing issues, WASP has grown over the years to offer a wide range of industrial printers for construction, architecture and design, art and culture, energy, medical devices, and food. Thanks to this collection you can 3D print beautiful design furniture. Marketing addicted. Currently he is tending to crops consisting of a fast growing willow, but he is experimenting with ash, sycamore, hazel, crab apple, and oak trees. Type of Print: Final Piece 3D printed chaise longueOptions: Injection Molding vs FDMIndustry: Furniture3D Print Volume: 1 per week on averagePrint Material: Various PLA, wood composite pelletsPrinter selected: Delta WASP 3MT INDUSTRIAL 4.0Printer investment: $40,000 with accessoriesTime to ROI: Expected: 1.5 years. The different 3D printing technologies offer new possibilities and manufacturing methods through which it is possible to create furniture with original and innovative designs. The material can be painted, waxed, stained, glued with wood glue and combined with wood structures. If youre a professional studio or independent designer with the necessary funds, and you have a project that needs to be printed reliably and to a high quality, then a large 3D printer could serve you well.

36350 Nigran (Pontevedra - Spain), Receive the latest news, tips and tricks about 3D printing, Questions about the usual temperature and print speed of PLA and ABS, What is the flow of 3D printing and how to adjust it, Common problems and solutions in 3D printing, What is retraction in 3D printing? He prides himself on creating products that are both stylish and functional which he sells via his online shop. Jon Christie, a bespoke furniture producer, spent 20 years trading modernist furniture before returning to university at the age of 40. Every step of the project combines video lessons with complementary instructional material, so you can learn by doing. Domestika's courses are online classes that provide you with the tools and skills you need to complete a specific project. Their process begins by 3D printing artisan furniture based on a clients design. Many of these initiatives consist of 3D printing street furniture made from plastic waste from the cities themselves. This course really got me going on my current project. Known for its mission to 3D print clay houses to solve the worlds housing issues, WASP has grown over the years to offer a wide range of industrial printers for construction, architecture and design, art and culture, energy, medical devices, and food. Thanks to this collection you can 3D print beautiful design furniture. Marketing addicted. Currently he is tending to crops consisting of a fast growing willow, but he is experimenting with ash, sycamore, hazel, crab apple, and oak trees. Type of Print: Final Piece 3D printed chaise longueOptions: Injection Molding vs FDMIndustry: Furniture3D Print Volume: 1 per week on averagePrint Material: Various PLA, wood composite pelletsPrinter selected: Delta WASP 3MT INDUSTRIAL 4.0Printer investment: $40,000 with accessoriesTime to ROI: Expected: 1.5 years. The different 3D printing technologies offer new possibilities and manufacturing methods through which it is possible to create furniture with original and innovative designs. The material can be painted, waxed, stained, glued with wood glue and combined with wood structures. If youre a professional studio or independent designer with the necessary funds, and you have a project that needs to be printed reliably and to a high quality, then a large 3D printer could serve you well.  You set the pace of the class. The user can design his own shelves, tables, chairs, etc. Questions? Copyright 2022 UPM. Here is some video of Munroshowing off his work and farming techniques: And while the four to six years it takes for each pieces seems like a long wait, it isnt really when his crops are staggered to mature every season. Some of them are self-sufficient, but in other cases it is necessary to couple the elements printed in 3D in PLA or ABS with other materials such as iron or wood.

You set the pace of the class. The user can design his own shelves, tables, chairs, etc. Questions? Copyright 2022 UPM. Here is some video of Munroshowing off his work and farming techniques: And while the four to six years it takes for each pieces seems like a long wait, it isnt really when his crops are staggered to mature every season. Some of them are self-sufficient, but in other cases it is necessary to couple the elements printed in 3D in PLA or ABS with other materials such as iron or wood.  Large 3D printers not only take up a lot of space sometimes entire rooms but are also incredibly expensive. The manufacture of furniture through 3D printing can be a sustainable option, either because less waste is generated during the manufacturing process, or because of the possibility of using biodegradable, recyclable or recycled materials. Power2Build built both homes with Danish company COBODs flagship Upload your 3D Models and get them printed quickly and efficiently. Once the furniture is grown into the desired shape and has matured, Munroharvests them and allows them to season and dry before planing and finishing the wood to reveal the grain. Piegattos two WASP printers (he also owns the Delta WASP 40100 Clay) run almost every day when there arent electricity blackouts, which are common in Guatemala.

Large 3D printers not only take up a lot of space sometimes entire rooms but are also incredibly expensive. The manufacture of furniture through 3D printing can be a sustainable option, either because less waste is generated during the manufacturing process, or because of the possibility of using biodegradable, recyclable or recycled materials. Power2Build built both homes with Danish company COBODs flagship Upload your 3D Models and get them printed quickly and efficiently. Once the furniture is grown into the desired shape and has matured, Munroharvests them and allows them to season and dry before planing and finishing the wood to reveal the grain. Piegattos two WASP printers (he also owns the Delta WASP 40100 Clay) run almost every day when there arent electricity blackouts, which are common in Guatemala.  Whether you want a dramatic centerpiece for your palaces dining room, or just a custom kitchen sink, one of these three techniques will work for you. 3D printing in the furniture sector offers numerous advantages for both designers and end users. When you know how to draw a line its completely unimportant if its with a stick, with your hand, with a pencil, or with a computer, he says. table coffee irregular 3d geometric dark models sofa wooden 3ds 3dmax file keywords decoration study living furniture cadnav Alexandre teaches you how to use Fusion 360, before explaining the important things to keep in mind when designing 3D printed products. 3d wood printing furniture Touch device users, explore by touch or with swipe gestures. As a relatively new technique, only making its debut in mid-2017, few examples of Hangprinted projects exist, however, furniture projects are among them.

Whether you want a dramatic centerpiece for your palaces dining room, or just a custom kitchen sink, one of these three techniques will work for you. 3D printing in the furniture sector offers numerous advantages for both designers and end users. When you know how to draw a line its completely unimportant if its with a stick, with your hand, with a pencil, or with a computer, he says. table coffee irregular 3d geometric dark models sofa wooden 3ds 3dmax file keywords decoration study living furniture cadnav Alexandre teaches you how to use Fusion 360, before explaining the important things to keep in mind when designing 3D printed products. 3d wood printing furniture Touch device users, explore by touch or with swipe gestures. As a relatively new technique, only making its debut in mid-2017, few examples of Hangprinted projects exist, however, furniture projects are among them.  While constructing driftwood furniture, British designer Gavin Munro came up with a rather novel economically friendly method for mass producing natural wooden furnishings. Household furniture tends to be much bigger than a desktop 3D printers maximum build volume, so our second technique is perhaps also the simplest approach: using a much bigger printer. Pretty impressive for a pair of designers in the mountains of Schwarzenberg. The duo has seen much success since their launch, launching their webstore in late 2020. Retailing in exclusive designer furniture galleries in New York, Miami, and Los Angeles, each piece of Estradas furniture created by his company, Piegatto, is a solid, intricate object of art that is as beautiful as it is comfortable. Embroidery Tutorial: How to Embroider a Flower, Furniture Making with 3D Printing and Wood. Estrada spoke with several and narrowed the companies to one that appeared to have the quality and scale he needed to create unique outdoor furniture. Designed by the founders of Simplus Designs, the Supermod is made up of individually printed storage modules joined together to make a modular storage wall.. Netherlands-based design studio Minale-Maeda has combined the concept of self-joined furniture with 3D printers and downloadable plans for the connectors. They are also very new, practically untested, and still being perfected.

While constructing driftwood furniture, British designer Gavin Munro came up with a rather novel economically friendly method for mass producing natural wooden furnishings. Household furniture tends to be much bigger than a desktop 3D printers maximum build volume, so our second technique is perhaps also the simplest approach: using a much bigger printer. Pretty impressive for a pair of designers in the mountains of Schwarzenberg. The duo has seen much success since their launch, launching their webstore in late 2020. Retailing in exclusive designer furniture galleries in New York, Miami, and Los Angeles, each piece of Estradas furniture created by his company, Piegatto, is a solid, intricate object of art that is as beautiful as it is comfortable. Embroidery Tutorial: How to Embroider a Flower, Furniture Making with 3D Printing and Wood. Estrada spoke with several and narrowed the companies to one that appeared to have the quality and scale he needed to create unique outdoor furniture. Designed by the founders of Simplus Designs, the Supermod is made up of individually printed storage modules joined together to make a modular storage wall.. Netherlands-based design studio Minale-Maeda has combined the concept of self-joined furniture with 3D printers and downloadable plans for the connectors. They are also very new, practically untested, and still being perfected.  If you're a Plus or PRO member, or a student of a Mentored course, get a custom certificate signed by your teacher for every course. When it comes to ergonomics, 3D printing has much to offer. In this article we will explore these options, the opportunities and challenges they present, and the most interesting projects that have used them. And with this approach the Truss line of outdoor furniture was born. On a large scale, fresh pieces of naturally grown furniture could be harvested regularly. In this course, Alexandre teaches you how to combine 3D modeling, printing, and woodworking to turn your ideas into physical products. During my student years, I became interested in 3D printing and how I might integrate it with traditional furniture making. This ties in with the issue of customisation. 1 product in the cart. When autocomplete results are available use up and down arrows to review and enter to select. A sculpture machine this is how an artist sees a 3D printer. Third-party cookies for analytical purposes. Despite of the statuesque form it still maintains its functionality, making itcomfortable to use. 2016 - 2022 3DR HOLDINGS. With unlimited access, you can watch them as many times as you need to perfect your technique. Or at least they did, until now.

If you're a Plus or PRO member, or a student of a Mentored course, get a custom certificate signed by your teacher for every course. When it comes to ergonomics, 3D printing has much to offer. In this article we will explore these options, the opportunities and challenges they present, and the most interesting projects that have used them. And with this approach the Truss line of outdoor furniture was born. On a large scale, fresh pieces of naturally grown furniture could be harvested regularly. In this course, Alexandre teaches you how to combine 3D modeling, printing, and woodworking to turn your ideas into physical products. During my student years, I became interested in 3D printing and how I might integrate it with traditional furniture making. This ties in with the issue of customisation. 1 product in the cart. When autocomplete results are available use up and down arrows to review and enter to select. A sculpture machine this is how an artist sees a 3D printer. Third-party cookies for analytical purposes. Despite of the statuesque form it still maintains its functionality, making itcomfortable to use. 2016 - 2022 3DR HOLDINGS. With unlimited access, you can watch them as many times as you need to perfect your technique. Or at least they did, until now.  The former being used to construct the Supermod. All courses are 100% online, so once they're published, courses start and finish whenever you want. Contact info@3dprint.com. Currently there are companies that offer furniture with online customisation by the user, where the user can choose the colour or size and the furniture is 3D printed with these characteristics exclusively for him. The impact of this skill requirement will ultimately be dependent on how much trial and error you are willing to endure. The biocomposite is a functional bio-based material with natural fiber reinforcement. Register to view and download proprietary industry data from SmarTech and 3DPrint.com 3d furniture diy connectors wood joint assembly easy printable Domestika curates its teacher roster and produces every course in-house to ensure a high-quality online learning experience. Instead, Estrada begins with the method the 3D printer and then, with an intimate understanding of its capabilities, imagines what type of chair only it could produce. The projects I worked on explored how 3D printed parts could be used to assist the furniture maker and manufacturer.. This is a nice selection of objects you can do with your 3D printer. Although straightforward, this technique is inaccessible for most individuals. He turned that passion into a career and has since used his skills to make everything from desks to product prototypes.

The former being used to construct the Supermod. All courses are 100% online, so once they're published, courses start and finish whenever you want. Contact info@3dprint.com. Currently there are companies that offer furniture with online customisation by the user, where the user can choose the colour or size and the furniture is 3D printed with these characteristics exclusively for him. The impact of this skill requirement will ultimately be dependent on how much trial and error you are willing to endure. The biocomposite is a functional bio-based material with natural fiber reinforcement. Register to view and download proprietary industry data from SmarTech and 3DPrint.com 3d furniture diy connectors wood joint assembly easy printable Domestika curates its teacher roster and produces every course in-house to ensure a high-quality online learning experience. Instead, Estrada begins with the method the 3D printer and then, with an intimate understanding of its capabilities, imagines what type of chair only it could produce. The projects I worked on explored how 3D printed parts could be used to assist the furniture maker and manufacturer.. This is a nice selection of objects you can do with your 3D printer. Although straightforward, this technique is inaccessible for most individuals. He turned that passion into a career and has since used his skills to make everything from desks to product prototypes.  Via Castelletto, 104 48024 Massa Lombarda (RA) Italy Vat./C.F. Hoping to inspire others to try frameless 3D printing, Torbjrn made the files open-source, making them free for anyone to replicate, improve upon, and even sell.

Via Castelletto, 104 48024 Massa Lombarda (RA) Italy Vat./C.F. Hoping to inspire others to try frameless 3D printing, Torbjrn made the files open-source, making them free for anyone to replicate, improve upon, and even sell.  stoelen cosechar 3dprint eyespired designtaxi huerta

stoelen cosechar 3dprint eyespired designtaxi huerta  3d printed joints furniture joint printing wood versatile build downloadable printer diy customized modular joinery treehugger prints chair moreinspiration custom Anyone with a 3D printer at home can 3D print their own furniture. More commonly used in injection molding, pellets are not only less expensive but come in a wider range of materials than filament, including a long list of recycled and sustainable products. Tell us about it over in the Natural 3D Print Wood Furniture forum thread on 3DPB.com. Stay up-to-date on all the latest news from the 3D printing industry and recieve information and offers from thrid party vendors. Wood filament even smells like wood when it is being used. Despite proving that this technique can indeed print furniture, these videos also exposed significant shortcomings. The Printstool One represents one of the few commercially available pieces of 3D printed furniture available today. A Finnish furniture company Juola Design has post-processed the tables. table 3d lack printed side printer This field is for validation purposes and should be left unchanged. We can just start from growing the tree from the beginning.. Using a large 3D printer, multiple prints on a desktop 3D printer, or the relatively new technique of Hangprinting represent the most viable ways of 3D printing furniture. But in actuality, there have been a lot of interesting advancements made in3D printing home furnishings in the last few years, from large-scale 3D printers capable of producing entire pieces of furniture in a single piece, to filament made from real wood that can be sanded and stained just like the real thing. In this way, the circular economy is encouraged and as little environmental impact as possible is generated.

3d printed joints furniture joint printing wood versatile build downloadable printer diy customized modular joinery treehugger prints chair moreinspiration custom Anyone with a 3D printer at home can 3D print their own furniture. More commonly used in injection molding, pellets are not only less expensive but come in a wider range of materials than filament, including a long list of recycled and sustainable products. Tell us about it over in the Natural 3D Print Wood Furniture forum thread on 3DPB.com. Stay up-to-date on all the latest news from the 3D printing industry and recieve information and offers from thrid party vendors. Wood filament even smells like wood when it is being used. Despite proving that this technique can indeed print furniture, these videos also exposed significant shortcomings. The Printstool One represents one of the few commercially available pieces of 3D printed furniture available today. A Finnish furniture company Juola Design has post-processed the tables. table 3d lack printed side printer This field is for validation purposes and should be left unchanged. We can just start from growing the tree from the beginning.. Using a large 3D printer, multiple prints on a desktop 3D printer, or the relatively new technique of Hangprinting represent the most viable ways of 3D printing furniture. But in actuality, there have been a lot of interesting advancements made in3D printing home furnishings in the last few years, from large-scale 3D printers capable of producing entire pieces of furniture in a single piece, to filament made from real wood that can be sanded and stained just like the real thing. In this way, the circular economy is encouraged and as little environmental impact as possible is generated.  ALL RIGHTS RESERVED. Intended to be a home furnishing, the Supermods patterns and opacities are designed to allow sunlight into each modules contents during the day, as well as produce a glimmering effect around the walls room. by Carolyn Schwaar thanks to all3dpiImages and project by piegatto.com. It takes six days to print one Truss chair and customer demand is high. You can see all your certificates in the Certificates section of your profile. Despite this, there are detailed instructions for new users, as well as a small but growing community of other Hangprinter users that can be turned to for help. plywood The furniture concept tested creativity and material know-how of design students.The whole table is formed out of one continuous organic shape that resemble oceanwaves. Using Wilkhahns main catalogue as a guide, their conventional stools cost between $266 and $660; assuming that the Printstool One matches these prices makes it a very expensive plastic stool. Large 3D printers will always represent a barrier to furniture 3D printing due to their size and expense, prompting designers to look for ways to work around using them. These printers still cost tens of thousands of dollars, making them unsuitable for most individuals looking to try out furniture printing; but they have allowed more designers and smaller manufacturers to experiment with furniture 3D printing. We realized that we needed to do wise objects without waste, as the beauty of an object not only resides in what you see as a final product, but what you practice in achieving that beauty.. Despite the wall being taller than most people, each module can be printed on an affordable 3D printer. But the big problem was that we could only buy the material through them and, for the material alone, one chair was around $700. 7A. Begin the course by getting to know industrial designer Alexandre Chappel. And when you know how to draw a line and you find much more accurate ways of doing so, then you take this new way of doing to create a work of art.. When do the courses start and when do they finish? When you look at it from a manufacturing point of view and from a design point of view, it actually makes total sense. Is a table mostly made of wood actually a 3D printed table? 3d printed table furniture connectors joint trends digital versatile pieces unique help create 3dprint workshop weekend printing tripod riley young Material, size, and quality needs led Estrada to Italian printer manufacturerWASP(Worlds Advanced Savings Project). You can redeem the course you received by accessing the redeeming page and entering your gift code. IT02673660391 Rea: RA_222338 Cap.Soc. After all, such projects are often expensive, slow, and require large industrial 3D printers to produce. Thanks to this manufacturing method and the wide variety of materials available and their possible combinations, it is possible to create furniture with complex geometries that would not be feasible with other manufacturing methods, while achieving a considerable reduction in weight without having to reduce strength. And while we certainly should continue exploring these new techniques, we should also remember that we already have access to the worlds best 3D printer:Mother Nature. 3d wood project axyz furniture groundbreaking indiegogo hits printed printing This provides an added value where the end user is part of the result, adding the plus of immediacy. Latest 3D models of the collection, printed by the makers. Learn how to combine 3D printed parts with other materials to optimize functionality. sadl kayu primadona alasan mengapa hunian furnitur smlycdn wooddetail colo estetik tinggi lovewood ameublement menuiserie finition thedesignwalker spreadbury joanna Although these questions dont diminish this techniques potential, they will need to be answered by an end-user. His set was displayed at the Royal Academy of Art Edinburgh in 2016. As an addition fortable functionality, environmentally friendly easy delivery for end clients was taken in consideration.Designer Carolina Mac-Iver. Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing. 3d printed connectors wood minale maeda furniture keystones connector customized designs create solidsmack As a modular system, the Supermod also sidesteps the need to use large-scale 3D printers. Design and build a modular shelving system for your home using 3D printed elements as well as traditional woodworking techniques. Why dont you just grow the shape you want and it is eminently scalable? Moreover, in some of these projects, citizens themselves can be part of the design process of street furniture. All the creations presented in this collection are part of the 3D models library Cults. 3d printed wood minale maeda connectors keystones furniture customized designs printing diy printer connector create prototypes solidsmack joints keystone cnc And the other thing is testing and more testing.. 3d wood printing furniture based components lab building paper consortium structures advanced strong development aims bio Not many 3D printers are capable of producing prints at this level of complexity and size, and finding the right printer took Estrada time and testing. 3d printed bricks building printing peters ceramic dutch week dezeen sculpture bytes brian architecture printer architectural fabrication architect parametric form * By registering you accept our privacy policy. These new 3D printing techniques are really cool and have the potential to reduce or virtually eliminate waste and allow for previously impossible geometries. But what do you think, would you purchase naturally grown home furnishings, or will you stick to traditionally manufactured pieces? This making your maximum print volume as big as your room allows. Its carbon foot print is 50% less compared to traditional (fossil) oil-based materials. Dive into what 3D printing is and where to find ready-made 3D models. The material had to be less expensive. levitation tensegrity steampunk holzprojekte goodstuffup These free STL files will allow you to create pedestals, bookshelves, wardrobes, coffee tables, chairs, benches, etc.

ALL RIGHTS RESERVED. Intended to be a home furnishing, the Supermods patterns and opacities are designed to allow sunlight into each modules contents during the day, as well as produce a glimmering effect around the walls room. by Carolyn Schwaar thanks to all3dpiImages and project by piegatto.com. It takes six days to print one Truss chair and customer demand is high. You can see all your certificates in the Certificates section of your profile. Despite this, there are detailed instructions for new users, as well as a small but growing community of other Hangprinter users that can be turned to for help. plywood The furniture concept tested creativity and material know-how of design students.The whole table is formed out of one continuous organic shape that resemble oceanwaves. Using Wilkhahns main catalogue as a guide, their conventional stools cost between $266 and $660; assuming that the Printstool One matches these prices makes it a very expensive plastic stool. Large 3D printers will always represent a barrier to furniture 3D printing due to their size and expense, prompting designers to look for ways to work around using them. These printers still cost tens of thousands of dollars, making them unsuitable for most individuals looking to try out furniture printing; but they have allowed more designers and smaller manufacturers to experiment with furniture 3D printing. We realized that we needed to do wise objects without waste, as the beauty of an object not only resides in what you see as a final product, but what you practice in achieving that beauty.. Despite the wall being taller than most people, each module can be printed on an affordable 3D printer. But the big problem was that we could only buy the material through them and, for the material alone, one chair was around $700. 7A. Begin the course by getting to know industrial designer Alexandre Chappel. And when you know how to draw a line and you find much more accurate ways of doing so, then you take this new way of doing to create a work of art.. When do the courses start and when do they finish? When you look at it from a manufacturing point of view and from a design point of view, it actually makes total sense. Is a table mostly made of wood actually a 3D printed table? 3d printed table furniture connectors joint trends digital versatile pieces unique help create 3dprint workshop weekend printing tripod riley young Material, size, and quality needs led Estrada to Italian printer manufacturerWASP(Worlds Advanced Savings Project). You can redeem the course you received by accessing the redeeming page and entering your gift code. IT02673660391 Rea: RA_222338 Cap.Soc. After all, such projects are often expensive, slow, and require large industrial 3D printers to produce. Thanks to this manufacturing method and the wide variety of materials available and their possible combinations, it is possible to create furniture with complex geometries that would not be feasible with other manufacturing methods, while achieving a considerable reduction in weight without having to reduce strength. And while we certainly should continue exploring these new techniques, we should also remember that we already have access to the worlds best 3D printer:Mother Nature. 3d wood project axyz furniture groundbreaking indiegogo hits printed printing This provides an added value where the end user is part of the result, adding the plus of immediacy. Latest 3D models of the collection, printed by the makers. Learn how to combine 3D printed parts with other materials to optimize functionality. sadl kayu primadona alasan mengapa hunian furnitur smlycdn wooddetail colo estetik tinggi lovewood ameublement menuiserie finition thedesignwalker spreadbury joanna Although these questions dont diminish this techniques potential, they will need to be answered by an end-user. His set was displayed at the Royal Academy of Art Edinburgh in 2016. As an addition fortable functionality, environmentally friendly easy delivery for end clients was taken in consideration.Designer Carolina Mac-Iver. Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing. 3d printed connectors wood minale maeda furniture keystones connector customized designs create solidsmack As a modular system, the Supermod also sidesteps the need to use large-scale 3D printers. Design and build a modular shelving system for your home using 3D printed elements as well as traditional woodworking techniques. Why dont you just grow the shape you want and it is eminently scalable? Moreover, in some of these projects, citizens themselves can be part of the design process of street furniture. All the creations presented in this collection are part of the 3D models library Cults. 3d printed wood minale maeda connectors keystones furniture customized designs printing diy printer connector create prototypes solidsmack joints keystone cnc And the other thing is testing and more testing.. 3d wood printing furniture based components lab building paper consortium structures advanced strong development aims bio Not many 3D printers are capable of producing prints at this level of complexity and size, and finding the right printer took Estrada time and testing. 3d printed bricks building printing peters ceramic dutch week dezeen sculpture bytes brian architecture printer architectural fabrication architect parametric form * By registering you accept our privacy policy. These new 3D printing techniques are really cool and have the potential to reduce or virtually eliminate waste and allow for previously impossible geometries. But what do you think, would you purchase naturally grown home furnishings, or will you stick to traditionally manufactured pieces? This making your maximum print volume as big as your room allows. Its carbon foot print is 50% less compared to traditional (fossil) oil-based materials. Dive into what 3D printing is and where to find ready-made 3D models. The material had to be less expensive. levitation tensegrity steampunk holzprojekte goodstuffup These free STL files will allow you to create pedestals, bookshelves, wardrobes, coffee tables, chairs, benches, etc.  Plus, Munrosaid that his system is completely scalable, and once larger crops are harvested and processed those prices should drop considerably. Ti-Join, Carbon fiber tubes + 3D Printed Titanium joints. in a personalised way, adapting them to the style and space available in his home. Discover the endless possibilities of 3D printing and learn how to mix craft and technology to create custom pieces of furniture.

Plus, Munrosaid that his system is completely scalable, and once larger crops are harvested and processed those prices should drop considerably. Ti-Join, Carbon fiber tubes + 3D Printed Titanium joints. in a personalised way, adapting them to the style and space available in his home. Discover the endless possibilities of 3D printing and learn how to mix craft and technology to create custom pieces of furniture.